Introduction to Lab Presses and Their Applications

Lab presses are versatile and essential tools that are used in various laboratory applications. They apply pressure to materials in a controlled environment, allowing for the extraction of valuable information about the material's properties and behavior. Lab presses are commonly used in materials science, geology, and engineering for applications such as sample preparation, material characterization, and quality control. They come in different types, including hydraulic, mechanical, and pneumatic presses, and can be customized to meet specific laboratory requirements. In the next sections, we will discuss the importance of pressure and temperature in lab presses, factors affecting pressure in lab presses, how to determine the required pressure for lab presses, and questions to ask when purchasing a lab press.

Table of Contents

Importance of Pressure and Temperature in Lab Presses

When it comes to laboratory equipment, lab presses are one of the most widely used machines in various industries. These machines are commonly used to apply pressure and heat to a sample, causing it to undergo a physical or chemical change.

Pressure Requirements of a Lab Press

The amount of pressure required for a specific process can vary widely, depending on the sample being processed. The pressure requirements of a lab press are important because they determine the amount of force applied to the sample, which can affect the quality and consistency of the final product. The pressure generated by a lab press is typically measured in pounds or tons per square inch (psi or tsi) and can range from 15 to upwards of 100 tons of compressive force.

Temperature Requirements of a Lab Press

The temperature of the lab press is equally important, since it can affect the speed and effectiveness of the process. Lab presses have heated platens that can range from 600°F to 1200°F. The temperature range required will depend on the type of sample being processed, as well as the desired outcome. In general, the temperature of the lab press must be carefully controlled to ensure that the sample is processed efficiently and effectively.

Pressure and Temperature Requirements

In general, the pressure and temperature requirements of a lab press will depend on the type of sample being processed, as well as the desired outcome. It is therefore essential for laboratory professionals to have an understanding of the pressure and temperature requirements of their lab presses, in order to ensure that they are able to achieve the desired results. By carefully controlling the pressure and temperature of their lab presses, researchers and technicians can create high-quality products and conduct accurate experiments, leading to new discoveries and innovations in various fields.

Considerations When Buying a Lab Press

When purchasing a lab press, it is important to consider how much pressure and temperature is needed for a specific sample. Other factors to consider include the size of the platens, the type of control system, how long the temperature needs to be held, how precisely the temperature needs to be controlled, and whether a benchtop or floor press would work best for the application and space.

Maintenance and Safety Tips

Lab presses experience repeated heat and high pressures, making regular maintenance important. Regularly inspect the press for leaking hoses and seals, cracks, and excessive vibration. Keep the working parts of the press clean from dirt and any leaking oil or fluid, and ensure the press is properly lubricated. Safety precautions should also be taken when using a lab press, including wearing hand and eye protection and creating an effective training procedure to introduce new users to safe lab press operation.

In conclusion, understanding the pressure and temperature requirements of lab presses is critical for achieving accurate and consistent results in various fields of research and development. When purchasing a lab press, it is important to consider the specific requirements of the application, and to take necessary safety precautions when using the equipment.

Factors Affecting Pressure in Lab Presses

When using a heated lab press, it is essential to determine the appropriate amount of pressure to use for optimal results. However, several factors affect the pressure needed in a lab press. Understanding these factors can help scientists achieve accurate and effective results in their research and experiments.

Material Type and Size

The type and size of the material being pressed are crucial factors that determine the amount of pressure required. Materials with larger particles or a larger surface area require more pressure to achieve the desired outcome. Conversely, smaller particles or smaller surface areas require less pressure. Therefore, it is important to consider the material type and size when determining the appropriate pressure needed.

Temperature

The temperature at which a heated lab press is being operated is another critical factor that affects the pressure required. As the temperature increases, the pressure required to achieve the desired outcome decreases. Conversely, as the temperature decreases, the pressure needed increases. Therefore, it is crucial to consider the operating temperature when determining the appropriate pressure required.

Desired Outcome

Determining the desired outcome is another factor that affects the pressure needed in a lab press. Different outcomes require different amounts of pressure. For example, creating a dense and compact material requires more pressure than creating a loosely packed material. Therefore, it is essential to determine the desired outcome when determining the appropriate pressure required.

Type of Press

Different presses have different maximum pressure capacities, which is another factor that affects the pressure needed. It is essential to choose the right type of press for the material being pressed to avoid overloading the press, which can cause it to become damaged or even destroyed. Therefore, it is crucial to consider the type of press being used when determining the appropriate pressure required.

Conclusion

In conclusion, determining the appropriate pressure needed in a lab press requires consideration of several factors. Material type and size, temperature, desired outcome, and type of press all play a critical role in determining the amount of pressure required. By considering these factors, scientists can achieve accurate and effective results in their research and experiments.

How to Determine the Required Pressure for Lab Presses

The required pressure for a heated lab press depends on several factors such as the material to be pressed, its size, and the desired thickness. The pressure needed can be determined by following these steps:

Step 1: Know the Properties of the Material

The properties of the material to be pressed are crucial in determining the required pressure for a lab press. The melting point, density, and hardness of the material are essential factors to consider. The operator should know if the material is elastic or plastic, as the required pressure for plastic materials is usually higher than for elastic materials.

Step 2: Consult the Material Data Sheet

Consulting the material data sheet is another way to determine the required pressure for a lab press. The data sheet contains information on the optimal pressure, temperature, and time required for pressing the material. This information can be used as a starting point for setting up the lab press.

Step 3: Consult with a Manufacturer

Consulting with a manufacturer is also a good way to determine the required pressure for a lab press. The manufacturer can provide information on the optimal pressure and temperature for the material based on their experience and expertise.

Step 4: Start with a Low Pressure

Starting with a low pressure and gradually increasing it until the desired outcome is achieved is another way to determine the required pressure for lab presses. This method is useful when the material data sheet or manufacturer's recommendation is not available. However, it is crucial to use proper safety precautions and follow the manufacturer's guidelines to avoid damaging the material or the equipment.

Step 5: Consider the Desired Outcome

The desired outcome is another important factor to consider when determining the required pressure for lab presses. The level of precision, control, and uniformity should be considered when setting up the lab press. For instance, if the desired outcome is high precision and uniformity, the pressure should be set higher than for a less demanding outcome.

In conclusion, determining the required pressure for a heated lab press is a critical step in achieving accurate and reliable results in laboratory experiments. The properties of the material, the material data sheet, consulting with a manufacturer, starting with a low pressure, and considering the desired outcome are essential factors to consider when setting up the lab press.

Questions to ask when purchasing a lab press

When purchasing a lab press, it is important to consider several factors to ensure that you choose the right press for your application. Here are some questions to ask when purchasing a lab press:

What is the pressure range of the lab press?

The pressure range of a lab press is an important consideration as it determines the amount of force that can be applied to the sample. Depending on the material and the desired outcome, the pressure required can vary greatly. It is important to consult with the manufacturer or supplier to determine the appropriate pressure range for your application.

What is the temperature range of the lab press?

The temperature range of the lab press is also an important consideration as some materials require higher temperatures to achieve desired results. It is important to ensure that the temperature range of the lab press is suitable for your specific application.

What is the size of the lab press?

The size of the lab press is an important consideration as it determines the size of the sample that can be processed. It is important to choose a lab press that is large enough to accommodate the size of your sample.

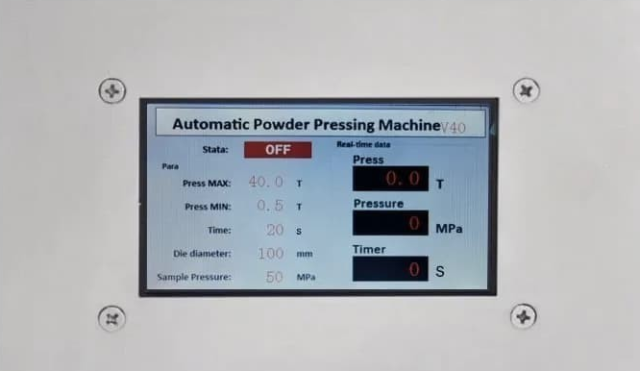

What is the level of automation of the lab press?

The level of automation of the lab press is an important consideration as it can greatly affect the efficiency and accuracy of the sample preparation process. An automatic lab press may be preferred for busy laboratories where technicians need to perform other tasks while the press is in operation.

What is the cost of the lab press?

The cost of the lab press is an important consideration as it can vary greatly depending on the features and capabilities of the press. It is important to consider the budget available for the lab press and to choose a press that provides the required features and capabilities within the budget.

What is the manufacturer or supplier's reputation?

The reputation of the manufacturer or supplier is an important consideration as it can provide an indication of the quality of the lab press and the level of support that can be expected. It is important to choose a reputable manufacturer or supplier that provides quality products and good customer support.

In conclusion, when purchasing a lab press, it is important to ask the right questions to ensure that you choose the right press for your application. The pressure range, temperature range, size, level of automation, cost, and manufacturer or supplier's reputation are important considerations that should be taken into account.

Related Products

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

Related Articles

- Automatic Hydraulic Press: The Ultimate Guide for Efficient Sample Preparation and Industrial Processes

- A Comprehensive Guide on Pressing XRF Pellets Using a KinTek Automatic Hydraulic Press

- Automatic flat plate heat press operating steps

- Manual Hydraulic Pellet Press: An Efficient Tool for Spectral Analyses Preparation

- Fully automatic tablet press operating steps and replacement accessories