Optical Materials

Infrared Transmission Coating Sapphire Sheet Substrate Window

Item Number : KTOM-ISS

Price varies based on specs and customizations

- Product tickness

- 0.1-10mm

- Translucent band

- 185-5000nm

- Surface finish

- 60/40 (both sides polished)

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

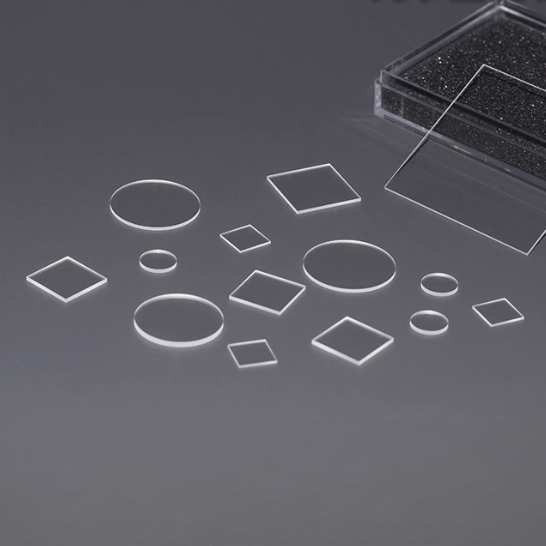

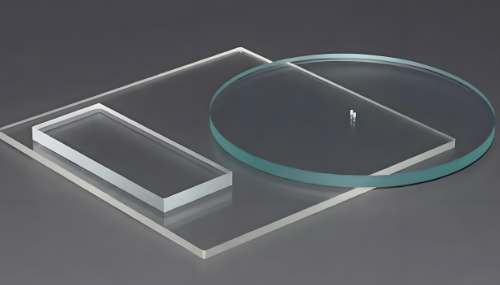

High-quality optical-grade sapphire wafers available in 2", 4", and 6" sizes with ultra-thin 0.05 mm thickness. Ideal for optics, semiconductors, and precision applications.

We offer full customization on size, thickness, surface finish, and crystal orientation to meet your exact requirements. With excellent hardness, thermal resistance, and chemical stability, sapphire is perfect for use in demanding environments.

Detail & Parts

Sapphire material properties

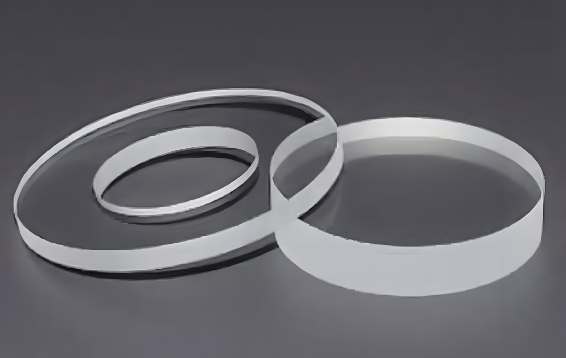

- Hardness & Durability: Second only to diamond, super-hard, pressure - and wear-resistant. In harsh scenarios (explosion-prone, deep - diving, high - speed), sapphire windows protect equipment, with a lifespan often exceeding the main device.

- Optical Property: Transmits light from near - UV to mid - far infrared, a multi - spectral material. Reduces equipment size/load, and with pressure & high - temperature resistance, suits detection, laser, aviation, etc.

- Cost - effectiveness: Due to above traits, its window offers far higher cost - effectiveness than others over service life.

Provide customized services

Through the implementation of innovative and state-of-the-art melting processes, we have acquired extensive expertise in the development and manufacture of quality glass products, offering a wide range of optical glass products for a variety of commercial, industrial and scientific applications. The company provides various specifications of optical glass such as raw glass, cut parts and finished components, and cooperates closely with customers to customize products according to customer needs. With an unwavering commitment to quality, we ensure our customers receive the perfect solution tailored to their requirements.

For further quotations, please contact us.

Trusted by Industry Leaders

FAQ

What Are The Main Types Of Glass Substrates?

What Is Soda-lime Glass Used For?

What Is Optical Glass Used For?

What Are The Advantages Of Using Sapphire Substrates?

What Is The Composition Of Optical Glass?

Why Is Boroaluminosilicate Glass Suitable For Laboratory Glassware And Cooking Utensils?

What Are The Most Common Optical Glasses?

What Are The Applications Of Optical Quartz Glass Sheets?

What Makes K9 Glass Special?

What Is A CaF2 Window Used For?

What Are The Properties Of Magnesium Fluoride Crystal Substrates?

What Is Silicon Used For In The Near-infrared Range?

What Are Glass Vibration Beads Used For In Laboratories?

4.9 / 5

Astounding! The sapphire sheet's clarity and transmission in the infrared range are beyond compare. It's a game-changer for our optical experiments.

4.7 / 5

The coating on this sapphire substrate is top-notch. It provides excellent corrosion resistance, making it perfect for our harsh lab environment.

4.8 / 5

The optical quality of this sapphire window is remarkable. It offers exceptional transmission in the UV and near/mid-IR regions, enabling precise measurements in our spectroscopy setup.

4.6 / 5

The durability of this sapphire substrate is impressive. It withstands high temperatures and resists scratches, ensuring longevity in our demanding research applications.

4.9 / 5

The craftsmanship of this sapphire glass is impeccable. The polished surface and low RMS roughness provide exceptional clarity and minimize optical distortion.

4.7 / 5

The chemical resistance of this sapphire substrate is outstanding. It's impervious to acids and alkalis, making it ideal for our corrosive environment.

4.8 / 5

The optical properties of this sapphire window are remarkable. The high refractive index and low birefringence ensure accurate and reliable measurements in our optical setups.

4.6 / 5

The thermal conductivity of this sapphire substrate is exceptional. It efficiently dissipates heat, preventing thermal distortions and ensuring stable performance in our high-power laser applications.

4.9 / 5

The clarity of this sapphire sheet is breathtaking. It allows for pristine image transmission in our advanced imaging systems.

4.7 / 5

The scratch resistance of this sapphire substrate is remarkable. It maintains its optical integrity even under harsh conditions, ensuring long-lasting performance in our demanding applications.

4.8 / 5

The transmission quality of this sapphire window is exceptional. It minimizes signal loss and ensures accurate data acquisition in our spectroscopy experiments.

4.6 / 5

The high temperature resistance of this sapphire substrate is impressive. It withstands extreme temperatures without compromising its structural integrity, making it ideal for our high-energy laser applications.

4.9 / 5

The low RMS roughness of this sapphire glass is remarkable. It minimizes surface scattering and ensures pristine image quality in our advanced microscopy setup.

4.7 / 5

The fast delivery of this sapphire substrate was a lifesaver. It arrived just in time for our crucial experiment, preventing any delays in our research.

4.8 / 5

The value for money of this sapphire window is unbeatable. Its exceptional optical properties and durability make it worth every penny.

4.6 / 5

The technological advancement embodied in this sapphire substrate is remarkable. It pushes the boundaries of optical performance and opens up new possibilities for our research.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Optical Window Glass Substrate Wafer Sheets Zinc Sulfide ZnS Window

Optics Zinc Sulphide (ZnS) Windows have an excellent IR transmission range between 8-14 microns.Excellent mechanical strength and chemical inertness for harsh environments (harder than ZnSe Windows)

Optical Window Glass Substrate Wafer Single Double Sided Coated K9 Quartz Sheet

K9 glass, also known as K9 crystal, is a type of optical borosilicate crown glass renowned for its exceptional optical properties.

Optical Window Glass Substrate Wafer Barium Fluoride BaF2 Substrate Window

BaF2 is the fastest scintillator, sought-after for its exceptional properties. Its windows and plates are valuable for VUV and infrared spectroscopy.

MgF2 Magnesium Fluoride Crystal Substrate Window for Optical Applications

Magnesium fluoride (MgF2) is a tetragonal crystal that exhibits anisotropy, making it imperative to treat it as a single crystal when engaging in precision imaging and signal transmission.

Optical Window Glass Substrate Wafer Quartz Plate JGS1 JGS2 JGS3

The quartz plate is a transparent, durable, and versatile component widely used in various industries. Made from high-purity quartz crystal, it exhibits excellent thermal and chemical resistance.

CF Ultra-High Vacuum Observation Window Stainless Steel Flange Sapphire Glass Sight Glass

Discover CF ultra-high vacuum observation windows with sapphire glass and stainless steel flanges. Ideal for semiconductor manufacturing, vacuum coating, and more. Clear observation, precise control.

KF Ultra-High Vacuum Observation Window Stainless Steel Flange Sapphire Glass Sight Glass

Discover the KF Ultra-High Vacuum Observation Window, featuring sapphire glass and stainless steel flange for clear, reliable observation in ultra-high vacuum environments. Ideal for semiconductor, vacuum coating, and scientific research applications

Related Articles

Optical Quartz Plate: A Comprehensive Guide to Applications, Specifications, and Usage

Discover the versatility of optical quartz plates, exploring their uses in various industries, key specifications, and factors that differentiate them from glass. Gain insights into their applications in ultraviolet transmission, precision optics, and more.

Unveiling the Exceptional Properties and Applications of Optical Quartz Plates

Discover the remarkable characteristics and diverse applications of optical quartz plates, including their superior ultraviolet transmission, thermal stability, and use in lenses, lighting devices, and semiconductor manufacturing.

Unlocking the Power of Optical Quartz Plates: Applications and Benefits

Delve into the world of optical quartz plates, exploring their exceptional properties, diverse applications in industries like optics, electronics, and more. Discover their advantages, including low thermal expansion, high temperature resistance, and precise optical clarity.

Revolutionize Your Spectroscopy Analysis with FTIR Pellet Press

FTIR (Fourier Transform Infrared) spectroscopy is a widely used technique to analyze the chemical composition of various materials. This method is particularly useful for samples that are difficult to analyze using other techniques.

Optical Window Sheet Selection Guide

A comprehensive guide on selecting optical window sheets based on substrate material, optical and mechanical precision, and coating options.

The Rise of Glass Substrates in Advanced Semiconductor Packaging

Explores the shift towards glass substrates in advanced semiconductor packaging, their advantages, and challenges.

Understanding Fused Silica: Properties, Applications, and Advantages

An in-depth look at fused silica, its unique properties, and its diverse applications in various industries.

Optical Components: Window Sheets and Their Applications

An overview of various types of optical window sheets, their materials, precision, and coating options.

Comprehensive Guide to Optical Windows: Material Properties and Surface Specifications

This article delves into the properties and specifications of optical windows, focusing on material properties, surface quality, and anti-reflection coatings.

Infrared Bands and Window Selection for Hypersonic Vehicles

Explores the challenges and solutions in selecting infrared bands and window materials for hypersonic vehicles, focusing on imaging and guidance systems.

Electron Beam Evaporation: Advanced Thin Film Creation

Explores the technology and applications of electron beam evaporation in thin film production.

Common Optical Materials and Their Properties

An overview of various optical materials, their properties, and applications across different spectral ranges.