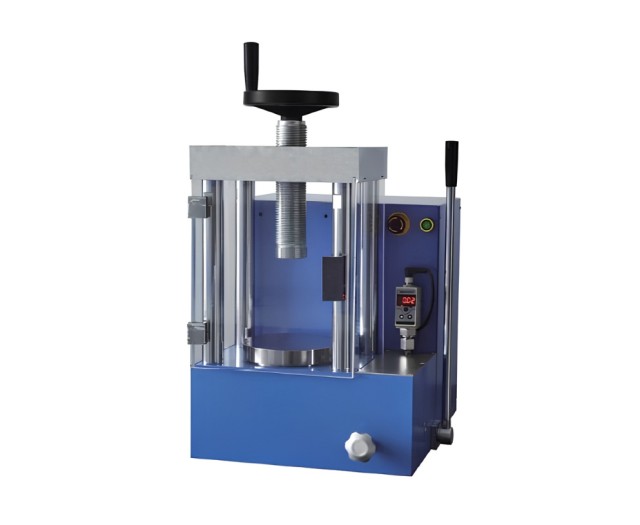

In the world of precision, the small isostatic tablet press shines with its compact design, high pressure, and user-friendly features. It's more than meets the eye – a gateway to streamlined manufacturing and enhanced product performance. Join us as we uncover the operating steps and precautions that make this technological marvel tick.

Operating steps of electric tablet press

1.Place the sample into the mold and assemble it.

2.Place the mold into the tablet press.

3.Press the mode key and the screen displays LocP.

4.Press the ▲ key again to set 0001, and then press the mode key to enter the control menu.

5.Select RL1F and press the mode key to enter the pressure setting interface.

6.Press the ▲/▼ key again to set the pressure stop value, and then press the mode key to return to the menu.

7.Select RL1H, then press the mode key to enter and set the pressure compensation value.

8.Press the mode key to return to the menu. After selecting End, press the mode key to exit the menu and save the record.

9.Tighten the drain valve stem.

10.Press the green start button.

11.The tablet press starts to pressurize according to the set pressure.

12.The tablet press reaches the set pressure, stops pressing, and maintains the pressure.

13.Micro-pressure can be applied manually.

14.Press the green switch to stop the device.

15.Loosen the oil release valve to relieve pressure.

16.Remove the mold.

Electric tablet press replacement hydraulic pump

1.Open the chassis side cover.

2.Unplug the switch connector.

3.Remove the power cord from the pump.

4.Remove the oil return pipe.

5.Remove the oil inlet pipe.

6.Remove the pump mounting screws.

7.Take out the hydraulic pump.

8.Replace with new hydraulic pump.

9.Install the pump retaining screws.

10.Tighten the oil return pipe.

11.Tighten the oil inlet pipe.

12.The tablet press reaches the set pressure, stops pressing, and maintains the pressure.

13.If the circuit board is damaged, the circuit board can be replaced.

14.Plug in the switch connector.

15.Loosen the oil filler hole screw.

16.Tighten the chassis side panels.

Precautions for electric tablet press

Question 1: Cylinder return stroke

The stroke of the cylinder of an electric tablet press should generally not exceed 30mm. If the sample deforms greatly, the cylinder needs to be reset and then pressurized after the cylinder rises to 30mm to prevent the piston from being unable to return due to deformation of the tension spring.

Question 2: Pressure gauge settings.

1. Set RL1F >RLIH to enable the device. 2.RL1D is the pressure sensitivity,Set RL1D =0000.

Question 3: High pressure oil pipe

High-pressure oil pipes and connecting parts should be checked regularly for oil leakage or oil pipe deformation.

Question 4: Speed regulating valve.

The function of the speed regulating valve is to solve the problem of pressure overshoot. When the actual pressure exceeds the set pressure too much, the speed regulating valve should be loosened. If the equipment pressure does not reach the set value, the speed regulating valve needs to be tightened.

Question 5: Loosen the oil filler hole.

When refueling, the refueling hole should not be too tight, otherwise the tablet press pump will not be able to pump out oil, resulting in no pressure.

Question 6: Replacing hydraulic oil.

It is advisable for the tablet press to use clean No. 46 anti-wear hydraulic oil. If the color turns black or there are many particles, it needs to be replaced in time.Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

Related Articles

- The working process of the tablet press you should know

- Operating steps and precautions for electric isostatic press

- Innovative tableting solutions: a comprehensive analysis of laboratory single punch tablet presses

- Lab Scale Mini Tablet Press: Applications, Processes, and Features

- Sample preparation and unloading method of electric tablet press