You’ve been here before. After weeks of meticulous work, you pull your latest component—a complex ceramic part or a specialized metal tool—from the sintering furnace. It looks perfect. But during quality control or, worse, in final testing, a hairline crack appears. The part fails at half its expected strength. The project is back to square one, and you’re left wondering: Was it the powder batch? The furnace temperature profile? Or just bad luck?

This experience isn't just frustrating; it’s a costly and common reality in many advanced materials labs and manufacturing facilities.

The High Cost of Chasing Symptoms

When a sintered part fails, the natural instinct is to scrutinize the most visible steps of the process. This leads to a familiar, and often fruitless, troubleshooting cycle:

- Tweak the Furnace: You adjust the sintering temperature, ramp rates, and hold times, burning through energy and time with each new test.

- Blame the Material: You question the powder quality, ordering more expensive batches or running extensive characterization tests, only to get the same inconsistent results.

- Invest in Complex Tooling: For traditional uniaxial pressing, you might commission a more intricate and extremely expensive hardened steel die, hoping a better mold will solve the problem.

Each of these "solutions" addresses a symptom, not the root cause. Meanwhile, the real consequences pile up. Project timelines stretch from weeks into months. Budgets are consumed by wasted high-value powders and furnace time. Most importantly, innovation grinds to a halt as you are forced to simplify designs or abandon ambitious projects because you can't guarantee reliable, repeatable part quality.

You’re trapped in a cycle of treating symptoms, while the underlying disease remains untouched.

The Real Culprit: A Flaw Forged in Pressure

The reason these fixes fail is that the critical flaw was introduced long before your part ever saw the heat of the furnace. The problem isn't in the sintering; it's in the initial pressing.

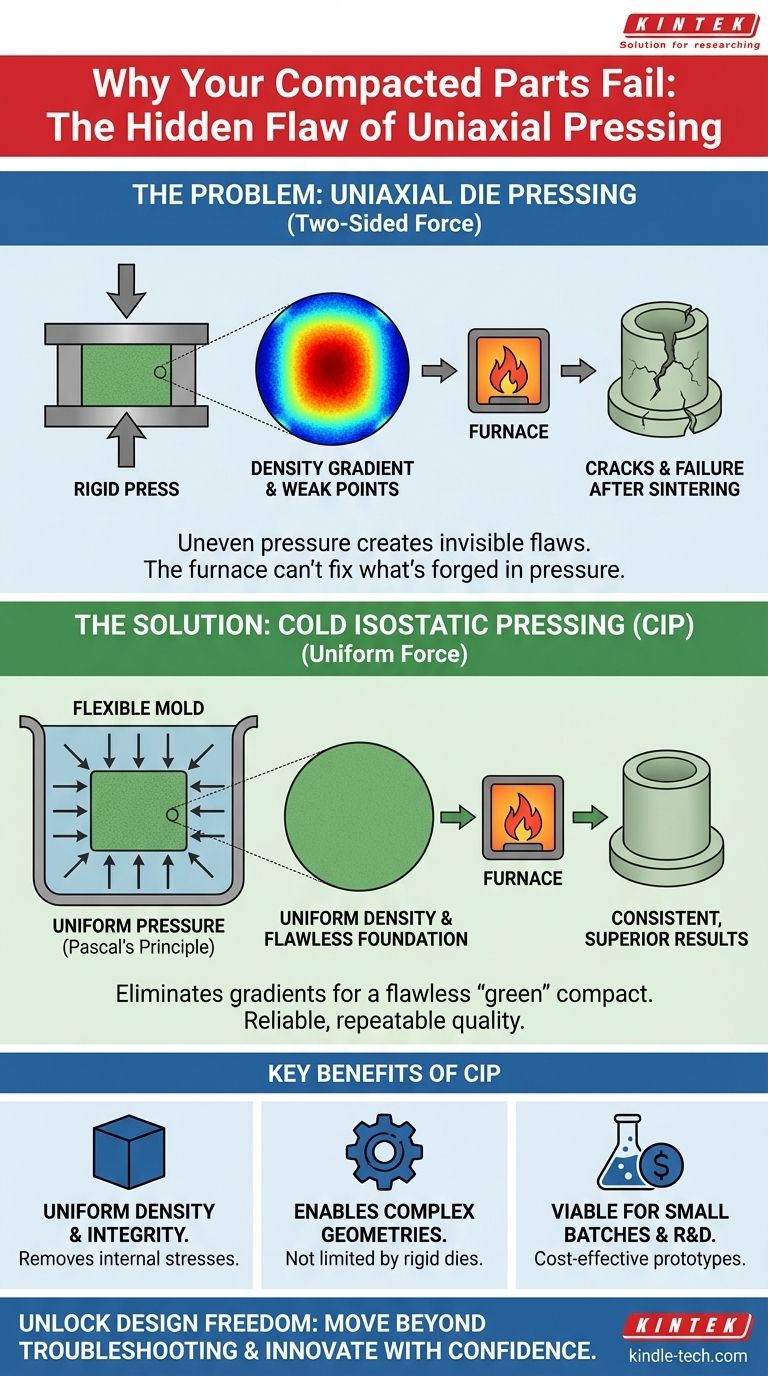

Most conventional methods, like uniaxial die pressing, compact powder by applying force from one or two directions (e.g., top and bottom). While simple, this method has a fundamental, unavoidable drawback: it creates density gradients.

Uniaxial vs. Isostatic: A Tale of Two Pressures

Imagine trying to pack a snowball by only pressing it between your two flat palms. The center of the ball, directly between your palms, becomes very dense. But the snow at the edges is barely compacted at all. This creates invisible weak points and internal stresses throughout the snowball.

Now, imagine putting that same loose snow inside a water balloon and then squeezing the balloon from all sides at once. The pressure is perfectly uniform. The result is a snowball that is equally dense all the way through, from its core to its surface.

This is the core difference between uniaxial pressing and isostatic pressing. The inconsistent parts that crack and fail are like that first snowball. They may look solid, but they are riddled with hidden density variations and internal stresses—defects that are literally pressed into the part from the very beginning. No amount of careful sintering can fully heal a part that was fundamentally flawed from the start.

The Right Tool for a Flawless Foundation: Cold Isostatic Pressing

If the root cause is uneven pressure, the solution must be a method that applies perfectly even, uniform pressure. This is precisely what Cold Isostatic Pressing (CIP) was designed to do.

A Cold Isostatic Press doesn’t use a rigid steel die. Instead, the powder is placed in a flexible, sealed mold. This mold is then submerged in a chamber of liquid, and the liquid is pressurized. Based on the fundamental laws of physics (Pascal's Principle), this pressure is transmitted equally and simultaneously to every single point on the surface of the mold.

This approach directly solves the core problem:

- It Eliminates Density Gradients: By applying uniform pressure, CIP creates a "green" compact with exceptionally uniform density. This removes the internal stresses that cause cracking and failure during sintering.

- It Enables Complex Geometries: Because the "die" is a flexible mold, you are no longer limited to simple shapes. CIP can produce parts with intricate details, undercuts, and complex internal cavities that are impossible with rigid tooling.

- It Makes Small Batches Viable: It avoids the massive upfront cost and long lead times of manufacturing hardened steel dies, making it highly cost-effective for prototypes, R&D, and low-volume production runs.

As a leading supplier of laboratory equipment, KINTEK provides state-of-the-art Cold Isostatic Presses that empower labs to build their components on a flawless foundation. Our systems are engineered to give you the control and reliability needed to move past the guesswork and achieve consistent, superior results.

Beyond Fixing Failures: Unlocking New Design Freedom

Once you eliminate inconsistent compaction as a variable, your focus shifts dramatically. You move from a defensive position of "How can we make this without it breaking?" to an offensive one of "What is the best possible design for this application?"

With the reliability of Cold Isostatic Pressing, you can now:

- Design for Performance, Not for Manufacturability: Create components with more complex internal channels, thinner walls, or optimized shapes that were previously too risky to produce.

- Accelerate R&D Cycles: Rapidly and cost-effectively produce prototypes of multiple designs, allowing you to iterate and innovate faster than ever before.

- Manufacture Large, Monolithic Parts: Confidently produce large, high-integrity components without the fear of weak spots or internal defects that plague other methods.

- Improve Final Product Reliability: Deliver end-products with superior mechanical strength and reliability, knowing they are free from the hidden flaws of uneven compaction.

In short, solving this fundamental pressing problem doesn’t just fix a frustrating production issue—it unlocks a new level of potential for your material science and engineering projects.

Whether you're developing next-generation ceramics, tooling for extreme environments, or prototyping complex metal components, the underlying principles of material integrity are the same. Our team can help you move beyond troubleshooting and start innovating with confidence. To explore how the right powder consolidation strategy can transform your projects, Contact Our Experts.

Visual Guide

Related Products

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Vacuum Cold Mounting Machine for Sample Preparation