Introduction to Isostatic Pressing

Isostatic pressing is a manufacturing process that involves applying uniform pressure to a material to achieve a specific shape or density. The process can be performed at room temperature (cold isostatic pressing or CIP) or at high temperatures (hot isostatic pressing or HIP). This technique is widely used in the production of ceramics and refractory materials, and offers several advantages over other manufacturing processes, including improved mechanical and wear/corrosion properties, flexibility in shape and size, and enhanced alloying possibilities. Isostatic pressing also offers predictability and consistency in the final product, making it a popular choice for a range of industries.

Table of Contents

- Introduction to Isostatic Pressing

- Cold Isostatic Pressing (CIP)

- Hot isostatic pressing (HIP)

- Advantages of Isostatic Pressing in Manufacturing

- Uniform Strength and Density

- Flexibility in Shape and Size

- Low Tooling Cost and Reduced Lead Times

- Enhanced Alloying Possibilities

- Improved Mechanical and Wear/Corrosion Properties

- Predictability and Consistency

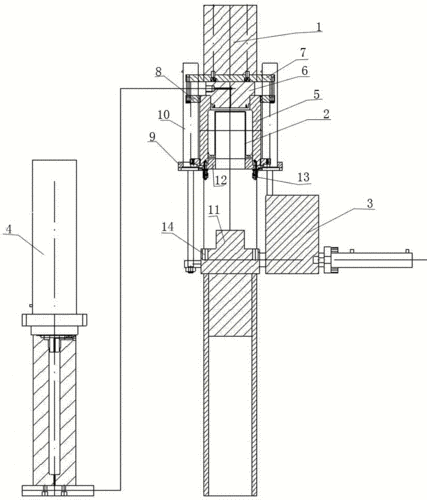

Cold Isostatic Pressing (CIP)

Cold isostatic pressing (CIP) is a manufacturing process that involves compressing a powder or slurry into a desired shape by applying equal pressure from all sides. It is a method of compacting powdered materials into a solid homogeneous mass before machining or sintering. This technique ensures that materials have a uniform density, which means that there will be uniform shrinkage when the material is going through other processes such as sintering.

Types of Cold Isostatic Pressing

There are two types of cold isostatic pressing currently recognized all over the world.

Wet Bag Technology

In this process, the powder is filled in a mold and sealed tightly. After filling the mold with powder, the mold is submerged in the pressure fluid within the pressure vessel. Then isostatic pressure is applied to the external surface of the mold, compressing the powder into a solid mass. This process is not as common as the other type of cold isostatic pressing.

Dry Bag Technology

In this process, the mold is fixed in the pressure vessel. The powder is filled in the mold while it is still in the pressure vessel. After this, isostatic pressure from the pressure liquid is applied to the external surface of the mold, compressing the powder into a solid mass with a compact microstructure. Dry bag technology is ideal for the mass production of materials.

Advantages of Cold Isostatic Pressing

One of the benefits of using cold isostatic pressing in manufacturing is the ability to produce products with precise dimensions and uniform density. Additionally, CIP can be used with a variety of materials, including ceramics, metals, and polymers. This versatility makes it an ideal choice for many industries, such as aerospace, automotive, and medical.

Cold isostatic pressing also has the advantage of being a non-destructive process, allowing for the reuse of materials and reducing waste. Furthermore, it can be used to produce products with improved strength, durability, and resistance to wear and tear.

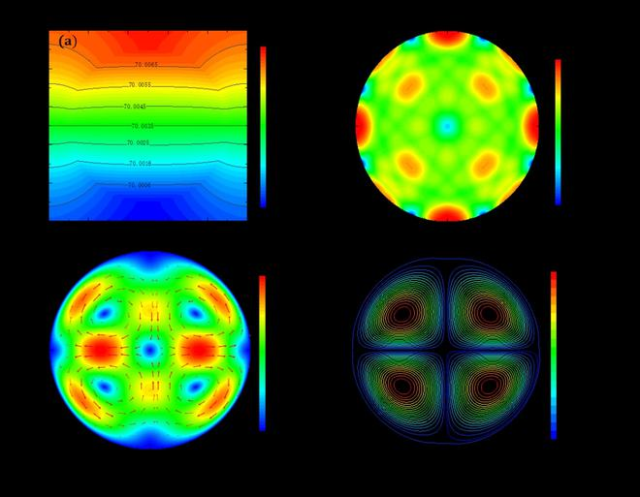

Compared with manual CIP, the electrical CIP can deliver better pressure control. Die-wall friction, which exerts a major influence on the density distribution of cold-pressed parts, is absent; so much more uniform densities are obtained. The elimination of die-wall lubricants also permits higher pressed densities and eliminates problems associated with lubricant removal prior to or during final sintering.

Because of the uniform compaction pressure, the cross section-to-height ratio of the part is not a limiting factor as it is with uniaxial pressing. In addition, cold isostatic pressing can be used to compact more complex shapes than possible with uniaxial pressing.

Isostatic pressing is a powder metallurgy (PM) forming process that applies equal pressure in all directions on a powder compact thus achieving maximum uniformity of density and microstructure without the geometrical limitations of uniaxial pressing.

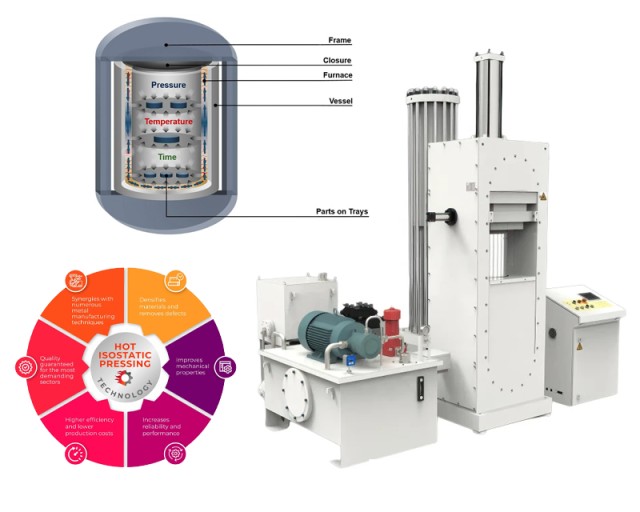

Hot isostatic pressing (HIP)

Hot isostatic pressing (HIP) is a manufacturing process that applies high temperature and pressure to materials such as metals and ceramics to improve their mechanical properties. The process is performed in a pressure vessel inside a high-temperature furnace, where parts are loaded and heated, pressurized with an inert gas such as argon, and held at this temperature and pressure for a specified amount of time. The heat and pressure are applied evenly to the part, forcing out porosity and creating a uniform microstructure in the material, which can improve properties.

How does HIPing work?

HIPing takes place in a pressure vessel inside a high-temperature furnace. Parts are loaded into the chamber which is then heated, pressurized with an inert gas such as argon, and held at this temperature and pressure for a specified amount of time. The heat and pressure are applied evenly to the part (isotropically), forcing out porosity. The HIPing process can also include pressurized rapid cooling, which functions as a quenching step. HIP cycles can take 8 to 12 hours or longer.

Benefits of HIP

Hot isostatic pressing (HIP) has numerous benefits in manufacturing. The process can create materials with superior mechanical properties, such as increased strength and toughness, due to the high pressure and temperature conditions during HIP that can cause the material to become more dense and uniform in structure. Additionally, HIP can be used to create complex shapes and designs that cannot be achieved through other manufacturing processes. This technique has also been shown to improve the fatigue life of materials, which is essential for products that are subject to repeated loading and unloading.

HIPing of 3D printed parts

HIPing is now used for post-processing of metal 3D printed parts, typically those produced by powder bed-based processes such as laser powder bed fusion (LPBF) and binder jetting, although directed energy deposition (DED) parts are sometimes also Processed this way. The printed parts are loaded into baskets and transferred to the chamber of the HIP furnace. The HIPing process can also include quenching, aging and other post-processing steps.

Application of HIP in manufacturing industry

Hot isostatic pressing (HIP) is a well-established process used to improve various materials such as titanium, steel, aluminum and high-temperature alloys. Using this process, voids within the casting can be reduced or eliminated, and the encapsulated powder can be combined to form a fully dense material. HIPing can reduce quality assurance inspection requirements by improving material properties and reducing performance dispersion. Often, the savings on radiography will pay for the HIP. Optimized material properties can be established to minimize subsequent heat treatment requirements. Machined parts have higher reliability and longer service life.

In summary, hot isostatic pressing (HIP) is an efficient manufacturing technology that produces high-quality materials with excellent strength and durability. The HIP process is widely used in the aerospace, medical and automotive industries due to its numerous advantages. The use of HIP can create materials with superior mechanical properties, such as increased strength and toughness, and can be used to create complex shapes and designs not possible through other manufacturing processes. HIPing has many benefits in manufacturing and can reduce quality assurance inspection requirements by improving material performance and extending service life.

Advantages of isostatic pressing in manufacturing

Isostatic pressing is a popular manufacturing process used in various industries including aerospace, defense and medical devices. It involves applying high pressure to powdered or compacted materials uniformly in all directions to produce high density and uniformity. Here are some of the advantages of isostatic pressing in manufacturing:

1. Complex shape and high precision

One of the main advantages of isostatic pressing is that it can produce complex shapes and parts with high precision and consistency. Apply pressure evenly, minimizing the risk of defects or inconsistencies in the final product. This makes isostatic pressing ideal for producing parts with complex geometries, such as turbine blades or engine components.

2. Improve strength and durability

Isostatic pressing can increase the strength, hardness and durability of materials, making them ideal for demanding applications such as aerospace, defense and medical devices. The process also reduces waste and material usage by allowing the production of near-net shapes, which require less machining and finishing.

3. Versatility and cost-effectiveness

Another advantage of isostatic pressing is that it can be used on a variety of materials, including ceramics, metals and composites, making it a versatile and cost-effective method for manufacturing high-quality parts. This allows manufacturers to produce a variety of parts with different properties, such as high temperature resistance or a high strength-to-weight ratio.

4. Uniformity and Consistency

Isostatic pressing exerts a uniform, equal force on the entire product, regardless of shape or size. This ensures products are produced with consistent density and microstructure, which is critical for high-performance applications. In addition, the use of isostatic pressing can eliminate internal micropores, thereby improving the mechanical properties of the casting.

5. Reduce machining and finishing

Isostatic pressing can produce near-net shapes, which require less machining and finishing. This can significantly reduce the time and costs involved in the production process, making isostatic pressing a cost-effective method of manufacturing high-quality parts.

Overall, isostatic pressing offers many benefits to manufacturers looking to produce high-performance materials with complex shapes and precise dimensions. These advantages include the ability to produce complex shapes with high precision, increased strength and durability, versatility and cost-effectiveness, uniformity and consistency, and reduced machining and finishing.

Uniform strength and density

Isostatic pressing is a manufacturing process widely used to produce high-performance components across a variety of industries. One of the most significant benefits of using isostatic pressing in manufacturing is the uniform strength and density of the final product.

Apply equal pressure

Isostatic pressing involves applying equal pressure to a powdered material from all directions. This process ensures that there are no weak points or areas of inconsistency in the manufactured components. In an industry where high-performance, reliable components are critical to preventing costly failures, downtime and safety hazards, final product uniformity is critical.

Improve purity

The isostatic pressing process produces high-purity components. This is possible because the process can be carried out in a vacuum or inert gas environment, eliminating the risk of ambient air contamination. The absence of contaminants enhances the mechanical properties of the finished product, making it more reliable and durable.

Complex shapes and designs

Isostatic pressing also allows the production of complex shapes and designs that are difficult or impossible to achieve with other manufacturing methods. This is because the powder material can be shaped and formed into the desired shape before undergoing the isostatic pressing process.

Shrinkage Uniformity

Uniform shrinkage and little or no warpage during sintering or hot isostatic pressing is an advantage of the isostatic pressing process. Eliminating die wall lubricant also allows for higher pressing densities and eliminates problems associated with lubricant removal before or during final sintering.

Versatility

Isostatic pressing can be used to produce difficult shapes that cannot be produced by other methods. Additionally, it can be used to produce large materials. The only limitation on the size of the material produced by this method is the size of the pressure vessel.

in conclusion

In summary, isostatic pressing is an efficient and versatile manufacturing process that offers several advantages over other similar processes. In an industry where high-performance, reliable components are critical to preventing costly failures, downtime and safety hazards, uniform strength and density of the final product is critical. Isostatic pressing is capable of producing parts of high purity and complex shapes and designs, making it an excellent choice for industries that require high-quality parts.

Flexibility in shapes and sizes

Isostatic pressing is a manufacturing process that involves applying uniform pressure to a material from all directions. This results in a high-density and uniform product that is ideal for producing components with complex designs and precise dimensions. One of the main benefits of using isostatic pressing is the flexibility it provides in terms of shape and size.

Complex Shapes and Sizes

Unlike other manufacturing processes that are limited by the shape and size of the mold or tool, isostatic pressing can be used to easily create complex shapes and sizes. This makes it ideal for producing components that require complex designs and precise dimensions. Flexibility in shape and size is due to uniform pressure on the material from all directions, which allows the material to assume any shape or size without any deformation.

Wide thickness range

Isostatic pressing can be used to manufacture products of various thicknesses from thin to thick plates. This thickness flexibility makes isostatic pressing a versatile manufacturing process that can be used in a variety of industries, including aerospace, automotive, and medical. Uniform pressure on the material ensures a consistent thickness throughout the product, which is important for components that require precise dimensions.

Material versatility

Isostatic pressing can be used on a variety of materials, including metals, ceramics, and composites. This makes it a valuable tool for producing a variety of products. The uniform pressure exerted on the material ensures a consistent density throughout the product, which is important for parts requiring high strength and durability. The material's versatility also makes isostatic pressing a cost-effective manufacturing process, as it can be used with a variety of materials without the need for additional tools or equipment.

In summary, shape and size flexibility, wide thickness range and material versatility make isostatic pressing a popular choice for producing high-quality components that meet the needs of modern industry. Isostatic pressing has the ability to create complex shapes and sizes and is a valuable tool for producing parts with complex designs and precise dimensions. The uniform pressure exerted on the material ensures consistent thickness and density throughout the product, which is important for parts requiring high strength and durability.

Low mold cost and short delivery time

Isostatic pressing is a manufacturing technique that is popular due to its many advantages. One of the main advantages of isostatic pressing is its low tooling cost, which makes it an affordable option for manufacturers looking to reduce production expenses. In traditional manufacturing processes, producing complex shapes often requires expensive tooling, which significantly increases overall production costs. However, with isostatic pressing, manufacturers can create complex shapes without the need for expensive tooling.

Low mold cost

Isostatic pressing offers manufacturers the advantage of lower tooling costs. The process involves placing powder or granular material into a mold and then using an isostatic press to press it at high pressure from all directions. The material then undergoes a consolidation process, where it becomes denser and takes on the shape of the mold. The process eliminates the need for expensive tooling typically required in traditional manufacturing processes. Manufacturers can use isostatic pressing to produce complex shapes without incurring high tooling costs.

Shorten delivery time

Another advantage of isostatic pressing is that it reduces delivery time. Traditional manufacturing processes can be very time-consuming, requiring multiple production stages and lengthy waiting times to create molds. However, isostatic pressing is a relatively straightforward process that can be accomplished quickly and efficiently. This means manufacturers can produce parts faster and thus meet customer demand more efficiently. With lead times reduced, manufacturers can increase productivity and increase revenue.

In conclusion

In summary, isostatic pressing is an efficient manufacturing technique that provides lower tooling costs and shorter lead times. The process allows manufacturers to create complex shapes without expensive tooling. This not only reduces overall production costs but also shortens delivery times, allowing manufacturers to meet customer demand more efficiently. As a result, isostatic pressing is becoming an increasingly popular option for manufacturers looking to optimize their production processes and reduce overall costs.

Enhanced alloying possibilities

Isostatic pressing is a manufacturing technique that involves compressing a powder or metal alloy using equal pressure from all directions. The process enhances alloying possibilities, resulting in stronger, more durable materials.

Uniform microstructure

Isostatic pressing can give the material a more uniform microstructure, thereby improving its mechanical properties. During this process, the equal pressure exerted on the material eliminates internal voids and porosity, resulting in a more uniform material structure. This uniformity improves mechanical properties such as increased strength, toughness and ductility.

Wide variety of materials

This technology is commonly used in the aerospace and defense industries, where critical applications require high-performance materials. Benefits of isostatic pressing include increased strength, corrosion and wear resistance, and the ability to create complex shapes and designs. Additionally, this manufacturing method can be used with a variety of materials, including ceramics, metals, and composites.

Enhanced alloying possibilities

Isostatic pressing can create alloys that are difficult or impossible to produce using other manufacturing techniques. The uniform pressure exerted during this process causes the powders to mix at the atomic level, allowing the creation of alloys with precise composition and properties.

Improve performance

The enhanced alloying possibilities offered by isostatic pressing can improve performance in a variety of applications. For example, the aerospace industry could benefit from the development of high-strength, lightweight alloys that can reduce fuel consumption and increase payload capacity. The medical industry can use isostatic pressing to create biocompatible alloys with improved wear resistance, corrosion resistance, and biocompatibility.

In conclusion

In summary, isostatic pressing is a valuable manufacturing technique that enhances alloying possibilities and improves material properties. The uniform pressure exerted during this process results in a stronger, more durable material with a more uniform microstructure. The technology is used in a variety of industries, including aerospace, defense and medical, and can be used with a variety of materials to create complex shapes and designs.

Improved mechanical and wear/corrosion properties

Isostatic pressing is a manufacturing process that involves applying high pressure to a material from all directions. This process improves the mechanical and wear/corrosion properties of the material.

Form materials with high density and uniform microstructure

Isostatic pressing is particularly useful in the production of ceramic materials. The process can form materials with high density and uniform microstructure. The high pressure applied to the material causes the particles to compact evenly, resulting in a denser, stronger material.

Improve strength and toughness

Isostatic pressing can produce materials with improved mechanical properties, such as increased strength and toughness. High pressure applied to the material refines the microstructure, thereby improving fracture toughness and fatigue resistance.

Improved wear and corrosion resistance

Isostatically pressed materials also exhibit better wear and corrosion resistance. High pressure applied to the material shrinks porosity and improves the metallurgical bonding between particles, making the material denser and more uniform. This in turn improves the material's resistance to wear and corrosion.

Production of complex shapes

Isostatic pressing can also be used to create complex shapes that are difficult to achieve with traditional manufacturing techniques. High pressure applied to the material can form complex shapes with high precision. This makes isostatic pressing an ideal process for producing parts with complex geometries, such as turbine blades and biomedical implants.

In summary, isostatic pressing is a versatile manufacturing process that can produce materials with improved mechanical and wear/corrosion properties. The process can produce materials with high density, uniform microstructure, increased strength and toughness, and improved wear and corrosion resistance. Additionally, isostatic pressing can be used to create complex shapes, making it an ideal process for a variety of applications in a variety of industries.

Predictability and consistency

Isostatic pressing is a manufacturing process that is highly beneficial in industries that require product predictability and consistency. The process can achieve a high level of precision and accuracy, ensuring the final product has a uniform shape and size. The predictability and consistency of isostatic pressing also extends to the mechanical and physical properties of the final product.

Control of Pressure and Temperature

Isostatic pressing allows for the control of both the pressure and temperature, which means that the manufacturing process can be fine-tuned to produce the desired results. The ability to control the manufacturing process and achieve consistent results makes isostatic pressing a popular choice for manufacturers who require high-quality products with predictable and consistent characteristics.

Achieve specific levels of density, porosity and strength

This process allows manufacturers to achieve specific levels of density, porosity and strength, which are critical in applications such as aerospace, medical devices and electronics. The uniformity of the isostatic compaction process distributes the material more evenly throughout the final product, which can improve its overall strength and durability.

Benefits to the aerospace and medical industries

In the aerospace industry, predictability and consistency are critical, as any defect in a component can lead to catastrophic failure. Isostatic pressing is commonly used to manufacture aerospace components such as turbine blades and fuel nozzles.

In the medical industry, isostatic pressing is used to form bioceramic materials for implants and prosthetics. Predictability and consistency in these products are critical to ensuring they can withstand the stresses and strains the human body will endure.

In conclusion

Overall, the predictability and consistency of isostatic pressing make it a valuable tool in many industries. Isostatic pressing’s ability to achieve specific levels of density, porosity and strength, and to control the pressure and temperature of the manufacturing process, makes isostatic pressing a popular choice for manufacturers who require high-quality products with predictable and consistent properties.

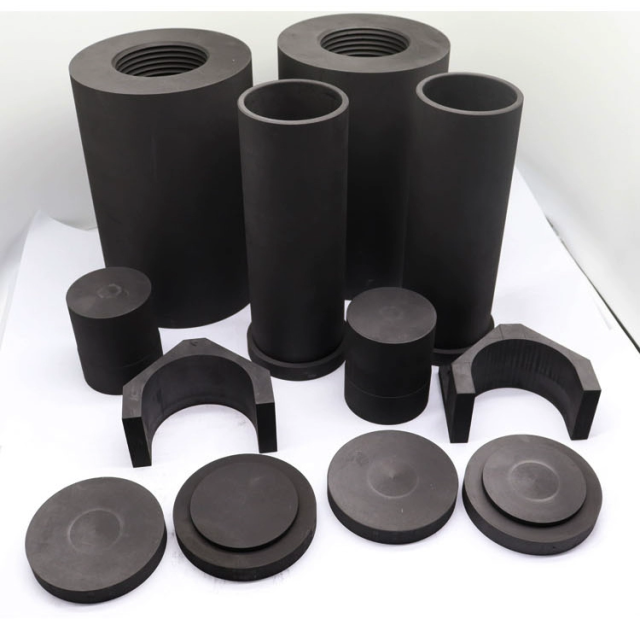

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Isostatic Molding Pressing Molds for Lab

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

Related Articles

- Essential Equipment for Mass Production of Solid-State Batteries: Isostatic Press

- Understanding the Basics of Isostatic Pressing

- How Isostatic Presses Help Eliminate Defects in Materials

- How to replace the rubber ring of isostatic press and what precautions should be taken

- Isostatic Pressing Technology in Solid-State Battery Production