Types of Optical Window Sheets

λ/4, λ/10 Visible Window Plate

A planar optical window sheet serves as a crucial protective layer for electronic sensors and detectors exposed to external environments. These parallel planar plates are designed to ensure optimal transmission of light, making them indispensable in various optical applications. The choice of material for these window sheets is highly dependent on the specific wavelength range they need to transmit effectively.

For applications in the ultraviolet (UV), visible (VIS), near-infrared (NIR), and short-wave infrared (SWIR) spectrums, materials such as Barium Fluoride (BaF2), Calcium Fluoride (CaF2), Zinc Sulfide (ZnS), Zinc Selenide (ZnSe), Silicon (Si), and Germanium (Ge) are commonly employed. These materials are particularly favored for their high transmission rates in the infrared range. Additionally, Fused Silica and Sapphire are preferred for ultraviolet applications due to their exceptional transparency in this wavelength region.

| Material | Application Spectrum |

|---|---|

| BaF2 | UV, VIS, NIR, SWIR |

| CaF2 | UV, VIS, NIR, SWIR |

| ZnS | NIR, SWIR |

| ZnSe | NIR, SWIR |

| Si | IR |

| Ge | IR |

| Fused Silica | UV |

| Sapphire | UV |

The precision of these optical glass sheets, often measured in terms of their flatness and parallelism, is another critical factor. For instance, a λ/10 window sheet ensures a flatness equivalent to one-tenth of a 632.8 nm wave, making it suitable for high-precision applications such as laser systems. In contrast, λ/4 window sheets, with their slightly less stringent flatness requirements, are more appropriate for imaging applications where a broader range of tolerances can be accommodated.

In summary, the selection of a λ/4 or λ/10 visible window plate hinges on the specific requirements of the application, including the desired wavelength transmission and the required optical precision.

K9 High Precision Double Sided Optical Flat Crystals

K9 high precision double-sided optical flat crystals serve as pivotal reference surfaces for testing and characterizing the flatness error of other high-finish optical components. These crystals are indispensable in ensuring the performance of bonding processes, offering unparalleled precision in flatness. Typically employed individually, these flat crystals come in two distinct surface types: λ/10 and λ/20, each catering to varying levels of precision requirements.

The λ/10 surface type is designed for applications where the utmost precision is paramount. This specification implies that the surface flatness error is within one-tenth of the wavelength of the light used for measurement, typically around 632.8 nm. Such high precision is crucial in environments where even the slightest deviation can significantly impact the performance of optical systems, such as in laser technology and high-resolution imaging.

On the other hand, the λ/20 surface type offers a balance between precision and cost-effectiveness. This specification ensures that the surface flatness error is within one-twentieth of the measurement wavelength. While not as stringent as the λ/10 specification, the λ/20 surface type still provides a high level of precision suitable for many advanced optical applications, including those in the aerospace and semiconductor industries.

| Surface Type | Flatness Error (λ) | Typical Application |

|---|---|---|

| λ/10 | 63.28 nm | Laser technology, high-resolution imaging |

| λ/20 | 31.64 nm | Aerospace, semiconductor industry |

These double-sided optical flat crystals are not only essential for quality control in manufacturing but also play a crucial role in research and development, where precise measurements are the cornerstone of innovation.

K9 High Precision Wedge Window Piece

The K9 high precision wedge window piece features two non-parallel planes with an angle of 31 arc minutes between them. This specific design serves a dual purpose: it effectively mitigates the interference effect, commonly known as the Etalon effect, which is typically induced by the reflection of light between the front and rear surfaces of high parallelism windows. By introducing this slight angle, the wedge window prevents the formation of standing waves that can otherwise degrade the quality of the transmitted light.

Moreover, the non-parallel planes of the wedge window also play a crucial role in safeguarding the stability of laser systems. In laser resonators, optical interference feedback can lead to significant issues such as poor laser output stability and mode jumps. The wedge window's design inherently reduces this feedback, thereby enhancing the overall performance and reliability of the laser system. This makes the K9 high precision wedge window piece an indispensable component in applications where maintaining precise and stable optical conditions is paramount.

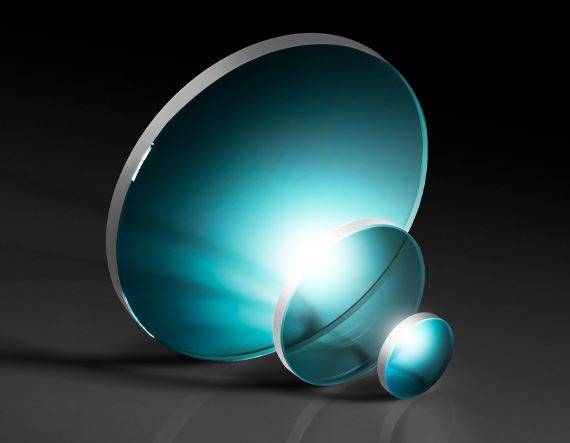

K9 Dome

A dome window, characterized by its hemispherical shell structure, serves as a protective window designed to accommodate applications requiring a broad angular range of incident light. This unique design is particularly advantageous for scenarios where the light source or sensor operates over a wide field of view, such as in detectors and optical sensors. The dome shape not only enhances the window's durability but also ensures that light is evenly distributed across the surface, minimizing any potential distortions or losses.

In contrast to planar window sheets, which are typically parallel planar plates, dome windows offer a more robust solution for environments where mechanical stress or impact is a concern. Their hemispherical geometry allows for better resistance to physical damage, making them ideal for use in rugged or high-stress applications. Additionally, the dome's ability to capture and distribute light across a wide angle makes it a preferred choice for optical systems that require precise and uniform light transmission.

The applications of K9 dome windows are diverse, extending beyond traditional optical sensors and detectors. They are also utilized in laser systems, where the wide-angle light capture is crucial for maintaining the stability and performance of the laser output. Furthermore, these windows are employed in various imaging technologies, where the need for a clear, undistorted view is paramount.

| Feature | Description |

|---|---|

| Shape | Hemispherical shell |

| Applications | Detectors, optical sensors, laser systems, imaging technologies |

| Advantages | Wide angular range of incident light, enhanced durability, uniform light distribution |

| Contrast with Planar Sheets | Better resistance to mechanical stress and impact, suited for rugged environments |

The K9 dome window stands out not only for its structural integrity but also for its ability to perform reliably in a variety of optical applications, making it a versatile component in the field of optical engineering.

Selection Guide for Optical Window Sheets

Substrate Material

The selection of substrate material for optical window sheets is a critical decision that hinges on several key factors. These include the wavelength of the light being transmitted, the refractive index of the material, the dispersion coefficient, density, coefficient of thermal expansion, softening temperature, and Knoop's hardness. Each of these properties plays a significant role in determining the suitability of a material for specific applications within different spectral bands.

For applications in the UV-visible near-infrared (NIR) band, common window materials include magnesium fluoride (MgF₂), barium fluoride (BaF₂), K9 glass, and quartz. These materials are chosen for their ability to efficiently transmit light within these wavelengths while maintaining structural integrity and optical clarity.

In the far-infrared (IR) band, different materials are preferred due to their unique properties. Calcium fluoride (CaF₂), silicon (Si), germanium (Ge), zinc sulfide (ZnS), zinc selenide (ZnSe), and sulfur-based glass are commonly used. These materials are selected for their low absorption and high transmittance in the far-IR range, making them ideal for applications requiring deep-infrared transmission.

| Spectral Band | Common Materials |

|---|---|

| UV-Visible NIR | Magnesium Fluoride (MgF₂), Barium Fluoride (BaF₂), K9 Glass, Quartz |

| Far-Infrared | Calcium Fluoride (CaF₂), Silicon (Si), Germanium (Ge), Zinc Sulfide (ZnS), Zinc Selenide (ZnSe), Sulfur-Based Glass |

The choice of material is further influenced by the specific requirements of the application, such as the need for high precision in optical instruments or the necessity to withstand extreme environmental conditions. Understanding these factors ensures that the selected substrate material will perform optimally within its intended spectral range and application context.

Optical and Mechanical Precision

Surface flatness, parallelism, and surface quality are pivotal attributes in the realm of optical window sheets. These characteristics directly influence the performance and reliability of the components in various applications.

Surface flatness is typically gauged relative to a 632.8 nm wavelength, with a 1/10 wave flatness being equivalent to the flatness of a 632.8 nm wave. This metric is crucial as it ensures minimal distortion and optimal light transmission. For instance, window sheets with a flatness of 1/10 wave or better are highly coveted in laser applications, where even the slightest aberration can lead to significant performance degradation. Conversely, in imaging applications, a flatness of 1/4 wave or better is often demanded to maintain high-resolution and clarity.

Parallelism, the degree to which the surfaces of the window sheet are parallel to each other, is another critical factor. High parallelism is essential to prevent internal reflections and interference, which can adversely affect the optical performance. This is particularly important in applications like laser resonators, where the stability of the laser output can be compromised by poor parallelism.

Surface quality, encompassing factors such as scratch and dig specifications, ensures that the window sheets are free from defects that could scatter light and reduce the overall efficiency. Lower precision window sheets, while suitable for less critical applications such as illumination and inspection, still require a certain level of surface quality to function effectively.

In summary, the precision of optical window sheets is a multifaceted consideration, balancing flatness, parallelism, and surface quality to meet the stringent demands of diverse optical applications.

Coating Options

Window sheets are frequently equipped with transmittance enhancement films to mitigate surface reflection losses and facilitate the seamless passage of light through the substrate. These coatings are crucial for optimizing the performance of optical components, especially in sensitive applications. The primary types of transmittance enhancement films include:

-

Single-Layer Transmittance Enhancement Film: This type of coating is designed to enhance light transmission at a specific wavelength, making it ideal for applications requiring precise spectral tuning.

-

Broadband Transmittance Enhancement Film: As the name suggests, this coating is effective across a wide range of wavelengths, providing a more versatile solution for various optical applications.

-

V-Shaped Transmittance Enhancement Film: This innovative coating offers a unique V-shaped profile that maximizes light transmission while minimizing reflection, making it particularly suitable for high-precision optical systems.

| Coating Type | Application Benefits |

|---|---|

| Single-Layer | Precision spectral tuning, ideal for specific wavelength applications. |

| Broadband | Versatility across a wide range of wavelengths, suitable for diverse optical needs. |

| V-Shaped | Enhanced light transmission and minimized reflection, optimal for high-precision systems. |

Each type of coating serves distinct purposes, ensuring that window sheets can be tailored to meet the specific requirements of different optical systems.

Related Products

- CVD Diamond Optical Windows for Lab Applications

- High Temperature Resistant Optical Quartz Glass Sheet

- MgF2 Magnesium Fluoride Crystal Substrate Window for Optical Applications

- Optical Window Glass Substrate Wafer Single Double Sided Coated K9 Quartz Sheet

- Optical Window Glass Substrate Wafer Barium Fluoride BaF2 Substrate Window

Related Articles

- Unlocking the Power of Optical Quartz Plates: Applications and Benefits

- CVD Diamond: Superior Material for Optical Windows

- Diamond Growing Machines For Modern Machining and Need for New Cutting Tools

- The Ethics of Diamond Growing Machines

- How to Achieve High Quality Single-Crystal Diamond with MPCVD