Thin Film Deposition Parts

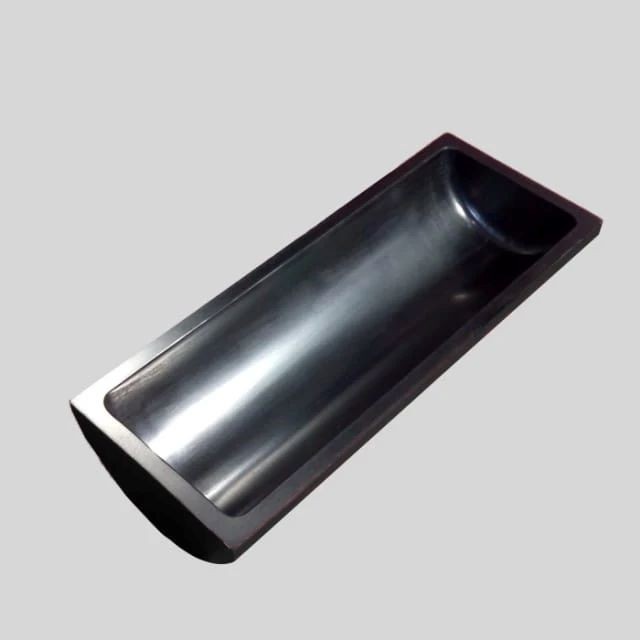

Carbon Graphite Boat -Laboratory Tube Furnace with Cover

Item Number : KM-D10

Price varies based on specs and customizations

- Material

- Graphite

- Specification

- 35*18*100*3.5mm / 45*150*23*5mm

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

Tube Furnace Carbon Graphite Boat with cover is a specialized container or vessel made of graphite material which is designed to withstand extreme heat and chemically aggressive environments. The hull is usually boat-shaped or rectangular, with high thermal conductivity and excellent thermal shock resistance. It is often used to heat or contain materials that need to be exposed to high temperatures while maintaining a controlled environment. A lid or lid on the boat helps protect the contents from the outside elements or contamination. Covered graphite boats are commonly used in applications such as chemical vapor deposition (CVD), and the graphite material used in these boats has several desirable properties, including high melting point, low thermal expansion, and chemical inertness. These properties make them suitable for applications involving corrosive or reactive substances and processes.

Covered graphite boats have a variety of applications in industrial and research environments involving high temperatures, corrosive environments, or controlled atmospheres. Some common applications include:

- Chemical Vapor Deposition (CVD): Covered graphite boats are widely used in CVD processes to grow thin films or coatings.

- Thermal Analysis: Graphite boats are used in thermal analysis techniques such as Thermogravimetric Analysis (TGA) or Differential Thermal Analysis (DTA).

- Materials Testing: Covered Graphite Boats for Materials Testing and Analysis

- Sample preparation: It can be used in sample preparation processes such as drying, calcination or ashing.

- Crucibles: Graphite boats can be used as crucibles for melting or evaporating substances in applications such as metallurgy, alloy production or chemical synthesis.

- Semiconductor Manufacturing: In the semiconductor industry, covered graphite boats are used in processes such as wafer annealing, chemical vapor deposition (CVD) for thin film deposition, and semiconductor epitaxial growth.

- Research and Development: Covered graphite boats are used in various research and development activities in the fields of materials science, chemistry, physics and engineering.

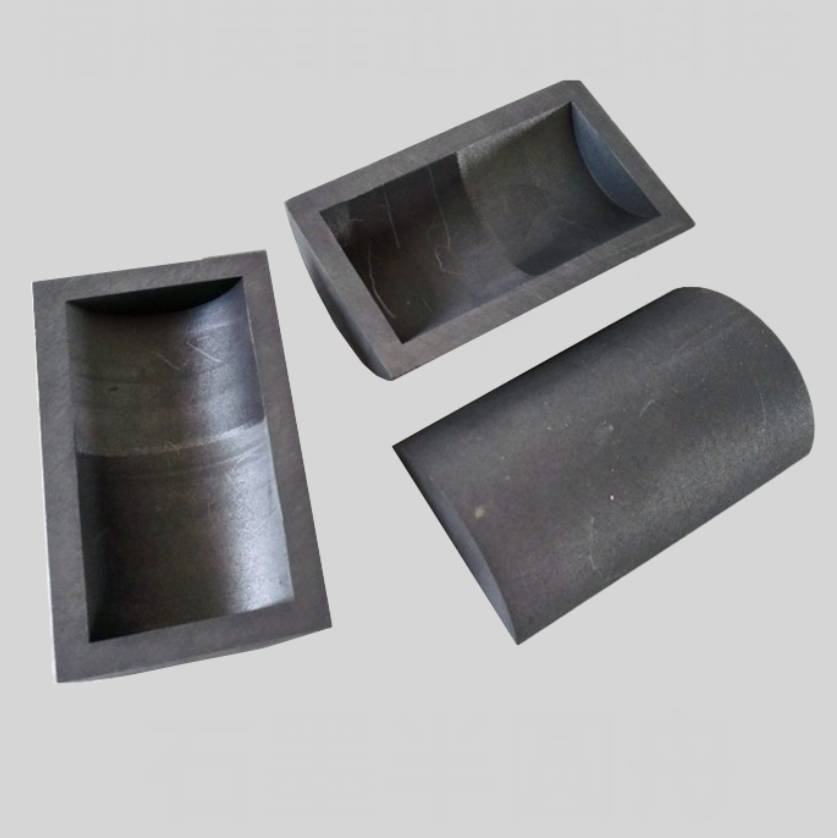

Detail & Parts

Technical specifications

| diameter / height / length / thickness | 35*18*100*3.5mm | 45*150*23*5mm |

The crucibles we show are available in different sizes and custom sizes are available on request.

Advantages

- Heat resistance: Graphite has a high melting point and can withstand extremely high temperatures, making graphite capping suitable for high-temperature applications.

- Thermal conductivity: Allows for efficient heat transfer and uniform heating or cooling of the ship's contents.

- Chemically Inert: It is corrosion resistant and does not react with most chemicals.

- Low Thermal Expansion: It does not expand or contract significantly with temperature changes.

- Mechanical Strength: Graphite boats are generally strong and have good mechanical strength.

- Conductivity: Advantageous in some applications where conduction or grounding is required.

- Design Versatility: Covered graphite boats come in a variety of shapes, sizes and configurations to suit different applications. Covers or lids add an extra layer of protection and containment for the contents.

- Stability in vacuum or inert atmospheres: Graphite boats exhibit stability and durability in vacuum or inert gas environments, making them suitable for processes requiring controlled atmospheres.

Trusted by Industry Leaders

FAQ

What Is A Tube Furnace?

Laboratory tube furnace is one classic external heating high temperature tube furnace, also named hot wall heating furnace.

According to the different working temperature, furnace tube material usually can be transparent quartz tubes, high purity alumina ceramic tubes and high strength metal alloy tubes.

To meet different thermal researching purposes, tube furnace can be designed with multi heating zones, so as to have a flexible control of temperature gradient in the tube working chamber; furnace tube can work with a controlled atmosphere working environment or a high vacuum working environment.

What Is A Graphitization Furnace?

How Does A Tube Furnace Work?

Tube furnace heating elements are placed surrounding the cylindrical cavity, furnace can only heat the samples in the cylindrical cavity through indirect thermal radiation, since furnace tube can prevent sample material from contacting with furnace heating elements and insulation materials, so tube furnace creates a clean isolated heat chamber and reduce risks of the sample material contaminating by the furnace.

What Are The Main Applications Of Graphitization Furnaces?

What Is The Application For Tube Furnace?

Tubular furnace is mainly used in metallurgy, glass, heat treatment, lithium anode and cathode materials, new energy, abrasives and other industries, and is a professional equipment for measuring materials under certain temperature conditions.

Tube furnace features simple structure, easy operation, easy control and continuous production.

Tube furnace is also widely applied in the CVD (chemical vapor deposition) and plasma enhanced CVD systems.

What Are The Different Types Of Graphitization Furnaces?

How Many Different Types Tube Furnace?

Tube furnace can work with different mechanical functions smoothly, so there are many different types tube furnace variations for different experiment purposes, typical furnace furnaces are as below:

- Horizontal tube furnace

- Vertical tube furnace

- Split tube furnace

- Rotary tube furnace

- Tilting tube furnace

- Sliding tube furnace

- Fast heating and cooling tube furnace

- Continuous feeding and discharging tube furnace

How Does A Graphitization Furnace Work?

What Are The Advantages Of Using A Tube Furnace?

What Are The Advantages Of Using A Graphitization Furnace?

What Safety Precautions Should Be Taken When Using A Tube Furnace?

4.9 / 5

I highly recommend this graphite boat! It's sturdy, heats up uniformly and is easy to clean.

4.7 / 5

Five stars for this durable and efficient graphite boat. It's a must-have for any laboratory.

4.8 / 5

I'm very satisfied with this graphite boat. It's well-made and performs consistently.

4.6 / 5

This boat is a great value for the price. It's made of high-quality materials and works well.

4.9 / 5

Excellent graphite boat. It's a great addition to my laboratory equipment.

4.7 / 5

I'm impressed with this boat's durability. It's holding up well in my lab.

4.8 / 5

This graphite boat is a great investment. It's reliable and heats up quickly.

4.6 / 5

I'm happy with this boat's performance. It's a good choice for my lab.

4.9 / 5

I'm very impressed with this boat's quality. It's made of top-notch materials.

4.7 / 5

This boat is a great value for the money. It's well-made and reliable.

4.8 / 5

I'm happy with this boat's performance. It's a great addition to my lab.

4.6 / 5

I'm satisfied with this boat's quality. It's a good choice for my lab.

4.9 / 5

I'm very impressed with this boat's durability. It's holding up well in my lab.

4.7 / 5

This boat is a great value for the money. It's well-made and reliable.

4.8 / 5

I'm happy with this boat's performance. It's a great addition to my lab.

4.6 / 5

I'm satisfied with this boat's quality. It's a good choice for my lab.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

KT-TF12 split tube furnace: high-purity insulation, embedded heating wire coils, and max. 1200C. Widely used for new materials and chemical vapour deposition.

Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

KT-PE12 Slide PECVD System: Wide power range, programmable temp control, fast heating/cooling with sliding system, MFC mass flow control & vacuum pump.

Glassy Carbon Sheet RVC for Electrochemical Experiments

Discover our Glassy Carbon Sheet - RVC. Perfect for your experiments, this high-quality material will elevate your research to the next level.

Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

Get your exclusive CVD furnace with KT-CTF16 Customer Made Versatile Furnace. Customizable sliding, rotating, and tilting functions for precise reactions. Order now!

Non Consumable Vacuum Arc Induction Melting Furnace

Explore the benefits of Non-Consumable Vacuum Arc Furnace with high melting point electrodes. Small, easy to operate & eco-friendly. Ideal for laboratory research on refractory metals & carbides.

1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

Discover our KT-12A Pro Controlled atmosphere furnace - high precision, heavy duty vacuum chamber, versatile smart touch screen controller, and excellent temperature uniformity up to 1200C. Ideal for both laboratory and industrial application.

Spark Plasma Sintering Furnace SPS Furnace

Discover the benefits of Spark Plasma Sintering Furnaces for rapid, low-temperature material preparation. Uniform heating, low cost & eco-friendly.

Aluminized Ceramic Evaporation Boat for Thin Film Deposition

Vessel for depositing thin films; has an aluminum-coated ceramic body for improved thermal efficiency and chemical resistance. making it suitable for various applications.

Related Articles

Unveiling Vacuum Graphite Furnaces: Performance, Applications, and Expert Insights

Delve into the world of vacuum graphite furnaces, exploring their exceptional performance, diverse applications, and crucial considerations. Our expert insights empower you to make informed decisions for your laboratory's high-temperature material treatment needs.

CVD furnace for the growth of carbon nanotubes

Chemical vapor deposition (CVD) furnace technology is a widely used method for growing carbon nanotubes.

Graphite Boats in PECVD for Cell Coating

Exploring the use of graphite boats in PECVD for efficient cell coating.

The Importance of Activated Carbon Regeneration in Water Treatment

In water treatment, activated carbon is often used as a means of removing unwanted contaminants, such as chlorine, chloramines, and organic matter, from drinking water and wastewater.

Optimizing Performance with Graphite Vacuum Furnaces: A Comprehensive Guide

Unlock the potential of graphite vacuum furnaces for high-temperature material treatment. Learn about their efficiency, customization options, automation, and key considerations for graphite rod usage.

High Purity Graphite Crucible: Features, Production, and Usage

An in-depth look at high purity graphite crucibles, their production processes, and their industrial applications.

Understanding Evaporation Boats in Vacuum Coating

An in-depth look at evaporation boats, their materials, arrangement, temperature control, and corrosion issues in vacuum coating processes.

Laboratory Jacketed Vessels

Overview of jacketed vessels, their types, and applications in various industries.

The Transparency Paradox: Mastering the Art of Quartz Tube Maintenance

In high-temperature furnaces, cleanliness is physics, not just aesthetics. Discover the systematic approach to cleaning quartz tubes and the critical role of prevention.

The Invisible Variable: Selecting the Heart of Your Vacuum Furnace

The heating element isn't just a component; it dictates your furnace's chemistry. Explore the engineering trade-offs between Graphite, Molybdenum, and Composites.

The Ritual of Clarity: A Systemic Approach to Cleaning Furnace Tubes

Cleaning a furnace tube isn't just maintenance; it's calibration. Learn the diagnostic process for quartz and alumina tubes to prevent contamination.