MPCVD

High Precision Diamond Wire Cutting Machine Laboratory Saw Precision Wire EDM Cutting Machine

Item Number : CM-1

Price varies based on specs and customizations

- Power supply voltage: 220V 50Hz; Maximum power:

- <100w

- Effective heating area (mm)

- Power supply voltage: 220V 50Hz; Maximum power:<100w

- Total length of cutting line: 20m

- 20M

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

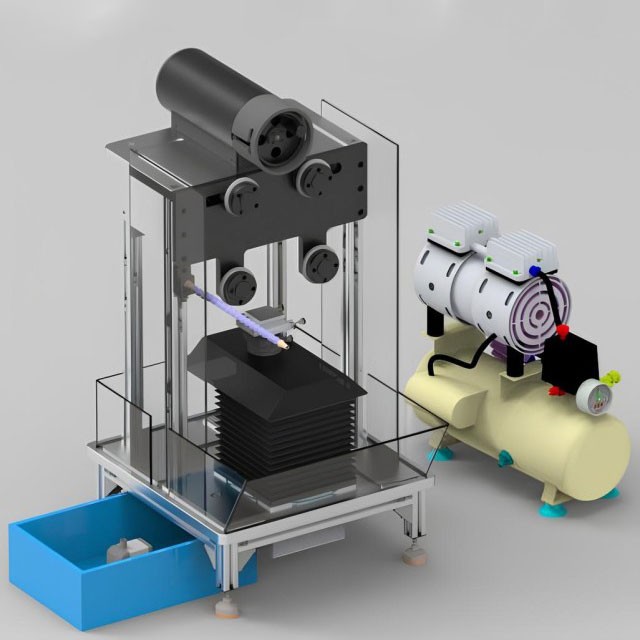

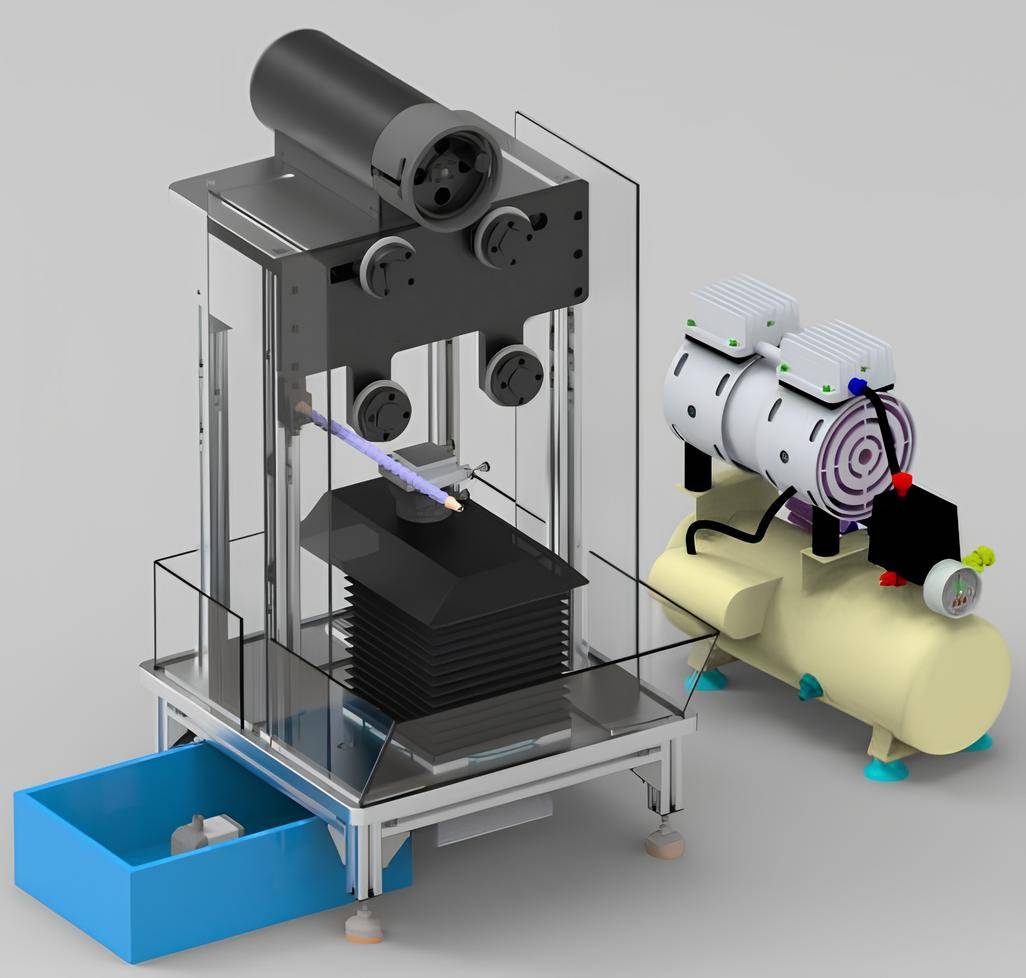

The high precision diamond wire cutting machine is a versatile and precise cutting tool designed specifically for material researchers. It utilizes a continuous diamond wire cutting mechanism, enabling precise cutting of brittle materials such as ceramics, crystals, glass, metals, rocks, and various other materials. The machine features a rotating turntable that allows for cutting at specific angles, enhancing its versatility. The small diamond wire cutting machine is renowned for its high sample size accuracy after cutting, within a range of 10 μm. Additionally, it employs a circular motion mode for the diamond wire, ensuring long service life and improved cutting efficiency. The tensioning wheel's spring tensioning mode maintains constant tension throughout the cutting process, ensuring optimal diamond wire tension.

Detail & Parts

Applications

The high precision diamond wire cutting machine is a versatile piece of equipment that can be used in a wide range of applications, including:

- Precision cutting of brittle materials such as ceramics, crystals, glass, metals, rocks, thermoelectric materials, infrared optical materials, composite materials, and biomedical materials

- Slicing, cutting, and squaring of materials

- Cutting samples at a certain angle using the rotating turntable

- Continuous cutting of materials after setting the cutting program

- Ultra-thin precision cutting with a thickness of up to 0.08mm

Principle

The high precision diamond wire cutting machine utilizes a continuous diamond wire that rotates in a circular motion. The diamond wire is tensioned using a spring-loaded tensioning wheel, which maintains a consistent tension throughout the cutting process. The sample is fed continuously through the cutting zone without manual adjustment, ensuring high accuracy and precision. The diamond wire cutting machine can perform various operations such as slicing, cutting, and squaring of brittle materials like ceramics, crystals, glass, metals, rocks, and composite materials. The thickness of the cut sheet can be as thin as 0.08mm, making it suitable for ultra-thin precision cutting applications.

Advantages

- High precision cutting: The sample size accuracy after cutting is high, within 10 μm.

- Continuous cutting: After setting the cutting program, the sample is continuously fed without manual adjustment.

- Long service life: The single wire has a long length of usable wires and a long service life, which improves cutting efficiency.

- Strong tensioning force: The tensioning wheel adopts a spring tensioning mode, with strong spring rigidity and high tensioning force.

- Ultra-thin precision cutting: The thickness of the cut sheet (within about 1 inch) can reach 0.08mm.

- Wear resistance: Diamond tools have high wear resistance and small changes in dimension, leading to good grinding quality and high grinding precision.

- Long lifespan: Diamond tools have a long lifespan and long dressing period, which greatly increases work efficiency and improves the workers' labor environment.

Technical specifications

| Power supply voltage | 220V 50Hz; Maximum power:<100w |

|---|---|

| Spindle speed | Adjustable within 2rpm to 260rpm |

| Control system | ① Manual control: Y axis and Z axis speed range 1 40mm/min; ② Automatic control: Y axis feed length 0.01 50mm; Z axis feed speed 0.05mm 40mm/min length 0.01 50mm; Z axis feed speed 0.05mm 40mm/min Z axis feed length 1 60mm; Automatic cutting frequency 1 99; |

| Total length of cutting line | 20m |

| Inner distance between two guide wheels | 95mm |

| Y-axis travel | ≤ 50mm |

| Z-axis travel | ≤ 60mm |

| 2D fixture | Horizontal rotation 0-360 °, left and right inclination 20° |

| Load plate size | 80mm× 51mm |

| Cutting depth | ≤ 50mm 11. Maximum sample size for cutting: Ø 50mm × 50mm |

Trusted by Industry Leaders

FAQ

What Is A Laboratory Saw And What Is It Used For?

What Materials Can Be Cut With A Diamond Wire Cutting Machine?

What Is CVD Diamond Machine?

What Are The Main Types Of Laboratory Saws?

What Types Of Diamond Growth Machines Are Available?

How Does A CVD Diamond Machine Work?

How Does A Diamond Wire Cutting Machine Work?

What Are The Advantages Of Lab Grown Diamonds?

What Are The Advantages Of Using CVD Diamond Machines?

What Are The Advantages Of Using A Diamond Wire Cutting Machine?

What Is The Price Of CVD Growing Machine?

What Considerations Should Be Made When Selecting A CVD Diamond Machine?

What Materials Can Be Cut Using A Laboratory Saw?

What Are The Common Applications Of Diamonds Produced By CVD Diamond Machines?

4.8 / 5

This high precision diamond wire cutting machine is a game-changer in our laboratory. Its incredible accuracy and precision have revolutionized our materials research capabilities.

4.9 / 5

The speed of delivery for this machine was exceptional. We were able to set it up and start using it within days of ordering, which was crucial for our time-sensitive project.

4.7 / 5

This machine offers incredible value for money. Its versatility and wide range of applications make it a valuable asset to our laboratory, and its durability ensures it will serve us well for years to come.

4.6 / 5

The quality of this machine is truly impressive. The diamond wire's long service life and the strong tensioning force ensure consistent and precise cuts every time.

4.8 / 5

The technological advancement of this machine is evident in its ultra-thin precision cutting capabilities. We can now produce samples with thicknesses as thin as 0.08mm, which was previously impossible.

4.9 / 5

The wear resistance of this machine is remarkable. The diamond tools maintain their sharpness and precision even after extensive use, reducing the need for frequent maintenance.

4.7 / 5

The long lifespan of this machine is a huge advantage. The diamond tools' long dressing period minimizes downtime and increases our productivity significantly.

4.8 / 5

This machine has significantly improved our work efficiency. The continuous cutting feature and the automatic control system make it incredibly user-friendly and efficient.

4.9 / 5

The strong tensioning force of this machine ensures precise cuts even in challenging materials. The tensioning wheel's spring rigidity is exceptional.

4.7 / 5

The ability to perform ultra-thin precision cutting with this machine has opened up new possibilities for our research. We can now analyze materials at a level of detail that was previously unattainable.

4.8 / 5

The versatility of this machine is truly impressive. It seamlessly handles various materials, including ceramics, crystals, glass, and metals, making it a valuable tool for our diverse research needs.

4.9 / 5

The high sample size accuracy of this machine is remarkable. The cuts are always precise and consistent, ensuring the reliability of our research data.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Precision Wire Saw Laboratory Cutting Machine with 800mm x 800mm Workbench for Diamond Single Wire Circular Small Cutting

Diamond wire cutting machines are mainly used for precision cutting of ceramics, crystals, glass, metals, rocks, thermoelectric materials, infrared optical materials, composite materials, biomedical materials and other material analysis samples. Especially suitable for precision cutting of ultra-thin plates with thickness up to 0.2mm.

CVD Diamond Cutting Tool Blanks for Precision Machining

CVD Diamond Cutting Tools: Superior Wear Resistance, Low Friction, High Thermal Conductivity for Non-Ferrous Materials, Ceramics, Composites Machining

Custom CVD Diamond Coating for Lab Applications

CVD Diamond Coating: Superior Thermal Conductivity, Crystal Quality, and Adhesion for Cutting Tools, Friction, and Acoustic Applications

Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

Professional tools for cutting lithium sheets, carbon paper, carbon cloth, separators, copper foil, aluminum foil, etc., with round and square shapes and different sizes of blades.

Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

Controlled environment lab press machine for glove box. Specialized equipment for material pressing and shaping with high precision digital pressure gauge.

Three-dimensional electromagnetic sieving instrument

KT-VT150 is a desktop sample processing instrument for both sieving and grinding. Grinding and sieving can be used both dry and wet. The vibration amplitude is 5mm and the vibration frequency is 3000-3600 times/min.

Vacuum Hot Press Furnace Machine for Lamination and Heating

Experience clean and precise lamination with Vacuum Lamination Press. Perfect for wafer bonding, thin-film transformations, and LCP lamination. Order now!

Precision Machined Yttria Stabilized Zirconia Ceramic Plate for Engineering Advanced Fine Ceramics

Yttrium-stabilized zirconia has the characteristics of high hardness and high temperature resistance, and has become an important material in the field of refractories and special ceramics.

Precision Machined Yttrium Stabilized Zirconia Ceramic Rod for Engineering Advanced Fine Ceramics

Zirconia ceramic rods are prepared by isostatic pressing, and a uniform, dense and smooth ceramic layer and transition layer are formed at high temperature and high speed.

Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

This machine is a single-pressure automatic rotating, continuous tableting machine that compresses granular raw materials into various tablets. It is mainly used for tablet production in the pharmaceutical industry, and is also suitable for chemical, food, electronics and other industrial sectors.

Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

Single punch manual tablet punching machine can press various granular, crystal or powdery raw materials with good fluidity into disc-shaped, cylindrical, spherical, convex, concave and other various geometric shapes (such as square, triangle, ellipse, capsule shape, etc.), and can also press products with text and patterns.

Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

A vacuum molybdenum wire sintering furnace is a vertical or bedroom structure, which is suitable for withdrawal, brazing, sintering and degassing of metal materials under high vacuum and high temperature conditions. It is also suitable for dehydroxylation treatment of quartz materials.

Laboratory High Pressure Vacuum Tube Furnace

KT-PTF High Pressure Tube Furnace: Compact split tube furnace with strong positive pressure resistance. Working temp up to 1100°C and pressure up to 15Mpa. Also works under controller atmosphere or high vacuum.

Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

Zirconia ceramic tweezers are a high-precision tool made of advanced ceramic materials, especially suitable for operating environments that require high precision and corrosion resistance. This type of tweezers not only has excellent physical properties, but is also popular in the medical and laboratory fields because of its biocompatibility.

Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

Efficient split chamber CVD furnace with vacuum station for intuitive sample checking and quick cooling. Up to 1200℃ max temperature with accurate MFC mass flowmeter control.

Multi Heating Zones CVD Tube Furnace Machine Chemical Vapor Deposition Chamber System Equipment

KT-CTF14 Multi Heating Zones CVD Furnace - Precise Temperature Control and Gas Flow for Advanced Applications. Max temp up to 1200℃, 4 channels MFC mass flow meter, and 7" TFT touch screen controller.

Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

Introducing our inclined rotary PECVD furnace for precise thin film deposition. Enjoy automatic matching source, PID programmable temperature control, and high accuracy MFC mass flowmeter control. Built-in safety features for peace of mind.

1200℃ Muffle Furnace Oven for Laboratory

Upgrade your lab with our 1200℃ Muffle Furnace. Achieve fast, precise heating with Japan alumina fibers and Molybdenum coils. Features TFT touch screen controller for easy programming and data analysis. Order now!

Assemble Lab Cylindrical Press Mold

Get reliable and precise molding with Assemble Lab Cylindrical Press Mold. Perfect for ultra-fine powder or delicate samples, widely used in material research and development.

Related Articles

Diamond Growing Machines For Modern Machining and Need for New Cutting Tools

Diamonds have become popular due to their exceptional hardness, superior thermal conductivity, and chemical stability.

Understanding the CVD Diamond Machine and How It Works

CVD (Chemical Vapor Deposition) diamond creation process involves the deposition of carbon atoms onto a substrate using a gas phase chemical reaction. The process starts with the selection of a high-quality diamond seed, which is then placed in a growth chamber along with a carbon-rich gas mixture.

The Ethics of Diamond Growing Machines

Lab-grown diamonds have gained significant popularity in recent years due to their ethical and environmental benefits.

The Pros and Cons of Different Lab Diamond Machine Methods

Lab-grown diamonds, also known as synthetic diamonds, are man-made diamonds produced in a laboratory setting.

Unlocking the Power of Sieving Machines: Functions, Applications and Maintenance

Discover the significance of sieving machines in various industries and the essential functions they serve. Learn about the the maintenance requirements for optimal performance. Explore the benefits of using sieve shakers for automating the particle separation process.

Isostatic Pressing of Ceramics: Process and Precision

When it comes to producing high-quality ceramic components, one of the most crucial processes is isostatic pressing. This technique ensures the uniformity and precision required for manufacturing ceramics used in various industries. Isostatic pressing involves carefully selecting the pressing powders and controlling the tools to achieve the desired uniformity. By understanding the process of isostatic pressing, manufacturers can ensure the production of ceramics that meet the strict standards of dimensional accuracy and performance.

Understanding Isostatic Pressing in Powder Metallurgy

Isostatic pressing is a powder processing technique that uses fluid pressure to compact the part. It involves placing metal powders in a flexible container, which acts as the mold for the part. Fluid pressure is then exerted over the entire outside surface of the container, causing it to press and form the powder into the desired geometry.

How to Achieve Uniform Pressure with Warm Isostatic Press

Warm Isostatic Pressing (WIP) is a manufacturing process that subjects materials to high pressure and high temperature simultaneously. The process involves using an isostatic press to apply uniform pressure to the material from all directions while it is heated to a specific temperature.

How To Turn XRF analysis sample preparation Into Success

In X-ray fluorescence (XRF) analysis, sample preparation is an important step because it can significantly impact both the quality and the efficiency of the analysis.

Understanding Cold Isostatic Pressing and its Types

Cold isostatic pressing (CIP) is a method of processing materials that is based on the principle proposed by Blaise Pascal, known as Pascal's law. According to this principle, pressure applied in an enclosed fluid is transmitted in all directions throughout the fluid without any change in magnitude.

Disc / Cup Vibratory Mill: A Comprehensive Guide to Its Functions and Applications

Discover the world of Disc / Cup Vibratory Mills with our in-depth guide. Learn about their working principles, applications, advantages, and key features. Explore the various types of vibratory mills and their suitability for different industries.

What Makes Hot Isostatic Pressing So Effective

Hot Isostatic Pressing (HIP) is a manufacturing process that uses high temperature and pressure to improve the mechanical properties of materials. The process involves placing a part in a sealed chamber and subjecting it to high temperatures and pressures.