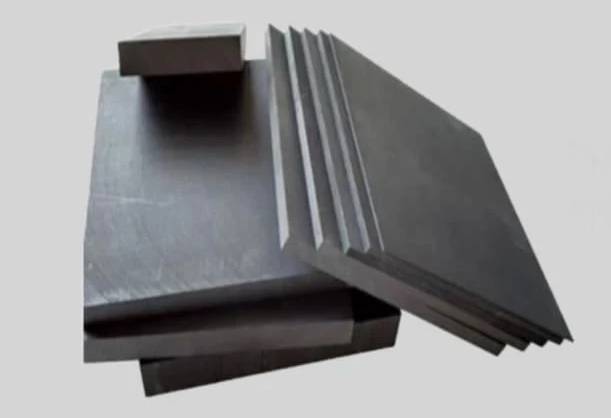

Thin Film Deposition Parts

Carbon Graphite Plate Manufactured by Isostatic Pressing Method

Item Number : KM-D11

Price varies based on specs and customizations

- Material

- Graphite

- Specification

- 1-50*100*100mm

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

Generally used in the following situations:

- Thermal Management: They effectively dissipate heat from electronic components such as the CPU, ensuring their optimal performance and preventing overheating.

- Gaskets and Seals: Excellent sealing performance due to its flexibility, elasticity and chemical resistance. Prevent fluid or gas leakage in high temperature and high pressure environments.

- Batteries and fuel cells: These provide a conductive path for electrons during electrochemical reactions, allowing efficient energy storage and release.

- Heat Exchangers: Graphite sheets are used in heat exchangers for efficient heat transfer between fluids.

- Consumer electronics: Dissipate heat generated by internal components. This helps prevent overheating, which can cause performance issues or even damage the device.

Detail & Parts

Technical specifications

| thickness / width / length | 1-50*100*100mm |

The produce we show are available in different sizes and custom sizes are available on request.

Advantages

- High thermal conductivity: achieves efficient heat transfer on its surface. This feature makes them ideal for applications where effective heat dissipation is critical.

- Excellent electrical conductivity: making it suitable for applications involving the transmission of electrical signals or power.

- Lightweight and flexible: Graphite sheets are lightweight and highly flexible, making them easy to handle and install.

- Chemical Resistance: Graphite flakes exhibit excellent resistance to chemicals, acids and bases, making them suitable for applications in corrosive environments.

- Low thermal expansion: ensures their stability and reliability under different thermal conditions.

In summary, graphite flakes are versatile materials that can be used in thermal management, sealing, energy storage, and heat transfer applications across various industries. Their excellent thermal and electrical conductivity, along with other favorable properties, make them extremely valuable in numerous technical and industrial applications.

Trusted by Industry Leaders

4.8 / 5

Fast delivery, great quality, and very durable.

4.9 / 5

The graphite plates are of superior quality and have met all our expectations.

4.7 / 5

Excellent thermal conductivity and electrical conductivity. Highly recommended!

4.6 / 5

The plates are lightweight and easy to handle, making them a pleasure to work with.

4.8 / 5

The isostatic graphite plates have enhanced the performance of our equipment significantly.

4.9 / 5

These plates are a great value for the price. I highly recommend them.

4.7 / 5

The graphite plates have improved the efficiency of our heat exchangers tremendously.

4.6 / 5

The plates are incredibly durable and have withstood harsh conditions without any issues.

4.8 / 5

The isostatic graphite plates are a testament to KINTEK SOLUTION's commitment to innovation and quality.

4.9 / 5

These plates have exceeded our expectations in terms of performance and reliability.

4.7 / 5

The graphite plates are highly versatile and can be used in a wide range of applications.

4.6 / 5

The plates are easy to machine, allowing for precise customization.

4.8 / 5

The isostatic graphite plates have significantly improved the lifespan of our equipment.

4.9 / 5

These plates are a great investment for any laboratory.

4.7 / 5

The graphite plates are a perfect fit for our high-temperature applications.

4.6 / 5

The plates are extremely resistant to thermal shock, making them ideal for our demanding applications.

4.8 / 5

The isostatic graphite plates have enabled us to achieve new levels of efficiency in our manufacturing process.

4.9 / 5

These plates are a valuable asset to our laboratory, providing exceptional performance and durability.

4.7 / 5

The graphite plates have proven to be an excellent choice for our research and development projects.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Manual Cold Isostatic Pressing Machine CIP Pellet Press

Lab Manual Isostatic Press is a high-efficient equipment for sample preparation widely used in material research, pharmacy, ceramics, and electronic industries. It allows for precision control of the pressing process and can work in a vacuum environment.

Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

Produce uniformly high-density materials with our Cold Isostatic Press. Ideal for compacting small workpieces in production settings. Widely used in powder metallurgy, ceramics, and biopharmaceutical fields for high-pressure sterilization and protein activation.

Carbon Graphite Boat -Laboratory Tube Furnace with Cover

Covered Carbon Graphite Boat Laboratory Tube Furnaces are specialized vessels or vessels made of graphite material designed to withstand extreme high temperatures and chemically aggressive environments.

Vertical High Temperature Graphite Vacuum Graphitization Furnace

Vertical high temperature graphitization furnace for carbonization and graphitization of carbon materials up to 3100℃.Suitable for shaped graphitization of carbon fiber filaments and other materials sintered in a carbon environment.Applications in metallurgy, electronics, and aerospace for producing high-quality graphite products like electrodes and crucibles.

Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

Bottom-out graphitization furnace for carbon materials, ultra-high temperature furnace up to 3100°C, suitable for graphitization and sintering of carbon rods and carbon blocks. Vertical design, bottom discharging, convenient feeding and discharging, high temperature uniformity, low energy consumption, good stability, hydraulic lifting system, convenient loading and unloading.

Large Vertical Graphite Vacuum Graphitization Furnace

A large vertical high-temperature graphitization furnace is a type of industrial furnace used for the graphitization of carbon materials, such as carbon fiber and carbon black. It is a high-temperature furnace that can reach temperatures of up to 3100°C.

Ultra-High Temperature Graphite Vacuum Graphitization Furnace

The ultra-high temperature graphitization furnace utilizes medium frequency induction heating in a vacuum or inert gas environment. The induction coil generates an alternating magnetic field, inducing eddy currents in the graphite crucible, which heats up and radiates heat to the workpiece, bringing it to the desired temperature. This furnace is primarily used for graphitization and sintering of carbon materials, carbon fiber materials, and other composite materials.

Infrared Heating Quantitative Flat Plate Press Mold

Discover advanced infrared heating solutions with high-density insulation and precise PID control for uniform thermal performance in various applications.

Related Articles

Isostatic Pressing for Aerospace and Defense Applications

Isostatic pressing is a manufacturing process that is widely used in the aerospace and defense industry to produce high-quality, high-performance parts. In this process, a ceramic or metal powder is placed in a flexible mold, which is then subjected to a uniform pressure from all sides using a high-pressure fluid.

Optimizing Performance with Graphite Vacuum Furnaces: A Comprehensive Guide

Unlock the potential of graphite vacuum furnaces for high-temperature material treatment. Learn about their efficiency, customization options, automation, and key considerations for graphite rod usage.

The Advantages of Using Isostatic Pressing for Oxygen Sensors

Isostatic pressing is a method of compacting powder or granulated materials into a desired shape and density. This process involves applying pressure uniformly from all directions to the material, typically using a fluid medium such as gas or liquid.

Comprehensive Analysis of Isostatic Pressing Techniques

sostatic pressing is an essential technique in the manufacturing industry, used for shaping and consolidating materials. It involves subjecting a material to uniform pressure from all directions, resulting in enhanced density and improved mechanical properties. Isostatic pressing is widely employed in various industries, including aerospace, automotive, and healthcare, due to its ability to produce complex and high-quality components.

Isostatic Presses for Aerospace Applications

Isostatic pressing is a manufacturing process that uses pressure to create uniform parts with consistent density and strength. The process involves placing a material in a flexible container, which is then pressurized from all sides to create a uniform shape.

Analysis of the Isostatic Pressing Market

Isostatic pressing, is a manufacturing process that involves applying high-pressure gas to a material in order to shape and consolidate it. This technique is widely used in various industries, including aerospace, automotive, and medical, due to its ability to produce high-quality, defect-free components.

Impact Analysis of COVID-19 on the Global Isostatic Pressing Market

Isostatic pressing systems, which use fluid or gas pressure to uniformly modify materials, are experiencing significant growth in the global market. These systems are used in various industries and offer numerous benefits, making them a popular choice for manufacturing high-performance components.

All About ACTIVATED CARBON THERMAL REGENERATION

Introduction, method and selection of activated carbon regeneration

Understanding Cold Isostatic Pressing and Its Applications

Cold isostatic pressing (CIP) is a method of processing materials. It involves compacting powders by enclosing them in an elastomer mold and applying uniform liquid pressure to compress the mold. This results in a highly compact solid. Cold isostatic pressing is commonly used for plastics, graphite, powdered metallurgy, ceramics, sputtering targets, and other materials.

CVD furnace for the growth of carbon nanotubes

Chemical vapor deposition (CVD) furnace technology is a widely used method for growing carbon nanotubes.

The Role of Powder Characteristics in Cold Isostatic Pressing

Cold Isostatic Pressing (CIP) is a powder compaction technique that involves applying uniform pressure to a powder-filled container from all directions.

How Isostatic Pressing Improves Mechanical Properties of Castings

Isostatic pressing (IP) is a manufacturing process used to improve the mechanical properties of castings. It involves applying uniform pressure from all directions to a material using a liquid or gas medium.