Introduction to Isostatic Pressing Molds

Isostatic pressing molds represent a critical advancement in material compaction technology, enabling the production of high-strength, uniform density products across various industries. Unlike traditional uniaxial compaction methods, isostatic pressing employs flexible molds and fluid pressure to ensure even distribution of force, resulting in superior product integrity. This comprehensive guide delves into the intricacies of isostatic pressing molds, exploring their types, processes, and applications, while highlighting their significance in modern manufacturing.

Understanding Isostatic Pressing: Basic Principles

Isostatic pressing is a sophisticated compaction technique that utilizes the principles of fluid mechanics to apply uniform pressure from all directions to a sample within a high-pressure vessel. This method employs an incompressible medium, typically a liquid or gas, which is pressurized via a pressure pump. The medium transfers pressure uniformly to the sample, ensuring that the pressure exerted from every direction within the vessel is equal. This uniform pressure distribution is crucial for achieving consistent compaction and density in the final product.

The process of isostatic pressing involves the use of flexible molds, which are essential for the uniform application of pressure. Unlike rigid molds used in conventional compaction methods, flexible molds allow for the reduction of friction between the powder and the mold wall. This results in a more uniform force distribution during compaction, leading to a uniform density distribution and significantly improved product performance.

Isostatic pressing is particularly advantageous for manufacturing parts that require high thickness-to-diameter ratios, larger sizes, or superior material properties. It is commonly preferred over traditional metallurgical techniques due to its ability to produce parts with more uniform density and fewer defects. However, isostatic pressing tends to have longer cycle times, making it more suitable for short production runs.

The process can be categorized into two main types: cold isostatic pressing (CIP) and hot isostatic pressing (HIP). Cold isostatic pressing uses a flexible membrane to isolate the powder from a liquid medium, which is then pressurized to densify the powder. Typical mold materials include latex, neoprene, urethane, and polyvinyl chloride. The flexibility of the mold allows it to move with the powder as it densifies, minimizing friction effects and enabling the production of parts with complex shapes and sizes.

Hot isostatic pressing, on the other hand, involves the application of both high pressure and high temperature to achieve densification. This method is particularly useful for enhancing the mechanical properties of materials and reducing porosity, making it ideal for applications requiring high structural integrity.

In summary, isostatic pressing is a highly effective compaction technique that leverages the uniform pressure transfer properties of incompressible media to achieve consistent and uniform compaction. By using flexible molds and applying pressure uniformly from all directions, this method ensures uniform density distribution and improved product performance. Whether through cold or hot isostatic pressing, this technology offers significant advantages for the production of high-quality, complex parts with superior material properties.

Types of Isostatic Pressing Molds

Isostatic pressing is a versatile technique used in various industries to achieve high densities and complex shapes in materials processing. This method applies equal pressure in all directions on a material, typically a powder, enclosed in a flexible mold. The process is categorized into two main types: wet bag and dry bag isostatic pressing. Each method has its unique operational characteristics and advantages, making them suitable for different production needs.

Wet Bag Isostatic Pressing

Wet bag isostatic pressing involves placing the powder into a flexible mold, often made of rubber or a similar elastomeric material, which is then sealed and placed inside a high-pressure chamber filled with a liquid medium. The mold is fully submerged in this liquid, which acts as the pressure transmission medium. As the pressure is applied, it is evenly distributed throughout the mold, ensuring uniform compaction of the powder.

This method is particularly advantageous for producing large and complex parts, as it allows for multiple parts of different shapes to be pressed simultaneously within the same chamber. Wet bag pressing is also favored in research and small-scale production due to its flexibility and relatively low cost. However, the process can be labor-intensive as it requires manual loading and unloading of the molds, which can limit productivity and automation capabilities.

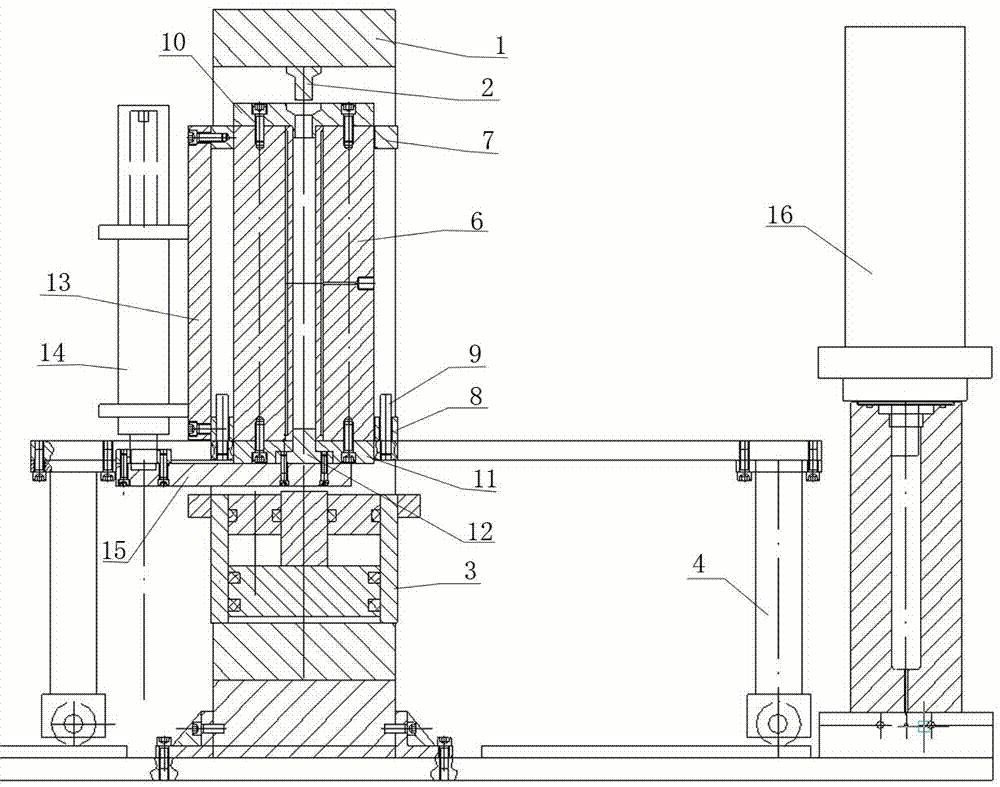

Dry Bag Isostatic Pressing

In contrast, dry bag isostatic pressing integrates the elastomeric mold directly into the press structure. The mold remains stationary within the pressure chamber, and the powder is loaded and unloaded within this fixed mold. This setup allows for higher automation and faster production rates, making it ideal for high-volume manufacturing scenarios such as the production of spark plug insulators.

The dry bag method is particularly effective for producing smaller, axisymmetric parts with complex geometries. The pressure is applied radially through a membrane in the pressing chamber, ensuring uniform distribution across the powder. This method supports the production of a wide range of components, including rods, tubes, bushes, and more, with minimal post-pressing machining required due to the near-net shape of the green compacts produced.

Comparative Advantages and Disadvantages

Both wet bag and dry bag isostatic pressing have their distinct advantages and challenges. Wet bag pressing offers greater flexibility in part size and complexity but suffers from lower productivity due to manual handling. Dry bag pressing, on the other hand, excels in automation and production rate but is more suited to simpler, smaller parts.

In summary, the choice between wet bag and dry bag isostatic pressing depends on the specific production requirements, including part size, complexity, and volume. Each method offers unique benefits that can be leveraged to optimize the manufacturing process in various industrial applications.

Materials Used in Isostatic Pressing Molds

Isostatic pressing is a sophisticated compaction technique that applies uniform pressure from all directions to achieve high densities and isotropic properties in the final product. This method is particularly advantageous for complex shapes and materials that require minimal density gradients. The molds used in isostatic pressing are typically made from elastomeric materials, which provide the necessary flexibility to distribute pressure evenly across the entire surface of the material being compacted. This section delves into the various materials used for isostatic pressing molds, such as latex, neoprene, and urethane, and discusses their properties that make them suitable for this application.

Latex Molds

Latex is one of the earliest materials used for isostatic pressing molds. It is known for its excellent elasticity, which allows it to conform to the shape of the material being pressed, ensuring uniform pressure distribution. Latex molds are also relatively inexpensive and easy to manufacture, making them a popular choice for initial prototyping and smaller-scale production runs. However, latex molds have a limited lifespan and can degrade under repeated high-pressure applications, which limits their use in large-scale industrial applications.

Neoprene Molds

Neoprene is another commonly used material for isostatic pressing molds. It is a synthetic rubber that offers superior resistance to abrasion, chemicals, and temperature variations compared to latex. Neoprene molds are more durable and can withstand higher pressures and longer service life, making them suitable for industrial-scale production. Additionally, neoprene has good tensile strength and elongation properties, which contribute to its effectiveness in maintaining uniform pressure during the pressing process. Despite its advantages, neoprene molds can be more expensive than latex molds and may require more complex manufacturing processes.

Urethane Molds

Urethane is a high-performance elastomeric material that is increasingly used in isostatic pressing molds. It combines the elasticity of latex with the durability and chemical resistance of neoprene, making it an ideal choice for demanding applications. Urethane molds can withstand very high pressures and have a long service life, which reduces the need for frequent replacements and maintenance. They also offer excellent dimensional stability, ensuring that the final product maintains its intended shape and dimensions. However, urethane molds are typically more expensive than both latex and neoprene molds and require specialized manufacturing techniques.

Other Elastomeric Materials

In addition to latex, neoprene, and urethane, other elastomeric materials such as polyvinyl chloride (PVC) and silicone are also used for isostatic pressing molds. PVC molds are known for their low cost and ease of fabrication, but they have lower durability and pressure resistance compared to urethane and neoprene. Silicone molds offer excellent temperature resistance and chemical inertness, making them suitable for specialized applications where these properties are critical. However, like urethane, silicone molds can be more expensive and require specialized manufacturing processes.

Advantages of Elastomeric Molds

The use of elastomeric molds in isostatic pressing offers several advantages over rigid molds used in axial-pressing. Elastomeric molds can conform to the shape of the material being pressed, ensuring uniform pressure distribution and minimizing density gradients. This results in higher-quality final products with consistent properties. Additionally, elastomeric molds can be easily manufactured into complex shapes, allowing for the production of intricate parts that would be difficult or impossible to achieve with rigid molds. The flexibility of elastomeric molds also reduces the risk of mold damage during the pressing process, which can extend the service life of the molds and reduce maintenance costs.

Challenges and Considerations

While elastomeric molds offer many advantages, there are also challenges and considerations to keep in mind. The selection of the appropriate material for the mold depends on various factors, including the specific requirements of the application, the properties of the material being pressed, and the desired production volume. The cost of elastomeric molds can be higher than that of rigid molds, especially for materials like urethane and silicone. Additionally, the manufacturing process for elastomeric molds can be more complex and time-consuming, which may impact the overall production schedule.

In conclusion, the choice of material for isostatic pressing molds is critical to achieving high-quality, consistent results. Latex, neoprene, and urethane are among the most commonly used materials, each offering unique properties and advantages. Understanding the characteristics and limitations of these materials can help in selecting the most appropriate mold for a given application, ensuring optimal performance and cost-effectiveness in the production process.

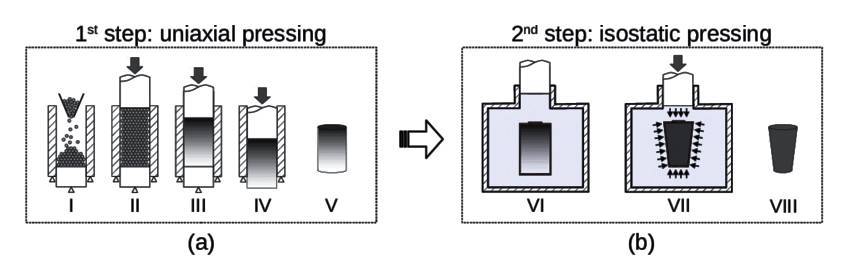

Process of Isostatic Pressing: Step-by-Step

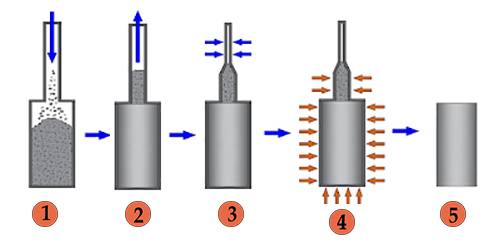

Isostatic pressing is a sophisticated method used to produce a wide range of materials from powder compacts by significantly reducing their porosity. This technique involves the application of pressure equally from all directions, which is crucial for achieving uniform compaction and density. The process begins with the preparation of the powder mixture, followed by its encapsulation in a flexible membrane or hermetic container, which acts as a barrier between the powder and the pressurizing medium (liquid or gas). Here, we delve into the detailed steps of the isostatic pressing process, highlighting the roles of pressure vessels and mandrels.

Powder Preparation

The initial step in isostatic pressing involves the careful selection and preparation of the powder mixture. This mixture must be homogeneous to ensure uniform compaction. The powders are typically mixed with binders or lubricants to enhance flowability and prevent adhesion during the pressing process. The choice of powder and additives depends on the final product's requirements, such as strength, density, and thermal properties.

Encapsulation and Sealing

Once the powder is prepared, it is encapsulated within a flexible membrane or placed in a hermetic container. This container is designed to withstand high pressures and acts as a pressure barrier, ensuring that the applied pressure is uniformly transferred to the powder from all directions. The encapsulation process must be meticulous to prevent any leaks or breaches that could compromise the integrity of the final product.

Loading into the Pressure Vessel

The encapsulated powder is then loaded into a pressure vessel, which is a critical component of the isostatic pressing setup. These vessels are engineered to withstand extremely high pressures, often exceeding 2000 bar. The vessel is sealed, and the pressurizing medium, typically a liquid such as oil or water, is introduced. The choice of medium depends on the specific requirements of the pressing process, including the desired pressure levels and the material's properties.

Application of Isostatic Pressure

With the powder encapsulated and the pressure vessel sealed, the pressurizing medium is subjected to high pressure. This pressure is uniformly applied from all directions, causing the powder to compact uniformly. The pressure is maintained for a specified duration, which can vary depending on the material and the desired density. During this phase, the pressure must be carefully monitored and controlled to ensure consistent results.

Pressure Relief and Decapsulation

Once the desired compaction is achieved, the pressure is gradually relieved, and the encapsulated product is removed from the pressure vessel. The encapsulation is then carefully opened, or decapsulated, to reveal the compacted product. This step requires precision to avoid damaging the product, which is often in the form of a green compact that still requires additional processing.

Post-Processing and Sintering

The green compact undergoes further processing, which may include trimming, sizing, and surface finishing. The final step in the isostatic pressing process is sintering, where the compacted product is heated to a high temperature but below its melting point. This heat treatment causes the particles to bond, enhancing the product's strength and density. Sintering is a critical step that significantly impacts the final properties of the material.

Types of Isostatic Pressing

Isostatic pressing can be categorized into two main types: cold isostatic pressing (CIP) and hot isostatic pressing (HIP). Cold isostatic pressing is performed at room temperature and is commonly used for materials that do not require high-temperature processing. In contrast, hot isostatic pressing involves both high pressure and high temperature, making it suitable for materials that require additional densification and bonding.

Applications and Benefits

Isostatic pressing is widely used in various industries, including ceramics, metallurgy, and advanced materials. It offers several advantages, such as uniform compaction, high density, and the ability to produce complex shapes. The process is particularly valuable for materials that are difficult to shape using conventional methods. Additionally, isostatic pressing can significantly improve the mechanical and thermal properties of the final product, making it an indispensable technique in modern manufacturing.

In conclusion, the process of isostatic pressing is a highly effective method for producing high-quality materials from powder compacts. By carefully controlling each step, from powder preparation to final sintering, manufacturers can achieve consistent results and superior product properties. The versatility and precision of isostatic pressing make it a vital technology in the advancement of materials science and engineering.

Advantages of Using Isostatic Pressing Molds

Isostatic pressing molds offer several advantages over traditional uniaxial pressing methods, making them a preferred choice in various industrial applications. These benefits include high density, even compaction, reduced internal stress in the final product, and the ability to achieve complex shapes.

High Density and Even Compaction

One of the primary advantages of isostatic pressing is the ability to achieve high compact densities. This method uses a flexible membrane to isolate the powder from a liquid medium that is pressurized, causing densification of the powder. The typical mold materials used are latex, neoprene, urethane, polyvinyl chloride, and other elastomeric compounds. Because the mold moves with the powder as it densifies, friction effects are minimized, leading to more uniform density throughout the product. This uniformity is crucial in applications where consistency in material properties is essential, such as in aerospace and automotive components.

Reduced Internal Stress

Isostatic pressing significantly reduces internal stress in the final product. The uniform application of pressure in all directions helps in minimizing the residual stresses that can occur during the compaction process. This reduction in internal stress leads to improved mechanical properties, such as higher strength and better machinability. Products made using isostatic pressing are less likely to deform or crack under stress, making them more reliable and durable.

Shape Flexibility

Isostatic pressing allows for the production of complex shapes that are difficult or impossible to achieve with traditional uniaxial pressing methods. The flexibility of the elastomeric molds enables the engineering of somewhat complex shapes, which can be tailored to specific design requirements. This flexibility extends the range of applications for isostatic pressing, making it suitable for industries that require intricate and precise components.

Component Size Range

Isostatic pressing supports a wide range of component sizes, from massive near-net shapes weighing several tons to smaller parts weighing less than 100 grams. The part sizes are limited only by the size of the isostatic pressure chamber, providing flexibility in production. This capability is particularly beneficial for industries that require a variety of component sizes, such as the automotive and aerospace sectors.

Low Tooling Cost

For short production runs, the tooling cost associated with isostatic pressing is relatively low compared to other manufacturing methods. The molds can be easily made and have a long service life, contributing to lower overall production costs. This cost-effectiveness makes isostatic pressing an attractive option for industries with varying production volumes.

Enhanced Alloying Possibilities

Isostatic pressing allows for the enhancement of alloying elements without inducing segregation in the material. The uniform pressure application ensures that the alloying elements are evenly distributed throughout the product, leading to improved material properties. This capability is particularly beneficial in the production of high-performance alloys used in critical applications.

In conclusion, isostatic pressing molds offer numerous advantages that make them a superior choice in various industrial applications. The high density, even compaction, reduced internal stress, shape flexibility, component size range, low tooling cost, and enhanced alloying possibilities are key factors that contribute to the widespread adoption of isostatic pressing in modern manufacturing processes.

Applications of Isostatic Pressing Molds

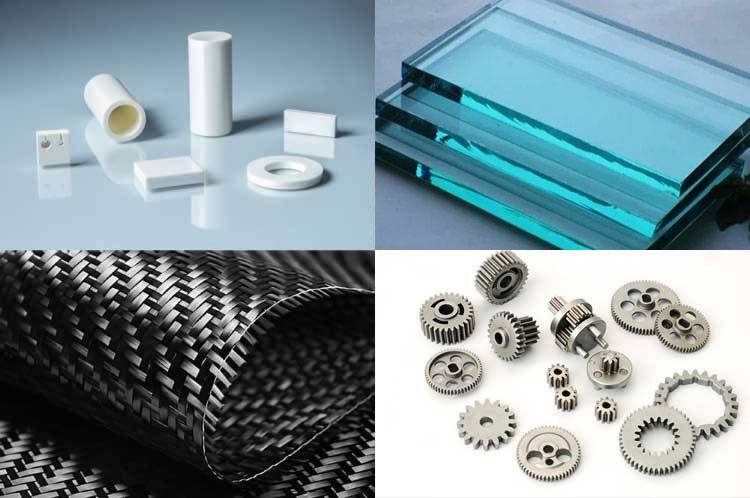

Isostatic pressing molds have become indispensable in various industries due to their ability to apply uniform pressure across the entire product, regardless of its shape or size. This technology, which was pioneered in the mid-1950s, has evolved from a research curiosity to a robust production tool, particularly beneficial for consolidating powders or healing defects in castings. The process is versatile, applicable to a range of materials including ceramics, metals, composites, plastics, and carbon.

Ceramic Applications

The range of ceramic products produced through isostatic pressing is extensive. Examples include balls, tubes, rods, nozzles, fuse tubes, teeming tubes, lighting tubes, grinding wheels, sodium-sulfur battery electrolyte, spark plug insulators, sewer pipes, dinnerware, crucibles, oxygen sensors, central heating water pump shafts, and rocket nose cones. Isostatic pressing offers several advantages over traditional methods like die compaction, extrusion, slip casting, and injection molding. These include low distortion on firing, consistent shrinkage, the ability to fire parts without drying, lower binder levels, and the capability to press compacts of very high length-diameter ratios.

Metal Applications

In the realm of metals, isostatic pressing is used for creating intricate shapes and high-density components that are challenging to produce through conventional methods. This technique is particularly useful in the aerospace and automotive industries where high-performance metal components are required. The uniform pressure applied ensures minimal internal stresses and high density, which are crucial for the durability and reliability of metal parts used in these industries.

Advanced Materials

Isostatic pressing also plays a significant role in the production of advanced materials. These include composites and specialty plastics that require precise shaping and high density. The technology is used to manufacture components for the oil and gas industry, medical devices, and electrical connectors. The ability to press parts with internal shapes, including threads, splines, serrations, and tapers, makes isostatic pressing an ideal choice for these applications.

Benefits and Challenges

The benefits of isostatic pressing are numerous. It allows for low distortion and consistent shrinkage, parts can be fired without drying, and there are lower levels of binder in the powder. Additionally, most green (unfired) compacts can be machined, and there are low internal stresses in the compact as pressed. However, there are also challenges such as lower accuracy of pressed surfaces adjacent to the flexible bag, which usually necessitates subsequent machining. Additionally, the process can be relatively expensive due to the need for spray-dried powder and has lower production rates compared to extrusion or die compaction.

Industrial Impact

The industrial impact of isostatic pressing is profound. It enables the production of high-quality, complex shapes that are essential in various sectors. For instance, in the aerospace industry, isostatically pressed ceramics offer improved mechanical properties such as high hardness, wear resistance, and thermal stability. In the medical field, this technology is used to manufacture implants and other devices that require precise and biocompatible materials.

In conclusion, isostatic pressing molds are a critical technology in modern manufacturing, offering unique capabilities that enhance the production of a wide array of products across multiple industries. Their ability to provide uniform pressure and shape complex geometries makes them an invaluable tool in the quest for high-performance and reliable components.

Challenges and Considerations in Isostatic Pressing

Isostatic pressing is a sophisticated powder metallurgy technique that offers significant advantages over traditional press and sinter methods, such as uniform compaction in all directions and enhanced final component density. However, this process comes with its own set of challenges and considerations that must be carefully managed to optimize outcomes.

Material Characterization

The success of isostatic pressing heavily relies on the careful characterization of the metal powder's properties. Unlike die pressing, which can suffer from friction effects leading to non-uniform densities, isostatic pressing minimizes these effects through uniform pressure application. However, the properties of the metal powder directly influence the final product's characteristics. Therefore, thorough characterization is essential to ensure the desired properties in the final component. Tools and technologies like those provided by Malvern Panalytical are crucial in this phase to analyze and optimize the powder's properties.

Pressure and Equipment Limitations

Isostatic pressing equipment typically operates at high pressures, often up to 415 MPa (60 ksi), although more advanced units can handle double this capacity. Despite these high pressures, the production rates in isostatic pressing are generally lower than those achieved in die pressing due to the flexibility required in the tooling. This flexibility, while beneficial for uniform pressure distribution, compromises on dimensional control, making it less precise compared to die pressing.

Mold Design and Pressure Control

The design of the mold is a critical aspect of isostatic pressing. The mold must be capable of withstanding high pressures and must be designed to ensure that the powder is evenly distributed. This is particularly challenging for parts with complex geometries, as the uniform distribution of powder becomes difficult to achieve. Additionally, the pressure control during the process must be precise to avoid any inconsistencies in the final product.

Size and Shape Capabilities

One of the significant challenges in isostatic pressing is the limitation in the size and shape of the parts that can be manufactured. The process is typically best suited for small to medium-sized parts with simple geometries. Larger parts or those with complex shapes require more sophisticated and expensive equipment, and the distribution of powder within the mold becomes increasingly difficult. This limitation extends to the thickness of the parts as well; thicker parts are challenging to manufacture due to the difficulty in achieving uniform powder distribution.

Cost Considerations

The cost of tooling for isostatic pressing can be substantial, especially for parts with complex shapes. The investment in equipment and the operational costs must be balanced against the benefits of the process, such as improved density and material properties. For many applications, the advantages of isostatic pressing justify the higher costs, but for others, alternative methods might be more cost-effective.

Conclusion

In conclusion, while isostatic pressing offers significant advantages in terms of material uniformity and density, it presents several challenges that must be carefully considered. These include the need for thorough material characterization, limitations in pressure and equipment capabilities, the complexity of mold design, and constraints in part size and shape. By understanding and addressing these challenges, manufacturers can optimize the isostatic pressing process to achieve high-quality, consistent results in their powder metallurgy applications.

Conclusion: The Impact of Isostatic Pressing Molds on Manufacturing

In conclusion, isostatic pressing molds have revolutionized manufacturing by ensuring uniform density and high-strength products across various industries. Through detailed exploration of their types, materials, processes, and applications, it is clear that these molds offer significant advantages over traditional compaction methods. As technology continues to advance, the future of isostatic pressing promises even greater efficiencies and innovations, further solidifying its critical role in modern manufacturing.

Related Products

- Isostatic Molding Pressing Molds for Lab

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

- Warm Isostatic Press for Solid State Battery Research

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

Related Articles

- Isostatic Pressing Technology: Principles, Classification, and Applications

- Comprehensive Guide to Isostatic Pressing:Processes, and Features

- Comprehensive Guide to Isostatic Pressing: Types, Processes, and Features(3)

- The Benefits of Using Isostatic Pressing in Manufacturing

- What is Isostatic Pressing Machine