Introduction

In the realm of advanced materials processing, precision and purity stand as the twin pillars upon which innovation thrives. At the heart of this pursuit lies the vacuum graphite furnace, a marvel of engineering that has revolutionized the way we manipulate and transform metals and alloys. From the intricate workings of laboratory research to the bustling floors of industrial manufacturing, these furnaces have left an indelible mark on diverse fields, offering unparalleled control over temperature, atmosphere, and material properties.

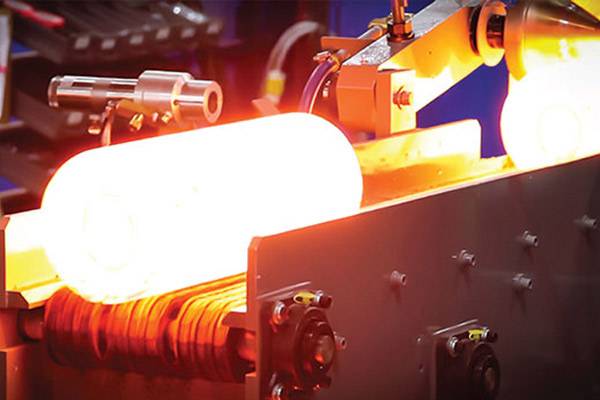

Graphite, with its exceptional thermal conductivity, mechanical strength, and resistance to high temperatures, emerged as the ideal candidate for heating elements within vacuum environments. Its ability to withstand extreme conditions while providing uniform heating paved the way for a new era of materials processing. Through innovative design and meticulous engineering, modern vacuum graphite furnaces boast sophisticated heating systems, precise temperature control mechanisms, and robust vacuum chambers, enabling a diverse range of applications with unmatched reliability and efficiency.

Understanding Ultra-Temperature Vacuum Graphite Furnaces

Explore the innovative features and design principles of ultra-temperature vacuum graphite furnaces, including advanced temperature control and material design. Learn how these furnaces create ideal conditions for high-temperature material treatments.

In the world of advanced manufacturing and materials processing, heat treatment plays a crucial role in enhancing the properties of various metals and alloys. Among the various heat treatment methods available, the vacuum furnace has emerged as a revolutionary technology. With its ability to achieve precise and controlled thermal environments, the vacuum furnace has transformed industries such as aerospace, automotive, medical, and tooling. This article explores the working principles, benefits, and applications of vacuum furnaces in detail.

Vacuum Graphite Furnace Horizontal Type up to 2200℃

The ultra-temperature vacuum graphite furnace is a performance intelligent heating furnace, adopt advanced temperature measurement, temperature control, intelligence, new material, and furnace chamber design. This furnace is mainly used for high-temperature treatment of materials in a vacuum or protective atmosphere environment.

Graphite-Based Furnace: A High Level of Thermal Efficiency

The graphite wafer is an excellent material which allows operation at very high temperatures. It has low density, reduced weight and modest thermal capacity. It creates the ideal black body conditions (emissivity about 1) inside the heating chamber for obtaining high uniformity.

Applications and Impact

The versatility of vacuum graphite furnaces transcends boundaries, finding applications in a myriad of industries and research disciplines. In the aerospace sector, these furnaces play a critical role in the development of high-performance alloys for turbine engines, where precise control over material composition and microstructure is paramount. Similarly, in the automotive industry, vacuum graphite furnaces are instrumental in producing lightweight, high-strength components that enhance fuel efficiency and vehicle performance.

Moreover, these furnaces find widespread use in electronics manufacturing, where the demand for pure, defect-free materials is ever-present. From semiconductor fabrication to the production of specialty metals for electronic components, the ability to create materials with exceptional purity and uniformity has propelled technological advancements and innovation.

In the realm of academic research, vacuum graphite furnaces serve as indispensable tools for studying the behavior of materials under extreme conditions. Whether investigating phase transformations in metals or synthesizing novel compounds, researchers rely on the precision and reproducibility offered by these furnaces to push the boundaries of scientific knowledge.

Key Considerations for Graphite Rod Usage

Graphite Rod in the Vacuum Furnace: Attention to the 4 Major Matters

Heating graphite rods are indispensable in high-temperature vacuum furnaces, acting as electric heaters facilitating product oxidation at elevated temperatures, streamlining product manufacturing processes. The widespread adoption of heating graphite rods can be attributed to their exceptional cost performance.

Energy Efficiency and Sustainability

At Graphite Furnace Systems, our commitment to environmental sustainability drives our innovation in vacuum furnace systems. Designed with energy efficiency at the forefront, our systems integrate cutting-edge features to minimize energy consumption while maximizing productivity. By curbing energy waste, users not only contribute to a greener future but also realize significant cost savings over time.

Unrivaled Technical Support and Service

Contemporary hot zone designs predominantly incorporate graphite in various forms such as sheets, felt, or board for insulation, alongside graphite components like heating elements, connectors, and furnace bases. A plethora of graphite grades and insulating components provide end-users with a diverse array of advanced material options.

The selection of appropriate materials is paramount and varies with each application. Optimal material choices enable controlled atmosphere and vacuum furnaces to operate at uniform temperatures exceeding 5250°F, minimizing contamination and power losses.

Description of Application of Graphite Rod in Vacuum Furnace

-

Red Heat Uniformity: Select graphite rods exhibiting uniform red heat distribution in the heating section. Discrepancies in red heat uniformity can compromise furnace temperature uniformity and shorten graphite rod lifespan. Over time, declining red heat uniformity may culminate in rod fracture.

-

Service Temperature Considerations: The lifespan of graphite rods diminishes with increasing service temperatures. Beyond 1500℃, accelerated oxidation rates curtail rod longevity. To prolong usage, mitigate excessively high surface temperatures of graphite rods.

Conclusion

Graphite Furnace Systems is dedicated to providing tailored solutions for diverse applications in industries such as aviation/aerospace, medical device manufacturing, and advanced ceramics. Our vacuum furnace systems are designed with energy efficiency, automation, and control in mind, enabling our clients to achieve their production goals while minimizing environmental impact.

By collaborating closely with our clients and leveraging our expertise, we ensure that our vacuum furnace solutions perfectly align with their specific requirements. With unrivaled technical support and service, we are committed to helping our clients optimize their processes and achieve the highest standards of quality and productivity.

If you are looking for a customized vacuum furnace solution for your industry or application, contact Graphite Furnace Systems today. Our team of experts is ready to assist you in finding the most efficient, reliable, and sustainable solution for your production needs. Together, we can drive innovation and success in your industry.

Related Products

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Large Vertical Graphite Vacuum Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

Related Articles

- What is activated carbon regeneration Rotary Furnace

- Comprehensive Guide to Atmosphere Furnaces: Types, Applications, and Benefits

- The Architecture of Emptiness: Mastering Material Selection in Vacuum Furnaces

- Guide to Bottom Loading Furnace

- Hydrogen Atmosphere Furnaces: Applications, Safety, and Maintenance