You’ve done everything by the book. You carefully weigh the powdered sample, mix it perfectly, and load it into the die. You place it in the hydraulic press, begin applying pressure, and watch the gauge climb. Then, as you release the pressure and retrieve your work, you hear it: the faint, disheartening crack. The pellet is fractured, useless for analysis. Another sample ruined, another hour wasted.

If this scene is painfully familiar, you are not alone.

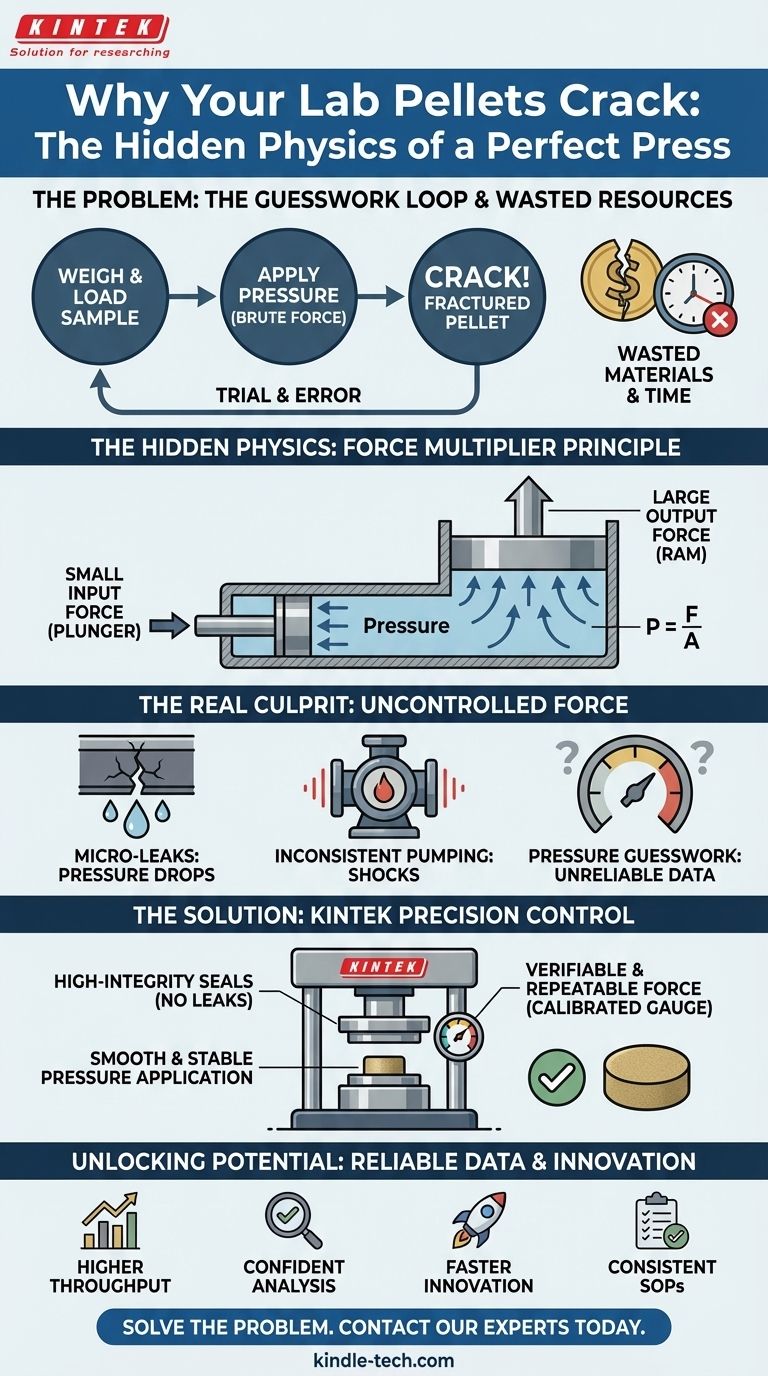

The Guesswork Loop: Chasing Consistency, Wasting Resources

In laboratories around the world, creating consistent, solid pellets for analysis—like X-Ray Fluorescence (XRF) or Fourier-Transform Infrared Spectroscopy (FTIR)—can feel more like a dark art than a science. When pellets crack, crumble, or have inconsistent density, the immediate suspects are always the same:

- "Maybe the powder was too coarse."

- "Did I use enough binding agent?"

- "Perhaps I need to hold the pressure for longer."

- "Let's just press it harder this time and see what happens."

This cycle of trial and error is more than just frustrating; it has direct business consequences. Every failed attempt consumes expensive sample materials and valuable technician time. More critically, it delays crucial analysis, which can create bottlenecks in R&D projects or halt production lines waiting for quality control clearance. An inconsistent sample preparation process leads to inconsistent data, undermining the integrity of your entire research or quality assurance program.

But what if the powder, the binder, and your technique aren't the real problems?

The Real Culprit: It's Not Brute Force, It's Physics

The common misconception is that a hydraulic press is simply a high-tech vise—a tool for applying brute force. This leads us to believe that "more force" is the solution. The reality is far more elegant and reveals the true source of our problems.

A hydraulic press is a force multiplier. It operates on a fundamental principle of fluid dynamics: pressure applied to a contained, incompressible fluid is transmitted equally in all directions.

Imagine a system with two connected pistons: one small (the plunger) and one very large (the ram). By applying a small, easy push to the tiny plunger, you create immense pressure in the hydraulic fluid. This pressure then acts on the large ram, generating a massive output force capable of compressing powder into a solid disc.

Here is the critical insight: The problem isn't the amount of force, but the consistency and control of that force.

Your pellets crack not because the force is too low, but often because it is unstable. Common hydraulic presses, especially those that are aging or not built for lab precision, suffer from issues that disrupt this delicate balance:

- Micro-leaks: Tiny, almost invisible leaks in seals or hoses can cause an unstable drop in pressure during compression.

- Inconsistent Pumping: A non-precision pump can deliver fluid in pulses, causing the force to fluctuate rather than build smoothly.

- Pressure Guesswork: Without a reliable gauge or precise controls, you are merely guessing how much force is being applied.

Trying to "press harder" with an unstable machine is like trying to draw a straight line during an earthquake. You are fighting the physics of the tool itself, and the result is a fractured, unreliable sample. The "common solutions" fail because they are treating the symptom (a bad pellet) instead of the disease (uncontrolled force).

Beyond Brute Force: The Shift to Precision Control

To create a perfect pellet every single time, you don't just need power. You need perfectly controlled, consistently delivered, and verifiable force. This requires a tool that is not just a "press," but a precision instrument designed with a deep understanding of the underlying physics.

This is precisely why KINTEK's laboratory hydraulic presses were developed. They are not just machines that squeeze; they are engineered systems designed to master the application of force.

Our presses directly address the root causes of failure:

- High-Integrity Systems: We use superior seals and precision-machined components to eliminate the micro-leaks that cause pressure drops, ensuring the force you set is the force that's delivered.

- Smooth & Stable Pressure: Our hydraulic power units and control valves are engineered for smooth, linear pressure application, preventing the sudden shocks that fracture delicate samples.

- Verifiable & Repeatable Force: A clear, calibrated pressure gauge allows you to see and apply the exact force required for your material, taking the guesswork out of the process and making your results repeatable, technician to technician.

A KINTEK press isn't just an accidental solution; it is the embodiment of the correct scientific approach, designed from the ground up to give you the control that the physics of sample preparation demands.

From Frustration to Foundation: What Reliable Sample Prep Unlocks

When you eliminate the guesswork and inconsistency from sample preparation, it's not just a minor frustration that disappears. You unlock new potential for your entire laboratory.

Instead of re-making samples, your team can spend more time on high-value analysis. You can develop new material formulations with confidence, knowing that your prep method is a stable, reliable constant. In a quality control environment, it means higher throughput and the assurance that you can catch product deviations, not chase phantom issues caused by bad pellets. You can now build standard operating procedures (SOPs) that work every time, making it faster to train new staff and ensure data integrity across your entire operation.

Ultimately, a reliable pellet is the foundation for reliable data. And reliable data is the foundation for faster innovation, better products, and smarter science.

A consistent sample is just the beginning. It's the key to unlocking a more efficient, accurate, and productive laboratory. If you're ready to solve this persistent problem for good and focus on the results that truly matter, our team is ready to help. Let's discuss the specific challenges in your lab. [Contact Our Experts](#ContactForm)

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

Related Articles

- Operating steps and precautions for electric tablet press

- Your Hydraulic Press Is Hot. Here’s Why It’s a Bigger Problem Than You Think.

- Operating of Automatic Lab xrf Pellet Press

- Hydraulic Tablet Press: Comprehensive Guide to Design, Operation, and Applications

- Applications and Importance of Hydraulic Press in Laboratories