Types of Graphite Crucibles

Clay Graphite Crucible

The clay graphite crucible is a cost-effective solution for melting applications, though it comes with notable trade-offs in durability and performance. Crafted through the meticulous blending of clay and graphite powder, this crucible offers a budget-friendly alternative to more advanced materials. However, its lower durability and less effective use outcomes signify a compromise in quality, making it suitable for less demanding or short-term applications.

| Attribute | Clay Graphite Crucible | High Purity Graphite Crucible |

|---|---|---|

| Material Composition | Made from a mixture of clay and graphite powder. | Made from 99.9% pure graphite. |

| Cost | Lower cost due to simpler production process. | Higher cost due to advanced materials and production techniques. |

| Durability | Poor durability; susceptible to wear and tear. | Superior durability; designed for prolonged use. |

| Performance | Less effective in terms of thermal conductivity and resistance to erosion. | Excellent performance with superior thermal conductivity and resistance to erosion. |

| Applications | Suitable for short-term or less critical melting tasks. | Ideal for industrial, analytical, and jewelry applications requiring high precision and durability. |

Despite its limitations, the clay graphite crucible remains a viable option for those seeking an economical solution without the need for extended service life or high-performance attributes. For more demanding applications, however, the high purity graphite crucible emerges as the preferred choice, offering enhanced durability and performance at a higher price point.

High Purity Graphite Crucible

High purity graphite crucibles are meticulously crafted from 99.9% pure graphite, a material renowned for its exceptional conductivity and thermal expansion properties. These crucibles are precision-machined using CNC technology, ensuring a seamless and smooth interior surface that minimizes the risk of material sticking during the melting process. This advanced manufacturing technique not only enhances the crucible's durability but also significantly improves its overall performance and longevity.

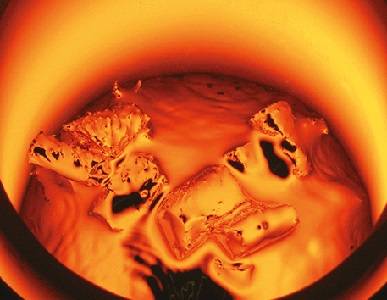

In industrial applications, high purity graphite crucibles are indispensable for tasks requiring high-temperature processing, such as melting metals like gold and silver. Their superior thermal shock resistance and corrosion resistance make them ideal for use in various industries, including metallurgy, analytical laboratories, and jewelry manufacturing. Unlike traditional ceramic or clay crucibles, these graphite crucibles can withstand extreme temperatures without degrading, ensuring consistent and reliable performance in demanding environments.

The high cost associated with high purity graphite crucibles is justified by their superior use effect and durability. The investment in these crucibles translates to long-term savings and efficiency, as they can handle repeated high-temperature applications without compromising their structural integrity or performance. This makes them a valuable asset in industries where precision and reliability are paramount.

Applications of Graphite Crucibles

Melting Non-Ferrous Metals

Graphite crucibles are predominantly employed in the melting of non-ferrous metals and their alloys, which include a variety of materials crucial for various industrial applications. These metals, such as copper, brass, gold, silver, zinc, and lead, are essential for their electrical conductivity, malleability, and resistance to corrosion. The ability to melt these metals efficiently and without contamination is paramount for maintaining the integrity and purity of the final product.

The process of melting these metals often requires high temperatures, which is where the superior thermal conductivity of graphite crucibles becomes indispensable. This high thermal conductivity ensures that the metals are heated uniformly, minimizing the risk of thermal stress and ensuring a consistent melt. Additionally, the corrosion-resistant properties of high-purity graphite crucibles help in maintaining the purity of the molten metal, preventing any unwanted chemical reactions that could degrade the quality of the final product.

Furthermore, the use of graphite crucibles in melting non-ferrous metals is not limited to just the initial melting process. These crucibles are also used in the subsequent refining and alloying stages, where precise temperature control and a contamination-free environment are critical. This multi-stage usage underscores the versatility and robustness of graphite crucibles in metallurgical applications.

Production Processes

Plastic Molding Production Process

The plastic molding production process for high purity graphite crucibles involves several outdated and environmentally detrimental steps. Initially, clay is employed as a binder, which not only lengthens the production cycle but also necessitates a significant amount of manual labor, thereby reducing overall efficiency.

Moreover, this method relies heavily on coal-fired furnaces for the sintering process, contributing to substantial environmental pollution. The combination of these factors results in a production process that is both time-consuming and labor-intensive, with minimal efficiency gains.

| Aspect | Description |

|---|---|

| Binder | Clay is used as the primary binder, which increases the complexity of the process. |

| Production Cycle | The production cycle is prolonged due to the nature of the binding material. |

| Labor Intensity | High levels of manual labor are required, making the process labor-intensive. |

| Efficiency | The overall efficiency of the process is low, leading to slower production rates. |

| Energy Source | Coal-fired furnaces are utilized, contributing to significant pollution. |

This traditional method, while still in use in some facilities, is increasingly being replaced by more advanced and environmentally friendly techniques, such as cold isostatic pressure molding, which offers shorter cycles and higher efficiency without the environmental drawbacks.

Cold Isostatic Pressure Molding Production Process

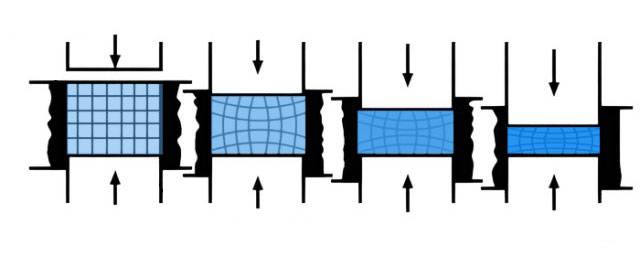

The cold isostatic pressure molding production process stands out for its environmental friendliness and efficiency. This method employs clean energy gas sintering, effectively mitigating pollution concerns associated with traditional production techniques. By using a mold made from elastomeric materials like urethane, rubber, or polyvinyl chloride, the process ensures that the fluid pressure, typically ranging from 60,000 lbs/in² (400 MPa) to 150,000 lbs/in² (1000 MPa), is uniformly applied. This uniformity is crucial for achieving a very uniform density in the powder compact.

However, one notable drawback of this process is the low geometric accuracy due to the flexible nature of the molds. Despite this, cold isostatic pressing (CIP) is highly advantageous for producing large or complex parts where the high initial cost of pressing dies is not justifiable. The process can handle a variety of powders, including metals, ceramics, plastics, and composites, with compacting pressures ranging from less than 5,000 psi to more than 100,000 psi (34.5 to 690 MPa).

The cycle of this production process is notably short, contributing to its high efficiency. Once the powder is compacted, the green compact is usually sintered conventionally to finalize the desired part. This streamlined approach not only reduces the number of production channels but also enhances overall productivity, making it a preferred method in industries where time and environmental impact are critical factors.

Characteristics of Graphite Crucibles

High Density and Thermal Conductivity

High purity graphite crucibles exhibit superior thermal conductivity compared to other imported crucibles, making them a preferred choice for various industrial applications. This enhanced thermal conductivity is attributed to the high density of the graphite material, which allows for more efficient heat distribution. The superior thermal performance of these crucibles ensures quicker and more uniform heating, which is crucial for processes requiring precise temperature control.

In comparison to clay graphite crucibles, which have lower thermal conductivity and durability, high purity graphite crucibles offer a significant advantage. The use of high purity graphite raw material processed by CNC machines results in a product that not only conducts heat better but also maintains its structural integrity over prolonged use. This makes them ideal for high-temperature applications such as melting non-ferrous metals like copper, brass, gold, and silver.

Moreover, the production process of these crucibles, particularly the cold isostatic pressure molding method, further enhances their thermal conductivity. This method, which uses clean energy gas sintering, not only resolves pollution issues but also ensures a shorter production cycle and higher efficiency. The resulting crucibles are not only environmentally friendly but also more durable and efficient in their thermal performance.

Corrosion Resistance

The corrosion resistance of high purity graphite crucibles is significantly enhanced through the application of a glaze layer and the use of dense molding materials. This improvement is crucial for prolonging the service life of the crucibles, making them more reliable and durable in industrial applications. The glaze layer acts as a protective barrier, shielding the crucible from Chemical attack and physical wear, while the dense molding material ensures that the structure remains intact under high-stress conditions.

In environments where non-ferrous metals and their alloys are melted, such as in the production of copper, brass, gold, and silver, the crucibles are exposed to highly corrosive substances. The advanced corrosion resistance of these crucibles allows them to withstand these harsh conditions, reducing the frequency of replacements and maintenance, thereby lowering operational costs.

Moreover, the production process, particularly the cold isostatic pressure molding method, contributes to the enhanced corrosion resistance by ensuring a uniform and dense structure. This method, which uses clean energy gas sintering, not only resolves pollution issues but also optimizes the material's resistance to corrosion, further extending the crucible's operational lifespan.

Thermal Conductivity and Handling

High purity graphite crucibles are renowned for their exceptional thermal conductivity, a feature that is primarily attributed to their graphite composition. This high thermal conductivity allows for efficient heat distribution, which is crucial for tasks such as melting non-ferrous metals. However, this property also necessitates careful handling to prevent thermal shock.

Immediately after heating, graphite crucibles should not be placed on cold metal surfaces. The rapid temperature change can cause thermal stress, potentially leading to cracks or fractures in the crucible. To mitigate this risk, it is advisable to use heat-resistant pads or to allow the crucible to cool gradually on a non-conductive surface.

This handling precaution is particularly important in industrial settings where the integrity of the crucible directly impacts the success of the melting process. By adhering to these guidelines, users can ensure the longevity and effectiveness of their high purity graphite crucibles.

Storage and Handling

Moisture-Proof Measures

Preventing moisture is essential to avoid critical issues such as rupture, bursting, and metal loss in high purity graphite crucibles. The storage environment plays a pivotal role in maintaining the integrity and longevity of these crucibles. To ensure optimal conditions, the storage room should be meticulously managed to maintain a dry, well-ventilated atmosphere with controlled temperature and humidity levels.

Maintaining a dry environment is crucial as moisture can seep into the graphite structure, leading to weakening and potential failure. Proper ventilation helps in dispersing any accumulated moisture, preventing it from condensing on the crucibles. Additionally, controlling the temperature and humidity within the storage area ensures a stable environment that minimizes the risk of moisture-related damages.

Implementing these measures not only safeguards the crucibles from immediate damage but also ensures their long-term performance and durability, making them reliable for various industrial applications.

Related Products

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- High Purity Pure Graphite Crucible for Evaporation

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- High Purity Pure Graphite Crucible for Electron Beam Evaporation

- Carbon Graphite Boat -Laboratory Tube Furnace with Cover

Related Articles

- Comparison of Pyrolytic Graphite and Pyrolytic Boron Nitride Crucibles

- Inorganic Non-Metallic Materials: Crucibles

- Graphite Crucible in the Future Production of Third Generation Semiconductor Compounds

- Ceramic Alumina Crucible for Thermal Analysis Test Containers

- Alumina Crucibles in Precision Casting