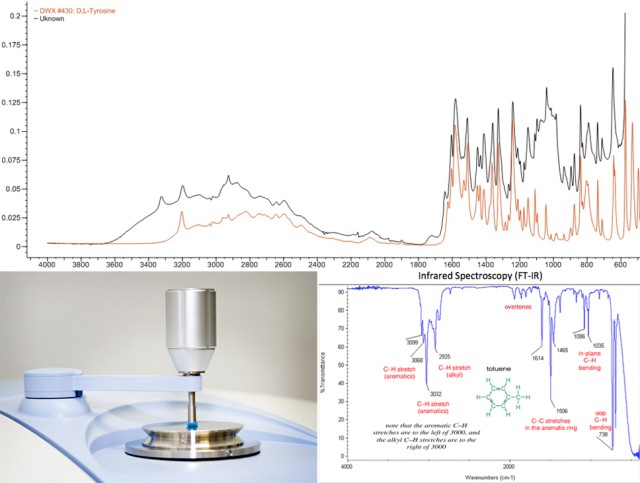

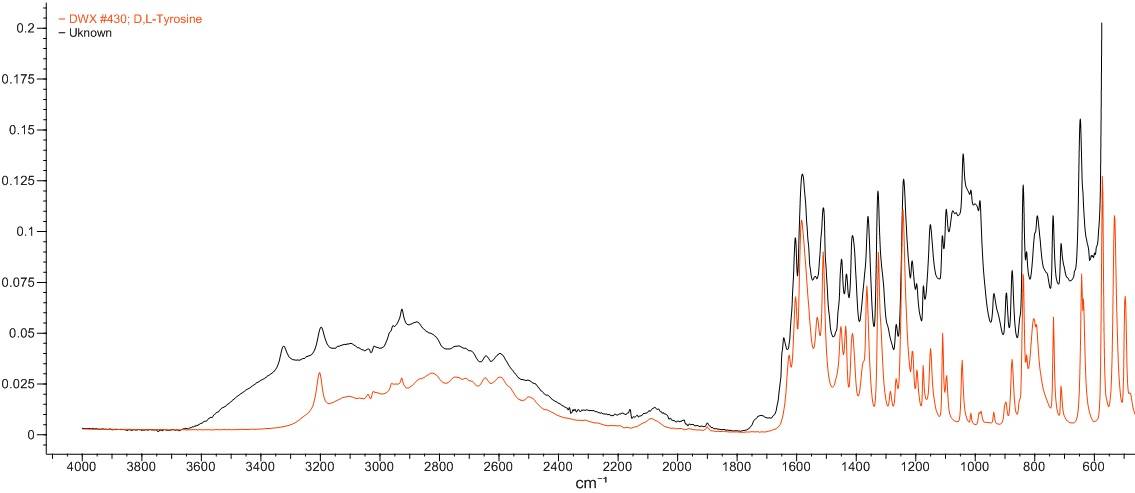

Introduction to FTIR Spectroscopy

FTIR (Fourier Transform Infrared) spectroscopy is a widely used technique to analyze the chemical composition of various materials. This method is particularly useful for samples that are difficult to analyze using other techniques. It works by measuring the absorption or transmission of infrared light by the sample and then plotting a spectrum of the results. FTIR spectroscopy is commonly used in fields such as chemistry, biology, and materials science. It can be used to identify unknown substances, monitor chemical reactions, and study the structure of materials. In order to obtain accurate results, it is important to properly prepare the sample and use high-quality equipment.

Table of Contents

Importance of Sample Preparation

Sample preparation is a crucial step in spectroscopy analysis, and the accuracy and reliability of results are highly dependent on the quality of the samples being analyzed. In this section, we will discuss the importance of sample preparation for spectroscopy analysis and how FTIR pellet presses can revolutionize your approach to sample preparation.

Ensuring High-Quality Samples

The quality of the sample being analyzed is critical to obtaining accurate results in spectroscopy analysis. Sample preparation is a crucial step in ensuring that the sample is of the highest quality. By using FTIR pellet presses, researchers can create uniform, high-density pellets that are ideal for spectroscopy analysis. These presses allow for consistent sample size, shape, and composition, which leads to more accurate and reliable results.

Avoiding Contamination

Contamination is a common problem in any scientific experiment, and it can significantly impact the outcome of spectroscopy analysis. During the sample preparation process, contamination is most likely to occur during the grinding process. External components from the sample preparation instrument can be passed into the sample or through cross-contamination from other samples. By using FTIR pellet presses, you can avoid this problem by creating uniform and homogenous samples that are less prone to contamination.

Choosing the Right Binder

During the sample preparation process, powders must be mixed with a binding agent to bind them together correctly. Using the right binder is essential to ensure that the powders are held together and reduce the risk of loose powders breaking away. FTIR pellet presses use a cellulose/wax mixture that homogenizes with the sample and binds the powders together during the mixing and pressing stages.

Dilution Ratio

The amount of binder used must remain the same for every sample to ensure accuracy levels and avoid over-diluting a sample. For most samples, a large amount of binder is used as weak pellets can break, damaging the spectrometer and destroying a sample. The most common sample dilution ratio is 20/30% binder to sample ratio.

Pressure Used for Pressing

The pressure used for pressing is also an important factor to consider during sample preparation. FTIR pellet presses use a pressure of between 15 and 35T, which is optimal for creating uniform, high-density pellets that are ideal for spectroscopy analysis.

In conclusion, sample preparation is a crucial step in spectroscopy analysis, and FTIR pellet presses can revolutionize your approach to sample preparation. By using FTIR pellet presses, researchers can create uniform, high-density pellets that are ideal for spectroscopy analysis, avoid contamination, ensure the use of the right binder and dilution ratio, and use the optimal pressure for pressing.

KBr Pellet Preparation Process

Fourier Transform Infrared (FTIR) spectroscopy is a widely used technique in material analysis. KBr pellets are an integral part of this technique, which are thin, transparent pellets containing a small amount of the sample mixed with IR-transparent KBr powder. In this section, we will discuss the KBr pellet preparation process in detail.

Equipment Required

To make KBr pellets, you will need a few specific pieces of equipment. These include a pellet press die set of the diameter required, a pestle and mortar, and KBr powder.

Sample Preparation

The first step in the KBr pellet preparation process is to mix the sample with KBr powder in a mortar. The sample should be added in small amounts to ensure thorough mixing with KBr powder. The ratio of KBr powder to the sample is typically 100:1, and only a few milligrams of the sample are required.

Grinding

The mixture is then ground to a fine powder in a mortar using a pestle. This step is crucial to obtain a homogeneous mixture of the sample with KBr powder. It is essential to use a smooth pestle and mortar, such as agate, to prevent contamination from hard materials and avoid the loss of the sample powder.

Pellet Pressing

Once the sample is ground, it is ready for pellet pressing. A pellet press die set of the required diameter is used to make the pellet. The mixture is placed inside the die, and controlled pressure and temperature are applied using the FTIR pellet press. The press applies several tonnes of pressure to the plunger, which solidifies the powder mixture into a thin disc. The size of the pellet depends on the diameter of the die set used.

Quality Control

The quality of the KBr pellet is critical for successful spectroscopy analysis. To ensure a good quality pellet, it is necessary to use spectroscopic grade KBr powder, which should be free from contamination. It is important to ensure that the sample is thoroughly blended with KBr powder and that the pellet is transparent and homogeneous.

In conclusion, KBr pellet preparation is a crucial step in FTIR spectroscopy analysis. With the advent of the FTIR pellet press, the process has become more accessible and efficient. By following the steps outlined in this section, it is possible to produce high-quality KBr pellets quickly and easily, making spectroscopy analysis more efficient and accurate.

Powder compaction for composite material study

Powder compaction is an essential process used in spectroscopy analysis to obtain reliable and reproducible results. When dealing with powders or composite materials, achieving accurate and consistent results can be challenging. However, with the use of an FTIR pellet press, researchers can eliminate the variability and inconsistencies caused by loose powders, resulting in more reliable and precise data.

Pressing powder samples with a pellet die

The first step in powder compaction is to use a pellet die to press powder samples. The purpose of pressing powder samples is to create a solid material that does not fall apart after the removal of the load. The powder grains are pushed into closer contact, closing the gaps between them and forcing them to flow and rearrange themselves into a closer packing. Once all available volume has been reduced, flow of particles ceases, and they then begin to undergo a range of plastic and elastic deformations which result in them bonding to one another.

The load required to achieve a fully bonded pellet depends greatly upon the materials involved. Hard and brittle materials generally have a harder time binding to each other than softer materials. Powders that do not flow easily in the die will also make for more difficult samples, since they cannot achieve sufficient packing for adhesion to occur. The required pressure for compaction can also depend on things like moisture content, particle size and distribution, and overall homogeneity of the materials.

Pressing pellets for FT-IR

If your lab will predominantly be pressing KBr pellets for FT-IR, the material is predominantly KBr salt with a small percentage of the analysis material added in. The two materials should be well mixed without allowing too much moisture to be absorbed. A load of 10 tonnes applied through a 13 mm diameter pellet die is usually more than adequate for the task, and this is often treated as a ‘rule of thumb’ for KBr pellet making.

Pressing pellets for XRF

To press pellets for XRF analysis, pellet diameters of 32 mm or 40 mm are common, which ensures that there will be enough space on the pellet surface for the X-ray beam. Materials studied by XRF can range from pharmaceutical compounds to powdered rocks, sands, and other geological materials. Since geological samples are often full of very hard, brittle minerals, their ability to form pellets is quite poor. They are usually ground to a very fine powder and mixed with a cellulose or boric acid binding agent before proceeding. Most samples will form a suitable pellet at a load of 10-20 tonnes to form pellets in a 40 mm die. However, loads of up to 40 tonnes are occasionally needed for very difficult samples.

Molding polymer films with a film maker

Analysis of polymers using spectroscopic techniques often requires a thin film to be produced. This can be achieved with heat and pressure using a heated platen and a film-making mold to set the thickness exactly.

Conclusion

In conclusion, powder compaction with the use of an FTIR pellet press is an essential step in spectroscopy analysis, especially when dealing with powders or composite materials. By using a pellet press, researchers can eliminate the variability and inconsistencies caused by loose powders, resulting in more reliable and precise data. The pellet press also allows for the analysis of small samples, minimizing waste and reducing costs.

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- kbr pellet press 2t

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

Related Articles

- A Comprehensive Guide on Pressing XRF Pellets Using a KinTek Automatic Hydraulic Press

- What is xrf analysis and how to making pressed xrf pellets

- Why Your Sample Prep Fails: The Hidden Flaw in Your Hydraulic Press

- Automated laboratory XRF and KBR pellet press operating procedures

- Understanding the Technical Aspects of Cold Isostatic Pressing