You know the sound. It might be a sudden bang followed by a hiss of hydraulic fluid. Or maybe it’s just a frustrating silence—the pressure gauge refuses to climb, no matter what you do. Your perfectly prepped sample is sitting on the platen, your project is on hold, and your hydraulic press, a machine that should be a workhorse of pure power, is suddenly a thousand-pound paperweight.

The most baffling part? You were nowhere near the machine's maximum tonnage rating. So, what went wrong?

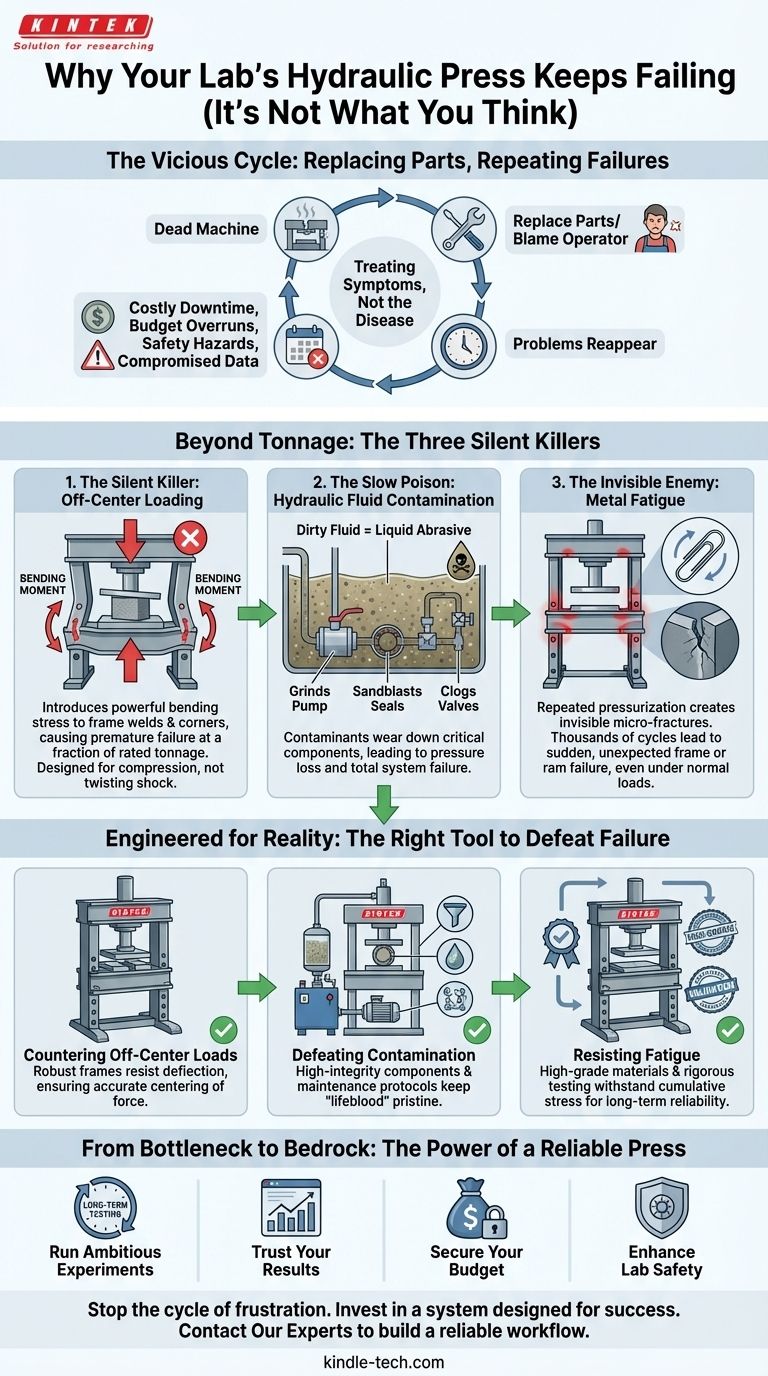

The Vicious Cycle: Replacing Parts, Repeating Failures

If this scenario feels familiar, you’re not alone. Unexpected press failure is a chronic headache in labs worldwide. Faced with a dead machine, a predictable and frustrating cycle begins:

- You might replace a ruptured hose or a blown seal, assuming it was just a faulty part.

- You might blame the operator for "pushing it too hard," even when the data doesn't support it.

- You might even invest in a new, more expensive press with a higher tonnage rating, believing more power is the solution.

But weeks or months later, the problem reappears. These "solutions" only treat the symptoms, not the disease. The business consequences are severe and predictable:

- Costly Downtime: Critical projects grind to a halt, delaying research and development timelines.

- Budget Overruns: Unplanned emergency repairs and machine replacements wreak havoc on your lab's budget.

- Safety Hazards: A failing press can leak high-pressure fluid or, in a catastrophic failure, create dangerous shrapnel from a shattered workpiece.

- Compromised Data: If a press is failing, can you trust the consistency and accuracy of the force it applied to your previous samples?

The core of the problem is a widespread misunderstanding. We see a hydraulic press as a simple tool of brute force, but its failure is rarely about force alone.

Beyond Tonnage: The Three Silent Killers of Hydraulic Presses

The tonnage rating on your press represents an ideal scenario: a perfectly uniform force applied to a perfectly centered load. The reality of a busy lab is far more complex. The true culprits behind most press failures are not dramatic overloads, but silent, cumulative errors in operation and maintenance.

1. The Silent Killer: Off-Center Loading

This is the single most common cause of catastrophic press failure. When you place a workpiece even slightly off-center, you are no longer just compressing it. You are introducing a powerful bending moment to the entire machine.

Think of it like trying to crack a walnut with a hammer. Hit it squarely, and the force is transferred efficiently. Hit it on its edge, and the nut flies sideways while your hand feels a painful twisting shock. A press frame is designed for the square hit (compression), not the twisting shock (bending). This off-center force concentrates immense stress on the frame's welds and corners, leading to metal fatigue and sudden failure at a fraction of the press's rated tonnage.

2. The Slow Poison: Hydraulic Fluid Contamination

The hydraulic fluid is the lifeblood of your press. When it's contaminated with microscopic particles of dirt, dust, or even water, it transforms from a lubricant into a liquid abrasive.

This "slow poison" silently grinds away at the system's heart. It wears down the expensive hydraulic pump, sandblasts the delicate internal seals, and clogs critical valves. The result is a slow but guaranteed death, starting with pressure loss and ending in total system failure.

3. The Invisible Enemy: Metal Fatigue

Like bending a paperclip back and forth, every time you pressurize and de-pressurize your press, you create micro-stresses in its metal structure. While a single cycle is harmless, thousands of cycles add up.

Over time, these repeated stresses can cause invisible micro-fractures to form and grow, especially around welds or sharp corners. Eventually, one of these cracks reaches a critical point, and the frame or ram fails suddenly and unexpectedly, under a load it has successfully handled hundreds of times before.

This is why simply buying a "stronger" press doesn't work. A 50-ton press subjected to an off-center load is more vulnerable than a 20-ton press used correctly.

Engineered for Reality: The Right Tool to Defeat Failure

Preventing these failures isn't about finding an indestructible machine. It's about choosing an instrument that is intelligently designed for real-world lab conditions and supported by expert guidance. It requires a system built to mitigate the risks of these silent killers.

This is the core philosophy behind KINTEK's laboratory equipment. Our hydraulic presses are engineered not just for power, but for precision, longevity, and safety. They are the physical embodiment of a deep understanding of why presses fail.

-

Countering Off-Center Loads: Our presses are built with robust, rigid frames that resist deflection and precision-machined platens that ensure a level surface. This engineering promotes the accurate centering of force, directly combating the primary cause of frame failure.

-

Defeating Contamination: KINTEK systems are built with high-integrity seals and components designed to work within a clean hydraulic environment. Crucially, we provide the clear maintenance protocols and quality consumables needed to protect your investment and keep your press's "lifeblood" pristine.

-

Resisting Fatigue: We utilize high-grade materials and validate our designs through rigorous cycle testing. This ensures the frame and critical components are built to withstand the cumulative stress of repeated use, giving you a reliable platform for long-term projects.

From Bottleneck to Bedrock: The Power of a Reliable Press

When you are no longer worried about your press failing, it transforms from a potential bottleneck into a bedrock of your lab's productivity. A truly reliable press, operated correctly, unlocks new potential:

- Run Ambitious Experiments: Undertake long-term, high-cycle material testing with confidence.

- Trust Your Results: Achieve superior consistency in sample preparation, leading to more accurate and repeatable data.

- Secure Your Budget: Eliminate the surprise costs and project delays caused by unexpected equipment failures.

- Enhance Lab Safety: Operate with the peace of mind that comes from using equipment designed to prevent the most common and dangerous failure modes.

Your work is too important to be derailed by a preventable equipment failure. Stop the cycle of frustration and invest in a system designed for success. If you're tired of treating symptoms and ready to address the root cause of press failure, our team is here to help you build a more reliable and productive laboratory workflow. Let's discuss the unique demands of your projects and how a better-engineered solution can make all the difference. Contact Our Experts.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Manual Lab Heat Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press