Introduction to Disc / Cup Vibratory Mills

Vibratory mills are essential laboratory equipment used to grind and pulverize materials. They find applications in various industries, including pharmaceuticals, ceramics, and metallurgy. Disc / cup vibratory mills are a type of vibratory mill that utilizes a rotating shaft with a grinder, pump blade, and dispersing disc. The grinder drives the grinding medium and materials, generating strong shearing and collision forces that grind and disperse the materials.

Working Principle of Disc / Cup Vibratory Mills

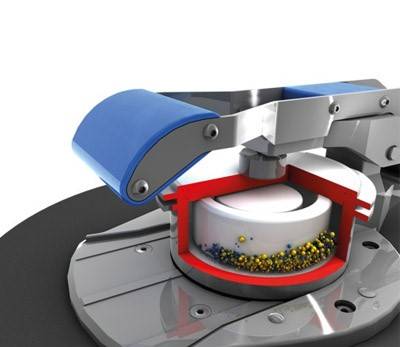

Disc / cup vibratory mills utilize a rotating shaft with a grinder, pump blade, and dispersing disc. The grinder drives the grinding medium and materials, generating strong shearing and collision forces that grind and disperse the materials. This process is based on the principles of impact and friction, where the grinding jars rotate around the center axis while the sun wheel rotates in the opposite direction. The balls inside the jars collide with the material to be ground, pulverizing it into a fine powder.

The speed and movement of the grinding jars and sun wheel can be precisely controlled to achieve desired grinding results. These mills are commonly employed in laboratories for grinding a diverse range of materials, including chemicals, minerals, ceramics, and more. They excel in grinding materials that are challenging to reduce to a fine powder using other methods and are ideal for preparing small quantities of materials for analysis.

In contrast to ball mills, which are designed for grinding materials such as ore, ceramics, and paint, disc / cup vibratory mills are primarily used for grinding and dispersing polymers and other materials. The grinding process involves placing the material in a grinding basket filled with high-strength grinding media. As the rotating shaft, grinder, pump blade, and dispersing disc rotate at high speed, the grinding medium and material collide, generating shearing and collision forces that effectively grind and disperse the material.

The ground materials are then drawn out of the grinding basket by the suction of the pump blade and dispersed by the dispersing disc. This process enables the achievement of optimal grinding results in a short period. The motor drives the rotating shaft at high speed, generating exciting vibrations. Centrifugal force causes the bowl puck and ring to collide, squeeze, and grind the sample, effectively crushing it.

Types of Disc / Cup Vibratory Mills

Vibratory mills are a type of laboratory equipment used to grind and pulverize materials. They are typically used in research and development laboratories, as well as in industrial settings. Vibratory mills work by vibrating a grinding chamber, which causes the material inside to be crushed and broken down.

There are many different types of vibratory mills available, each with its own unique features and benefits. Some of the most common types of vibratory mills include:

- Disc vibratory mills: These mills use a rotating disc to grind materials. The disc is typically made of a hard material, such as steel or ceramic, and is coated with an abrasive material.

- Cup vibratory mills: These mills use a rotating cup to grind materials. The cup is typically made of a hard material, such as steel or ceramic, and is coated with an abrasive material.

- Planetary vibratory mills: These mills use a rotating planetary head to grind materials. The planetary head is typically made of a hard material, such as steel or ceramic, and is coated with an abrasive material.

Vibratory mills are a versatile piece of laboratory equipment that can be used to grind a wide variety of materials. They are relatively easy to operate and maintain, and they can produce high-quality results.

Applications of Disc / Cup Vibratory Mills

Disc / cup vibratory mills are versatile and find applications in various industries, including:

-

Paint and Ink Production: These mills are widely used in the grinding and dispersion of pigments, resins, and other components in paint and ink formulations. The high-energy mixing action of the vibratory mill helps achieve uniform particle size distribution and prevents agglomeration, resulting in improved product quality and performance.

-

Color Paste Production: Vibratory mills are commonly employed in the manufacturing of color pastes used in plastics, textiles, and other industries. The ability of these mills to grind and disperse pigments into a fine and homogeneous paste ensures consistent color reproduction and enhanced product aesthetics.

-

Adhesive Production: In the adhesive industry, vibratory mills are used to grind and mix various components, including resins, fillers, and tackifiers. The high shear forces generated by the mill's vibration help break down agglomerates and create a uniform adhesive mixture with optimal bonding strength and performance.

-

Pilot Production: Disc / cup vibratory mills are well-suited for pilot production runs, where small batches of materials need to be processed for testing, evaluation, or small-scale production. These mills offer flexibility and ease of operation, allowing for quick and efficient production of small quantities of products for research, development, or quality control purposes.

-

Other Applications: Beyond the aforementioned industries, vibratory mills find applications in various other fields, including:

- Pharmaceutical: Grinding of active pharmaceutical ingredients (APIs) and excipients for drug formulations.

- Cosmetics: Dispersion of pigments and other ingredients in cosmetic products to achieve smooth and uniform consistency.

- Food: Grinding of spices, herbs, and other food ingredients to enhance flavor and texture.

- Materials Science: Preparation of advanced materials, such as nanoparticles, composites, and functional materials.

- Recycling: Size reduction of waste materials for recycling and resource recovery.

Advantages of Disc / Cup Vibratory Mills

Vibratory mills offer several advantages, including low noise and vibration, programmable milling segments, and reliable heavy-duty designs.

Increased Power and Extended Lifetime

Vibratory mills utilize a universal shaft driven by vee-belts from a stationary electric motor. This arrangement provides enhanced power transmission to the grinding bowls and optimizes motor longevity. Unlike traditional integral vibratory motor-driven mills, the motor is not subjected to direct vibration, ensuring extended operational life.

Versatile Capacity and Exceptional Efficiency

Multiple grinding bowls with varying capacities can be installed in our pulverizer series, enabling simultaneous grinding of samples up to a maximum total weight of 1600 grams. This versatility caters to diverse sample sizes and throughput requirements.

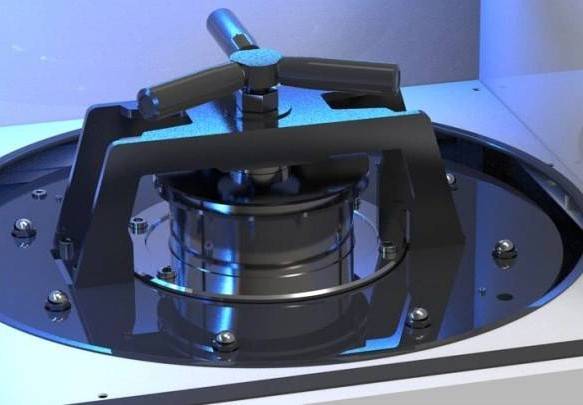

Hydraulic, Pneumatic, and Mechanical Lifting Options

Hydraulic, pneumatic, or mechanical lifting mechanisms can be employed based on user preference, ensuring reliable and smooth rack operation.

Advanced Frequency Conversion Control

Advanced frequency conversion control enables precise speed regulation, allowing for optimal adjustment to suit specific sample characteristics and desired outcomes.

Rapid Results

Vibratory mills facilitate efficient grinding, minimizing processing time and expediting the attainment of desired particle size reduction.

Features of Disc / Cup Vibratory Mills

Key Features of Vibratory Mills

Some of the key features of vibratory mills include:

- LCD control panels: LCD control panels make it easy to operate and monitor vibratory mills. They typically display information such as the speed, time, and temperature of the mill.

- Safety mechanisms: Vibratory mills are equipped with a variety of safety mechanisms to protect the operator from injury. These mechanisms include interlocks that prevent the mill from operating if the door is open, and emergency stop buttons.

- Stable rotation speeds: Vibratory mills are designed to operate at stable rotation speeds. This ensures that the material is ground evenly and consistently.

- Customized power supply options: Vibratory mills are available with a variety of power supply options to meet the needs of different users. These options include 110V, 220V, and 380V.

If you are looking for a versatile and efficient way to grind materials, a vibratory mill is a great option. Vibratory mills are available in a variety of sizes and configurations to meet the needs of different users.

Related Products

- Laboratory Disc Cup Vibratory Mill for Sample Grinding

- Disc Cup Vibrating Mill Multi-Platform for Lab

- Lab Vibration Mill

- Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

- High Energy Vibratory Ball Mill for Lab Use

Related Articles

- What is a Laboratory Crusher Used For?

- Disc / Cup Vibratory Mill: A Comprehensive Guide for Laboratory Experts

- Sieving technology for particle size analysis and its applications

- Laboratory Crushers: A Comprehensive Guide to Their Uses and Functionality

- The Scientific Principle of Sieving: Understanding Particle Size Distribution and Laboratory Test Sieves