Introduction to Isostatic Pressing

Isostatic pressing is a manufacturing process that is widely used in the aerospace and defense industry to produce high-quality, high-performance parts. In this process, a ceramic or metal powder is placed in a flexible mold, which is then subjected to a uniform pressure from all sides using a high-pressure fluid. This results in a part with a uniform density and minimal porosity, which is crucial for parts that need to withstand extreme conditions. Isostatic pressing offers several advantages over other manufacturing methods, including the ability to produce complex shapes and the ability to use a wide range of materials.

Table of Contents

- Introduction to Isostatic Pressing

- Advantages of Isostatic Pressing

- Applications of Isostatic Pressing

- Aerospace and Defense Industry Overview

- Importance of Isostatic Pressing in Aerospace and Defense

- Isostatic Pressing for Ceramic Parts in Aerospace and Defense

- Isostatic Pressing for Metal Parts in Aerospace and Defense

- Conclusion: Isostatic Pressing in Aerospace and Defense

Advantages of Isostatic Pressing

Isostatic pressing is an effective manufacturing process that offers numerous advantages for various industries, including aerospace and defense. Here are some of the key benefits of isostatic pressing:

Uniform and High Density

One of the primary advantages of isostatic pressing is that it can achieve uniform density throughout the material, regardless of its shape or size. By applying equal pressure from all directions, isostatic pressing can produce products with high and uniform density. Since no lubricant is needed in this process, it can achieve high and uniform density with no internal defects.

Complex Shapes and Intricate Designs

Isostatic pressing is an ideal process for creating complex shapes and intricate designs with high precision and accuracy. It can create parts with unique geometries that would be difficult to achieve with other manufacturing methods. This feature makes isostatic pressing a popular choice for the aerospace and defense industries, which often require parts with complex geometries.

Improved Mechanical Properties

Isostatic pressing can improve the mechanical properties of the final product. By reducing the porosity of the powder mixture, isostatic pressing can achieve high density and homogenous density distribution, resulting in improved mechanical properties such as strength, ductility, and toughness.

Unique Properties

Isostatic pressing can be used to create parts with unique properties such as high thermal conductivity, improved wear resistance, and excellent corrosion resistance. This feature makes isostatic pressing an ideal process for creating parts for critical applications in aerospace and defense industries.

Material Utilization

Isostatic pressing is a highly efficient manufacturing process that is applicable to difficult-to-compact and expensive materials such as superalloys, titanium, tool steels, stainless steel, and beryllium. Since isostatic pressing can achieve high and uniform density with no internal defects, it can reduce the amount of material required to achieve the desired final product.

In conclusion, isostatic pressing is a versatile and effective manufacturing process that offers numerous advantages for various industries, including aerospace and defense. It can achieve high and uniform density, create complex shapes and intricate designs, improve mechanical properties, offer unique properties, and improve material utilization. These features make isostatic pressing a popular choice for the production of critical components such as turbine blades, rocket nozzles, and missile components in the aerospace and defense industries.

Applications of Isostatic Pressing

Isostatic pressing is a versatile manufacturing process that has numerous applications in the aerospace and defense industries. Here are some of the most common applications of isostatic pressing:

Aerospace Industry

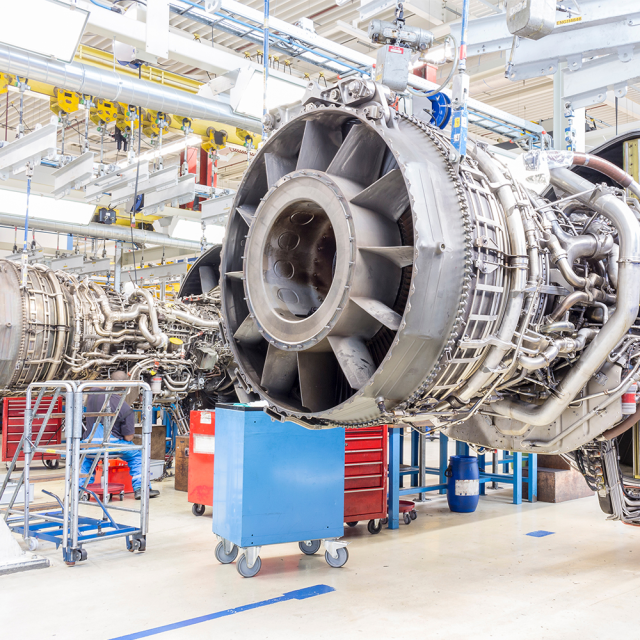

Isostatic pressing is commonly used in the aerospace industry to manufacture components such as turbine blades, heat shields, and rocket nozzles. These components require high levels of strength and durability, and isostatic pressing can help achieve these properties.

Defense Industry

In the defense industry, isostatic pressing is used to create armor plates, ballistic helmets, and other protective equipment. Isostatically pressed materials have excellent resistance to impact and shock, making them ideal for these applications.

Materials with Specific Properties

Isostatic pressing can be used to create materials with specific properties, such as high thermal conductivity or electrical conductivity. This makes them suitable for use in a range of applications, including satellites, missiles, and other defense systems.

Ceramics

Isostatic pressing is frequently used in the production of ceramics, including balls, tubes, rods, nozzles, fuse tubes, teeming tubes, lighting tubes, grinding wheels, sodium-sulfur battery electrolyte, spark plug insulators, sewer pipes, dinnerware, crucibles, oxygen sensors, central heating water pump shafts, and rocket nose cones. This process is particularly useful for creating long, thin-walled parts and weak powders.

Powder Compaction

Isostatic pressing is also used for powder compaction, particularly for powders that are difficult to press, such as hard metals. Cold isostatic pressing allows the production of simple-shaped small or large powder compacts (up to 2000 kg) with a uniform green density even for large height/diameter ratio parts (impossible by uniaxial pressing).

In summary, isostatic pressing has a wide range of applications in the aerospace and defense industries, including the manufacture of complex components, ceramics, and powder compaction. Its ability to create materials with specific properties, such as high thermal and electrical conductivity, makes it a valuable technique for a range of applications.

Aerospace and Defense Industry Overview

The aerospace and defense industries have unique requirements for their components such as high strength, durability, and resistance to extreme temperatures and forces. Isostatic pressing has proven to be a reliable and efficient method for meeting these requirements. Isostatic pressing is a manufacturing process that involves the application of uniform pressure on a material from all directions, resulting in a uniform density and strength. The aerospace and defense industries have used isostatic pressing to produce high-performance components such as turbine blades, rocket nozzles, and armor plates.

Advantages of Isostatic Pressing

Isostatic pressing applies a uniform, equal force over the entire product, regardless of shape or size, which leads to the creation of products with uniform density. Products with uniform density have a reduction of internal stresses, eliminating cracks, strains, and laminations. Isostatic pressing also presses products that have a higher “green strength,” which allows for close tolerances, complex shapes, and better machinability. In addition, isostatic pressing has been particularly useful in the production of parts with complex geometries and in materials with high melting points, such as ceramics and refractory metals.

Isostatic Pressing for Aerospace and Defense Components

The aerospace and defense industries have used isostatic pressing to produce high-performance components such as turbine blades, rocket nozzles, and armor plates. Isostatic pressing has also been used to produce near-net shape components, reducing the need for additional machining and thus lowering manufacturing costs.

Types of Isostatic Pressing

There are two main types of isostatic presses: cold isostatic presses (CIP) that function at room temperature and hot isostatic presses (HIP) that function at elevated temperatures. Cold isostatic pressing is used to compact green parts at ambient temperatures, while hot isostatic pressing is used to fully consolidate parts at elevated temperatures by solid-state diffusion. HIP can also be used to remove defects from castings and heat-treat creep damaged products.

Isostatic Pressing Market in Aerospace and Defense

The global isostatic pressing market is segmented by type, offering, process type, capacity, and end-user industry. The aerospace and defense industries continue to invest in the development of new materials and manufacturing processes, and isostatic pressing is expected to remain an important technology in the production of high-performance components for these industries.

In conclusion, isostatic pressing has been widely used in the aerospace and defense industries to produce high-performance components. The process has been particularly useful in the production of parts with complex geometries and in materials with high melting points. The aerospace and defense industries have strict requirements for their components, such as high strength, durability, and resistance to extreme temperatures and forces, and isostatic pressing has proven to be a reliable and efficient method for meeting these requirements.

Importance of Isostatic Pressing in Aerospace and Defense

Isostatic pressing is a critical process in the aerospace and defense industries for manufacturing high-performance components with complex shapes. This process is particularly useful for producing parts with near-net shapes, reducing the amount of material waste and machining required. Isostatic pressing is commonly used to fabricate components such as rocket nozzles, turbine blades, heat exchangers, and armor plates.

Improved Mechanical Properties

The benefits of isostatic pressing include improved mechanical properties, such as increased wear and corrosion resistance, and enhanced thermal stability. Isostatic pressing enables the production of high-quality components with superior performance, reliability, and durability, which is critical in the aerospace and defense industries.

Wide Range of Material Applications

Isostatic pressing can be used with a wide range of materials, including metals, ceramics, composites, and polymers, which makes it a versatile and adaptable technology. Metal injection molded parts or metal 3D printed products also use this process to eliminate internal porosity and micro-cracks and improve the overall performance of the product.

Densification Treatment

Hot isostatic pressing technology is currently the main, and the most mature application is the densification treatment of castings, such as aluminum, titanium, high-temperature alloy castings, to eliminate its internal defects caused by uneven cooling rates in various areas of the forming process. Hot isostatic treatment is still a necessary process for subsequent processing of titanium alloys. In addition to castings, there are also metal injection molded parts or metal 3D printed products that use this process to eliminate internal porosity and micro cracks and improve the overall performance of the product.

Cold Isostatic Pressing

Cold isostatic pressing is also a valuable process for forming powdered materials at room temperature using rubber or plastic as the encasing mold material and liquid as the pressure medium. This process provides blanks for further sintering or hot isostatic pressing processes. The uniform compaction pressure of cold isostatic pressing enables the compacting of more complex shapes than possible with uniaxial pressing.

In conclusion, isostatic pressing plays a critical role in the aerospace and defense industries, enabling the production of high-quality components with superior performance, reliability, and durability. The benefits of isostatic pressing include improved mechanical properties, increased wear and corrosion resistance, and enhanced thermal stability. The versatility of isostatic pressing allows for a wide range of material applications, including metals, ceramics, composites, and polymers. Cold isostatic pressing is also a valuable process for forming powdered materials at room temperature.

Isostatic Pressing for Ceramic Parts in Aerospace and Defense

Isostatic pressing is widely used in the aerospace and defense industries for the production of ceramic parts that meet the stringent requirements of high performance and durability under extreme conditions. The process involves applying uniform pressure to a material from all directions, resulting in a highly dense and homogeneous product.

Advantages of Isostatic Pressing

Isostatic pressing offers several advantages over other production methods, such as die compaction, extrusion, slip casting, and injection molding. The advantages of the process are as follows:

- Low distortion on firing

- Consistent shrinkage on firing

- Lower levels of binder in the powder are possible

- Most green (unfired) compacts can be machined

- Low internal stresses in compact as pressed

- Very large pressed part capability (wet bag)

- Low tooling cost (wet bag)

- Higher density for a given pressing pressure than can be achieved with mechanical pressing

- Ability to press compacts of very high length-diameter ratio (> 200)

- Ability to press parts with internal shapes, including threads, splines, serrations, and tapers

- Ability to press long thin-walled parts

- Ability to press weak powders

- Lower accuracy of pressed surfaces adjacent to the flexible bag, compared with mechanical pressing or extrusion, usually necessitating subsequent machining

Ceramic Materials in Aerospace and Defense

Ceramic materials are preferred for aerospace and defense applications due to their excellent thermal and mechanical properties, making them ideal for use in high-temperature environments and applications where wear resistance is critical. Ceramic parts are used in components such as heat shields, engine parts, and missile casings.

Isostatic Pressing for Metal Parts in Aerospace and Defense

Isostatic pressing is a widely used manufacturing process in the aerospace and defense industries for producing high-strength metal parts. This process involves applying pressure from all directions to a material, resulting in a uniform distribution of stress throughout the part. The absence of wall friction and uniform compaction pressure produce parts of practically uniform grain structure and density, irrespective of their shape.

Cold Isostatic Pressing (CIP)

Cold isostatic pressing is used to compact green parts at ambient temperatures. In this process, metal powder is placed inside a flexible mold made of rubber, urethane, or PVC. The assembly is pressurized hydrostatically in a chamber, usually using water, with pressures ranging from 400 to 1000MPa. The powder gets compacted, and the green compact is taken out and sintered. CIP is commonly used for parts that are too large to be pressed in uniaxial presses and that do not require high precision in the sintered state.

Hot Isostatic Pressing (HIP)

Hot isostatic pressing is used to fully consolidate parts at elevated temperatures by solid-state diffusion. In the HIP process, a metal powder is stressed using an inert gas inside a metal container with a high melting point. Pressure of 100MPa at 1000oC is used, and the inert gas acts as the pressuring media. HIP produces compacts with essentially 100% density, good metallurgical bonding among the particles, and good mechanical properties. As a result, it is often used to make super alloy components for the aerospace industry, as well as for the densification of WC cutting tools and PM tool steels. It is also used to close internal porosity and improve properties in superalloy and Ti alloy castings for the aerospace industry.

Advantages of Isostatic Pressing

Isostatic pressing produces parts with exceptional strength and durability. It is capable of producing complex shapes and designs that are difficult to achieve using traditional manufacturing methods. The process is not only highly efficient but also cost-effective, which is crucial for companies operating in these industries. The uniform distribution of stress and the absence of die-wall friction produce compacts of practically uniform grain structure and density, irrespective of shape.

Conclusion

Isostatic pressing is an essential manufacturing process in the aerospace and defense industries, allowing for the production of high-quality, high-performance metal parts that are essential for these critical applications. The process is capable of producing complex shapes and designs that are difficult to achieve using traditional manufacturing methods. Both cold and hot isostatic pressing techniques are used depending on the requirements of the product. The advantages of isostatic pressing make it the ideal choice for producing metal parts in aerospace and defense applications.

Conclusion: Isostatic Pressing in Aerospace and Defense

In conclusion, isostatic pressing is a critical manufacturing process in the aerospace and defense industry. It provides a way to create strong and durable metal and ceramic parts that can withstand harsh conditions, high temperatures, and extreme pressure. Isostatic pressing offers advantages such as uniform material density, improved mechanical properties, and reduced porosity. With its ability to produce complex geometries and intricate details, isostatic pressing is an ideal method for creating parts for defense and aerospace systems. As these industries continue to demand high-performance parts that can withstand the most challenging environments, isostatic pressing will remain a valuable technology for manufacturing critical components.

Related Products

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

- Warm Isostatic Press for Solid State Battery Research

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

Related Articles

- Comprehensive Guide to Isostatic Pressing: Types, Processes, and Features(3)

- What is Isostatic Pressing Machine

- Isostatic Pressing Technology: Principles, Classification, and Applications

- How Isostatic Presses Help Eliminate Defects in Materials

- Comprehensive Guide to Isostatic Pressing:Processes, and Features