Introduction to FTIR and its importance

Table of Contents

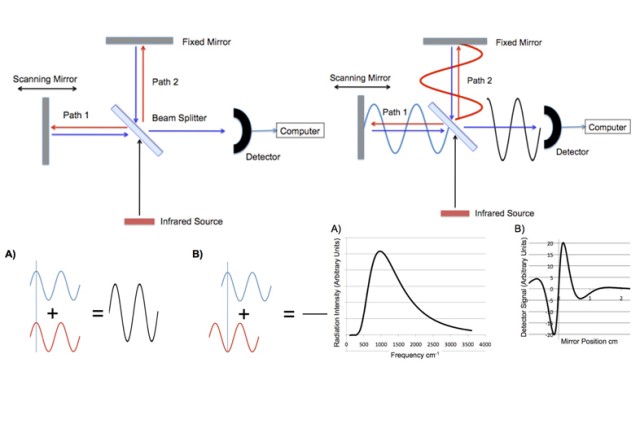

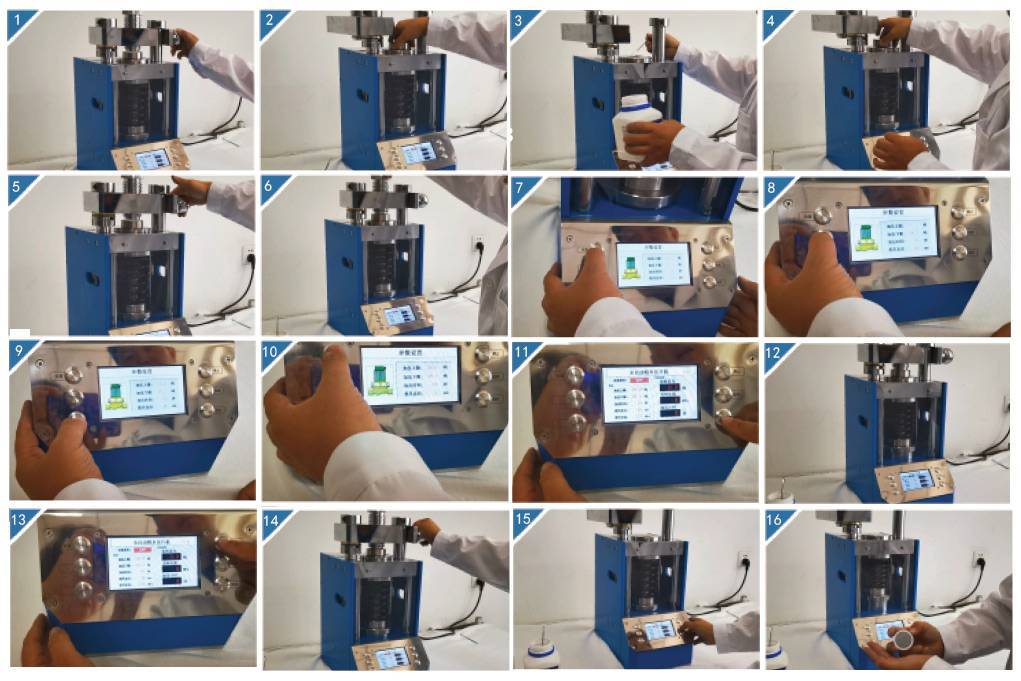

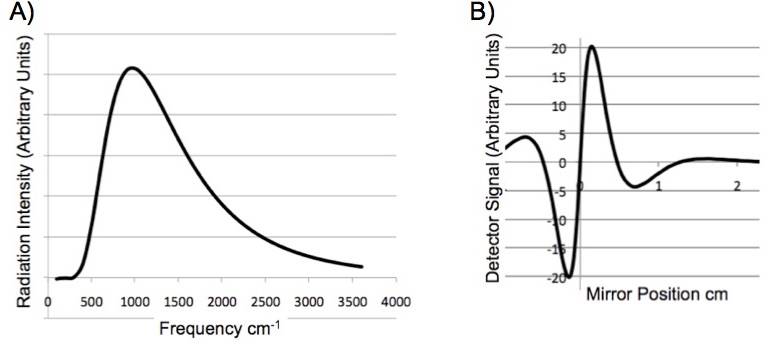

Fourier Transform Infrared Spectroscopy (FTIR) is a widely used analytical technique in the field of chemistry and materials science. It is a non-destructive method that allows the identification and quantification of chemical compounds in a sample. FTIR analysis provides information about the chemical structure, functional groups, and molecular vibrations of a compound, making it an essential tool for the characterization of materials. FTIR is used in various applications, including pharmaceuticals, polymers, food, and environmental analysis, among others. Its importance lies in its ability to provide valuable insights into the composition and properties of a sample, enabling researchers to make informed decisions about the materials they are working with.

What is a FTIR Pellet Press?

FTIR (Fourier Transform Infrared) spectroscopy is an analytical technique used to identify and quantify the functional groups present in a sample by measuring the absorption of infrared radiation. However, one of the limitations of FTIR spectroscopy is that the sample needs to be in a solid form to obtain accurate and reproducible data. This is where the FTIR pellet press comes in.

A FTIR pellet press is a laboratory equipment used to prepare solid samples for FTIR spectroscopy analysis. It works by compressing a small amount of the sample into a small, flat pellet using a hydraulic press. The resulting pellet is uniform in thickness and can be easily placed in the sample holder of the FTIR spectrometer.

The use of a FTIR pellet press is a game-changer in the field of spectroscopy analysis as it allows for more accurate and reproducible data. It eliminates the variability that can occur when analyzing samples in different forms such as powders or liquids. Additionally, it also enables the analysis of small or difficult to handle samples.

The hydraulic press is an essential component of a FTIR pellet press. It is typically used to apply a force to the sample and KBr powder to compress them into a flat, thin pellet. The hydraulic press applies an evenly distributed pressure over the sample, which transforms refractive material into transparent films that can be used for spectroscopic analysis.

The process of creating a FTIR pellet using a hydraulic press is relatively straightforward. First, the sample is mixed with KBr powder and ground to a fine powder using a pestle and mortar. It is then put inside a durable container called a ‘pellet die’, which uses an internal plunger to compress the sample. When a load of several tonnes is applied to the plunger using the hydraulic press, it solidifies the powder into a disc, which can then be placed inside the spectrometer for examination.

The FTIR pellet press is a crucial tool in FTIR spectroscopy analysis as it allows for the preparation of solid samples in a uniform and reproducible form. It has revolutionized the field of spectroscopy analysis by providing more accurate and reliable data.

In summary, a FTIR pellet press is a laboratory equipment used to compress a small amount of the sample and KBr powder into a small, flat pellet. It enables the analysis of small or difficult to handle samples and eliminates the variability that can occur when analyzing samples in different forms such as powders or liquids. The hydraulic press is an essential component of a FTIR pellet press as it applies an evenly distributed pressure over the sample, which transforms refractive material into transparent films that can be used for spectroscopic analysis.

Advantages of using a FTIR pellet press

FTIR (Fourier Transform Infrared) spectroscopy is a powerful analytical technique used in various fields such as chemistry, biology, and material science. One of the major challenges of FTIR spectroscopy is the preparation of high-quality samples, which can be time-consuming and challenging. However, the use of a FTIR pellet press has revolutionized the process of sample preparation. In this section, we will discuss the advantages of using a FTIR pellet press.

Eliminates the Need for Solvents

The use of solvents can be harmful and time-consuming to remove, but the FTIR pellet press eliminates the need for solvents altogether. The sample preparation process with the FTIR pellet press is fast and easy, and it produces high-quality pellets for FTIR analysis without the use of solvents. This not only saves time but also reduces the risk of exposure to harmful solvents.

Produces Uniform Pellets

Uniformity is an essential aspect of FTIR analysis, and the FTIR pellet press produces uniform pellets. The uniformity of the pellets ensures reproducibility of results, making the FTIR pellet press an indispensable tool for any laboratory using FTIR spectroscopy. The uniformity of the pellets also results in more accurate and reliable data.

Handles a Wide Range of Sample Types

The FTIR pellet press can handle a wide range of sample types, including powders, liquids, and gels. This versatility makes it easier for laboratories to analyze different types of samples, reducing the need for multiple sample preparation techniques and equipment.

Easy to Use

The FTIR pellet press is easy to use, and the sample preparation process can be completed quickly. The sample is mixed with a binding agent, added to a die, and pressed with a hydraulic sample press under 25-35T of pressure to ensure no void spaces are present in the pellet. Most samples will require pressing for 1-2 minutes. This simple process makes the FTIR pellet press ideal for laboratories that need to process a large number of samples quickly.

Produces High-Quality Pellets

The pellets produced by the FTIR pellet press are of high quality, which results in more accurate and reliable data. The pressing process ensures that the pellets are homogeneous, free of voids, and have a smooth surface. The high-quality pellets produced by the FTIR pellet press provide better signal-to-noise ratios, resulting in more accurate and reliable spectral data.

In conclusion, the FTIR pellet press is a game-changer in spectroscopy analysis, providing a quick, easy, and reliable method for sample preparation. The FTIR pellet press eliminates the need for solvents, produces uniform pellets, can handle a wide range of sample types, and produces high-quality pellets. These advantages make it an indispensable tool for any laboratory using FTIR spectroscopy.

How to Prepare Samples for FTIR Analysis

Introduction

FTIR (Fourier Transform Infrared) spectroscopy is a powerful analytical tool used in many industries for identifying and analyzing the chemical composition of materials. However, to obtain accurate and reliable results from FTIR analysis, the samples need to be prepared in a specific way. In this section, we will discuss how to prepare samples for FTIR analysis using a pellet press.

Sample Preparation with KBr Pellet Press

KBr pellet preparation is one of the most common techniques used for preparing solid samples for FTIR analysis. The process involves compressing the sample into a small, flat disc, or pellet, which is then placed in the instrument for analysis. Here are the steps for preparing samples with a KBr pellet press.

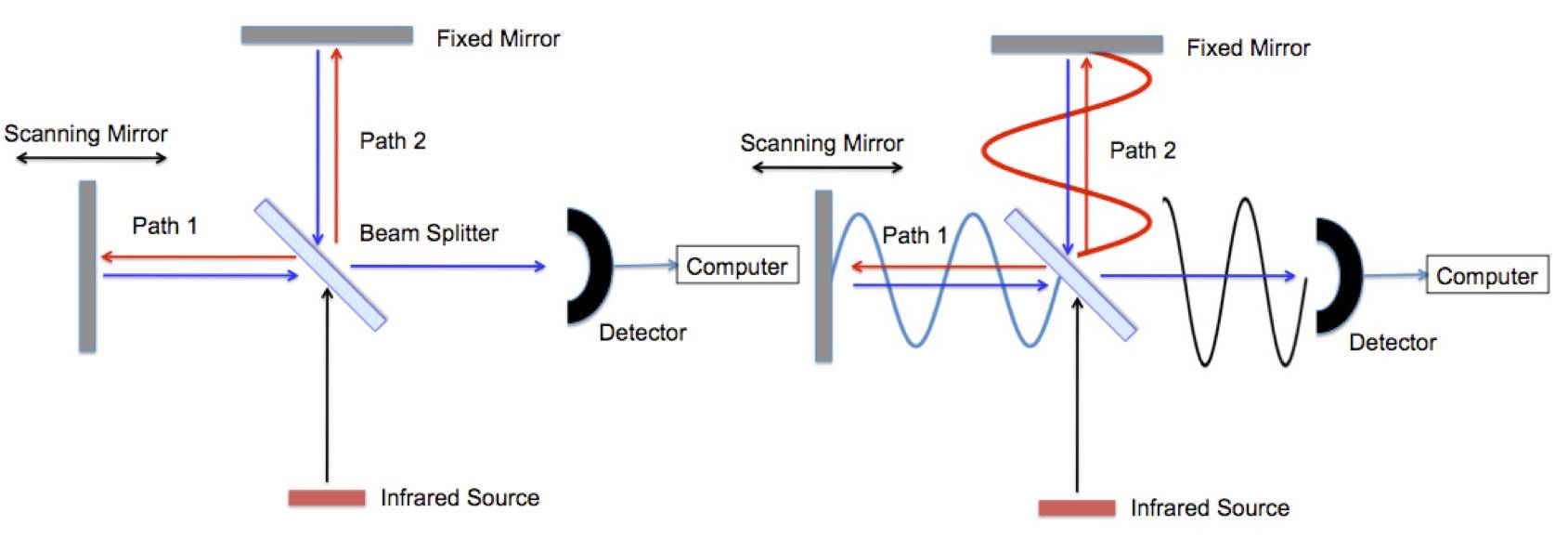

- Clean all the parts of the die with chloroform or a lubricant spray, then dry them with a tissue.

- Clean the mortar and pestle with chloroform or acetone, then dry them with a tissue.

- Transfer a speck of sample into the mortar. Be careful not to add too much sample, which may cause over-saturation.

- Scoop out dry KBr into the mortar, and grind using the pestle for one or two minutes to get a homogeneous mix.

- Fix the pellet press together and insert the die into the cavity.

- Transfer the ground sample mix into the cavity using a metal spatula. Make sure it's evenly spread. Depending on the thickness of the pellet, we put the amount of powder. Putting excess makes it thicker.

- Insert the bolt press and rotate into the cavity to distribute the particles.

- Transfer the whole die set to the hydraulic pellet press and rotate the wheel to secure it tightly.

- Close the valve of the hydraulic press. Pull the level to put pressure until the handle becomes tight.

- To release the die, first need to loosen the pressure, then move up the upper wheel of the press and then take out the die.

- Take out the bottom plunger and place the die in the ejector. Apply pressure to release the pellet from the die.

Sample Preparation for XRF Pellets

The process of preparing XRF pellets suitable for spectroscopic measurement involves milling/grinding the sample to a suitable fineness, mixing the powdered sample with x-ray powder or a similar binder, inserting the mixture into a pellet die, and finally compressing the die at pressures between 15 and 40 tons. Here are the steps for making XRF pellets.

- Confirm the spectrometer's XRF sample preparation needs. The sample requirements of the spectrometer should be determined.

- Mill your sample to a fine powder for XRF. Powders to be pressed should be as fine as possible but also with consistent particle size.

- Choose between a standard or ring XRF pellet die.

- Standard XRF pellet die: It is possible to directly press a sample in a die. However, the most common method is to use a crushable aluminum support cup. Upon placing the cup in the die, the milled sample is then placed into the cup. The die is assembled and pressed. The aluminum cup is crushed and acts as a support for the sample.

- Ring XRF pellet die: Some spectrometers offer an automated loading system or a tool that can be used to load the sample. In these cases, samples are pressed into a metal ring. There are different rings available, and this again depends on the requirements of the spectrometer.

Sample Preparation with Loose Powders

There are two main sample preparation techniques for measuring powders with FTIR: pressed and loose powder methods. Powders that are difficult to be formed into pellets can be pelletized by mixing a binder with the sample, ideally by pulverization. Without binder, fine powder particles may fall off or scatter from the pellet surface and cause contamination of the instrument's sample chamber in vacuum mode. Here are the steps for preparing loose powders.

- Prepare the sample. Grind the sample to a fine powder with a mortar and pestle or a ball mill.

- Add the sample to a sample cup. Make sure the cup is clean and dry.

- Press the sample cup with a press to form a pellet.

- Place the pellet in the FTIR instrument's sample holder.

Conclusion

FTIR analysis is a powerful tool used in many industries. To obtain accurate and reliable results from FTIR analysis, the samples need to be prepared in a specific way. We hope this guide has provided you with a better understanding of how to prepare samples for FTIR analysis using a pellet press.

Key Considerations for Preparing FTIR Pellets

Sample Preparation

The first step in preparing FTIR pellets involves the preparation of the sample for analysis. The sample must be finely ground and mixed with a binder such as KBr or Polyethylene, which provides stability to the pellet.

Pressure Application

The next step is to apply pressure to the mixture using the pellet press. It is essential to ensure that the pressure is applied evenly to avoid any inconsistencies in the pellet.

Pellet Thickness

The pellet should also be of the right thickness, typically around 1-2 mm, to ensure accurate results.

Pellet Press Cleaning

Moreover, the FTIR pellet press should be cleaned regularly to avoid contamination of the sample.

Sample Homogeneity

The homogeneity of the sample is also an important consideration. Any inconsistencies or impurities in the sample can lead to inaccurate results.

Sample Quantity

The quantity of the sample used is another important consideration. Using too much or too little sample can lead to inaccurate results.

Binder Selection

The selection of the binder is also important. The binder should be chosen based on the sample type and the desired outcome.

Temperature and Humidity Control

Temperature and humidity control can also impact the quality of the FTIR pellet. The ideal temperature and humidity levels should be maintained to ensure the best results.

By keeping in mind these key considerations, scientists and researchers can ensure that they are getting the most out of their FTIR analysis. The FTIR pellet press simplifies the preparation of samples for FTIR analysis and provides accurate and reliable results.

Conclusion: The FTIR Pellet Press as a Game-Changer

In conclusion, the FTIR pellet press has revolutionized the way we perform infrared spectroscopy analysis. The use of a pellet press has several advantages, including the ability to analyze a wide range of samples with high reproducibility and accuracy. With the use of a pellet press, it is possible to prepare KBr pellets that are uniform in size, shape, and thickness, ensuring reliable and consistent results. The equipment needed for making KBr FTIR pellets is relatively simple, making it accessible to many laboratories. Overall, the FTIR pellet press is a game-changer that has greatly enhanced the efficiency and accuracy of FTIR analysis.

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- kbr pellet press 2t

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

Related Articles

- Guide for Xrf Pellet Press

- What is xrf analysis and how to making pressed xrf pellets

- Understanding Cold Isostatic Pressing: Process, Comparisons, and Applications

- Automated laboratory XRF and KBR pellet press operating procedures

- Effective Preparation of Samples for XRF Analysis via Pressed Pellets Method