It’s a scenario every lab technician knows and dreads. You’ve spent the morning meticulously preparing a sample—perhaps grinding KBr for an FTIR pellet. You load the die into your hydraulic press, apply pressure with practiced care, and then you hear it: a faint but distinct crack. You release the ram, and your heart sinks as you retrieve a fractured, cloudy, and utterly useless pellet. Hours of work are down the drain, and you have to start all over again.

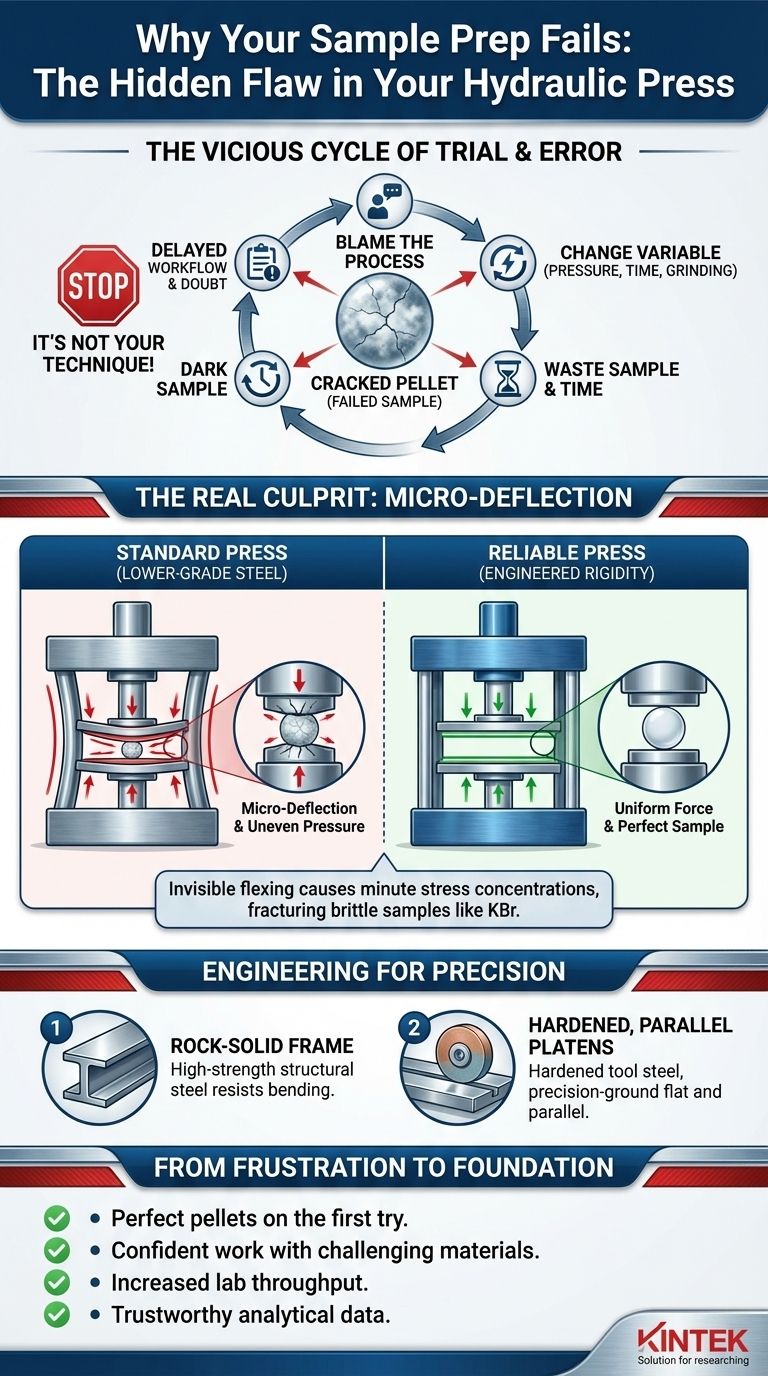

The Vicious Cycle of Trial and Error

If this sounds familiar, you’re not alone. This is one of the most common frustrations in labs that rely on hydraulic presses for sample preparation. When a pellet cracks or a compacted sample fails, what’s the first instinct? We blame the process.

We start a frustrating guessing game:

- "Did I apply the pressure too quickly?"

- "Was the powder not ground finely enough?"

- "Maybe I held the pressure for too long... or not long enough?"

- "Is the vacuum not pulling properly?"

Each attempt involves changing one variable, consuming more precious sample material and, more importantly, valuable time. The consequences ripple outwards. Analytical workflows are delayed, project timelines slip, and a seed of doubt is planted about the consistency of your lab's results. In a QC environment, this can lead to production holds and costly investigations. In a research setting, it erodes confidence in your data.

But what if the problem isn’t your technique at all?

The Real Culprit: It's Not Your Technique, It's the Steel

The frustrating truth is that you can have a perfect technique and still get terrible results if your press is not built correctly. While a hydraulic press looks like an immovable block of metal, the immense forces it generates—often many tons—can cause the machine itself to flex and deform in microscopic ways.

This is the hidden flaw: micro-deflection.

The problem lies in the materials used for the press's construction. A press built with lower-grade or thinner structural steel in its frame will subtly bend under load. A press with platens (the work surfaces) made from softer steel will deform at the point of contact.

Why Your "Fixes" Don't Work

This invisible flexing is the true cause of your failed samples. Even a deflection of a few microns means the force is no longer being applied perfectly evenly across your sample die. This creates minute stress concentrations within the pellet. And when you’re dealing with brittle crystalline materials like KBr, that tiny, uneven pressure point is all it takes to initiate a fracture.

This is why your process adjustments feel like a random game of chance. You’re trying to correct a fundamental physical limitation of the tool itself. You can’t perfect a technique to compensate for a press that is physically incapable of delivering uniform force.

Engineering for Precision: What a Reliable Press is Actually Made Of

To permanently solve this problem, you don't need a new technique; you need a tool that is engineered to eliminate the root cause. A truly reliable press must be built on a foundation of unyielding rigidity.

This requires a deep understanding of material science, where design choices are made specifically to counteract the immense forces at play:

-

A Rock-Solid Frame: The frame must be constructed from thick, high-strength structural steel. This provides the exceptional rigidity needed to resist bending and ensure the entire assembly remains perfectly aligned under tons of pressure.

-

Hardened, Parallel Platens: The bed and ram platen—the surfaces that contact your die—must be made from hardened tool steel. They are then ground to be perfectly flat and parallel. This ensures that the force they transmit is distributed absolutely evenly, without creating the stress points that ruin samples.

This is not a matter of simply overbuilding a machine; it is a deliberate engineering philosophy. At KINTEK, our laboratory presses are designed based on this first principle. We use certified, high-strength steel alloys for our frames and hardened, precision-ground steel for our platens. They aren't just built to be strong; they are engineered to be rigid, providing the uniform force distribution that sensitive sample preparation demands.

From Frustration to Foundation: A New Era of Reliable Analysis

When you stop fighting your equipment, you unlock new potential. By eliminating the hidden variable of micro-deflection, you transform your press from a source of frustration into a reliable foundation for your work.

Imagine a workflow where:

- Your KBr pellets come out perfectly clear and intact on the first try, every time.

- You can confidently work with more challenging or novel materials, knowing the force applied is precise and repeatable.

- Your lab's throughput increases because you've eliminated the time wasted on failed sample prep.

- Most importantly, you have complete confidence in your analytical data, knowing it originates from a perfectly prepared sample.

This is what happens when your tools are designed with a true understanding of the challenges you face. You spend less time troubleshooting and more time advancing your research or clearing your QC queue.

A reliable hydraulic press is more than just a piece of heavy machinery; it's the bedrock for trustworthy data and an efficient lab. The principles of material integrity are critical whether you are preparing samples, testing material strength, or performing any task that demands precise force. If you're tired of inconsistent results, it might be time to look at the foundation of your process. Our team of experts is ready to go beyond a simple product sheet and discuss the specific challenges of your project. Contact Our Experts.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

Related Articles

- Sample preparation and unloading method of electric tablet press

- Applications and Importance of Hydraulic Press in Laboratories

- Hydraulic Tablet Press: Comprehensive Guide to Design, Operation, and Applications

- Your Hydraulic Press Is Hot. Here’s Why It’s a Bigger Problem Than You Think.

- Operating steps and precautions for electric tablet press