Introduction to Electric Lab Cold Isostatic Press (CIP)

The Electric Lab Cold Isostatic Press (CIP) represents a cutting-edge technology that revolutionizes material processing across multiple industries. This innovative system operates on the fundamental principles of applying uniform pressure to materials enclosed in a flexible mold, enhancing their structural integrity and performance. By delving into the intricacies of CIP, including its operational mechanisms, diverse applications, and the benefits it offers, this article aims to provide a comprehensive overview of how CIP technology is shaping the future of manufacturing and research. Join us as we explore the versatility, efficiency, and customization options that make Electric Lab CIP a pivotal tool in modern technological advancements.

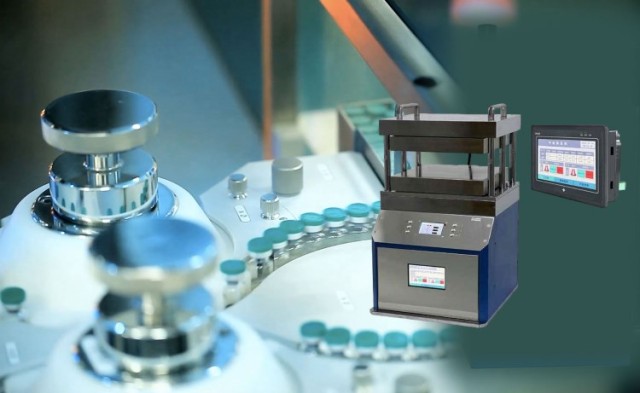

How Electric Lab Cold Isostatic Press (CIP) Works

Cold Isostatic Pressing (CIP) is a sophisticated technique used in various industries to compact powders into dense, uniform shapes. This method involves the use of elastomer molds, pressure chambers, and liquid mediums to apply uniform pressure from all directions, ensuring high-quality parts with increased shape capability compared to traditional uniaxial pressing methods.

The Process of Cold Isostatic Pressing

The CIP process begins with placing a low-density green part or loose powder into a sealed, flexible container made of elastomer materials such as urethane, rubber, or polyvinyl chloride. This container, also known as a mold, is then submerged in a liquid medium within a pressure vessel. The liquid medium is typically oil or water, which is capable of transmitting pressure uniformly.

Once the mold is submerged, a high pressure of several thousand bar (typically ranging from 400 MPa to 1000 MPa) is applied. This pressure compresses the powder or green compact as close to its maximum packing density as possible. The uniform pressure from all sides ensures that the material is compacted evenly, leading to a higher initial density. This higher density significantly speeds up the consolidation to final density during subsequent thermal processing cycles.

Types of Isostatic Pressing

There are two primary methods of carrying out isostatic pressing: wet-bag and dry-bag.

- Wet-bag isostatic pressing: In this method, the powder is encased in a rubber sheath that is immersed in a liquid. The liquid transmits the pressure uniformly to the powder, ensuring even compaction.

- Dry-bag isostatic pressing: This method differs by not immersing the tooling in a fluid. Instead, the tooling is built with internal channels into which high-pressure fluid is pumped. This method allows for more controlled and localized pressure application.

Applications and Benefits of CIP

CIP is utilized across various industries, including powdered metallurgy, cemented carbides, refractory materials, graphite, ceramics, plastics, and more. The primary benefits of using CIP include:

- Greater uniformity of compaction: The uniform pressure application ensures that the final product has consistent density and quality.

- Increased shape capability: CIP allows for the production of complex shapes that would be difficult to achieve with traditional pressing methods.

- Efficient material utilization: The high-pressure application ensures minimal waste and efficient use of raw materials.

Challenges and Considerations

While CIP offers numerous advantages, it also presents some challenges. One notable disadvantage is the potential for low geometric accuracy due to the flexible nature of the elastomer molds. Additionally, the high pressures involved require robust equipment and careful handling to ensure safety and prevent equipment failure.

In conclusion, Cold Isostatic Pressing (CIP) is a powerful technique for achieving high-quality, dense, and uniform parts from various powders. By understanding the process, types, and applications of CIP, industries can leverage this technology to enhance their production capabilities and achieve superior results.

Applications of Electric Lab Cold Isostatic Press (CIP)

The Electric Lab Cold Isostatic Press (CIP) is a versatile and powerful tool with a wide range of applications across various industries, including aerospace, military, industrial, and medical sectors. This technology utilizes uniform pressure in all directions to achieve consistent density and strength in the materials being processed, making it an invaluable asset in the production of high-quality components and products.

Aerospace Industry

In the aerospace industry, the reliability and performance of components are critical. CIP is employed to manufacture parts with uniform density and strength, which are essential for the safety and efficiency of aircraft. For instance, CIP is used to produce complex-shaped components from advanced ceramics and composites that can withstand extreme temperatures and pressures encountered in aerospace applications. According to industry reports, the use of CIP in aerospace has led to a significant reduction in component failure rates, enhancing overall aircraft safety.

Military Sector

The military sector also benefits greatly from CIP technology. It is used to manufacture durable and lightweight components for various military equipment, including armor, missile components, and communication devices. The uniform strength and density achieved through CIP ensure that these components can withstand harsh environmental conditions and high mechanical stresses, making them ideal for military applications.

Industrial Applications

In the industrial sector, CIP is utilized for a variety of applications, including the production of high-performance ceramics, powder metallurgy components, and advanced composites. These materials are used in machinery and equipment where durability and precision are paramount. For example, CIP is used to produce wear-resistant parts for heavy machinery, which can significantly extend the lifespan of these machines and reduce maintenance costs.

Medical Industry

The medical industry leverages CIP for the production of medical devices and implants. The uniform density and strength provided by CIP are crucial for ensuring the reliability and safety of these devices. For instance, CIP is used to manufacture orthopedic implants with precise dimensions and consistent material properties, which are essential for successful surgical outcomes. Additionally, CIP is employed in the production of dental implants and prosthetics, where the quality and precision of the materials are critical.

Other Industries

Beyond the aforementioned sectors, CIP finds applications in pharmaceuticals, explosives, chemicals, nuclear fuel, and ferrites. In the pharmaceutical industry, CIP is used to produce tablets with uniform density, ensuring consistent dosing and efficacy. In the chemical industry, CIP is employed to produce high-performance ceramics and composites used in chemical processing equipment.

Advantages of Cold Isostatic Pressing

Cold Isostatic Pressing (CIP) offers several advantages that make it a preferred method for material processing:

-

Uniform Density: CIP ensures that materials have a uniform density, which leads to uniform shrinkage during subsequent processes like sintering. This uniformity is attributed to the equal pressure applied to all parts of the material.

-

Uniform Strength: The pressure used in CIP is equal in all directions, resulting in materials with uniform strength. This is particularly beneficial for components that require consistent performance across all directions.

-

Versatility: CIP can produce complex shapes and large-sized materials that are challenging to achieve with other methods. The size of the materials produced is limited only by the size of the pressure vessel.

-

Corrosion Resistance: CIP improves the corrosion resistance of materials, extending their lifespan and enhancing their durability.

-

Improved Mechanical Properties: CIP enhances the mechanical properties of materials, including ductility and strength, making them more suitable for demanding applications.

-

Powder Metallurgy: CIP is used in the compacting step of powder metallurgy, which precedes the sintering step. It is particularly useful for producing complex shapes and dimensions in powder metallurgy.

-

Refractory Metals: CIP is used to produce refractory metals such as tungsten, molybdenum, and tantalum. These metals are known for their high melting points and resistance to wear and tear.

-

Sintering: CIP products typically have high green strength, allowing them to be sintered faster than other materials. This accelerates the production process and improves efficiency.

Types of Cold Isostatic Pressing

There are two main types of cold isostatic presses:

-

Cold Isostatic Presses (CIP): These operate at room temperature and are used to produce unsintered or green die-compacted metal powder components. CIP systems are widely used by companies worldwide to produce flawless components for various industries.

-

Hot Isostatic Presses (HIP): These operate at elevated temperatures and are used for similar applications but with additional benefits of high-temperature processing.

In conclusion, the Electric Lab Cold Isostatic Press (CIP) is a highly versatile and efficient technology with a broad range of applications across multiple industries. Its ability to produce materials with uniform density and strength makes it an indispensable tool for the production of high-quality components and products.

Benefits of Using Electric Lab Cold Isostatic Press (CIP)

Cold Isostatic Pressing (CIP) technology has revolutionized the field of material processing, offering a range of benefits that traditional uniaxial pressing methods cannot match. This advanced technique involves the application of equal pressure to all parts of a material, resulting in improved green strength, efficient densification, and significant cost-effectiveness. Here, we delve into the key advantages of using Electric Lab Cold Isostatic Press (CIP) in various industries.

Enhanced Green Strength

One of the primary benefits of CIP is the significant improvement in green strength. Green strength refers to the ability of a molded material to withstand manipulation before it is fully hardened. Materials processed through CIP exhibit high green strength, allowing for easier handling and faster subsequent processing steps such as sintering or machining. This advantage is particularly crucial in industries where rapid turnaround is essential, such as aerospace and medical device manufacturing.

Uniform Density and Strength

CIP ensures that materials achieve a uniform density throughout, which is critical for maintaining consistent quality in the final product. The uniform application of pressure across the material means that every part experiences the same force, leading to uniform shrinkage during subsequent processes like sintering. This homogeneity in density and strength translates to more reliable and predictable product performance, reducing the likelihood of defects and inconsistencies.

Greater Flexibility in Product Shapes and Sizes

Unlike uniaxial pressing, which is limited in the shapes and sizes it can produce, CIP offers greater flexibility. It allows for the creation of complex geometries and longer aspect ratios, such as long, thin pellets, which are challenging to produce with other methods. This flexibility is invaluable in industries that require bespoke components with specific dimensions and shapes, such as in the aerospace and military sectors.

Improved Densification and Compaction

CIP excels in improving the densification of powders, leading to higher quality finished products. The uniform pressure distribution ensures that powders are compacted more effectively, resulting in denser materials with fewer voids. This improved compaction is particularly beneficial for materials that are difficult to press, as it allows for dry pressing without the need for water, lubricants, or binders.

Reduced Cycle Times and Improved Productivity

Another significant advantage of CIP is the reduction in cycle times. The efficient pressure application and uniform densification process mean that materials can be processed faster than with traditional methods. This increased productivity is a major boon for manufacturers, allowing them to meet higher production demands without compromising on quality.

Ability to Process Diverse Materials

CIP is versatile enough to handle a wide range of materials with different characteristics and shapes. This versatility makes it an ideal choice for industries that work with a variety of materials, from metals to ceramics. The ability to process these diverse materials efficiently and effectively ensures that manufacturers can produce high-quality components for a broad spectrum of applications.

In conclusion, the Electric Lab Cold Isostatic Press (CIP) offers numerous benefits that enhance the efficiency, quality, and cost-effectiveness of material processing. With its superior green strength, uniform density, flexibility in product shapes, improved densification, reduced cycle times, and versatility in material processing, CIP stands out as a superior technology in the manufacturing industry. Whether in aerospace, military, industrial, or medical applications, CIP ensures that manufacturers can produce flawless components with consistent quality and reliability.

Customization and Size Options for Electric Lab Cold Isostatic Press (CIP)

The versatility and adaptability of electric lab cold isostatic presses (CIP) make them indispensable tools across various industries, from research laboratories to large-scale industrial applications. These presses are designed to accommodate a wide range of sizes and operational pressures, ensuring that they can meet the specific needs of diverse applications.

Size Variability

Cold isostatic presses are available in a spectrum of sizes, catering to both small-scale laboratory experiments and large industrial processes. For instance, laboratory units can have an inner diameter as small as 77 mm (3”), making them suitable for research and development activities where space and resource utilization are critical. On the other end of the spectrum, industrial-grade presses can exceed 2 meters (6 ft) in width, capable of handling bulk production requirements efficiently.

Operational Pressure Levels

The operational pressure levels of these presses are equally impressive, ranging from less than 5,000 psi to over 100,000 psi (34.5 to 690 MPa). This broad pressure range allows for the compaction of a variety of materials, including metals, ceramics, plastics, and composites. High-pressure capabilities, such as those reaching up to 900 MPa (130,000 psi), are particularly useful in industries where extreme pressure is necessary to achieve the desired material properties.

Customization Options

One of the most significant advantages of electric lab CIPs is their customizable nature. Manufacturers design these presses to accommodate specific dimensions and product characteristics, ensuring that each unit is optimized for its intended use. This customization extends beyond mere size and pressure adjustments. For instance, some presses come with fully automated loading and unloading systems, enhancing efficiency and reducing manual labor. Others feature high pressurization rates and customized depressurization profiles, tailored to the unique requirements of specialized applications.

Standard vs. Custom Solutions

While custom-designed presses offer unparalleled adaptability, standard off-the-shelf solutions are also available for those who require immediate equipment without the need for extensive modifications. These standard units are pre-engineered to perform a range of common processes, such as consolidation, stamping, and resin transfer molding (RTM), making them a cost-effective choice for many users.

Applications

The applications of electric lab CIPs are vast and varied. In research settings, these presses are used for densification of ceramics, consolidation of superalloy powders, and carbon impregnation, among other processes. In industrial contexts, they play a crucial role in the production of complex parts where traditional pressing methods are either impractical or too costly.

Conclusion

In summary, electric lab cold isostatic presses offer a remarkable blend of size variability, operational pressure flexibility, and customization options. Whether for small-scale laboratory research or large-scale industrial production, these presses provide the necessary tools to achieve precise and efficient material compaction. Their adaptability ensures that they remain a cornerstone in both research and manufacturing sectors, driving innovation and productivity across various industries.

Automation in Electric Lab Cold Isostatic Press (CIP) Systems

Automation in laboratory Cold Isostatic Press (CIP) systems has revolutionized the way materials are processed, offering significant advancements in efficiency, precision, and safety. These systems now include features such as automated loading and unloading, high pressurization rates, and customizable depressurization profiles, which are essential for achieving uniform microstructures and high green strength in processed materials.

Automated Loading and Unloading

One of the key advancements in automated CIP systems is the integration of automated loading and unloading mechanisms. This automation reduces the manual labor required, minimizes human error, and significantly speeds up the process. For instance, systems equipped with robotic arms can precisely place and retrieve materials from the pressure vessel, ensuring consistency and reducing the risk of contamination.

High Pressurization Rates

Automated CIP systems are capable of achieving high pressurization rates, which are crucial for efficiently consolidating metal powders into dense compacts. These systems can rapidly increase the pressure to the required level, typically within a few seconds, and maintain it for a specified dwell period. This rapid pressurization ensures that the powder particles consolidate uniformly, leading to a more homogeneous microstructure and higher green strength.

Customizable Depressurization Profiles

Another significant feature of automated CIP systems is the ability to customize depressurization profiles. The gradual release of pressure is critical to prevent the formation of defects such as cracks or voids in the final product. Automated systems allow for precise control over the depressurization rate, ensuring that the flexible tool retracts to its original shape while the powder converts from a loose aggregate into a partially dense compact. This customization is particularly important for materials with complex geometries or those that are difficult to press.

Efficiency and Safety

Automated CIP systems also enhance efficiency and safety in the laboratory setting. By automating the entire process from loading to demoulding, these systems ensure high efficiency and stable quality, reducing the risk of medium pollution associated with traditional CIP methods. Additionally, monitoring the stress and deformation of high-pressure components helps in eradicating potential accidents, making the process safer for laboratory personnel.

Application in Various Materials

Automated CIP systems are versatile and can be used for a wide range of materials and applications. They are particularly beneficial for pressing materials that are difficult to process, such as powders that require dry pressing without water, lubricants, or binders. These systems are also suitable for producing long bars or pipes, which are challenging to manufacture using traditional pressing methods.

Cost and Space Efficiency

In a laboratory setting, automated CIP systems offer significant cost and space efficiency. They are designed to be compact, lightweight, and easy to move between labs, making them ideal for research environments where space is often limited. Additionally, these systems require less maintenance, thanks to longer-lasting static O-rings and other durable components, reducing overall operational costs.

Conclusion

In conclusion, the advancements in automated CIP systems have brought about significant improvements in efficiency, precision, and safety in laboratory settings. These systems offer automated loading and unloading, high pressurization rates, and customizable depressurization profiles, making them indispensable tools for researchers and engineers working with a variety of materials. As technology continues to evolve, the future of automated CIP systems looks promising, with even more innovative features and capabilities on the horizon.

Future Trends in Electric Lab Cold Isostatic Press (CIP) Technology

The field of Cold Isostatic Pressing (CIP) technology is poised for significant advancements, driven by innovations in materials science, automation, and digital simulation. As industries such as aerospace, medical, and ceramics continue to demand higher performance and more complex components, the future of CIP technology looks promising with several emerging trends and research directions.

Advancements in Material Compatibility

One of the key areas of development in CIP technology is the expansion of material compatibility. Traditional CIP processes have been primarily used for metal and ceramic powders, but recent research is exploring the feasibility of using CIP for a broader range of materials, including advanced composites and biodegradable polymers. This expansion could open new applications in sectors like biomedicine and environmental technology.

Enhanced Automation and Control Systems

The integration of advanced automation and control systems in CIP technology is another significant trend. The "dry-bag" process, known for its high-volume production capabilities, is seeing improvements in automation, which reduces manual intervention and increases precision. This trend is expected to continue, with more sophisticated sensors and control algorithms being developed to monitor and adjust pressure, temperature, and other critical parameters in real-time.

Digital Twin Technology

Digital twin technology, which creates a virtual replica of the physical CIP process, is gaining traction. This technology allows for predictive modeling and simulation, enabling manufacturers to optimize process parameters before actual production. By reducing trial-and-error in setup configurations, digital twins can significantly cut down on production time and material waste.

Sustainable and Energy-Efficient Practices

As sustainability becomes a critical concern across industries, CIP technology is also moving towards more energy-efficient and environmentally friendly practices. Innovations in insulation materials and pressure systems are reducing the energy consumption of CIP operations. Additionally, the development of closed-loop systems that recycle the pressurizing fluid is being explored to minimize waste and environmental impact.

Customization and Complexity in Shapes

The ability to produce highly customized and complex shapes is a growing demand in various industries. Future CIP technology is expected to offer more versatility in tool design, allowing for the production of intricate components that were previously challenging to manufacture. This trend is particularly relevant in the aerospace and medical sectors, where component performance often depends on complex geometries.

Integration with Other Manufacturing Processes

Another exciting trend is the integration of CIP with other manufacturing technologies. For instance, combining CIP with additive manufacturing (AM) could leverage the strengths of both processes—CIP for densification and AM for complex geometries. This hybrid approach could lead to new materials and components that are stronger, lighter, and more efficient.

Conclusion

The future of Electric Lab Cold Isostatic Press (CIP) technology is bright, with numerous innovations on the horizon that promise to enhance its capabilities and expand its applications. As research and development continue, we can expect CIP to play a pivotal role in the next generation of high-performance materials and components, driving advancements across multiple industries.

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

Related Articles

- Hot & Cold Isostatic Pressing: Applications, Process, and Specifications

- Understanding Cold Isostatic Pressing and its Types

- Understanding Cold Isostatic Pressing Method for Powdered Materials

- Isostatic Pressing Technology: Revolutionizing Ceramic Material Densification

- Cold Isostatic Pressing: An Overview and its Industrial Applications