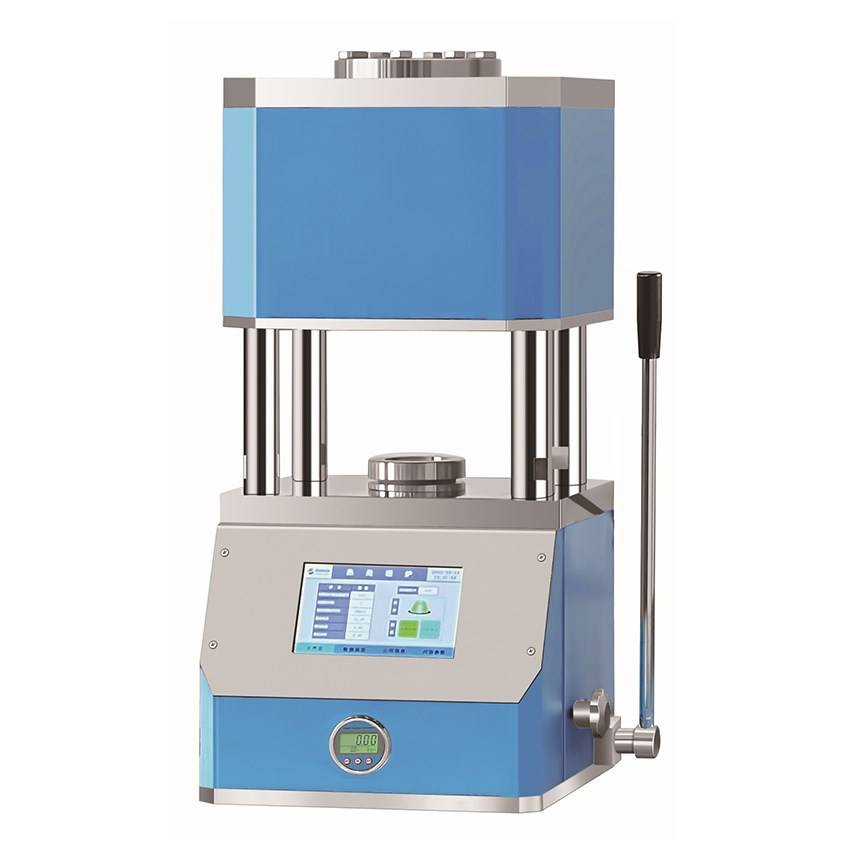

Manual Heated Lab Press

Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

Item Number : CPCL

Price varies based on specs and customizations

- Cylinder stroke

- 80mm

- Heating temperature

- Up to 1000℃

- Sample size

- Φ10-30mm

- Mold shape

- Φ50x90mm

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

The Manual Hot Press is a versatile device designed for creating permanent electrical and mechanical connections between components. Utilizing advanced heating technology, it melts and flows solder to ensure a robust bond. This machine features a titanium indenter for even temperature distribution, a digitally controlled pressure gauge, and an adjustable pressure head for precise application. Ideal for various applications, it operates through a manual hydraulic system, applying controlled pressure and heat to the material placed on the piston.

Applications

Manual Hot Press machines are versatile tools used across various industries for creating strong, permanent connections between materials through heat and pressure. These machines are particularly valued for their ability to maintain constant pressure and temperature, ensuring high-quality end products. Below are the main application areas where Manual Hot Press machines are utilized:

- Electronics Manufacturing: Used for soldering components onto circuit boards, ensuring a secure and reliable electrical connection.

- Composite Material Fabrication: Ideal for pressing layers of composite materials together, such as carbon fiber or fiberglass, to create strong and durable structures.

- Ceramic and Glass Bonding: Employed in bonding ceramic or glass components, often used in the production of advanced ceramics and specialty glass products.

- Polymer Processing: Used in the manufacturing of polymer-based products, where precise temperature and pressure control are crucial for achieving desired material properties.

- Research and Development: Widely used in laboratories for prototyping and developing new materials or products, thanks to their flexibility and precision control.

- Automotive Industry: Applied in the production of automotive parts, where strong and durable bonds are required for safety-critical components.

Detail & Parts

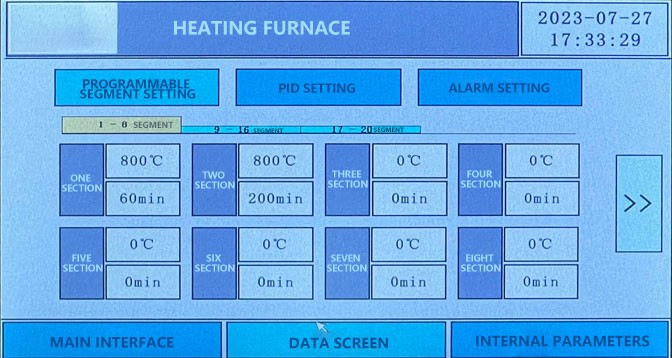

- Step 1: Select the data screen to enter the settings interface

- Step 2: Select "Program Control Section Settings"

- Step 3: There are 20 temperature control programs in the program. Select the first section.

- Step 4: Set the temperature and speed of the first section according to the experimental requirements.

- Step 5: If multiple temperature control programs are needed, you can set the 20 section program.

- Step 6: After setting, press the main interface to return to the operation interface

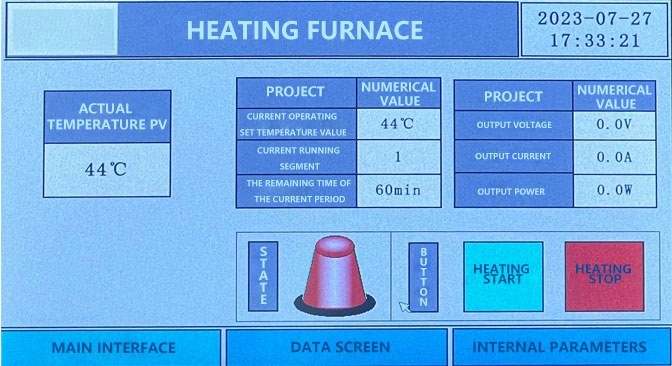

- Step 7: On the main interface, press "heating start".

- Step 8: The device starts to heat up according to the program.

- Step 9: The equipment will automatically stop after heating up. If the setting is incorrect, such as not reaching the set temperature within the specified time, the device will automatically terminate

Features

The Manual Hot Press is a versatile and precise laboratory equipment designed to facilitate heat transfer processes with high accuracy and efficiency. This machine is equipped with several advanced features that ensure optimal performance and durability, making it an essential tool for various scientific and industrial applications.

- Adjustable Pressure Head: This feature allows for even distribution of pressure across the components being processed, ensuring consistent results and preventing damage to delicate materials.

- Titanium Indenter: The use of a titanium indenter ensures even temperature distribution, rapid heat-up, and extended service life, contributing to reliable and efficient operations.

- Digital Pressure Gauge: With a preset pressure range, this gauge provides precise control over the pressure applied, enhancing the accuracy of the pressing process.

- Multiple Program Storage: The ability to pre-store multiple programs allows for quick and easy access to different settings, streamlining the workflow and increasing productivity.

- Touch-Operated Interface: A user-friendly interface with program password protection ensures secure and straightforward operation, reducing the risk of errors and unauthorized access.

- Automatic Press Control: This feature permits setting multiple pressure regulation steps within the molding cycle, offering greater flexibility and control over the pressing process.

- Press Logger: Equipped with a USB port, the press logger allows for the continuous recording of press conditions such as temperature, pressure, and cycle step, facilitating detailed analysis and documentation.

- Custom Moulds: Available moulds for producing plates and different types of samples according to international standards, with options for custom designs and company logo engraving.

- Calibration Service: Regular maintenance and calibration services ensure the longevity and accuracy of the machine, maintaining its performance over time.

Principle

The Manual Hot Press operates by controlling temperature and pressure to facilitate bonding processes. It uses a hydraulic system driven by oil pressure and compressed air, ensuring adjustable vacuum levels for precise pressure application. The machine features a titanium alloy indenter designed for even pressure distribution, rapid heating, and extended durability. Temperature control is digitally managed for accuracy, and a digital pressure gauge allows for preset pressure ranges, ensuring consistent and reliable bonding outcomes.

Advantages

-

Enhanced Safety Features: The manual hot press is equipped with a two-hand start button, an emergency rise switch, imported safety hand grating, and a three-sided seal safety door, ensuring a high level of safety for operators.

-

Customizable Configuration: This machine can be installed according to specific production process requirements, such as under the top cylinder or left and right clamping cylinder. It also supports non-standard customization, making it versatile for various applications.

-

Efficient Heat Conduction: The manual hot press significantly reduces the time required for heat conduction, especially for workpieces up to 20 millimeters thick. This efficiency minimizes the influence of workpiece thickness on heating, enhancing overall productivity.

-

Cost-Effective Equipment: Despite lower pressure compared to isostatic pressing, the manual hot press offers refined pressure bearing materials, improved temperature field uniformity, and reduced energy consumption. This makes it a cost-effective choice for large diameter material preparation.

-

IT Technology Integration: The hot press machine can be controlled by IT technology, allowing for effective control of the densification process and material quality, ensuring consistent and reliable outcomes.

-

Affordable and Reliable: Unlike automatic counterparts, the manual hydraulic press lacks electronic components, making it more affordable. While it requires more physical effort, it remains a reliable choice for those seeking a cost-effective solution.

Technical specifications

| Instrument model | PC-900L |

|---|---|

| Pressure Range | 0-5.0 tons |

| Pressurization process | Manual pressurization |

| Cylinder stroke | 80mm |

| Heating temperature | Up to 1000°C |

| Mold material | Nickel-based alloy (high temperature resistant material) |

| Sample size | Φ10-30mm |

| Mold shape | Φ50x90mm |

| The caliber of the furnace | Φ60mm |

| Size of the whale machine | 400x380x780(LxWxH) |

| power supply | 220V 50Hz |

| Dimensional diagram of powder tablet press |  |

Operation steps

1.Place the sample into the mold.

2.Put the mold into the hot press.

3.Now pre press the sample.

4.Click on the data screen to set the heating temperature.

5.In the data screen, up to 20 heating programs can be set, and the heating speed can be adjusted.

6.Return to the main interface and start heating.

7.When the temperature reaches the set temperature, start pressurizing.

8.Take out the sample.

Trusted by Industry Leaders

FAQ

What Are Laboratory Hydraulic Machines?

What Is A Lab Press?

What Are The Advantages Of Using A Hydraulically Heated Laboratory Press?

What Are The Advantages Of Using Laboratory Hydraulic Machines?

What Is The Purpose Of A Hydraulic Press In Lab?

What Does A Hydraulic Lab Heat Press Do?

What Are The Applications Of Laboratory Hydraulic Machines?

What Are Different Type Of Lab Presses?

What Types Of Samples Or Materials Can Be Processed In A Hydraulically Heated Laboratory Press?

What Are The Main Components Of A Laboratory Hydraulic Machine?

How Does A Hydraulically Heated Laboratory Press Work?

What Considerations Should Be Taken When Selecting A Laboratory Hydraulic Machine?

How Can The Performance Of A Hydraulically Heated Laboratory Press Be Optimized?

4.7 / 5

Impressive build quality and precise temperature control. Highly recommend!

4.8 / 5

Fast delivery and excellent value for money. Durable and efficient!

4.9 / 5

Technologically advanced with a user-friendly interface. A game-changer in the lab!

4.7 / 5

Reliable and sturdy. Perfect for our lab's needs. Great service too!

4.8 / 5

Efficient and easy to operate. Saves us so much time in our experiments!

4.9 / 5

Top-notch durability and performance. A must-have for any lab!

4.7 / 5

Quick setup and fantastic results. Very satisfied with the purchase!

4.8 / 5

Outstanding technological features. Makes our work so much easier and precise!

4.9 / 5

Exceptional quality and support. Highly recommend for any lab setup!

4.7 / 5

Great value for the price. Durable and performs beyond expectations!

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

Efficiently process heat-pressing samples with our Integrated Manual Heated Lab Press. With a heating range up to 500°C, it's perfect for various industries.

Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

The Automatic High Temperature Heat Press is a sophisticated hydraulic hot press designed for efficient temperature control and product quality processing.

Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

Efficiently prepare your samples with our Automatic Heated Lab Press. With a pressure range up to 50T and precise control, it's perfect for various industries.

Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

Enhance your lab's precision with our lab press for vacuum box. Press pills and powders with ease and precision in a vacuum environment, reducing oxidation and improving consistency. Compact and easy to use with a digital pressure gauge.

30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

Discover our split automatic heated lab press 30T/40T for precise sample preparation in material research, pharmacy, ceramics, and electronics industries. With a small footprint and heating up to 300°C, it's perfect for processing under vacuum environment.

Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

The lab press for vacuum box is a specialized piece of equipment designed for laboratory use. Its main purpose is to press pills and powders according to specific requirements.

Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

Efficiently prepare your samples with our Split Manual Heated Lab Press. With a pressure range up to 40T and heating plates up to 300°C, it's perfect for various industries.

Laboratory Manual Hydraulic Pellet Press for Lab Use

Efficient sample preparation with small footprint Manual Lab Hydraulic Press. Ideal for material researching labs, pharmacy, catalytic reaction, and ceramics.

Laboratory Manual Hydraulic Pellet Press for Lab Use

Efficient Manure Lab Hydraulic Press with Safety Cover for sample preparation in material research, pharmacy, and electronic industries. Available in 15T to 60T.

Special Heat Press Mold for Lab Use

Square, round and flat plate forming dies for hot presses.

Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

Experience efficient sample preparation with our Automatic Lab Press Machine. Ideal for material research, pharmacy, ceramics, and more. Features a compact size and hydraulic press functionality with heating plates. Available in various sizes.

Electric Heated Hydraulic Vacuum Heat Press for Lab

The Electric Vacuum Heat Press is a specialized heat press equipment that operates in a vacuum environment, utilizing advanced infrared heating and precise temperature control for high quality, rugged and reliable performance.

Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

Controlled environment lab press machine for glove box. Specialized equipment for material pressing and shaping with high precision digital pressure gauge.

kbr pellet press 2t

Introducing the KINTEK KBR Press - a handheld laboratory hydraulic press designed for entry-level users.

Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

Fast and easy xrf sample pellet preparation with KinTek Automatic Lab Pellet Press. Versatile and accurate results for X-ray fluorescence analysis.

Vacuum Hot Press Furnace Machine for Lamination and Heating

Experience clean and precise lamination with Vacuum Lamination Press. Perfect for wafer bonding, thin-film transformations, and LCP lamination. Order now!

Laboratory Hydraulic Press Lab Pellet Press for Button Battery

Efficiently prepare samples with our 2T Button Battery Press. Ideal for material research labs and small-scale production. Small footprint, lightweight, and vacuum-compatible.

Ball Press Mold for Lab

Explore versatile Hydraulic Hot Press molds for precise compression molding. Ideal for creating various shapes and sizes with uniform stability.

Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

Reduce forming pressure & shorten sintering time with Vacuum Tube Hot Press Furnace for high-density, fine-grain materials. Ideal for refractory metals.

Related Articles

Precision Under Pressure: The Physics and Psychology of the Hydraulic Hot Press

Discover how the synergy of heat and pressure in a hydraulic hot press transforms materials, guided by the elegant physics of Pascal's Law.

More Than a Squeeze: The Physics and Psychology of the Hydraulic Hot Press

An insight into the hydraulic hot press, where Pascal's Law meets thermodynamics to reshape materials. A story of force, heat, and control.

The Physics of Flawless Materials: Deconstructing the Hydraulic Hot Press

Discover how the synergy of Pascal's Law and thermal energy in a hydraulic hot press enables precise, repeatable material bonding and forming.

Pressure and Heat: Forging Certainty into Matter

A hot press doesn't just shape materials; it eliminates hidden flaws and forges atomic-level trust. Learn the physics of material integrity.

Why Your Composite and Polymer Parts Keep Failing: The Secret Is Simultaneous Heat and Pressure

Struggling with inconsistent composite or polymer bonding? Discover why separate heating and pressing fails and how a hot hydraulic press ensures repeatable, high-quality results.

Beyond Brute Force: Why the Strongest Materials Fail and How Your Lab Can Predict It

Learn why focusing on brute force is a mistake. Discover how understanding material microstructure—not just specs—prevents failure and how to fix it.

Manual Hydraulic Presses for Laboratory Use: A Comprehensive Guide

Explore the intricacies of manual hydraulic presses in labs, including operation, benefits, and comparison with automatic models. Ideal for those seeking detailed insights on sample preparation and cost-effectiveness.

Comprehensive Guide to Integrated Manual Heated Lab Pellet Presses

Explore the features and applications of integrated manual heated lab pellet presses. Learn about customization options, capacities, and benefits for spectroscopy and analysis.

Comprehensive Guide to Metal Mold Pressing: Techniques, Equipment, and Applications

Explore the detailed process of metal mold pressing, including equipment, techniques, and applications. Learn how hydraulic presses shape materials like metal and rubber efficiently.

Hydraulic Heated Lab Pellet Press: Comprehensive Guide to Selection and Usage

Explore the features and applications of hydraulic heated lab pellet presses. Learn how to choose the right model for your research needs and maximize efficiency in material science labs.

Force and Fire: A Guide to Material Transformation with Hot and Cold Pressing

Hot and cold pressing aren't just about temperature; they are different philosophies of material creation. Learn when to use force vs. force and fire.

Why Your Molded Parts Fail: The Hidden Truth About Heat and Pressure

Struggling with warped or inconsistent parts? Learn why pressure isn't the problem and how precise thermal control in a hydraulic press is the key.