Milling Equipment

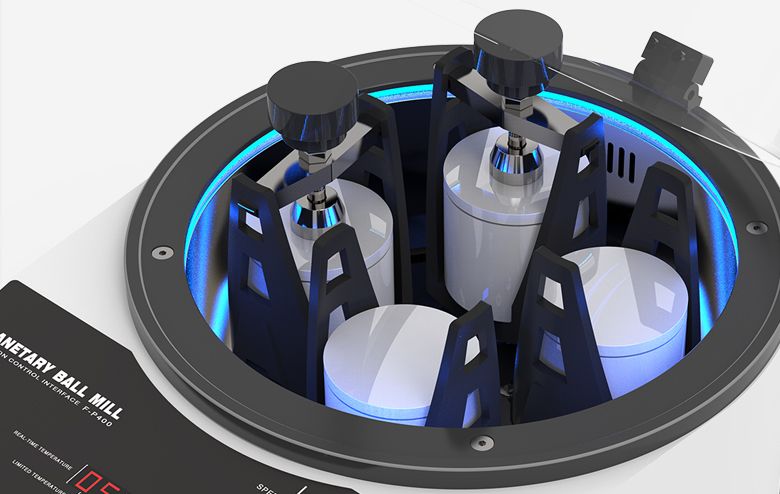

Mini Planetary Ball Mill Machine for Laboratory Milling

Item Number : KT-P400

Price varies based on specs and customizations

- Materials input size

- < 2 mm

- Materials output size

- 0.1-20 um

- Processing volume

- < 400 ml

- Grinding jar speed

- 0-900 r/min

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

KT-P400 is one small desktop planetary ball mill, equipped with 4 grinding jars,each jar volume is 100ml, it is used for grinding or mixing micro and small samples in the laboratory. This ball mill has excellent processing ability, higher practicability, stable performance, operability and long service life, it is the best choice for the researching labs.

Applications

The Mini Planetary Ball Mill is a versatile and high-performance tool primarily used in laboratory settings for the fine grinding and synthesis of materials down to nano-sized particles. This equipment is particularly effective in scientific research and development, where the precise control of particle size and properties is crucial. The applications of the Mini Planetary Ball Mill span across various fields, including materials science, pharmaceuticals, and energy research.

- Materials Synthesis: Used for the production of nano powders with sizes ranging from 2 to 20 nm, which are essential for advanced materials development.

- Mechanical Alloying: Effective in blending multiple components to enhance solid-state chemical reactivity, which is crucial for creating new alloys and composites.

- Powder Processing: Ideal for grinding and refining materials such as ores, pigments, and ceramics, ensuring uniformity and fine particle distribution.

- Pharmaceutical Manufacturing: Helps in the reduction of drug particle sizes, improving bioavailability and efficacy of pharmaceutical compounds.

- Energy Storage Research: Utilized in the production of materials for energy storage solutions, such as the separation and storage of gases like hydrogen in powder form.

- Scientific Research: Widely used in academic and industrial research labs for the synthesis and characterization of new materials, including the production of amorphous materials and the study of crystal defects.

Detail & Parts

Features

The Mini Planetary Ball Mill is a compact, high-performance milling solution designed specifically for routine laboratory work. This equipment is engineered to efficiently grind sample materials down to ultrafine and nano-sized particles, which are crucial for the development of innovative products. Here are the key features that make the Mini Planetary Ball Mill an indispensable tool in laboratory settings:

- High-Energy Milling: The mill utilizes a unique mechanism where the rotation directions of the bowl and turn disc are opposite, creating a synchronized alternation of centrifugal forces. This setup results in a high impact energy of the milling balls, which is up to 40 times higher than that due to gravitational acceleration, enabling high-speed milling and efficient size reduction.

- Versatile and Safe: Designed to handle various sample types and operate with potentially dangerous solvents, the Mini Planetary Ball Mill is equipped with robust safety features. It is engineered to withstand constant vibration and can be left unattended for long periods, ensuring user safety and operational reliability.

- Compact and Durable: Despite its powerful capabilities, the Mini Planetary Ball Mill is compact in size, making it suitable for laboratory environments where space is a premium. Its sturdy construction ensures durability and long-term reliability, even under demanding conditions.

- Production of Nano Powders: Capable of producing nano powders ranging from 2 to 20 nm in size, this mill is ideal for applications requiring the synthesis of materials at the nanoscale. The size of the nano powder can be adjusted by varying the speed of the rotation of the balls.

- Cost-Effective and Easy to Use: As a mechanical process, ball milling is relatively inexpensive and straightforward to operate. It does not require complex setups or extensive training, making it accessible for a wide range of laboratory personnel.

These features collectively make the Mini Planetary Ball Mill an excellent choice for laboratories looking to achieve precise and efficient grinding of materials for various research and development applications.

Advantages

The Mini Planetary Ball Mill offers a range of significant advantages for laboratory grinding applications:

- High Grinding Efficiency: The mill's unique design, where the rotation directions of the bowl and turn disc are opposite, creates a synchronized centrifugal force. This results in a high impact energy of up to 40 times higher than gravitational acceleration, enabling rapid and efficient grinding of materials, even those with high hardness and viscosity. The fineness of the ground product can reach sub-micron levels, making it ideal for producing nano powders of 2 to 20 nm in size.

- Versatility and Wide Range of Application: This mill is suitable for grinding a variety of materials, including magnetic materials, inorganic non-metallic materials, organic chemical materials, and biomedical materials. Its ability to handle different sample types makes it a versatile tool in research and development settings.

- Simple Maintenance and User-Friendly Operation: With a simple structure, the Mini Planetary Ball Mill is easy to use and maintain. Users only need to focus on the addition of materials and basic daily maintenance to ensure the equipment's normal operation, reducing downtime and operational complexity.

- Safety and Reliability: Designed to withstand constant vibration and long grinding times, the mill is equipped with robust safety features. This is crucial as the equipment may be left unattended for extended periods and used with potentially hazardous solvents. The sturdy drive concepts and stable operation enhance the mill's reliability and safety.

- High Precision Grinding: The mill's dynamic interaction between frictional and impact forces provides a high degree of size reduction with precision. This is particularly beneficial for applications requiring fine grinding and high precision, such as in the production of colloid particles and other nanomaterials.

- Energy-Efficient and Cost-Effective: Despite its high-speed milling capabilities, the Mini Planetary Ball Mill is an energy-efficient solution. It is also cost-effective, as it requires minimal operational costs and maintenance, making it an economical choice for laboratories.

These advantages make the Mini Planetary Ball Mill an indispensable tool for researchers and scientists looking to achieve high-quality grinding results in a safe, reliable, and efficient manner.

Functions

- Continuous and intermittent operation

- Emergency stop

- Timing

- Power failure memory

- Overload and dangerous operation protection

Technical specifications

| Grinding principle | Impact & friction force |

| Suitable materials | Small and medium-low hardness; Brittle; Dry or wet |

| Materials input size | < 2 mm |

| Materials output size | 0.1-20 um |

| Processing volume | < 400 ml |

| Grinding jar speed | 0-900 r/min |

| Grinding jar material | Tungsten carbide; Ceramic; Agate; Stainless steel; Harden steel; Nylon, etc. |

| Number of grinding jar | 4 pcs |

| Grinding jar volume | < 100 ml |

| Grinding ball material | Tungsten carbide; Zirconia; Alumina; Agate; Stainless steel, etc. |

| Motor power | 250W |

| Net weight | 35 kg |

| Dimensions | L500 * W300 * H350 mm |

| Protection level | IP65 |

| Quality standards | CE |

Warnings

Operator safety is the top important issue! Please operate the equipment with cautions. Working with inflammable& explosive or toxic gases is very dangerous, operators must take all necessary precautions before starting the equipment. Working with positive pressure inside the reactors or chambers is dangerous, operator must fellow the safety procedures strictly. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

FAQ

What Is Milling Equipment Used For?

What Are The Different Types Of Milling Equipment?

What Materials Can Be Processed Using Milling Equipment?

How Does Milling Equipment Work?

What Are The Advantages Of Using Milling Equipment?

What Factors Should Be Considered When Selecting Milling Equipment?

4.9 / 5

Incredible value! The grinding efficiency is phenomenal, producing nano powders with ease. A game-changer for our materials research.

4.8 / 5

Superb quality and so durable. It handles long, unattended runs flawlessly. The safety features are a massive relief for our lab.

4.7 / 5

Arrived faster than expected! The technological advancement is clear—high-energy milling in such a compact, user-friendly design.

4.9 / 5

Precision grinding at its finest. The versatility for different materials is outstanding. Worth every penny for serious R&D.

4.8 / 5

A robust workhorse! The build quality is exceptional. It simplifies our pharmaceutical sample prep dramatically.

4.7 / 5

The speed and consistency are unmatched. Fantastic investment that has accelerated our energy storage research projects.

4.9 / 5

Absolutely love it! The ease of use and maintenance is a huge plus. Delivers professional-grade results reliably.

4.8 / 5

Top-tier performance. The cost-effectiveness for producing 2-20nm powders is incredible. A must-have lab instrument.

4.8 / 5

A robust workhorse! The build quality is exceptional. It simplifies our pharmaceutical sample prep dramatically.

4.7 / 5

The speed and consistency are unmatched. Fantastic investment that has accelerated our energy storage research projects.

4.9 / 5

Absolutely love it! The ease of use and maintenance is a huge plus. Delivers professional-grade results reliably.

4.8 / 5

Top-tier performance. The cost-effectiveness for producing 2-20nm powders is incredible. A must-have lab instrument.

4.9 / 5

Incredible value! The grinding efficiency is phenomenal, producing nano powders with ease. A game-changer for our materials research.

4.8 / 5

Superb quality and so durable. It handles long, unattended runs flawlessly. The safety features are a massive relief for our lab.

4.7 / 5

Arrived faster than expected! The technological advancement is clear—high-energy milling in such a compact, user-friendly design.

4.9 / 5

Precision grinding at its finest. The versatility for different materials is outstanding. Worth every penny for serious R&D.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

The KT-P2000H uses a unique Y-axis planetary trajectory, and utilizes the collision, friction and gravity between the sample and the grinding ball.

Small Injection Molding Machine for Lab Use

The small injection molding machinehas fast and stable movements; good controllability and repeatability, super energy saving; the product can be automatically dropped and formed; the machine body is low, convenient for feeding, easy to maintain, and no height restrictions on the installation site.

Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

Discover the Liquid Nitrogen Cryogenic Grinding Machine, perfect for lab use, ultra-fine pulverization, and preserving material properties. Ideal for pharmaceuticals, cosmetics, and more.

Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

Precision metallographic mounting machines for labs—automated, versatile, and efficient. Ideal for sample prep in research and quality control. Contact KINTEK today!

Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

The single-punch electric tablet press is a laboratory-scale tablet press suitable for corporate laboratories in pharmaceutical, chemical, food, metallurgical and other industries.

Double Plate Heating Press Mold for Lab

Discover precision in heating with our Double Plate Heating Mold, featuring high-quality steel and uniform temperature control for efficient lab processes. Ideal for various thermal applications.

Powerful Plastic Crusher Machine

KINTEK's powerful plastic crusher machines process 60-1350 KG/H of diverse plastics, ideal for labs and recycling. Durable, efficient, and customizable.

Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

KT-VD200 can be used for sieving tasks of dry and wet samples in the laboratory. The screening quality is 20g-3kg. The product is designed with a unique mechanical structure and an electromagnetic vibrating body with a vibration frequency of 3000 times per minute.

Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

Efficiently prepare your samples with our Automatic Heated Lab Press. With a pressure range up to 50T and precise control, it's perfect for various industries.

Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

The herbal powder sterilization autoclave machine for Chinese medicine uses saturated steam for effective sterilization. It utilizes the heat and penetrative properties of steam, achieves sterilization after heat preservation, and maintains a good drying effect with a dedicated drying system.

High Precision Diamond Wire Cutting Machine Laboratory Saw Precision Wire EDM Cutting Machine

The high precision diamond wire cutting machine is a versatile and precise cutting tool designed specifically for material researchers. It utilizes a continuous diamond wire cutting mechanism, enabling precise cutting of brittle materials such as ceramics, crystals, glass, metals, rocks, and various other materials.

Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

The cast film machine is designed for the molding of polymer cast film products and has multiple processing functions such as casting, extrusion, stretching, and compounding.

Lab Blown Film Extrusion Three Layer Co-Extrusion Film Blowing Machine

Lab blown film extrusion is mainly used to detect the feasibility of film blowing of polymer materials and the colloid condition in the materials, as well as the dispersion of colored dispersions, controlled mixtures, and extrudates;

Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

Rotary tablet punching machine is an automatic rotating and continuous tableting machine. It is mainly used for tablet manufacturing in the pharmaceutical industry, and is also suitable for industrial sectors such as food, chemicals, batteries, electronics, ceramics, etc. to compress granular raw materials into tablets.

Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

The electric tablet punching machine is a laboratory equipment designed for pressing various granular and powdery raw materials into discs and other geometric shapes. It is commonly used in pharmaceutical, healthcare products, food, and other industries for small batch production and processing. The machine is compact, lightweight, and easy to operate, making it suitable for use in clinics, schools, laboratories, and research units.

Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

The wet three-dimensional vibrating sieving instrument focuses on solving the sieving tasks of dry and wet samples in the laboratory. It is suitable for sieving 20g - 3kg dry, wet or liquid samples.

Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

The desktop fast steam sterilizer is a compact and reliable device used for rapid sterilization of medical, pharmaceutical, and research items. It efficiently sterilizes surgical instruments, glassware, medicines, and resistant materials, making it suitable for various applications.

Related Articles

Planetary Ball Mills: Research Tools for Efficient Mixing and Nanoscale Grinding

Planetary ball mills are indispensable tools in modern laboratories, serving a crucial role in the mixing, fine grinding, and preparation of small samples. These mills are particularly adept at dispersing nanomaterials and facilitating the development and small-scale production of high-tech materials.

Advantages of Planetary Ball Mill in Laboratory Applications

Discover the advantages of using planetary ball mills in laboratory settings. Learn about its ability to produce fine powder, suitability for toxic materials, wide range of applications, continuous operation, and usage for milling abrasive materials. Explore how planetary ball mills differ from traditional milling machines and their function in creating ultrafine and nano-sized materials.

Features of Different Laboratory Mills: An Overview

Laboratory mills are specialized machines used to reduce non-homogenous batch samples into smaller, representative samples that are more uniform in composition.

Maximizing Grinding Efficiency: The Power of Planetary Ball Mills

Discover why planetary ball mills offer higher grinding efficiency than ordinary ball mills. Learn about the technology behind their high-performance all-round capabilities. Find out the key factors influencing the productivity and specific energy consumption of ball mills.

Key Features of the Micro Tissue Grinder: Usage, Advantages, and Applications

Discover the key features of the Micro Tissue Grinder, including usage instructions, advantages, and application fields. Learn the principles and structure of the Micro Tissue Grinder, and explore its benefits in sample preparation and industrial settings.

Disc / Cup Vibratory Mill: A Comprehensive Guide to Grinding Equipment

Discover the world of Disc / Cup Vibratory Mills! This guide covers everything from types and features to applications and benefits. Explore the versatility of these mills for grinding various materials in industries like pharmaceuticals, food, and chemicals.

Choosing the Best Material for Ball Mill: Essential Factors and Recommendations

Discover the best material for ball mill applications and grinding success. Learn about the features and benefits of stainless steel, ceramic, agate, and tungsten carbide media. Find out how to ensure grinding success and the ideal grinding jars and media for planetary ball milling. Explore the applications of ball mills and the advantages of high-energy ball mills for ultra-fine particles.

10 Common Dry Ultrafine Crushing Processes

Overview of various dry ultrafine crushing methods and their components.

Application of Low-Temperature Pulverization Technology in the Spice Industry

Explores the benefits of low-temperature pulverization for maintaining spice quality and efficiency.

Techniques and Methods of Freeze Pulverization for Powdered Rubber

An overview of various methods for producing powdered rubber through freeze pulverization, including liquid nitrogen and air turbine expander cold methods.

Why Your Laminator Keeps Ruining Documents—And How to Stop It for Good

Tired of your laminator turning thermal prints or photos into black smudges? Discover the simple reason it happens and how to choose the right method.

Why Your Compression Tests Are Failing (And It’s Not Your Sample’s Fault)

Discover the hidden reason your material compression tests fail and damage equipment. Learn why the press platen, not the sample, is often the culprit.