Introduction to Freeze Pulverization

Raw Materials and Isolation Agents

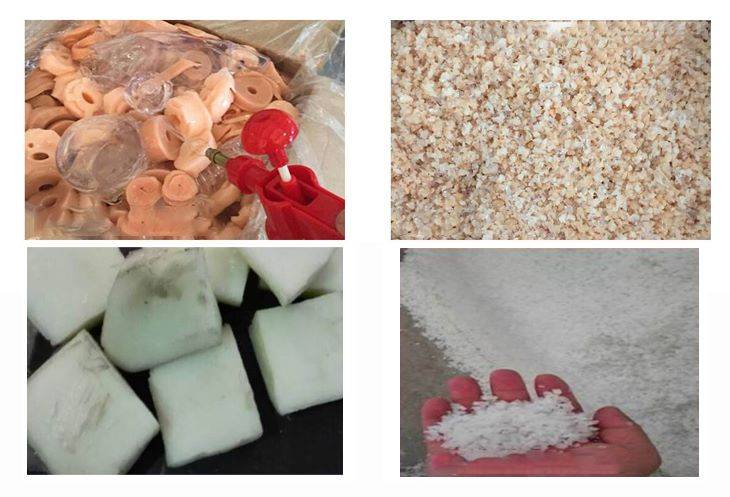

The raw materials commonly employed in the freeze pulverization process for powdered rubber include raw rubber blocks, raw rubber granules, and waste rubber. These materials are selected due to their ability to withstand the extreme cold conditions without compromising their structural integrity. The choice of raw materials is crucial as it directly impacts the quality and consistency of the final powdered rubber product.

In addition to the raw materials, the use of isolation agents is essential to prevent agglomeration and ensure the uniform dispersion of the powdered rubber. Commonly used isolation agents include silicon carbon black and silica. These agents act as barriers, preventing the rubber particles from sticking together during the grinding process. The effectiveness of these isolation agents is paramount, as their proper application can significantly enhance the efficiency and output of the freeze pulverization process.

| Isolation Agent | Function |

|---|---|

| Silicon Carbon Black | Prevents agglomeration and ensures uniform dispersion of rubber particles |

| Silica | Acts as a barrier to prevent rubber particles from sticking together |

The selection and application of both raw materials and isolation agents are critical steps in the freeze pulverization process, influencing the overall quality and performance of the powdered rubber produced.

Types of Refrigerants

In the process of freeze pulverization for powdered rubber, the choice of refrigerant plays a crucial role in determining the efficiency and quality of the final product. The two primary refrigerants employed in this process are liquid ammonia and air turbine expanders. Each of these methods has its unique characteristics and applications, contributing to the diverse range of powdered rubber products available.

Liquid Ammonia Freezing Method

The liquid ammonia freezing method involves the use of liquid ammonia as a refrigerant to rapidly freeze the rubber material. This method is particularly effective due to ammonia's high thermal conductivity, which allows for rapid heat transfer and efficient freezing. The rapid freezing process helps in preserving the molecular structure of the rubber, thereby maintaining its inherent properties. This method is often preferred for applications where the preservation of rubber's elasticity and flexibility is critical.

Air Turbine Expander Cold Method

In contrast, the air turbine expander cold method utilizes the Joule-Thomson effect to achieve cooling. This method involves expanding high-pressure air through a turbine, which results in a significant drop in temperature. The cold air produced is then used to freeze the rubber material. This technique is advantageous in industrial settings due to its energy efficiency and scalability. It is particularly suitable for large-scale operations where continuous and efficient cooling is required.

Both methods have their distinct advantages and are chosen based on the specific requirements of the production process, such as the desired particle size, production volume, and the need to preserve certain material properties. The selection of the appropriate refrigerant method is thus a critical decision in the freeze pulverization process, influencing the overall efficiency and quality of the powdered rubber produced.

Methods of Cryogenic Pulverization

Two-step Liquid Nitrogen Spraying Method

The process begins with the glue block being meticulously cut into uniform pieces measuring 150mm x 150mm. These pieces are then subjected to an initial spray of liquid nitrogen, which rapidly lowers their temperature to an ultra-cold -80℃. At this frigid temperature, the rubber block becomes brittle, allowing for its coarsely crushing to particles less than 2mm in size.

Following this initial crushing, the rubber particles, now reduced to below 2mm, undergo a second round of liquid nitrogen spraying. This secondary freezing step ensures that the particles are uniformly chilled, further enhancing their brittleness. Subsequently, the particles are subjected to fine crushing, a process that continues until over 95% of the pellets achieve a particle size of less than 150um. This two-step approach not only ensures a high yield of fine powder but also maintains the integrity and quality of the rubber material throughout the process.

Deep Cooling Method

In the deep cooling method, the entire rubber block is submerged in a liquid nitrogen bath, subjected to rapid deep freezing at temperatures as low as -160°C. This extreme cold causes the rubber to become brittle, enabling it to shatter into smaller pieces. These smaller rubber fragments are then fed into a hammer mill crusher. As the rubber is being crushed, liquid nitrogen is continuously sprayed at -80°C to maintain the material's brittleness and facilitate further fragmentation. This process continues until the rubber particles are reduced to a size of 150 micrometers or less.

This method is particularly effective for materials that are difficult to pulverize at normal temperatures due to their elasticity and resilience. The use of liquid nitrogen not only ensures that the rubber remains in a brittle state but also prevents the material from adhering to the machinery, thereby enhancing the efficiency of the crushing process. The deep cooling method is a critical step in the production of powdered rubber, offering a reliable and efficient means of achieving the desired particle size for various industrial applications.

Normal Temperature and Low Temperature Combination Method

The exclusive reliance on either the normal temperature method or the low temperature method presents significant challenges in producing finely powdered rubber. The normal temperature method often falls short in achieving the desired fineness, while the low temperature method, though effective, incurs excessive energy costs. Consequently, a hybrid approach that integrates both room temperature and low temperature processes emerges as a pragmatic solution.

Initially, the rubber is subjected to a preliminary crushing phase at room temperature, reducing the bulk material into manageable 6mm fragments. This step facilitates the subsequent cryogenic treatment, where the fragmented rubber is exposed to -80°C liquid nitrogen. The rapid freezing immobilizes the rubber particles, rendering them brittle and susceptible to fine crushing.

Upon achieving the desired brittleness, the frozen rubber is subjected to either a tooth disc mill or a hammer mill for the final crushing stage. This meticulous process ensures that the rubber particles are reduced to an average diameter of less than 150μm. Alternatively, the frozen fragments can be introduced into a cryogenic grinder, which employs similar principles to achieve the requisite particle size.

This combined methodology not only optimizes the energy expenditure but also enhances the fineness and uniformity of the powdered rubber, making it a superior choice in industrial applications.

Benefits of Cryogenic Grinding

Efficiency in Grinding

Cryogenic grinding significantly enhances the recovery capacity of various materials, particularly those traditionally challenging to pulverize through conventional methods. This technique leverages ultracold media to achieve more efficient grinding processes. For instance, materials like plastics and rubbers, which are known for their toughness and flexibility, can be effectively ground by subjecting them to extreme cold temperatures.

One of the most common methods involves freezing these materials at temperatures as low as -160°C using liquid nitrogen. This deep cooling method not only hardens the materials but also makes them more brittle, facilitating easier and more precise grinding. The process can be broken down into several key steps:

- Material Preparation: Raw materials, such as rubber blocks or plastic granules, are first cut into manageable pieces.

- Initial Freezing: These pieces are then exposed to liquid nitrogen, rapidly lowering their temperature to -160°C.

- Coarse Grinding: The frozen pieces are subjected to coarse grinding, reducing them to smaller fragments.

- Secondary Freezing: The smaller fragments are again exposed to liquid nitrogen to ensure uniform freezing.

- Fine Grinding: Finally, these uniformly frozen fragments are finely ground to the desired particle size, often less than 150 micrometers.

This systematic approach ensures that the materials are not only ground more efficiently but also to a consistent and uniform particle size, which is crucial for various industrial applications.

Related Products

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Powerful Plastic Crusher Machine

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

- Mini Planetary Ball Mill Machine for Laboratory Milling

Related Articles

- Application of Ultra-Micro Pulverization Technology in the Food Industry

- Development and Principles of Frozen Tissue Crushers

- Exploring the World of Molecular Cuisine

- Why Ultra-Low Temps are Non-Negotiable: The Science Behind Preserving Critical Biological Materials

- Cryogenic Pulverization Technology and Its Applications