Introduction to Manual Lab Hydraulic Pellet Press

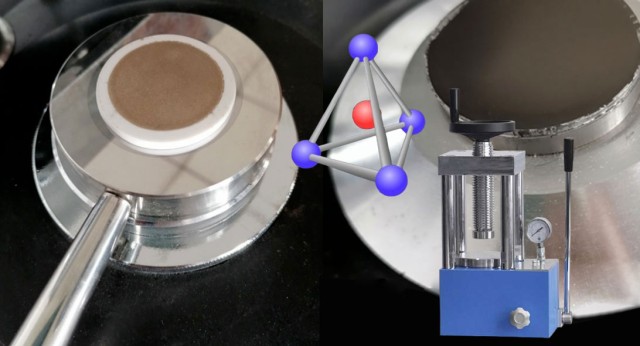

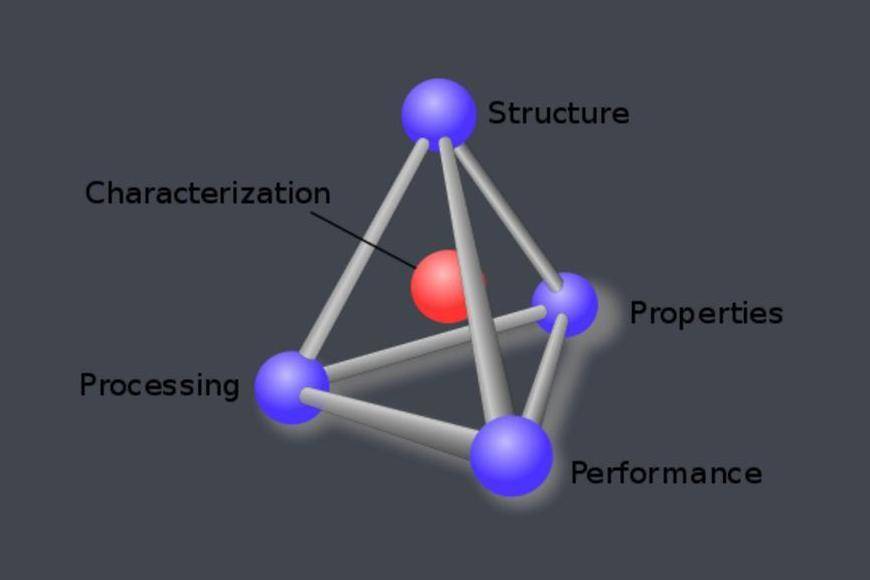

In the realm of spectral analyses such as X-ray fluorescence and infrared spectroscopy, the precision of sample preparation is paramount. Manual Lab Hydraulic Pellet Presses emerge as critical tools in laboratory settings, enabling the creation of high-quality pellets essential for accurate data collection. This comprehensive guide delves into the significance and applications of these presses, highlighting their features, operational procedures, and maintenance requirements. By exploring the intricacies of setting up and using a manual hydraulic pellet press, we aim to equip laboratory professionals with the knowledge and skills necessary for optimal performance and reliable results.

Key Features of Manual Hydraulic Pellet Presses

Manual hydraulic pellet presses are essential tools in laboratories for preparing high-quality pellets used in various analytical techniques such as X-ray fluorescence and infrared spectroscopy. These presses are designed to create pellets with a smooth, homogeneous surface, ensuring accurate and reliable results. Here, we delve into the key features that make manual hydraulic pellet presses indispensable in laboratory settings.

Variable Pressure Force

One of the standout features of manual hydraulic pellet presses is their ability to apply variable pressure forces. These presses can deliver up to 250 kN of force, which is crucial for accommodating different types of samples and achieving the desired pellet density. The pressure force can be adjusted in increments of 10 kN, providing precise control over the pressing process. This variability ensures that users can tailor the pressure to suit the specific requirements of their samples, whether they are solid or highly permeable.

Different Diameter Pressing Tools

Manual hydraulic pellet presses come equipped with pressing tools of various diameters, typically including 40 mm, 32 mm, and 15 mm options. This versatility allows users to select the appropriate tool based on the size of the sample and the desired pellet diameter. The availability of multiple tool sizes ensures that the press can handle a wide range of applications, from small-scale experiments to larger, more robust samples.

Ease of Use and Maintenance

The design of manual hydraulic pellet presses prioritizes ease of use and maintenance. The operation is straightforward, involving a simple hand lever that controls the pressure application. This user-friendly interface minimizes the learning curve, making it accessible even to those with minimal technical expertise. Additionally, the presses are designed for easy cleaning, which is essential for maintaining hygiene and preventing cross-contamination between samples. The solid and compact construction, along with impact-resistant cladding, ensures durability and longevity, reducing the need for frequent maintenance.

Safety Features

Safety is a paramount consideration in laboratory equipment, and manual hydraulic pellet presses are equipped with several safety features. One notable feature is the automatic pressure relief mechanism, which activates in case of overstress. This ensures that the press does not exceed its operational limits, protecting both the equipment and the user from potential damage or injury. The clear pressure force display also aids in monitoring the pressure levels, allowing users to operate the press safely and efficiently.

Single-Stage Piston Stroke

The single-stage piston stroke, with a maximum length of 25 mm, is another critical feature of manual hydraulic pellet presses. This design ensures consistent and controlled movement, facilitating the uniform application of pressure. The piston stroke length is sufficient to accommodate various sample sizes, ensuring that the entire sample is uniformly compressed into a pellet.

Applications

Manual hydraulic pellet presses are widely used in various analytical applications, including elemental analysis through X-ray fluorescence and infrared spectroscopy. The high-quality pellets produced by these presses provide a homogeneous surface, which is essential for accurate and reproducible results. Whether for research, quality control, or industrial applications, these presses are invaluable tools for ensuring the integrity and reliability of analytical data.

In conclusion, manual hydraulic pellet presses are characterized by their variable pressure force, different diameter pressing tools, ease of use and maintenance, safety features, and single-stage piston stroke. These features collectively make them indispensable in laboratory settings, where precision and reliability are paramount. Whether for academic research or industrial applications, these presses provide the necessary tools to produce high-quality pellets for a wide range of analytical techniques.

Setting Up and Operating the Pellet Press

The manual hydraulic pellet press is a critical tool in laboratories for preparing high-quality pellets used in various analytical techniques such as X-ray fluorescence analysis and infrared spectroscopy. This section provides a comprehensive guide on how to assemble, load samples, and operate the manual hydraulic pellet press, including essential safety precautions and troubleshooting common issues.

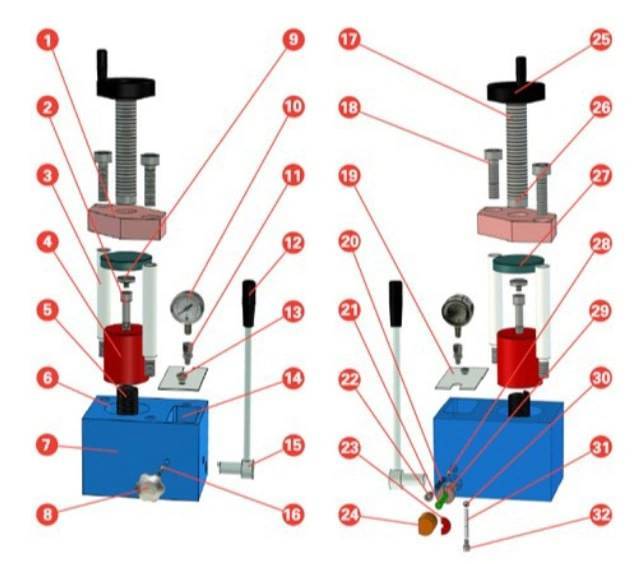

Assembly of the Pellet Press

To begin, ensure the workspace is clean and free of any obstructions that could hinder the operation or safety of the press. The assembly process involves the following steps:

-

Insert the Die: Place the appropriate die into the cavity of the press. The die size should match the intended pellet diameter, with common sizes including 40 mm, 32 mm, and 15 mm.

-

Load the Sample: Carefully transfer the ground sample mix into the die cavity using a metal spatula. It is crucial to spread the sample evenly to ensure a uniform pellet. The amount of powder should be adjusted based on the desired pellet thickness.

-

Distribute the Sample: Insert the bolt press into the cavity and rotate it to evenly distribute the sample particles within the die.

-

Secure the Die Set: Transfer the assembled die set to the hydraulic pellet press. Rotate the wheel to secure it tightly in place.

Operating the Pellet Press

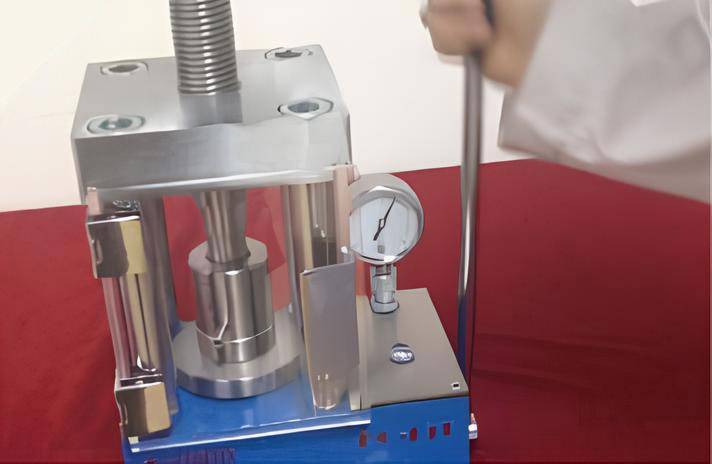

Operating the manual hydraulic pellet press involves applying controlled pressure to create a solid pellet. Here’s how to proceed:

-

Close the Valve: Ensure the valve of the hydraulic press is closed to maintain pressure within the system.

-

Apply Pressure: Pull the lever of the press gradually to apply pressure. The handle will become tight as the desired pressure is reached. The pressure should be monitored using the force gauge, which is typically displayed in 10 kN steps.

-

Release Pressure: To remove the die, first, loosen the pressure by slowly releasing the lever. Then, move the upper wheel of the press to unlock the die.

Safety Precautions

Safety is paramount when operating a hydraulic pellet press. Always wear appropriate personal protective equipment (PPE), such as gloves and safety glasses. Ensure that the press is stable and secure on the workbench to prevent any accidental movement during operation.

Troubleshooting Common Issues

Common issues with hydraulic pellet presses include uneven pellet formation and difficulty in achieving the desired pressure. If pellets are not forming uniformly, check the sample distribution within the die and ensure the pressure application is consistent. If the desired pressure is not being reached, verify the integrity of the hydraulic system and ensure there are no leaks or blockages.

Conclusion

Proper setup and operation of a manual hydraulic pellet press are essential for obtaining high-quality pellets for analytical purposes. By following the steps outlined in this guide and adhering to safety protocols, laboratory technicians can efficiently produce consistent and reliable pellets for their analytical needs.

Maintenance and Cleaning of the Pellet Press

Proper maintenance and cleaning of the pellet press are essential to ensure its longevity and consistent performance. This section will provide detailed instructions on how to clean and maintain the pellet press, along with handling and storage tips.

Regular Cleaning Procedures

To maintain the efficiency and cleanliness of the pellet press, regular cleaning is crucial. Here are the steps to follow:

-

Disassemble the Press: Start by disassembling the pellet press. Remove the die, plunger, and any other removable parts. This allows for a thorough cleaning of each component.

-

Clean the Die: Use a soft brush or cloth to remove any residual material from the die. If the material is stubborn, you can use a mild solvent, but ensure it is compatible with the material being pressed. Rinse the die thoroughly and dry it completely before reassembling.

-

Clean the Plunger: Similarly, clean the plunger with a soft brush or cloth. Ensure there is no residual material that could affect the quality of future pellets.

-

Clean the Base and Top Plate: Wipe down the base and top plate to remove any dust or debris. This helps prevent contamination and ensures smooth operation.

-

Reassemble the Press: Once all parts are clean and dry, reassemble the pellet press. Ensure all components are correctly aligned and tightened.

Maintenance Tips

Regular maintenance can prevent many common issues and extend the life of the pellet press. Here are some maintenance tips:

-

Lubrication: Periodically lubricate the moving parts of the pellet press. Use a high-quality lubricant that is compatible with the materials being pressed. This helps reduce friction and wear.

-

Check for Wear: Regularly inspect the die and plunger for signs of wear. If you notice any cracks, chips, or significant wear, it is time to replace the part. Worn components can affect the quality of the pellets and cause the press to operate less efficiently.

-

Adjust Pressure Settings: If you notice that the pellets are not consistent in size or quality, adjust the pressure settings. Over time, the press may require adjustments to maintain optimal performance.

-

Store Properly: When not in use, store the pellet press in a clean, dry place. Cover it with a dust cover to protect it from dust and debris. Ensure all parts are dry before storing to prevent rust or corrosion.

Handling Tips

Proper handling of the pellet press is also important for maintaining its performance. Here are some handling tips:

-

Handle with Care: Always handle the pellet press with care. Avoid dropping or banging the components, as this can cause damage.

-

Use Appropriate Force: When pressing pellets, use the appropriate force. Overloading the press can cause damage and produce poor-quality pellets. Follow the manufacturer's guidelines for force and pressure settings.

-

Use Suitable Materials: Ensure the materials you are pressing are suitable for the pellet press. Some materials may be too abrasive or sticky, which can damage the press or produce poor-quality pellets.

-

Monitor Temperature: Pay attention to the temperature of the pellets during pressing. High temperatures can cause the material to degrade or stick to the die. If necessary, use cooling methods to maintain an optimal temperature.

Conclusion

By following these maintenance and cleaning procedures, you can ensure that your pellet press operates efficiently and produces high-quality pellets. Regular cleaning, proper maintenance, and careful handling are key to the longevity and performance of the pellet press. Remember to store the press properly when not in use and always use the appropriate force and materials for pressing. With these practices in place, your pellet press will continue to provide reliable and consistent results.

Comparing Different Types of Hydraulic Presses

Hydraulic presses are indispensable tools in laboratory settings, offering precise control over pressure and force for various applications. These presses come in different types, each with unique features and benefits. This section delves into the comparison between manual hydraulic presses and other types such as mini presses, highlighting the benefits and limitations of each type in laboratory applications.

Manual Hydraulic Presses

Manual hydraulic presses are operated using a hand-operated lever, which controls a piston moving in a cylinder filled with hydraulic oil. This mechanism allows users to apply and adjust pressure on a sample by turning the lever back and forth. While manual presses are straightforward and cost-effective, they require significant physical effort to operate, making them labor-intensive for frequent use. Additionally, the pressure applied can vary slightly with each use, depending on the operator's strength and technique, which may affect the repeatability and accuracy of the results.

Automatic Hydraulic Presses

In contrast, automatic hydraulic presses utilize an electric motor to drive the pump and electric switches to control the relief valve. This automation allows for high accuracy and repeatability, ensuring that the pressure applied is consistent across different uses. Automatic presses, such as the APEX 400, are particularly beneficial in busy laboratories where workflow efficiency is crucial. Once programmed, these presses can operate autonomously, freeing up technicians to focus on other tasks. The reduced labor requirement and enhanced precision make automatic presses a preferred choice for many laboratory applications.

Hydraulic Mini Presses

Hydraulic mini presses are compact and portable, making them ideal for laboratories with limited space or those requiring mobility. Despite their small size, these presses can generate substantial pressure, often up to 2 tons. The operation of a mini press involves using a pump to generate pressure that moves an oil-filled plunger, which then compresses fluids or gases to exert force on the object. The pressure can be regulated through the system’s valves, allowing for adjustments based on specific task requirements. Mini presses are particularly favored in pharmaceutical labs due to their handheld, low-cost, and mobile nature.

Comparative Analysis

When choosing a hydraulic press for laboratory use, several factors come into play, including the frequency of use, required precision, and available space. Manual presses are suitable for infrequent use and budget-conscious setups but may not offer the precision and repeatability needed for critical applications. Automatic presses provide superior accuracy and efficiency, making them ideal for high-throughput laboratories. Hydraulic mini presses, on the other hand, offer a balance of portability and functionality, suitable for labs needing a flexible and compact solution.

In conclusion, the choice of a hydraulic press depends on the specific needs and constraints of the laboratory. Each type of press—manual, automatic, and mini—offers distinct advantages and limitations. By understanding these differences, laboratory managers can make informed decisions to optimize their workflow and achieve the desired outcomes in their research and experiments.

Advanced Techniques and Tips for Pellet Preparation

Achieving high-quality pellets is crucial for accurate and reliable analytical results, particularly in applications such as X-ray fluorescence (XRF) spectroscopy. This section delves into advanced techniques and tips for optimal sample preparation, pressure application, and troubleshooting common pellet defects.

Optimal Sample Preparation

The foundation of a high-quality pellet lies in the preparation of the sample. It is essential to ensure that the sample is homogeneous and free of any clumps before loading it into the die. This can be achieved by thorough mixing and, if necessary, by passing the sample through a sieve to achieve a uniform particle size distribution. The particle size of the sample is a critical factor as it affects the density and uniformity of the pellet. Smaller particle sizes generally result in denser and more uniform pellets, which are crucial for accurate analytical results.

Pressure Application

Applying the correct amount of pressure is another critical aspect of pellet preparation. Too little pressure can result in a loose and porous pellet, while too much pressure can cause the pellet to crack or shatter. The optimal pressure depends on the type of sample and the equipment used. For instance, using a Specac automatic hydraulic press, it is important to follow the manufacturer’s instructions to ensure correct usage. Typically, pressures ranging from 15 to 20 tons are recommended for most samples, but this may vary based on the specific requirements of the analysis.

Use of High-Quality Equipment

Using high-quality XRF pellet dies is essential to ensure consistent pellet shapes and sizes. The die should be made of a material that can withstand high pressures without deforming. Additionally, using a pellet pressing lubricant can prevent the sample from sticking to the die, ensuring easy removal of the pellet without damage.

Troubleshooting Common Pellet Defects

Several common defects can occur during pellet preparation, including cracks, porosity, and uneven surfaces. Cracks in pellets are often caused by applying too much pressure or by using a sample that is not homogeneous. To prevent this, ensure that the sample is well mixed and that the pressure applied is within the recommended range. Porosity in pellets can be reduced by using smaller particle sizes and ensuring that the sample is evenly distributed in the die. Uneven surfaces may be due to an uneven distribution of the sample in the die or insufficient pressure.

Safety Considerations

When working with powdered samples, it is crucial to wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Additionally, always follow the manufacturer’s instructions for the operation of the pellet press to ensure safety and optimal performance.

Applications of Pellet Pressing

Pellet presses are used in various fields, including construction materials, recycling, metallurgy, glass, and ceramics, where pellets in powdered form are required. The quality of the sample preparation significantly impacts the accuracy of the analysis. Therefore, it is essential to consider all individual milling parameters, such as material properties, feed size and volume of the sample, grinding time, desired final particle size, and any abrasion of the grinding parts.

Summary

The most common contributors to error in the preparation of pressed pellets include the particle size of the sample, the choice of binder, the dilution ratio, the amount of pressure applied, the thickness of the final pellet, and sample-to-sample cross-contamination. The best practices for limiting this error require good method development coupled with attention to detail and consistency. By following these advanced techniques and tips, you can achieve high-quality pellets that ensure accurate and reliable analytical results.

Future Trends and Innovations in Laboratory Press Technology

Laboratory press technology is continually evolving, driven by the need for more efficient, accurate, and user-friendly equipment. This section explores emerging trends and innovations in laboratory press technology, particularly focusing on manual hydraulic pellet presses and their potential impact on laboratory practices.

Automation and Precision

One of the most significant trends in laboratory press technology is the shift towards automation. Automated hydraulic presses offer several advantages over their manual counterparts. They are designed to operate autonomously once programmed, allowing technicians to focus on other tasks. This not only increases efficiency but also reduces the risk of human error, leading to more consistent and reliable results.

For instance, automated presses for XRF pellet preparation are specifically adapted to the demands of preparing large quantities of samples. These presses feature integrated pellet dies and have swifter operations for repeated use, focusing on automations and mechanical systems for quickly extracting the pellet and leaving the press available for the next sample. This level of automation ensures high throughput and consistent quality, which is crucial for laboratories running XRF measurements on a large scale.

Cost-Effectiveness and Portability

While automated presses offer numerous benefits, manual hydraulic presses still have their place, especially in laboratories with budget constraints or infrequent use. Manual presses are generally more affordable and can be a cost-effective addition to a laboratory setup. However, they require more physical effort to operate and can be less repeatable, as each sample is pressurized to a slightly different load by the operator.

To address these challenges, manufacturers are developing mini hydraulic presses that are not only affordable but also portable and easy to use. These compact presses offer a balance between cost-effectiveness and functionality, making them suitable for small-scale operations and fieldwork.

Advancements in Material Science

Another area of innovation in laboratory press technology is the use of advanced materials. Traditional hydraulic presses are often made from steel, which can be heavy and cumbersome. However, new materials such as lightweight alloys and composites are being explored to create more portable and durable presses. These materials not only reduce the weight of the equipment but also enhance its durability and performance.

Moreover, advancements in material science are also leading to the development of more efficient hydraulic systems. For example, the use of high-performance seals and lubricants can reduce friction and improve the overall efficiency of the press. This not only extends the lifespan of the equipment but also reduces maintenance requirements.

Integration with Digital Technologies

The integration of digital technologies is another significant trend in laboratory press technology. Modern hydraulic presses are increasingly equipped with digital controls and monitoring systems. These systems allow technicians to program and monitor the press remotely, providing real-time data on pressure, temperature, and other critical parameters. This level of control and monitoring enhances the accuracy and reliability of the press, ensuring consistent results.

Furthermore, digital technologies are also enabling the development of smart presses that can learn and adapt to different sample types and pressing conditions. These smart presses use machine learning algorithms to optimize the pressing process, ensuring the best possible results for each sample.

Environmental Considerations

Environmental sustainability is becoming an increasingly important consideration in laboratory equipment design. Hydraulic presses, like other laboratory equipment, consume energy and generate waste. Manufacturers are therefore exploring ways to make these presses more energy-efficient and environmentally friendly.

For example, some manufacturers are developing hydraulic presses that use renewable energy sources or are designed to consume less energy during operation. Additionally, efforts are being made to reduce the amount of waste generated during the manufacturing process and to make the equipment more recyclable at the end of its lifecycle.

Conclusion

In conclusion, the future of laboratory press technology is bright, with numerous innovations and advancements on the horizon. Automation, cost-effectiveness, advancements in material science, integration with digital technologies, and environmental considerations are all driving the evolution of this technology. These trends are not only enhancing the efficiency and accuracy of laboratory presses but also making them more user-friendly and environmentally sustainable. As these innovations continue to develop, they will undoubtedly have a significant impact on laboratory practices, enabling researchers to achieve more reliable and consistent results.

Related Products

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

Related Articles

- Manual Hydraulic Presses for Laboratory Use: A Comprehensive Guide

- Automatic Hydraulic Press: The Ultimate Guide for Efficient Sample Preparation and Industrial Processes

- Understanding Hydraulic Pellet Press: Working Mechanism and Applications

- Manual Hydraulic Pellet Press: An Efficient Tool for Spectral Analyses Preparation

- Comprehensive Guide to Manual Hydraulic Pellet Press