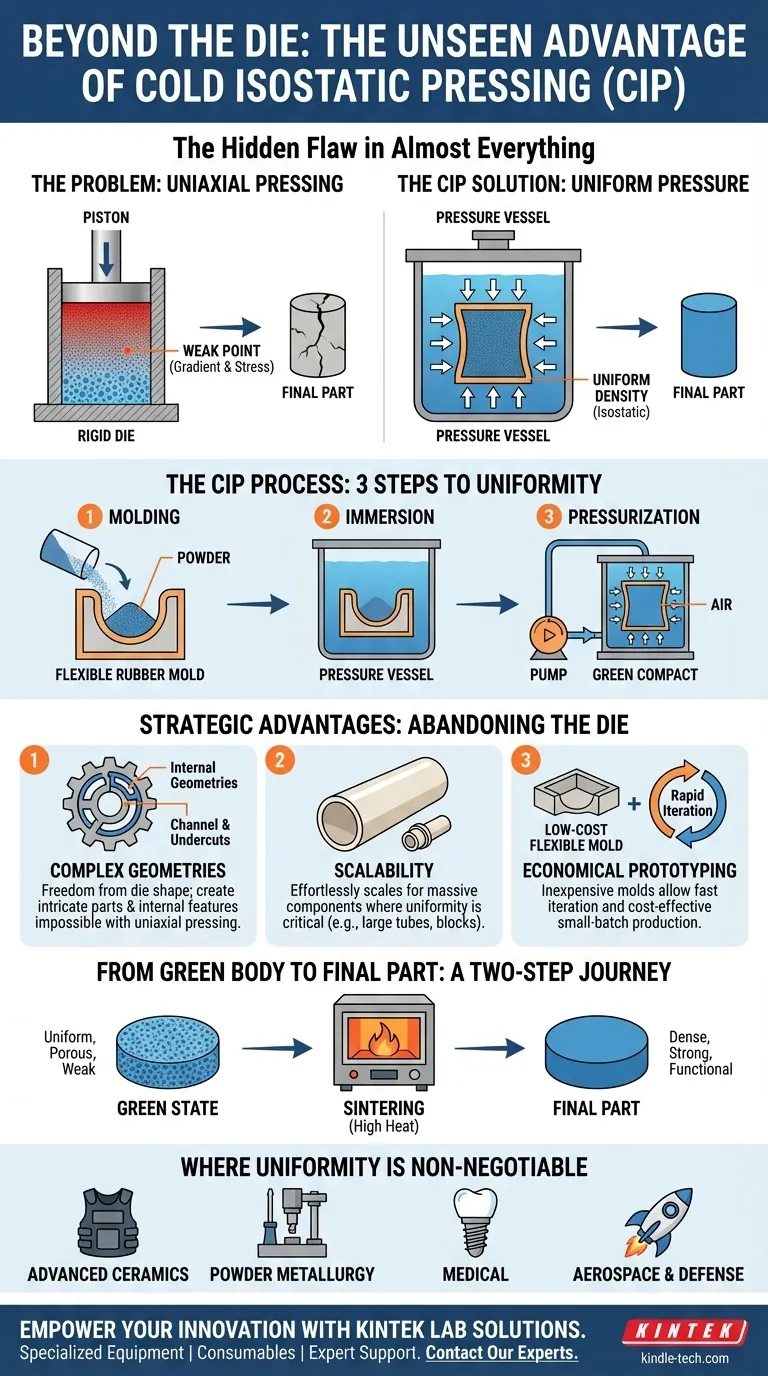

The Hidden Flaw in Almost Everything

Most things fail at their weakest point.

This isn't a profound statement. It's a simple truth. But in materials science, the weakest point is often invisible. It’s a subtle variation in density, a hidden void left by uneven pressure during manufacturing.

When you press a powder from one direction—the standard uniaxial method—you create a gradient. The top is dense, the bottom less so. This internal stress is a ticking clock, a built-in point of failure.

Cold Isostatic Pressing (CIP) was developed to solve this fundamental problem. It doesn’t just press a material; it surrounds and consolidates it, eliminating the weak points before they are ever created.

The Physics of Uniformity: A Lesson from the Deep Ocean

The principle behind CIP is disarmingly simple. It trades the brute force of a piston for the elegant, inescapable pressure of a liquid.

Imagine an object sinking into the ocean. The pressure doesn't just come from above; it comes from every direction equally. This is the essence of "isostatic" pressure.

The Process in Practice

The execution is just as elegant.

- Molding: A raw powder—be it advanced ceramic, metal, or a composite—is loaded into a sealed, flexible mold made of rubber or urethane.

- Immersion: This mold is submerged in a pressure vessel filled with a liquid, typically water or oil.

- Pressurization: A pump increases the liquid's pressure, which is transmitted perfectly and uniformly to every surface of the flexible mold. The powder particles are forced together, expelling air and forming a solid mass.

The result is a "green" compact. It's not the final product, but it's a perfect intermediate: a solid object with virtually uniform density throughout its entire structure.

The Strategic Trade-Offs: When to Abandon the Die

Choosing a manufacturing process is an exercise in managing constraints. Traditional die pressing is fast and precise for high-volume production of simple shapes. But its rigidity creates three distinct problems that CIP elegantly solves.

1. The Tyranny of Geometric Simplicity

A hard steel die can only create what its shape allows. It struggles with undercuts, internal cavities, or highly complex geometries.

CIP uses a flexible mold. This freedom allows for the formation of intricate parts—like components with internal cooling channels or non-symmetrical designs—that are physically impossible to produce with uniaxial pressing.

2. The Barrier of Scale

The forces required for uniaxial pressing grow exponentially with the size of the part. Making very large components requires impossibly large and powerful presses.

Because CIP applies pressure via a liquid, it scales effortlessly. It is the go-to method for producing large ceramic tubes, refractory blocks, and other massive components where uniformity is critical.

3. The Economics of Prototyping

Machining a hardened steel die is expensive and time-consuming. This cost is only justifiable with massive production runs.

For prototyping, R&D, or small-batch production, CIP is vastly more cost-effective. The flexible molds are inexpensive to create, allowing engineers and scientists to iterate quickly without a prohibitive initial investment.

From Green Body to Final Part: A Two-Step Journey

It's crucial to understand that CIP is not the end of the story. The "green" compact it produces has handling strength, but it has not yet achieved its final material properties.

- The "Green" State: This intermediate part is a uniformly dense arrangement of powder particles. It is still porous and lacks the hardness or strength for its end-use application.

- The Sintering Imperative: To achieve final density and strength, the green compact must be sintered—a high-temperature heat treatment that fuses the particles together.

This two-step process means that final dimensional tolerance must account for shrinkage during sintering. The gift of CIP is not perfect final-form precision; it is a perfect starting point for creating a flawless final part.

Where Uniformity is Non-Negotiable

The applications for CIP exist where material integrity cannot be compromised.

| Industry Vertical | Application Example | Why CIP is Essential |

|---|---|---|

| Advanced Ceramics | Silicon carbide wear parts, body armor | Eliminates density voids that could lead to catastrophic failure under stress. |

| Powder Metallurgy | Tool steel blanks, carbide forming tools | Ensures even wear and longer tool life by removing weak spots. |

| Medical | Zirconia dental implants, ceramic artificial joints | Guarantees biocompatibility and structural integrity required for in-body use. |

| Aerospace & Defense | Isotropic graphite, refractory metal components | Produces large, complex parts with predictable and uniform thermal/mechanical properties. |

The Right Tool for the Right Problem

Cold Isostatic Pressing isn't a replacement for all other compaction methods. It is a specialized tool for solving specific, often difficult, problems.

You choose it when uniformity is more important than raw speed. You choose it when geometric complexity or large scale makes traditional dies impractical. And you choose it when the economics of low-volume production demand a smarter approach.

For research labs and development teams pushing the boundaries of material science, mastering these processes is key. Whether you are creating prototypes from novel ceramic powders or developing small-batch, high-performance components, having the right laboratory-scale equipment is crucial. At KINTEK, we provide the specialized lab equipment and consumables that empower this innovation.

If you are facing challenges with material uniformity, complex geometries, or cost-effective prototyping, we can help you find the right solution. Contact Our Experts

Visual Guide

Related Products

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Vacuum Cold Mounting Machine for Sample Preparation

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

Related Articles

- Isostatic Pressing Technology in Solid-State Battery Production

- Understanding the Basics of Isostatic Pressing

- Isostatic Pressing Technology: Revolutionizing Ceramic Material Densification

- The Benefits of Using Isostatic Pressing in Manufacturing

- Cold Isostatic Pressing (CIP): A Proven Process for High-Performance Parts Manufacturing