Milling Equipment

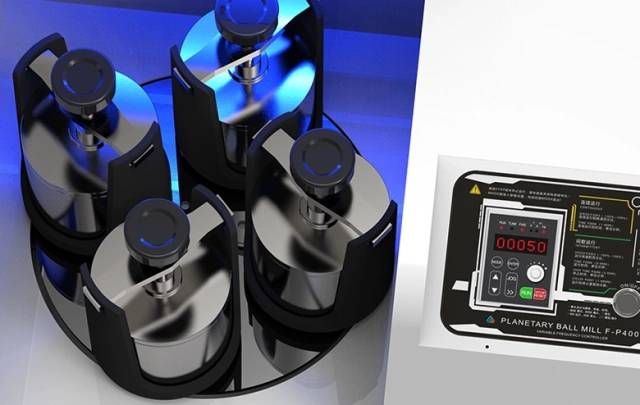

High Energy Planetary Ball Mill Milling Machine for Laboratory

Item Number : KT-P4000

Price varies based on specs and customizations

- Maximum injection size

- < 10 mm

- Sample particle size range

- 0.1-20um

- Maximum processing volume

- 4000ml

- Maximum speed of the ball mill

- 800 r/min

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Principle

The High Energy Planetary Ball Mill operates by rotating grinding jars on a sun wheel and their own axes in opposite directions, generating high centrifugal and Coriolis forces. This rapid acceleration enhances impact and friction between milling balls and materials, achieving ultra-fine particle sizes efficiently.

Applications

High Energy Planetary Ball Mills are versatile tools used in various scientific and industrial applications for the grinding and synthesis of materials down to nano-sized particles. These mills are particularly effective in laboratories where the need for ultrafine and nano-sized materials is crucial for the development of innovative products. The high-energy ball milling process is known for its ability to mechanically induce structural and chemical changes in materials, making it a valuable technique in several fields.

- Material Science: For the synthesis of nano powders, mechanical alloying, and the development of new materials with specific properties.

- Pharmaceuticals: To produce fine powders necessary for drug formulations, enhancing the dissolution rate and bioavailability of active pharmaceutical ingredients.

- Ceramics: For the preparation of homogeneous ceramic powders, which are essential for the manufacturing of high-quality ceramic products.

- Metallurgy: In the production of metal powders and the blending of different metal alloys to achieve desired properties.

- Environmental Science: For the grinding of samples prior to analysis, aiding in the study of pollutants and their effects on the environment.

- Nanotechnology: In the creation of nanomaterials with unique properties for various applications, including electronics and energy storage.

- Chemical Industry: For the fine grinding of chemicals and the preparation of homogeneous mixtures for chemical reactions.

Advantages

The High Energy Planetary Ball Mill offers a range of advantages that make it a superior choice for laboratory work, particularly in the synthesis and grinding of materials down to ultrafine and nano-sized particles. Here are some of the key benefits:

- High Efficiency in Size Reduction: The planetary ball mill utilizes a unique mechanism where grinding jars are arranged eccentrically on a sun wheel, and their movement is opposite to that of the sun wheel. This setup results in the generation of Coriolis forces, which, combined with frictional and impact forces, release high dynamic energies. This interplay of forces ensures a very effective degree of size reduction, making it ideal for producing nano powders of 2 to 20 nm in size.

- Enhanced Impact Energy: The design of the planetary ball mill allows for the centrifugal forces to be alternately synchronized, resulting in friction and impact between the milling balls and the powder mixture. This leads to impact energy that is up to 40 times higher than that due to gravitational acceleration, facilitating high-speed milling and rapid processing times.

- Versatility in Applications: High-energy ball mills are not only effective for grinding hard and brittle materials like metals, alloys, ceramics, and minerals but are also suitable for mechanical alloying, mixing, and homogenization of various materials. This versatility makes them indispensable in laboratories where a variety of materials need to be processed.

- Cost-Effective and Easy to Operate: Despite their high-performance capabilities, these mills are relatively inexpensive and easy to operate. The mechanical process of ball milling does not require complex, costly setups or extensive training, making it accessible for routine laboratory work.

- Production of Crystal Defects: The mechanical energy applied during the milling process can produce crystal defects, which can be beneficial for certain applications, such as enhancing the reactivity of materials or altering their physical properties.

- Compact and Space-Saving Design: Planetary ball mills are smaller than common ball mills, making them ideal for laboratory settings where space is often limited. Their compact design does not compromise on performance, ensuring high-quality results in a smaller footprint.

The High Energy Planetary Ball Mill is a powerful, efficient, and versatile tool for laboratories aiming to achieve precise and rapid size reduction of materials, with the added benefits of ease of use and a compact design.

Detail & Parts

Functions

- Continuous and intermittent operation

- Emergency stop

- Timing

- Power failure memory

- Overload and hazardous operation protection

- LED Lighting

- Heat Dissipation

Features

High-energy planetary ball mills are essential tools for achieving rapid and efficient size reduction in materials. These mills are designed to handle hard and brittle materials, making them ideal for applications in metals, alloys, ceramics, and minerals. The unique design of these mills, with their opposite rotation directions of the bowl and turn disc, creates a synchronized centrifugal force that enhances the grinding process. This results in a high-impact energy that is up to 40 times higher than that due to gravitational acceleration, facilitating high-speed milling and the production of ultra-fine particles.

- Ultra-Fine Particle Production: The high-energy impact and friction generated by the milling balls allow for the production of nano powders ranging from 2 to 20 nm in size. This capability is crucial for applications requiring extremely fine materials.

- Efficient and Rapid Grinding: The planetary ball mill's design ensures rapid acceleration of grinding balls, significantly increasing grinding energy. This efficiency allows for the production of even smaller particle sizes compared to other types of ball mills, making it ideal for high-throughput applications.

- Versatility in Material Processing: These mills are not only effective for grinding but also for mechanical alloying, mixing, and homogenization. This versatility makes them indispensable in routine laboratory work and for the development of innovative materials.

- Crystal Defects Creation: The mechanical energy applied during ball milling can produce crystal defects, which can be beneficial for altering material properties and enhancing certain characteristics in synthesized materials.

- Cost-Effective and Simple Operation: Despite their high performance, these mills are relatively inexpensive and easy to operate, making them accessible for various research and industrial applications.

These features highlight the high-energy planetary ball mill's role as a high-performance all-rounder in laboratory settings, capable of handling a wide range of grinding and material synthesis tasks with precision and efficiency.

Technical specifications

| Grinding principle | Impact & friction force |

| Suitable materials | Small and medium-low hardness; brittle; dry or wet |

| Materials input size | < 10 mm |

| Materials output size | 0.1-20 um |

| Processing volume | 4000ml |

| Disc panspeed | 800 r/min |

| Grinding panmaterial | Tungsten carbide;Ceramic; Agate; Stainless steel; Harden steel; Nylon, etc. |

| Planetary disk space movement mode | X axis planetary movement |

| Motor power | 100-120V/200-240V AC ,50-60Hz,750W |

| Net weight | 106kg |

| Dimensions | L720*W500*H500 mm |

| Protection level | IP65 |

| Quality standards | CE |

Warnings

Operator safety is the top important issue! Please operate the equipment with cautions. Working with inflammable& explosive or toxic gases is very dangerous, operators must take all necessary precautions before starting the equipment. Working with positive pressure inside the reactors or chambers is dangerous, operator must fellow the safety procedures strictly. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

FAQ

What Is A Planetary Ball Mill?

What Is A Laboratory Ball Mill?

What Is The Advantage Of Using A Planetary Ball Mill For Colloidal Grinding?

What Are High-energy Ball Mills Used For?

How Do High-energy Ball Mills Differ From Other Types Of Ball Mills?

Can High-energy Ball Mills Produce Nano-sized Particles?

What Is The Typical Duration For Ball Milling To Achieve Uniform Fine Powder?

Are There Any Disadvantages To Using High-energy Ball Mills?

How Does A Planetary Ball Mill Operate?

What Are The Main Applications Of Planetary Ball Mills?

What Are The Applications Of A Laboratory Ball Mill?

What Is Milling Equipment Used For?

What Are The Key Features Of Planetary Ball Mills?

What Are The Main Types Of Laboratory Ball Mills?

What Are The Different Types Of Milling Equipment?

What Are The Advantages Of Using A Planetary Ball Mill?

What Is The Working Principle Of A Laboratory Ball Mill?

What Materials Can Be Processed Using Milling Equipment?

What Types Of Planetary Ball Mills Are Available?

What Are The Advantages Of Using A Laboratory Ball Mill?

How Does Milling Equipment Work?

How Does The Automatic Reversal Mechanism In Planetary Ball Mills Work?

What Materials Can Be Processed Using A Laboratory Ball Mill?

What Are The Advantages Of Using Milling Equipment?

What Makes Planetary Ball Mills Suitable For Small Particle Samples?

What Are The Key Features Of A High-energy Planetary Ball Mill?

What Factors Should Be Considered When Selecting Milling Equipment?

What Is The Difference Between A Planetary Ball Mill And A Vibratory Ball Mill?

4.9 / 5

The planetary ball mill is a lifesaver in our lab. It's incredibly efficient and provides us with consistent results every time.

4.7 / 5

I'm impressed with the build quality and durability of this machine. It's a solid investment that will last for years.

4.8 / 5

This planetary ball mill is a game-changer for our research. It's easy to operate and has helped us achieve significant breakthroughs.

4.6 / 5

The speed of delivery was impressive. We received the machine within a week of placing the order.

4.7 / 5

The value for money is exceptional. This machine is worth every penny.

4.9 / 5

The technological advancement of this planetary ball mill is remarkable. It's a testament to the company's commitment to innovation.

4.8 / 5

The durability of this machine is outstanding. It has been running flawlessly for months without any issues.

4.7 / 5

The quality of the materials used in this machine is top-notch. It's evident that the company has paid attention to every detail.

4.9 / 5

The customer service provided by KINTEK SOLUTION is exceptional. They are always prompt and helpful in addressing any queries.

4.8 / 5

The versatility of this planetary ball mill is impressive. It can handle a wide range of materials and applications with ease.

4.7 / 5

The machine is incredibly user-friendly. Even our new lab technicians were able to operate it without any problems.

4.9 / 5

The compact design of this planetary ball mill is perfect for our small laboratory. It saves us valuable bench space.

4.8 / 5

The noise level of this machine is surprisingly low. It doesn't disrupt our other experiments.

4.7 / 5

The energy efficiency of this planetary ball mill is commendable. It helps us save on our energy bills.

4.9 / 5

The safety features on this machine are top-notch. It gives us peace of mind knowing that our lab is safe.

4.8 / 5

The warranty provided by KINTEK SOLUTION is comprehensive and gives us confidence in the quality of their product.

4.7 / 5

The machine is aesthetically pleasing and looks great in our laboratory.

4.9 / 5

The machine is easy to clean and maintain, which saves us valuable time.

4.8 / 5

The machine is portable and easy to move around, which is convenient for our lab setup.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

The KT-P2000E is a new product derived from the vertical high-energy planetary ball mill with a 360°rotation function. The product not only has the characteristics of the vertical high-energy ball mill, but also has a unique 360°rotation function for the planetary body.

High Energy Planetary Ball Mill Milling Machine for Laboratory

Experience fast and effective sample processing with the F-P2000 high-energy planetary ball mill. This versatile equipment offers precise control and excellent grinding capabilities. Perfect for laboratories, it features multiple grinding bowls for simultaneous testing and high output. Achieve optimal results with its ergonomic design, compact structure, and advanced features. Ideal for a wide range of materials, it ensures consistent particle size reduction and low maintenance.

High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

The KT-P4000E is a new product derived from the vertical high-energy planetary ball mill with a 360° swivel function. Experience faster, uniform, and smaller sample output results with 4 ≤1000ml ball mill jars.

Laboratory Planetary Ball Mill Rotating Ball Milling Machine

KT-P400E is a desktop multi-directional planetary ball mill with unique grinding and mixing capabilities. It offers continuous and intermittent operation, timing, and overload protection, making it ideal for various applications.

Mini Planetary Ball Mill Machine for Laboratory Milling

Discover the KT-P400 desktop planetary ball mill, ideal for grinding and mixing small samples in the lab. Enjoy stable performance, long service life, and practicality. Functions include timing and overload protection.

Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

The vertical cabinet structure combined with ergonomic design enables users to obtain the best comfortable experience in standing operation. The maximum processing capacity is 2000ml, and the speed is 1200 revolutions per minute.

High Energy Planetary Ball Mill for Laboratory Horizontal Tank Type Milling Machine

KT-P4000H uses the unique Y-axis planetary motion trajectory, and utilizes the collision, friction and gravity between the sample and the grinding ball to have a certain anti-sinking ability, which can obtain better grinding or mixing effects and further improve the sample output.

High Energy Vibratory Ball Mill for Lab Use

The high-energy vibrating ball mill is a high-energy oscillating and impacting multifunctional laboratory ball mill. The table-top type is easy to operate, small in size, comfortable and safe.

Laboratory Horizontal Planetary Ball Mill Milling Machine

Improve sample uniformity with our Horizontal Planetary Ball Mills. KT-P400H reduces sample deposition and KT-P400E has multi-directional capabilities. Safe, convenient and efficient with overload protection.

High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

The KT-P2000H uses a unique Y-axis planetary trajectory, and utilizes the collision, friction and gravity between the sample and the grinding ball.

Laboratory Ten-Body Horizontal Jar Mill for Lab Use

The Ten-body horizontal jar mill is for 10 ball mill pots (3000ml or less). It has frequency conversion control, rubber roller movement, and PE protective cover.

Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

Discover the versatile stainless steel dry powder/liquid horizontal ball mill with ceramic/polyurethane lining. Ideal for ceramic, chemical, metallurgical, and building materials industries. High grinding efficiency and uniform particle size.

Small Injection Molding Machine for Lab Use

The small injection molding machinehas fast and stable movements; good controllability and repeatability, super energy saving; the product can be automatically dropped and formed; the machine body is low, convenient for feeding, easy to maintain, and no height restrictions on the installation site.

Lab Vibration Mill

Vibration Mill for Efficient Sample Preparation, Suitable for Crushing and Grinding a Variety of Materials with Analytical Precision. Supports Dry / Wet / Cryogenic Grinding and Vacuum/Inert Gas Protection.

Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

zirconia ceramic ball have the characteristics of high strength, high hardness, PPM wear level, high fracture toughness, good wear resistance, and high specific gravity.

Anion Exchange Membrane for Laboratory Use

Anion exchange membranes (AEMs) are semipermeable membranes, usually made of ionomers, designed to conduct anions but reject gases such as oxygen or hydrogen.

Small Lab Rubber Calendering Machine

Small lab rubber calendering machine is used for producing thin, continuous sheets of plastic or rubber materials. It is commonly employed in laboratories, small-scale production facilities, and prototyping environments to create films, coatings, and laminates with precise thickness and surface finish.

Assemble Lab Cylindrical Press Mold

Get reliable and precise molding with Assemble Lab Cylindrical Press Mold. Perfect for ultra-fine powder or delicate samples, widely used in material research and development.

Related Articles

Maximizing Grinding Efficiency: The Power of Planetary Ball Mills

Discover why planetary ball mills offer higher grinding efficiency than ordinary ball mills. Learn about the technology behind their high-performance all-round capabilities. Find out the key factors influencing the productivity and specific energy consumption of ball mills.

Planetary Ball Mills: Research Tools for Efficient Mixing and Nanoscale Grinding

Planetary ball mills are indispensable tools in modern laboratories, serving a crucial role in the mixing, fine grinding, and preparation of small samples. These mills are particularly adept at dispersing nanomaterials and facilitating the development and small-scale production of high-tech materials.

Advantages of Planetary Ball Mill in Laboratory Applications

Discover the advantages of using planetary ball mills in laboratory settings. Learn about its ability to produce fine powder, suitability for toxic materials, wide range of applications, continuous operation, and usage for milling abrasive materials. Explore how planetary ball mills differ from traditional milling machines and their function in creating ultrafine and nano-sized materials.

Choosing the Best Material for Ball Mill: Essential Factors and Recommendations

Discover the best material for ball mill applications and grinding success. Learn about the features and benefits of stainless steel, ceramic, agate, and tungsten carbide media. Find out how to ensure grinding success and the ideal grinding jars and media for planetary ball milling. Explore the applications of ball mills and the advantages of high-energy ball mills for ultra-fine particles.

Features of Different Laboratory Mills: An Overview

Laboratory mills are specialized machines used to reduce non-homogenous batch samples into smaller, representative samples that are more uniform in composition.

Disc / Cup Vibratory Mill: A Comprehensive Guide to Its Functions and Applications

Discover the world of Disc / Cup Vibratory Mills with our in-depth guide. Learn about their working principles, applications, advantages, and key features. Explore the various types of vibratory mills and their suitability for different industries.

Disc / Cup Vibratory Mill: A Comprehensive Guide for Laboratory Experts

Discover the world of Disc / Cup Vibratory Mills! This comprehensive guide provides an in-depth understanding of their types, working principles, advantages, and applications in various industries, including pharmaceuticals, chemicals, and food processing.

Understanding the Tablet Press Machine R&D Lab Model and its Features(2)

The Tablet Press Machine R&D Model, also known as a single punch tablet press, is designed for the development and small batch production of tablets. It is widely used in industries such as pharmacy, chemical, food, and metallurgy. This machine operates automatically, continuously filling, pressing, and ejecting tablets. Its key features include high precision filling, low noise, low material consumption, and smooth operation. It is particularly useful for research and development in laboratories, hospitals, and plants, catering to small-scale production needs.

The Three Stages of Lab Crushing: A Comprehensive Guide

Learn about the three stages of crushing: primary, secondary, and tertiary, and how they are used in sample preparation for scientific analysis. Discover the different types of crushers and their applications in reducing bulky materials into smaller particles.

Disc / Cup Vibratory Mill: A Comprehensive Guide to Grinding Equipment

Discover the world of Disc / Cup Vibratory Mills! This guide covers everything from types and features to applications and benefits. Explore the versatility of these mills for grinding various materials in industries like pharmaceuticals, food, and chemicals.

What is a Laboratory Crusher Used For?

Discover the uses and working mechanism of laboratory crushers. Explore various types of crushing equipment and their applications. Learn how laboratory crushers play a crucial role in scientific analysis and environmental studies.

How To Turn XRF analysis sample preparation Into Success

In X-ray fluorescence (XRF) analysis, sample preparation is an important step because it can significantly impact both the quality and the efficiency of the analysis.