Sieving Machine

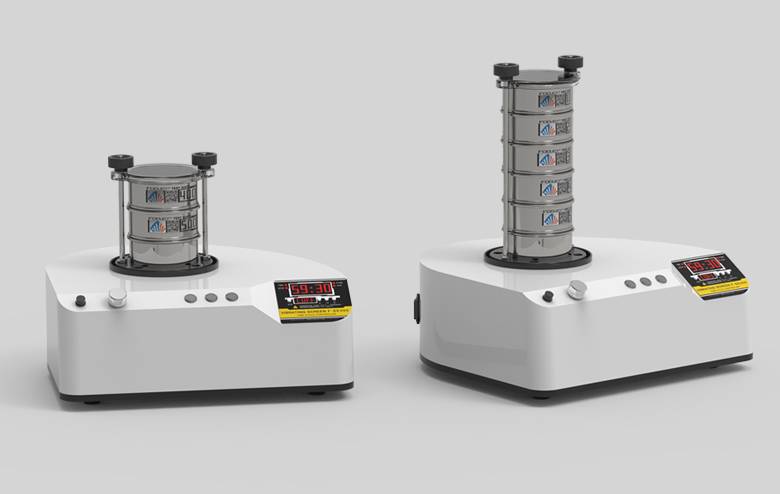

Three-dimensional electromagnetic sieving instrument

Item Number : KT-VT150

Price varies based on specs and customizations

- Screen layers

- 1-5 floors

- Maximum sieve mass

- 3kg

- Amplitude

- 5 mm

- Vibration frequency

- 3000-3600 times/minute

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

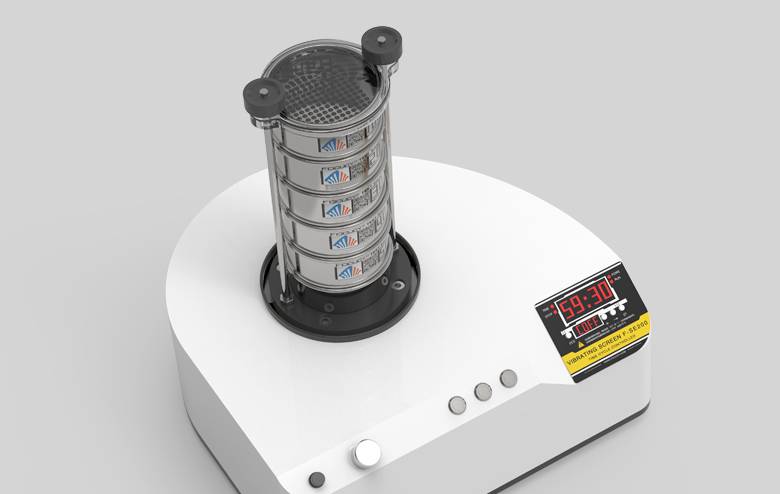

KT-VT150 is a desktop sample processing instrument for both sieving and grinding. Grinding and sieving can be used both dry and wet. The vibration amplitude is 5mm and the vibration frequency is 3000-3600 times/min. 5 layers of 100mm or 150mm diameter analytical sieves with a sieving accuracy of 20um-63mm. For grinding applications, a 150ml grinding pot with a curved bottom can be used with large-diameter grinding balls of 40-60mm, and can achieve softness, elasticity, The fibrous sample is continuously ground under the condition of liquid nitrogen soaking and brittleness; the digital display time control system can realize continuous operation, intermittent operation, and timing start; the universal grinding tank and the fast locking platen of the analytical sieve.

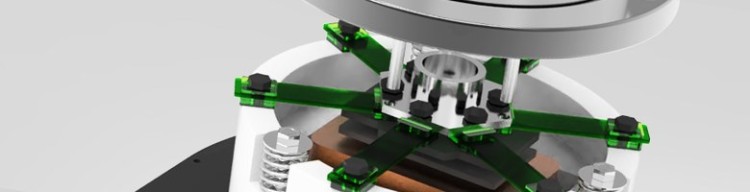

- Processing principle: high-frequency two-dimensional parabolic motion

- Application samples: powder | granules | small pieces | loose | suspended solids, etc.

- Process Type Particle Sizing, Separation, Classification

- Main Functions Digital Control | Timing | Continuous Screening | Intermittent Screening

Applications

The Two-Dimensional Vibrating Sieve is a versatile tool used in various industries for the precise separation and classification of materials. This sieve is particularly effective in environments where the uniformity of particle size is critical, such as in the pharmaceutical, food processing, chemical, and mineral industries. The sieve's ability to provide a consistent and accurate particle size distribution makes it an indispensable piece of equipment in quality control processes and research and development settings.

- Pharmaceutical Industry: Used for the separation of pharmaceutical powders and granules to ensure the uniformity of dosage forms.

- Food Processing: Essential for grading and sorting grains, seeds, and other food ingredients to meet quality standards.

- Chemical Industry: Employed for the classification of chemicals and catalysts to achieve desired reactivity and performance.

- Mineral Processing: Utilized for the separation of ores and minerals to optimize extraction processes and product quality.

- Environmental Applications: Helps in the separation of waste materials for recycling and waste management processes.

- Agricultural Sector: Used for grading seeds and soil to enhance crop yield and quality.

- Research and Development: Critical in laboratories for materials testing and development of new products and processes.

Features

The dry three-dimensional vibrating screener is a versatile laboratory instrument designed for precise screening and filtering of solid particles. Its unique structural features not only enhance its performance but also provide significant benefits to the user. Here are the key features that make this equipment a valuable asset in laboratory settings:

- Multi-layer Screen Structure: This feature allows the screener to classify and screen materials of different particle sizes with high accuracy and precision. Each layer of the screen is equipped with different aperture sizes, enabling effective separation and grading of particles.

- Adjustable Amplitude: The ability to adjust the amplitude of the vibration ensures that the equipment can adapt to various particle sizes and properties. This flexibility not only improves screening efficiency but also enhances overall work efficiency by accommodating a wide range of materials.

- 3-D Throwing Motion: The sieve shaker utilizes a unique 3D motion that agitates the sieve stack, moving particles in a flat plane while simultaneously causing them to jump up and down. This motion facilitates the separation of different particle sizes and enhances the precision of the screening process.

- Fast, Repeatable Results: With its high-frequency, small-amplitude vibration mode, the screener ensures quick passage and separation of granular materials on the sieve body. This results in rapid, consistent outcomes, which are crucial for efficient laboratory operations.

- Material and Sieve Diameter Compatibility: The screener is designed to accommodate a variety of materials, from coarse aggregates to fine powders. Its compatibility with different sieve diameters ensures that it can be effectively used for a wide range of particle size analyses.

These features collectively make the three-dimensional vibrating screener an indispensable tool for laboratories, enhancing the efficiency and accuracy of particle size analysis, morphology analysis, and distribution analysis.

Detail & Parts

Advantages

The Two-Dimensional Vibrating Sieve offers a range of advantages that make it an essential tool in various laboratory settings, particularly in materials science and chemical engineering. Here are some of the key benefits:

- Enhanced Sieving Efficiency: The two-dimensional vibration allows for a more thorough and efficient separation of particles. This is particularly useful in applications where precise particle size distribution is crucial, such as in the preparation of materials for vacuum sintering or other high-precision processes.

- Versatile Application: This sieve can be effectively used in the pre-processing stages of materials intended for vacuum sintering, ensuring that the raw materials are free from impurities and have the desired granularity. This leads to better quality end products with improved mechanical properties.

- Reduced Human Error: The automated nature of the two-dimensional vibrating sieve minimizes the chances of human error in the sieving process. This is critical in maintaining consistent quality and reliability in the final product, especially in industries like semiconductors and aerospace where precision is paramount.

- Time and Cost Savings: By providing a more efficient sieving process, this equipment helps in reducing the overall processing time and costs. It allows for faster throughput without compromising on the quality of the sieved materials, which is beneficial for high-volume production environments.

- Improved Material Properties: The precise control over particle size distribution achieved by this sieve can lead to materials with enhanced properties. For instance, in vacuum sintering, using optimally sieved materials can result in products with higher density, better wear resistance, and increased strength.

- Clean and Safe Operation: The design of the two-dimensional vibrating sieve ensures a clean operation, reducing the risk of contamination of the materials being processed. This is particularly important in industries where cleanliness is a critical factor, such as in the production of medical devices and pharmaceuticals.

- Adaptable to Various Shapes and Sizes: The flexibility of the sieve allows it to handle different shapes and sizes of materials, making it a versatile tool in the laboratory. This adaptability is crucial for meeting the diverse needs of various contracts and specific project requirements.

In summary, the Two-Dimensional Vibrating Sieve is a powerful tool that enhances the efficiency and precision of material preparation processes, leading to higher quality end products and significant time and cost savings. Its application in vacuum sintering and other high-precision industries underscores its importance in modern laboratory equipment.

Technical specifications

| Product name | Micro three-dimensional vibrating screener |

|---|---|

| Processing principle | High frequency three-dimensional parabolic motion |

| Application sample characteristics | Powder | granular | small pieces | loose suspension, etc. |

| Processing type | Particle size determination, separation, classification |

| Maximum load | 3kg |

| Number of screen layers | 1-8 floors |

| Maximum sieve tower mass | 2kg |

| Amplitude | 0.2-3 mm |

| Vibration frequency | 3000 times/minute |

| Screening particle size range | 20um-125mm |

| Maximum screen diameter available | 100mm |

| Maximum screen tower height | 510mm |

| The main function | Timing|Password lock|Continuous screening|One-key reset for intermittent screening|Alarm sound|Dry and wet screening|Amplitude adjustment |

| Additional features | Comfortable visual screen pressure plate | liquid circulation system |

| Screening method | Dry |

| Electrical description | 100-120V/200-240V AC,50-60Hz,100W |

| Power port | National standard/European standard/American standard/British standard, etc. |

| Net weight | 42kg |

| Dimensions (width, depth, height) | 430*400*620mm |

| Protection level | IP65 |

| Standard | CE/ISO9001 |

Warnings

Operator safety is the top important issue! Please operate the equipment with cautions. Working with inflammable& explosive or toxic gases is very dangerous, operators must take all necessary precautions before starting the equipment. Working with positive pressure inside the reactors or chambers is dangerous, operator must fellow the safety procedures strictly. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

FAQ

What Is A Test Sieve?

What Are The Main Applications Of Laboratory Sieve Shakers?

What Are The Main Applications Of Test Sieves?

What Are The Key Features Of Laboratory Sieve Shakers?

How Does A Test Sieve Work?

How Does A Laboratory Sieve Shaker Work?

What Are The Different Types Of Test Sieves?

What Are The Advantages Of Using A Laboratory Sieve Shaker?

What Are The Advantages Of Using A Test Sieve?

What Types Of Laboratory Sieve Shakers Are Available?

Can Test Sieves Be Used For Both Dry And Wet Samples?

What Is A PTFE Mesh Sieve, And Where Is It Used?

4.8 / 5

The speed of delivery was amazing! I received my order in just 2 days.

4.7 / 5

I'm so impressed with the quality of this product. It's made of durable materials and it's built to last.

4.9 / 5

This product is an excellent value for money. It's affordable and it does an amazing job.

4.9 / 5

This product is so easy to use. I was able to set it up and start using it in no time.

4.8 / 5

I'm amazed by the technological advancements in this product. It's so innovative and it makes my work so much easier.

4.7 / 5

The customer service I received from this company was outstanding. They were so helpful and they answered all my questions.

4.9 / 5

I highly recommend this product to anyone who is looking for a high quality sieve shaker.

4.8 / 5

This product has exceeded my expectations. It's even better than I thought it would be.

4.9 / 5

The sieving time can be set by oneself, and the machine will shut down automatically. The time is adjustable from 1s to 99h to ensure the repeatability and consistency of the experiment.

4.9 / 5

This product is so versatile. It can be used for a variety of applications, which makes it a great value for money.

4.8 / 5

This product is so easy to clean and maintain. It saves me a lot of time and effort.

4.9 / 5

I'm so glad I purchased this product. It's made my work so much easier and more efficient.

4.7 / 5

I would definitely recommend this product to anyone who is looking for a reliable and durable sieve shaker.

4.8 / 5

This product is a great investment. It's worth every penny.

4.9 / 5

I'm so impressed with this product. It's the best sieve shaker I've ever used.

4.7 / 5

This product is a game changer. It's made my work so much faster and easier.

4.9 / 5

I highly recommend this product to anyone who is looking for a top of the line sieve shaker.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Laboratory Test Sieves and Vibratory Sieve Shaker Machine

Efficiently process powders, granules, and small blocks with a high-frequency vibration sieve. Control vibration frequency, screen continuously or intermittently, and achieve accurate particle size determination, separation, and classification.

Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

KT-T200TAP is a slapping and oscillating sieving instrument for laboratory desktop use, with 300 rpm horizontal circular motion and 300 vertical slapping motions to simulate manual sieving to help sample particles pass through better.

Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

KT-VD200 can be used for sieving tasks of dry and wet samples in the laboratory. The screening quality is 20g-3kg. The product is designed with a unique mechanical structure and an electromagnetic vibrating body with a vibration frequency of 3000 times per minute.

High Energy Vibratory Ball Mill for Lab Use

The high-energy vibrating ball mill is a high-energy oscillating and impacting multifunctional laboratory ball mill. The table-top type is easy to operate, small in size, comfortable and safe.

Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

The wet three-dimensional vibrating sieving instrument focuses on solving the sieving tasks of dry and wet samples in the laboratory. It is suitable for sieving 20g - 3kg dry, wet or liquid samples.

Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

The KT-V200 product focuses on solving common sieving tasks in the laboratory. It is suitable for sieving 20g-3kg dry samples.

Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

Discover the Liquid Nitrogen Cryogenic Grinding Machine, perfect for lab use, ultra-fine pulverization, and preserving material properties. Ideal for pharmaceuticals, cosmetics, and more.

Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

Controlled environment lab press machine for glove box. Specialized equipment for material pressing and shaping with high precision digital pressure gauge.

Laboratory Ten-Body Horizontal Jar Mill for Lab Use

The Ten-body horizontal jar mill is for 10 ball mill pots (3000ml or less). It has frequency conversion control, rubber roller movement, and PE protective cover.

Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

Discover the versatile stainless steel dry powder/liquid horizontal ball mill with ceramic/polyurethane lining. Ideal for ceramic, chemical, metallurgical, and building materials industries. High grinding efficiency and uniform particle size.

Related Articles

Innovative screening technology: Laboratory three-dimensional vibrating screen leads the new industry standard

Learn about the working principle of the dry three-dimensional vibrating screener and its applications. Understand the vibration force generation and three-dimensional throwing motion. Discover the adjustment function and intelligent control of the screener. Explore the features and benefits of using the dry three-dimensional vibrating screener in laboratory and industrial settings.

Three-Dimensional Vibrating Sieve: Working Principle and Application Fields

Discover the working principle and application fields of the three-dimensional vibrating screener. Learn how this laboratory equipment uses vibration force to efficiently separate and analyze granular materials. Explore its uses in the pharmaceutical, chemical, and various other industries.

The Scientific Principle of Sieving: Understanding Particle Size Distribution and Laboratory Test Sieves

Learn about the scientific principle of sieving, including the process of separating particles based on size, types of laboratory test sieves. Discover how sieving impacts various industries and the accuracy of particle sizing measurements.

Sieving technology for particle size analysis and its applications

Introducing screening technology, explaining the working principle of vibrating screens and the advantages of using them for particle size analysis in screening technology. Learn about the types of vibrating screens and how to choose one.

Revolutionizing Lab Efficiency: The Ultimate Guide to Laboratory Sieving Machines

Discover the common sieving methods used in laboratory analysis. Learn about single sieve and sieve set sieving, dry and wet sieving, and other techniques for effective particle separation. Find out how sieving has evolved over time and its importance in quality assurance.

Unlocking the Power of Sieving Machines: Functions, Applications and Maintenance

Discover the significance of sieving machines in various industries and the essential functions they serve. Learn about the the maintenance requirements for optimal performance. Explore the benefits of using sieve shakers for automating the particle separation process.

The Ultimate Guide to the Application and Benefits of Vibratory Sieve Shaker in Laboratory Testing

Discover the extensive application of vibratory sieve shaker in laboratory testing for industries such as food, medicine, chemical, and more. Learn about the benefits of using a sieve shaker.

FTIR Pellet Press The Game-Changer in Spectroscopy Analysis

Fourier Transform Infrared Spectroscopy (FTIR) is a widely used analytical technique in the field of chemistry and materials science. It is a non-destructive method that allows the identification and quantification of chemical compounds in a sample.

The Three Stages of Lab Crushing: A Comprehensive Guide

Learn about the three stages of crushing: primary, secondary, and tertiary, and how they are used in sample preparation for scientific analysis. Discover the different types of crushers and their applications in reducing bulky materials into smaller particles.

How to Use FTIR Pellet Press to Prepare Samples for Analysis

Fourier Transform Infrared (FTIR) spectroscopy is a powerful analytical technique used to identify and quantify chemical compounds in a wide range of samples. FTIR analysis requires the sample to be in the form of a pellet, which is prepared by compressing the sample with a suitable matrix material.

Revolutionize Your Spectroscopy Analysis with FTIR Pellet Press

FTIR (Fourier Transform Infrared) spectroscopy is a widely used technique to analyze the chemical composition of various materials. This method is particularly useful for samples that are difficult to analyze using other techniques.

Ultimate Guide to Handheld Alloy Analyzers: Features, Applications, and Advantages

Explore the world of handheld alloy analyzers, their applications in various industries, and the benefits they offer. Discover how these devices provide rapid, accurate, and non-destructive analysis for quality control and material verification.