Introduction to Split Automatic Heated Lab Pellet Press

In the realm of laboratory analysis, precision in pellet preparation is paramount. The split automatic heated lab pellet press emerges as a pivotal tool, ensuring consistent results across various analytical applications. This article delves into the advanced features and benefits of these innovative presses, which are particularly suited for high-throughput laboratories. By automating key processes, providing heated dies, and offering variable pressure settings, these presses significantly enhance workflow efficiency and pellet quality, reducing the need for manual labor. Join us as we explore how these sophisticated instruments are revolutionizing the field of laboratory analysis.

Key Features of Split Automatic Heated Lab Pellet Press

The Split Automatic Heated Lab Pellet Press is a sophisticated piece of equipment designed to facilitate precise and efficient sample preparation in laboratory settings. This press is equipped with a range of advanced features that enhance its functionality and usability, making it an indispensable tool for researchers and technicians.

Automatic Operation

One of the standout features of the Split Automatic Heated Lab Pellet Press is its automatic operation. This feature allows for the seamless execution of the pelletization process, from pressurization to the release of pressure, without the need for manual intervention. The automatic system ensures consistency and reproducibility in sample preparation, which is crucial for accurate and reliable results. The press can be programmed to perform specific tasks such as pressurization, holding pressure, and pressure replenishment, ensuring that the sample is subjected to uniform pressure throughout the process.

Heated Dies

The press is equipped with heated dies, which are essential for processing temperature-sensitive materials. The heated dies can be controlled to maintain precise temperatures, ensuring that the sample is not subjected to excessive heat, which could alter its properties. The temperature control is highly accurate, with a temperature sampling frequency of 0.1 seconds, ensuring uniform temperature distribution across the die surface. This feature is particularly beneficial for materials that require specific temperature conditions to achieve optimal pelletization.

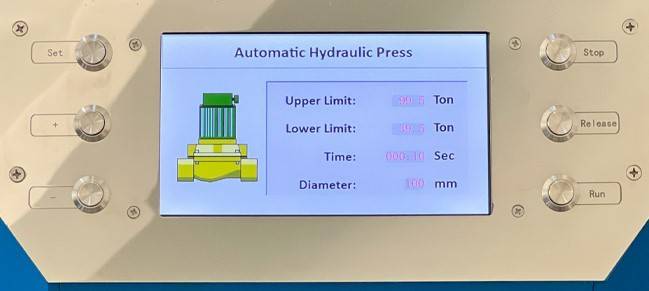

Variable Pressure Settings

Another key feature of the Split Automatic Heated Lab Pellet Press is its variable pressure settings. The press can be adjusted to apply different levels of pressure, ranging from low to high, depending on the specific requirements of the sample. This flexibility allows for the processing of a wide range of materials, each with its unique pressure requirements. The pressure settings can be easily adjusted using the user-friendly touch screen display, making it convenient for operators to customize the process according to their needs.

Compatibility with Different Die Sizes

The press is designed to be compatible with different die sizes, which enhances its versatility and utility. Whether working with small or large samples, the press can accommodate various die sizes, ensuring that it can handle a broad spectrum of applications. This compatibility eliminates the need for multiple presses, streamlining the sample preparation process and reducing the overall cost of equipment.

Advanced Electronic Control

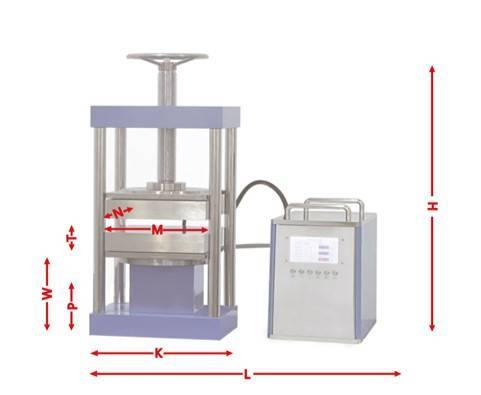

The Split Automatic Heated Lab Pellet Press is equipped with advanced electronic control systems that facilitate precise and efficient operation. The press uses a hydraulic system with a closure force of up to 25 tons, ensuring that the sample is subjected to consistent and uniform pressure. The mechanical structure of the press features four columns with a 60 mm diameter and a sliding platen driven by self-lubricating bushings, which enhances its stability and durability.

Safety Features

Safety is a paramount consideration in laboratory settings, and the Split Automatic Heated Lab Pellet Press is designed with several safety features to ensure the protection of operators and the integrity of the samples. The press includes protection doors with safety locks, preventing unauthorized access and accidental operation. Additionally, the press is CE labeled, indicating that it meets the stringent safety standards required for laboratory equipment.

User-Friendly Interface

The press is equipped with a user-friendly touch screen display that allows operators to easily program and control the pelletization process. The interface permits the free definition of the molding cycle by setting parameters such as the displacements of the moving platen of the press. This intuitive interface simplifies the operation of the press, making it accessible even to those with minimal technical expertise.

Efficient Heat Distribution

The press features specifically designed flat heating elements that ensure uniform temperature distribution over the platen surface. This efficient heat distribution is crucial for maintaining the integrity of the sample and preventing any thermal gradients that could affect the quality of the pellet. The heat plate of the machine is made of solid longitudinal drilled steel plate, which provides good precision and durability of the pressure plate.

Low Heat Consumption

The heating system and heat conduction system of the press are designed in sections, with low heat consumption and uniform heat conduction. This design not only conserves energy but also ensures that the sample is subjected to consistent heat throughout the pelletization process. The low heat consumption feature makes the press environmentally friendly and cost-effective to operate.

In conclusion, the Split Automatic Heated Lab Pellet Press is a highly advanced and versatile piece of equipment that offers a range of features to facilitate precise and efficient sample preparation. Its automatic operation, heated dies, variable pressure settings, compatibility with different die sizes, advanced electronic control, safety features, user-friendly interface, efficient heat distribution, and low heat consumption make it an indispensable tool for researchers and technicians in various laboratory settings.

Applications of Split Automatic Heated Lab Pellet Press

The split automatic heated lab pellet press is a versatile piece of equipment with applications spanning across various analytical techniques and industries. Its ability to produce high-quality, consistent pellets makes it an indispensable tool in fields such as X-ray fluorescence (XRF) analysis, infrared spectroscopy, and pharmaceutical development.

X-ray Fluorescence Analysis

XRF analysis is a non-destructive method used to determine the elemental composition of materials. The quality of the pellet prepared significantly impacts the accuracy and reproducibility of the XRF results. The split automatic heated lab pellet press ensures that samples are compressed uniformly, which is crucial for maintaining consistent X-ray intensity. By keeping the sample amount and pressure constant, this press minimizes errors due to variations in pelletization pressure. Moreover, the press can operate at pressures where X-ray intensity saturates, further enhancing the reproducibility of the sample preparation process.

Infrared Spectroscopy

Infrared spectroscopy involves the analysis of molecular vibrations within a sample. The split automatic heated lab pellet press is commonly used to prepare pellets from a matrix of potassium bromide (KBr) and an organic sample. These pellets are then analyzed to identify the molecular structure of the organic compound. The press's ability to produce uniform pellets ensures that the infrared spectrum obtained is clear and free from artifacts, which can be caused by uneven compression.

Pharmaceutical Development

In the pharmaceutical industry, the split automatic heated lab pellet press is used for various applications, including the preparation of drug formulations for analysis and the production of tablets for testing. The press's automated features allow for high-throughput sample preparation, which is essential in a fast-paced research environment. Additionally, the press can be used to produce thin polymer films using heated platens, which are essential for transmission sampling by IR spectroscopy.

Other Applications

Beyond the aforementioned applications, the split automatic heated lab pellet press is also used in composite material studies, where it compresses powder into a desired shape to create composite materials. It is also employed in tasks such as pill making and laminating, demonstrating its versatility in various laboratory settings.

Advantages of Pressed Pellets

Using pressed pellets for analytical techniques such as XRF analysis offers several advantages. Pressed pellets deliver better results compared to no preparation at all, providing greater consistency and faster sample production. The automated system of the split automatic heated lab pellet press ensures that the same pellet quality is achieved regardless of the speed of production. This method is considered a convenient, cost-effective, and reliable sample preparation technique that has become an industry standard.

In conclusion, the split automatic heated lab pellet press is a versatile and essential tool in modern laboratories. Its ability to produce high-quality, consistent pellets makes it invaluable for a wide range of analytical techniques and applications. Whether it is for XRF analysis, infrared spectroscopy, or pharmaceutical development, this press ensures that samples are prepared with the highest level of precision and reproducibility.

Benefits of Using Split Automatic Heated Lab Pellet Press

The adoption of split automatic heated lab pellet presses in modern laboratories has revolutionized the sample preparation process, particularly for techniques like X-ray fluorescence (XRF) analysis. These advanced systems offer numerous benefits that enhance workflow efficiency, improve pellet quality, and reduce the need for manual labor, thereby contributing to overall laboratory productivity and accuracy.

Improved Workflow Efficiency

One of the most significant advantages of using a split automatic heated lab pellet press is the substantial improvement in workflow efficiency. These presses are designed to operate autonomously once programmed, allowing laboratory technicians to focus on other critical tasks. The automation feature ensures that the pressing process is consistent and uninterrupted, which is crucial in high-throughput environments. For instance, in laboratories conducting XRF measurements on a large quantity of samples, a high-throughput hydraulic press specifically adapted for XRF sample preparation can significantly speed up the process. These presses feature integrated pellet dies and have swifter operations for repeated use, focusing on automations and mechanical systems for quickly extracting the pellet and preparing for the next sample.

Enhanced Pellet Quality

The quality of pellets produced using split automatic heated lab pellet presses is superior to those made using traditional methods. These presses ensure uniformity in pellet size and density, which is essential for accurate and reliable XRF analysis. The consistency in pellet quality eliminates variations that could arise from manual pressing, thereby improving the accuracy of the analytical results. Additionally, the heated feature of these presses allows for better control over the pressing conditions, which can be adjusted to optimize pellet formation for different types of samples. This level of precision is particularly beneficial when dealing with sensitive or difficult-to-press materials.

Reduced Manual Labor

Manual labor is significantly reduced with the use of split automatic heated lab pellet presses. The automated nature of these presses minimizes the need for continuous technician intervention, reducing the physical strain and time spent on repetitive tasks. This not only improves the working conditions for laboratory staff but also allows them to allocate their time and skills to more complex and value-added activities. The reduction in manual labor also decreases the likelihood of human error, which can be a significant source of variability in the sample preparation process.

Cost-Effectiveness

Despite their advanced features, split automatic heated lab pellet presses are designed to be cost-effective. They offer a high return on investment by improving efficiency and reducing labor costs. The ability to produce high-quality pellets consistently means fewer reworks and retests, which can be costly and time-consuming. Additionally, the durability and low maintenance requirements of these presses contribute to their overall cost-effectiveness. Laboratories can achieve significant savings in the long run by investing in these advanced systems.

Flexibility and Versatility

Split automatic heated lab pellet presses are highly flexible and versatile, making them suitable for a wide range of applications beyond XRF analysis. They can handle various types of materials, including powders, granules, and irregularly shaped samples, ensuring that laboratories can use them for multiple purposes. This versatility reduces the need for multiple pieces of equipment, saving space and further contributing to cost savings. The adjustable settings on these presses allow for customization to meet the specific requirements of different samples, ensuring optimal results in every application.

In conclusion, the benefits of using split automatic heated lab pellet presses in laboratory settings are profound. These advanced systems enhance workflow efficiency, improve pellet quality, reduce manual labor, and offer cost-effectiveness and versatility. By adopting these presses, laboratories can achieve higher productivity, accuracy, and reliability in their sample preparation processes, ultimately leading to better analytical outcomes.

Comparison with Manual and Semi-Automatic Pellet Presses

In the realm of laboratory sample preparation, the choice between manual, semi-automatic, and fully automatic pellet presses significantly impacts the efficiency, accuracy, and consistency of the results. This section delves into the comparative advantages and drawbacks of these systems, particularly focusing on their application in X-ray fluorescence (XRF) analysis.

Efficiency and Ease of Use

Fully automatic hydraulic presses stand out in busy laboratories where workflow optimization is crucial. Once programmed, these presses can operate autonomously, freeing up technicians to attend to other tasks. Available in various tonnage configurations (30, 40, and 60 tonnes), these presses are less labor-intensive compared to their manual counterparts, making them ideal for high-frequency pressing tasks. For laboratories conducting XRF measurements on a large number of samples, high-throughput hydraulic presses specifically designed for XRF sample preparation are particularly beneficial. These presses feature integrated pellet dies and streamlined operations that enhance repeatability and speed.

In contrast, manual and semi-automatic presses require more direct operator involvement, which can be physically demanding and time-consuming. Manual presses, for instance, necessitate significant physical effort to operate, and their use can become laborious if frequent pressing is required. Semi-automatic models offer a middle ground, reducing some of the physical exertion but still relying on operator input for certain operations.

Accuracy and Consistency

The accuracy and consistency of the pellet preparation process are critical for reliable XRF analysis. Automatic presses excel in this regard due to their ability to apply consistent pressure and maintain precise control over the pressing parameters. This consistency minimizes variability in sample preparation, leading to more reliable and reproducible analytical results.

Manual presses, while cost-effective for infrequent use, are prone to operator-induced variability. Each sample may be subjected to slightly different pressures, depending on the operator's technique and effort. This variability can introduce errors in XRF analysis, as the intensity of X-rays can vary with the pressure applied during pelletization.

Space and Resource Management

Space efficiency is another factor to consider. Mini presses, which weigh around 4 kilos and can apply up to 2 tons of pressure, are particularly advantageous in this regard. They produce smaller pellets (7 mm diameter) and require less counter space for use and storage. Additionally, they often include pressure gauges, allowing operators to apply consistent loads and improve sample repeatability.

Cost Considerations

The cost of acquisition and maintenance is a significant factor in the choice of pellet press. Automatic presses, while more expensive upfront, offer long-term savings through reduced labor costs and improved efficiency. Manual and semi-automatic presses, on the other hand, are more budget-friendly but may incur higher labor costs and potential inaccuracies due to operator variability.

Conclusion

In summary, the choice between manual, semi-automatic, and fully automatic pellet presses depends on the specific needs and constraints of the laboratory. Automatic presses offer the highest levels of efficiency, accuracy, and consistency, making them ideal for high-throughput laboratories conducting XRF analysis. Manual and semi-automatic presses, while more labor-intensive and less consistent, provide cost-effective solutions for less frequent use. Ultimately, the decision should balance the need for reliable results, operational efficiency, and budgetary considerations.

Customization Options and Accessories

In the realm of laboratory equipment, the ability to customize and accessorize is paramount for meeting specific research needs and enhancing overall functionality. This section delves into the various customization options available for laboratory presses, including different die sizes, pressure settings, and a plethora of additional accessories that can significantly augment the performance and versatility of these essential tools.

Die Size Variability

One of the fundamental aspects of customization in laboratory presses is the option to select from a range of die sizes. Dies are available in various diameters and heights, catering to the pressing of different materials and the production of pellets or samples of specific dimensions. For instance, standard die sizes might range from small, precise measurements suitable for micro-samples to larger sizes designed for bulk material processing. This flexibility ensures that researchers can obtain samples that are directly applicable to their experimental setups, thereby streamlining the research process and reducing the need for additional sample preparation.

Pressure Settings and Control

Customization also extends to the pressure settings of the press. Modern laboratory presses come equipped with sophisticated pressure control systems that allow users to set and maintain precise pressure levels. This is crucial for experiments where the integrity and uniformity of the pressed materials are critical. The ability to adjust pressure settings can also prevent over-compression or under-compression of samples, which can affect the quality and reliability of experimental results. Some advanced presses even offer the capability to store multiple pressure profiles, enabling users to quickly switch between different experimental conditions without manual recalibration.

Additional Accessories

To further enhance the functionality of laboratory presses, a variety of accessories are available. These can include:

- Cooling Systems: Essential for thermoplastic materials, these systems control the cooling rate of the platens, ensuring the material solidifies at the correct temperature before the mold is opened.

- Force Control Options: These provide accurate control over the closure force, which is particularly important for applications requiring precise force application.

- Protective Shields and Safety Features: These are crucial for maintaining a safe working environment, especially when operating at high pressures.

- Extended Plungers and Die Sleeves: These are designed for pressing long or tall pellets, offering additional fill height for powders and enhancing the versatility of the press.

Quality and Certification

When considering customization options, it is also important to note the quality and certification of the equipment. Many high-quality presses are built to meet stringent standards such as CE, ISO, and SGS, ensuring reliability and safety. The use of high-strength alloy steel and chrome-plated surfaces in the construction of components like columns and platens enhances durability and resistance to wear.

Conclusion

In conclusion, the customization options and accessories available for laboratory presses are extensive and cater to a wide range of research needs. From variable die sizes and precise pressure control to a variety of additional features that enhance safety and functionality, these customizations ensure that laboratory presses can be tailored to meet the specific requirements of any research project. By investing in a press with these customizable features, researchers can significantly enhance their experimental capabilities and achieve more accurate and reliable results.

Maintenance and Care for Split Automatic Heated Lab Pellet Press

Maintaining and caring for your split automatic heated lab pellet press is crucial to ensure its longevity and optimal performance. Proper maintenance not only extends the life of the equipment but also ensures that the quality of the pellets produced remains consistent. Here are detailed guidelines on how to maintain and care for your lab pellet press, including cleaning procedures and troubleshooting common issues.

Regular Cleaning Procedures

-

Daily Cleaning: After each use, it is essential to clean the platens and the interior of the press. Use a soft cloth or brush to remove any residual powder or debris. For stubborn residues, a mild solvent can be used, but ensure it is compatible with the materials of the press to avoid damage.

-

Weekly Cleaning: Once a week, perform a more thorough cleaning. This includes checking and cleaning all seals, hoses, and connectors for any signs of wear or damage. Replace any components that show signs of degradation to prevent leaks and ensure a tight seal.

-

Monthly Cleaning: Monthly, check the hydraulic system for any leaks or unusual noises. Clean the hydraulic fluid reservoir and replace the fluid if necessary. Ensure that the hydraulic oil used is of the correct type and viscosity recommended by the manufacturer.

Lubrication

Regular lubrication of moving parts is essential to prevent friction and wear. Use a high-quality lubricant recommended by the manufacturer. Lubricate the moving parts of the press, including the hydraulic cylinder, pistons, and any mechanical joints. This should be done at least once a month or as specified in the user manual.

Temperature and Pressure Maintenance

-

Temperature Control: The heated lab pellet press relies on precise temperature control for consistent pellet quality. Regularly check and calibrate the temperature control system to ensure it is functioning correctly. Any deviation from the set temperature can affect the quality of the pellets.

-

Pressure Maintenance: Ensure that the pressure settings are within the recommended range. Over time, the hydraulic system may require adjustments to maintain the correct pressure. Regularly check the pressure gauge and make adjustments as needed.

Troubleshooting Common Issues

-

Leaks: If you notice any leaks, immediately inspect the seals, hoses, and connectors. Replace any damaged components to prevent further issues.

-

Excessive Vibration: Excessive vibration can be caused by unbalanced pressure or misaligned components. Check the alignment of the platens and the hydraulic system. Adjust as necessary to reduce vibration.

-

Inconsistent Pellet Quality: If the quality of the pellets is inconsistent, check the temperature and pressure settings. Ensure they are within the recommended range and properly calibrated. Also, inspect the dies for any wear or damage.

Preventive Measures

-

Regular Inspections: Conduct regular inspections of the press to identify any potential issues before they become major problems. Check for signs of wear, cracks, or damage in all components.

-

Training: Ensure that all users are properly trained on how to operate the press. Proper operation reduces the risk of damage and ensures consistent pellet quality.

-

Documentation: Keep a maintenance log to document all cleaning, lubrication, and inspection activities. This helps in tracking the maintenance schedule and identifying any recurring issues.

By following these maintenance and care guidelines, you can ensure that your split automatic heated lab pellet press remains in optimal condition, providing consistent and high-quality pellets for your analytical needs. Regular maintenance not only saves costs in the long run but also ensures the safety and reliability of the equipment.

Related Products

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- 30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use