You open the furnace door, filled with anticipation. And there it is again: another cracked part. That intricate component you spent days designing, milling the powder for, and carefully pressing is ruined. A tiny fissure, formed during sintering, has just invalidated a week's worth of work. It’s a frustratingly common story in materials science labs and advanced manufacturing facilities.

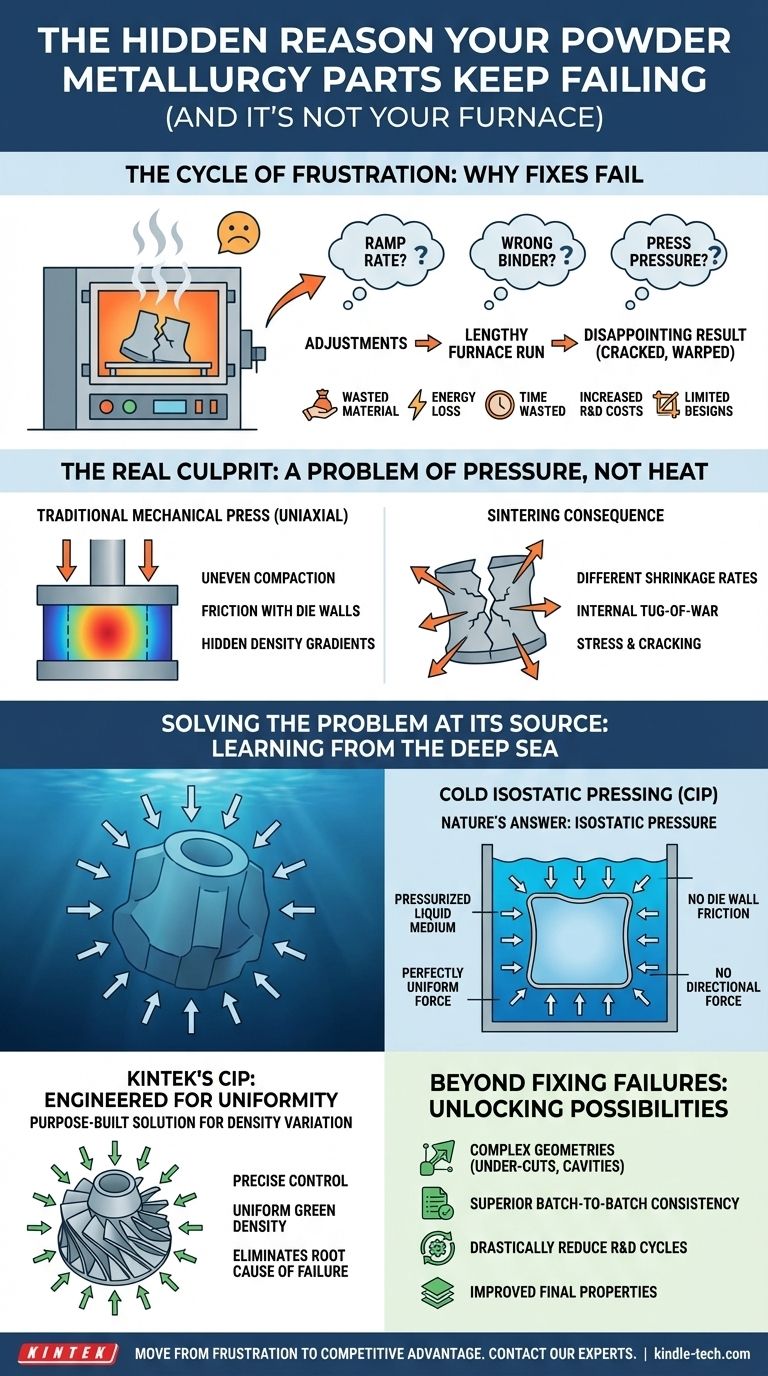

The Cycle of Frustration: Why Aren't Our Fixes Working?

If this scene is familiar, you’ve likely been down the same rabbit hole of troubleshooting. You start questioning every step of your process:

- "Was the sintering ramp rate too aggressive? Let's try a slower, longer cycle."

- "Did we use the wrong binder, or was the powder batch inconsistent?"

- "Maybe we need to adjust the pressure on our mechanical press."

Each attempted fix involves tedious adjustments and another lengthy, expensive furnace run, only to often yield the same disappointing result: warped, cracked, or inconsistent parts.

This isn't just a technical headache; it's a significant business problem. Each failed part represents wasted material, energy, and valuable technician time. Project timelines get pushed back, R&D costs spiral, and your ability to produce reliable, high-performance components is called into question. You start avoiding complex designs, knowing the risk of failure is just too high.

The Real Culprit: A Problem of Pressure, Not Heat

What if the problem isn't the sintering process at all? What if the fatal flaw was locked into your part before it ever entered the furnace?

The root cause of these failures is almost always non-uniform density.

When you use a traditional mechanical press, which applies force from one or two directions (uniaxially), the powder doesn't compact evenly. Think of packing a suitcase: when you press down from the top, the clothes in the center become tightly packed, but the clothes along the sides and in the corners remain looser.

The same thing happens in a rigid die. Friction between the powder and the die walls prevents pressure from being distributed equally. This creates hidden high-density "tight spots" and low-density "loose spots" throughout the part.

During sintering, these different density zones shrink at different rates. The high-density areas shrink less, and the low-density areas shrink more. This creates an internal tug-of-war, generating immense stress that your part simply cannot withstand. The result is the crack you see when you open the furnace door.

This is why your sintering adjustments often fail. You're trying to manage a symptom—cracking from heat—while the disease—uneven density from pressing—remains untreated.

Solving the Problem at Its Source: Learning from the Deep Sea

To prevent this internal conflict, you must form a part with exceptionally uniform density from the very beginning. The question is, how do you apply pressure perfectly evenly to a complex shape?

Nature already has the answer: isostatic pressure. An object submerged deep in the ocean is compressed by water pressure equally from all directions—top, bottom, and all sides.

Cold Isostatic Pressing (CIP) is the technology that harnesses this fundamental principle for manufacturing.

A CIP works by placing your powder-filled flexible mold into a chamber of liquid. This liquid is then pressurized, transmitting that force perfectly and uniformly to every single point on the mold's surface. It's like a controlled version of deep-sea pressure. There are no die walls to cause friction and no directional force to create density gradients.

KINTEK's CIP: Engineered for Uniformity

This is not a happy accident; it's by design. A Cold Isostatic Press is not just another piece of lab equipment; it is a purpose-built solution to the fundamental problem of density variation.

KINTEK's CIP systems are engineered to give you precise control over this process. They use a high-pressure fluid medium to ensure every particle in your component—whether it's a simple rod or a complex turbine blade with internal channels—experiences the exact same compressive force.

The result is a "green" part that is free from the hidden stresses caused by uneven compaction. You've eliminated the root cause of sintering failure before the part even gets warm.

Beyond Fixing Failures: Unlocking New Manufacturing Possibilities

Once you stop fighting inconsistent results, a new world of opportunity opens up. Solving the density problem is not just about reducing scrap rates; it’s about elevating what your lab or production line is capable of achieving.

With a reliable CIP process, you can:

- Confidently manufacture complex geometries—like parts with undercuts, internal cavities, or long aspect ratios—that are impossible with traditional die pressing.

- Achieve superior batch-to-batch consistency, which is critical for applications in aerospace, medical implants, and high-performance electronics.

- Drastically reduce R&D cycles, as you are no longer wasting time on iterative troubleshooting and can move from design to reliable prototype much faster.

- Improve the final properties of your components, as uniform green density leads to more predictable and homogenous material properties after sintering.

Solving this persistent problem moves your process from a source of frustration to a source of competitive advantage. It empowers you to take on the ambitious projects you once deemed too risky.

This foundational shift from fighting symptoms to addressing the root cause is what separates good results from groundbreaking innovation. Whether you're developing next-generation ceramics, high-strength metal alloys, or advanced polymers, consistent material forming is the bedrock of success. Our team of specialists understands these challenges deeply and can help you determine the precise process your project requires. Let's discuss how to move your material processing from a point of frustration to a competitive advantage. Contact Our Experts.

Visual Guide

Related Products

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Vacuum Cold Mounting Machine for Sample Preparation

Related Articles

- The Benefits of Using Isostatic Pressing in Manufacturing

- Automatic isostatic press operation steps

- Comprehensive Guide to Isostatic Pressing Molds: Types, Processes, and Applications

- Understanding the Basics of Isostatic Pressing

- Electric Lab Cold Isostatic Press (CIP): Applications, Benefits, and Customization