Table of Contents

- Unveiling the Properties of Optical Quartz Plates

- Applications in Optics and Beyond

- Benefits of Optical Quartz Plates

- Manufacturing and Customization of Optical Quartz Plates

- Quartz Glass: Properties, Applications, and Role in Laboratory Equipment

- Applications in Research and Development

- Conclusion: The Versatility of Optical Quartz Plates

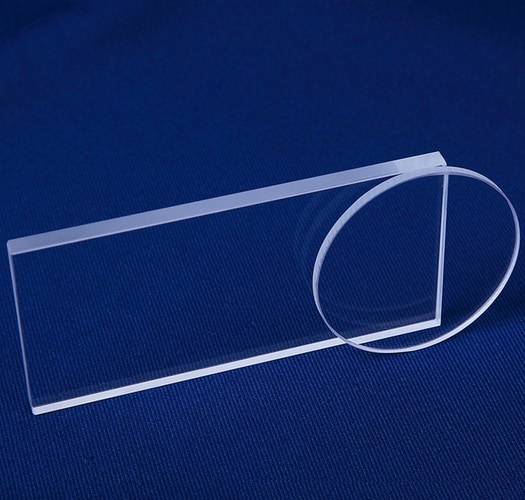

Unveiling the Properties of Optical Quartz Plates

Optical quartz plates stand out with their unique properties, including exceptionally low thermal expansion, remarkable resistance to high temperatures, and unmatched optical clarity. These properties make them ideal for various applications, including:

1. High Thermal Stability: Optical quartz plates exhibit an extremely low coefficient of thermal expansion, making them highly resistant to thermal shock. They can withstand drastic temperature changes without experiencing significant deformation or damage. This property is crucial for applications involving rapid temperature fluctuations or extreme environments.

2. Exceptional Optical Clarity: Optical quartz plates possess superior optical clarity and transmittance across a wide range of wavelengths, from the ultraviolet to the infrared spectrum. This makes them ideal for optical components such as lenses, prisms, and windows, where high-quality image transmission is essential.

3. Chemical Purity and Resistance: Optical quartz plates are highly resistant to chemical reactions, making them suitable for use in corrosive environments. They exhibit low levels of impurities and maintain their chemical integrity over time, ensuring consistent optical performance.

4. High Temperature Resistance: Optical quartz plates can withstand elevated temperatures without losing their structural or optical properties. They are commonly used in high-temperature applications such as semiconductor processing, laser optics, and aerospace components.

5. Electrical Insulation: Optical quartz plates have excellent electrical insulation properties, making them suitable for use in electrical and electronic applications. They exhibit high dielectric strength and low electrical conductivity, preventing current leakage or electrical interference.

6. Mechanical Strength: Optical quartz plates are mechanically robust and can withstand significant forces without breaking. Their exceptional elasticity allows them to absorb shocks and vibrations without compromising their optical integrity.

7. Applications in Optics: Due to their unique combination of properties, optical quartz plates find applications in various optical systems, including:

- Lenses and prisms for imaging and spectroscopy

- Windows for optical instruments and lasers

- Substrates for precision mirrors

- Optical fibers for telecommunications and sensing

In conclusion, optical quartz plates are highly versatile materials with exceptional properties that make them ideal for demanding applications in optics, electronics, and other industries. Their low thermal expansion, high temperature resistance, optical clarity, and chemical purity contribute to their widespread use in scientific research, industrial manufacturing, and consumer electronics.

Applications in Optics and Beyond

Optical quartz plates are widely used in optics, electronics, and other industries. In optics, they are vital components in eyeglasses, self-cleaning windows, and lasers. In electronics, they are essential for computer chips, displays, and communication devices.

Optics

- Eyeglasses: Optical quartz plates are used in eyeglasses to correct vision. They can be ground to precise shapes to correct a variety of vision problems, including nearsightedness, farsightedness, and astigmatism.

- Self-cleaning windows: Optical quartz plates can be coated with a thin film of titanium dioxide (TiO2), which makes them self-cleaning. The TiO2 coating breaks down organic matter when exposed to sunlight, which allows the rain to wash away the dirt and debris.

- Lasers: Optical quartz plates are used in lasers to generate and transmit laser light. They are highly resistant to heat and have a low coefficient of thermal expansion, which makes them ideal for use in high-power lasers.

Electronics

- Computer chips: Optical quartz plates are used in computer chips to insulate electrical components. They have a high electrical resistivity and are resistant to heat, which makes them ideal for use in high-performance computers.

- Displays: Optical quartz plates are used in displays to protect the screen from scratches and damage. They are transparent and have a high refractive index, which makes them ideal for use in touchscreens.

- Communication devices: Optical quartz plates are used in communication devices to transmit light signals. They are transparent and have a low loss, which makes them ideal for use in fiber optic cables.

Other Applications

In addition to optics and electronics, optical quartz plates are also used in a variety of other applications, including:

- Ultraviolet transmission: Optical quartz plates have a low coefficient of thermal expansion and are resistant to ultraviolet radiation, which makes them ideal for use in ultraviolet transmission applications.

- Clear lenses: Optical quartz plates can be used to create clear lenses for cameras, telescopes, and other optical devices.

- Thermocouple protection tubes: Optical quartz plates can be used to protect thermocouples from high temperatures and corrosive environments.

- Quartz tubes and rods: Optical quartz tubes and rods are used in a variety of applications, including sight glasses, level gauges, X-ray tubes, vacuum tubes, and CVD (chemical vapor deposition) and diffusion procedures.

Benefits of Optical Quartz Plates

Optical quartz plates offer numerous advantages that make them ideal for a wide range of applications. Their exceptional properties, including low thermal expansion, high temperature resistance, optical clarity, and high chemical purity, contribute to their widespread use in various industries.

Low Thermal Expansion and Dimensional Stability

Optical quartz plates exhibit an extremely low coefficient of thermal expansion, which ensures that they maintain their dimensions even under significant temperature fluctuations. This property makes them highly stable and suitable for applications requiring precise dimensional control.

High Temperature Resistance

Optical quartz plates can withstand high temperatures, making them suitable for use in harsh environments. They can withstand temperatures up to 1100 degrees Celsius, allowing them to be used in applications involving extreme heat.

Optical Clarity and Precise Light Transmission

Optical quartz plates possess exceptional optical clarity, enabling precise light transmission with minimal distortion or interference. This property makes them ideal for use in optical systems, spectroscopy, and other applications requiring accurate and reliable light transmission.

High Chemical Purity and Minimized Contamination Risks

Optical quartz plates are made from high-purity quartz, which minimizes the risk of contamination. This purity is crucial in applications where the presence of impurities can affect the performance or accuracy of the device.

Applications of Optical Quartz Plates

Due to their unique properties, optical quartz plates find applications in various industries, including:

- Laser Systems: Optical quartz plates are used as laser windows, lenses, and other optical components in laser systems due to their high temperature resistance and optical clarity.

- Spectroscopy: Optical quartz plates are used in spectrophotometers and other spectroscopy equipment due to their ability to transmit light across a wide spectral range.

- Semiconductors: Optical quartz plates are used in the production of semiconductors due to their high purity and resistance to contamination.

- Medical Devices: Optical quartz plates are used in medical devices, such as endoscopes and surgical instruments, due to their ability to withstand sterilization and transmit light effectively.

- Optical Communications: Optical quartz plates are used in optical communication systems due to their low optical loss and high durability.

Manufacturing and Customization of Optical Quartz Plates

Optical quartz plates, renowned for their exceptional properties, are meticulously crafted to meet specific requirements in various applications. Through advanced manufacturing techniques, these plates can be customized in dimensions, shapes, and sizes, enabling tailored solutions for diverse optical systems.

Precision Manufacturing

Optical quartz plates are manufactured with utmost precision, ensuring high dimensional accuracy. They are cut to exact lengths using specialized equipment, resulting in clean and precise edges. Fire polishing further enhances the surface finish, eliminating sharp edges and minimizing light scattering.

Versatile Customization

The versatility of quartz allows for customization in a wide range of shapes and sizes. From rectangular plates to complex geometric configurations, quartz plates can be tailored to meet specific application requirements. This customization ensures optimal performance in optical systems, maximizing light transmission and minimizing distortions.

Tailored Solutions

Through customization, optical quartz plates can be engineered to meet specific wavelength requirements. By controlling the thickness and orientation of the crystal, plates can be optimized for specific optical wavelengths, ensuring maximum transmission and minimizing energy loss.

Enhanced Durability

To enhance durability and extend the lifespan of optical quartz plates, they can undergo additional treatments, such as fine grinding. This precision process results in a smooth and uniform surface, reducing surface defects and increasing scratch resistance.

Quality Assurance

Rigorous quality control measures are employed throughout the manufacturing process to ensure the highest quality of optical quartz plates. Each plate undergoes thorough inspection, including raw material verification, chemical composition analysis, and dimensional accuracy checks. This comprehensive inspection process guarantees the reliability and performance of the plates.

Wide-Ranging Applications

The versatility and exceptional properties of optical quartz plates make them suitable for a wide range of applications, including:

- Precision optics

- Ultraviolet transmission

- Optical mirrors

- Thermocouple protection

- Semiconductor manufacturing

- Chemical processing

By leveraging advanced manufacturing techniques and customization capabilities, optical quartz plates can be tailored to meet the specific requirements of various optical systems, ensuring optimal performance and durability.

Quartz Glass: Properties, Applications, and Role in Laboratory Equipment

Composition and Manufacturing

Quartz glass, also known as silica glass, is a type of glass with a high content of silicon dioxide (SiO2). It is manufactured by melting pure natural quartz crystals with a SiO2 content of at least 99.9%. The molten quartz is then cooled to form the desired shape and dimensions. Due to its low trace element content, quartz glass is highly resistant to chemical corrosion and thermal shock, making it ideal for various applications in laboratory equipment and consumables.

Key Differentiating Factors from Glass

Quartz glass differs from regular glass in several key aspects:

- SiO2 Content: Quartz glass contains at least 99% SiO2, while regular glass has a maximum SiO2 content of 80%.

- Chemical Structure: Quartz glass has a symmetrical crystalline structure, while regular glass has an amorphous structure with randomly arranged molecules.

- Lead Content: Regular glass often contains lead to enhance its refractive index, while quartz glass is lead-free.

Properties and Applications

Quartz glass possesses several unique properties that make it valuable for laboratory applications:

- High Purity: The high purity of quartz glass makes it suitable for use in semiconductor manufacturing, where the presence of metal impurities can be detrimental to the process.

- UV Transmission: Fused quartz exhibits excellent ultraviolet (UV) transmission, making it ideal for lenses and optical devices.

- Thermal Resistance: Quartz glass has high thermal resistance and can withstand extreme temperatures without deforming or cracking.

- Chemical Inertness: Quartz glass is highly resistant to chemical corrosion, making it suitable for use in contact with harsh chemicals.

Due to its exceptional properties, quartz glass is used in a wide range of laboratory applications, including:

- Spectroscopy: Quartz cells and cuvettes are used in spectroscopy to hold and analyze samples.

- Chromatography: Quartz columns are used in chromatography for separating and analyzing chemical compounds.

- Vacuum Equipment: Quartz tubes and rods are used in vacuum systems as sight glasses, level gauges, and other components.

- High-Temperature Applications: Quartz crucibles and boats are used in high-temperature applications, such as melting and sintering.

Applications in Research and Development

In research and development, optical quartz plates play a vital role. They enable precise measurements, facilitate optical experiments, and contribute to advancements in various scientific fields.

Optics and Photonics

Optical quartz plates are used in a wide range of optics and photonics applications, including:

- Lenses and other optical components due to their excellent light transmission and low thermal expansion coefficient

- Polarizers and waveplates for controlling the polarization of light

- Interferometers and other precision measurement devices

- Lasers and other light sources

Semiconductor Fabrication

Quartz plates are essential in semiconductor fabrication, where they are used as:

- Substrates for growing semiconductor crystals

- Masks for photolithography

- Components in etching and deposition processes

Chemical and Biological Sciences

Optical quartz plates are also widely used in chemical and biological sciences for:

- Spectrophotometry and other analytical techniques

- Cell culture and microscopy

- Bioassays and other diagnostic tests

Other Applications

In addition to the above, optical quartz plates have numerous other applications in research and development, including:

- High-temperature applications due to their high melting point and thermal stability

- Electrical insulation due to their high electrical resistivity

- Environmental monitoring due to their resistance to corrosion and chemical degradation

The versatility and performance of optical quartz plates make them indispensable tools for a wide range of research and development applications.

Conclusion: The Versatility of Optical Quartz Plates

In conclusion, optical quartz plates have revolutionized industries with their remarkable properties and versatility. Their exceptional low thermal expansion, high temperature resistance, and optical clarity make them ideal for applications in optics, electronics, and research. From eyeglasses to lasers, computer chips to communication devices, optical quartz plates empower countless innovations. Their customizable nature and unwavering quality ensure tailored solutions and reliable performance. As technology continues to advance, optical quartz plates will undoubtedly remain indispensable components, unlocking new possibilities and shaping the future of optics and beyond.

Related Products

- High Temperature Resistant Optical Quartz Glass Sheet

- Optical Window Glass Substrate Wafer Quartz Plate JGS1 JGS2 JGS3

- CVD Diamond Optical Windows for Lab Applications

- Optical Ultra-Clear Glass Sheet for Laboratory K9 B270 BK7

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

Related Articles

- Optical Quartz Plate: A Comprehensive Guide to Applications, Specifications, and Usage

- Unveiling the Versatility of Heated Lab Presses: A Comprehensive Guide

- Technological Innovations in the Fused Silica Industry

- How to Save Money When Buying a Rotary Evaporator (Rotavapor)

- A Step-by-Step Guide to Cleaning Laboratory Glassware