Introduction to Ultra-Micro Pulverization Technology

Emergence and Development

Ultra-micro pulverization technology represents a significant leap forward in food processing, emerging from the convergence of advancements in multiple high-tech fields. This innovative technology has been shaped by the rapid progress in modern chemical engineering, electronics, biology, materials science, and the mineral industries. Each of these disciplines has contributed unique insights and methodologies that have collectively pushed the boundaries of what is possible in food processing.

The development of ultra-micro pulverization technology is not merely an extension of existing methods but a paradigm shift that leverages cutting-edge scientific research. For instance, advancements in chemical engineering have enabled the creation of more efficient and precise grinding mechanisms, while innovations in electronics have facilitated the integration of sophisticated control systems to optimize processing parameters. Biological insights have informed the selection of optimal conditions to preserve the nutritional and sensory qualities of food products.

Moreover, the materials science and mineral industries have played crucial roles in developing robust, high-performance materials for grinding tools and equipment, ensuring durability and efficiency in the pulverization process. This multidisciplinary approach has culminated in a technology that not only enhances the texture and quality of food products but also opens new avenues for product innovation and market expansion.

In essence, the emergence and development of ultra-micro pulverization technology reflect the synergistic effects of various scientific and industrial advancements, positioning it as a cornerstone of modern food processing.

Global Applications

Ultra-micro pulverization technology has found widespread application across various countries, particularly in the United States and Japan, where it has been instrumental in the development and marketing of innovative food products. This technology has enabled the creation of a diverse range of products, including fruit-flavored herbal teas, freeze-dried fruit powders, and ultra-low-temperature frozen turtle powders. These products not only cater to the growing consumer demand for natural and healthy food options but also leverage the advanced processing capabilities offered by ultra-micro pulverization.

In the United States, the technology has been pivotal in enhancing the texture and nutritional profile of herbal teas, making them more appealing to health-conscious consumers. Similarly, Japan has utilized ultra-micro pulverization to produce high-quality, freeze-dried fruit powders that retain the natural flavors and nutrients of the fruits, even after extensive processing. Additionally, the ultra-low-temperature freezing technique employed in turtle powder production ensures that the nutritional integrity of the turtle meat is preserved, making it a premium product in the market.

The success of these applications underscores the versatility and effectiveness of ultra-micro pulverization technology in meeting the evolving demands of the global food industry. By refining and enhancing the processing techniques, this technology continues to open new avenues for innovation and product development, contributing to the overall advancement of the food sector.

Principles and Advantages of Ultra-Micro Pulverization

Technology Principles

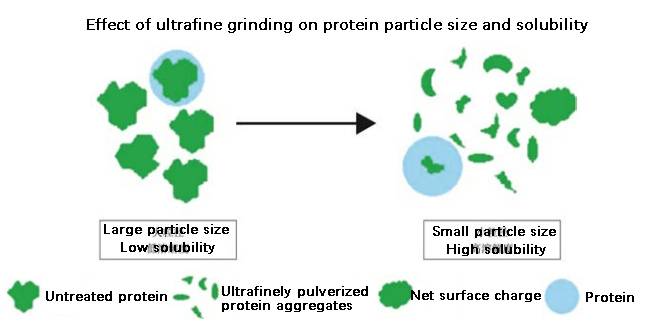

Ultra-micro-grinding technology represents a sophisticated method of material processing, leveraging specialized equipment such as laboratory mill equipment to reduce particles to dimensions significantly below 25μm. This precision grinding not only refines the physical structure of the materials but also amplifies their interfacial activity and functional properties.

The core principle revolves around the application of high-energy milling techniques that break down larger particles into ultra-fine sizes. This process is akin to a controlled explosion of material integrity, where the force exerted by the grinding tools disintegrates the material at a molecular level. The result is a homogenous distribution of particles, each contributing to enhanced surface area and reactivity.

In practical terms, this technology is akin to a microscopic sculptor, meticulously carving away at the material to reveal its hidden potential. The ultra-fine particles produced are not merely smaller versions of their original selves; they are transformed entities with heightened capabilities. This transformation is crucial in industries where material interaction and reactivity are paramount, such as in the development of advanced pharmaceuticals, high-performance materials, and, notably, in the food industry where nutrient absorption and flavor enhancement are key.

The implications of this technology extend beyond mere size reduction. It introduces a paradigm shift in how materials are perceived and utilized, opening new avenues for innovation and application. By harnessing the power of ultra-micro-grinding, industries can unlock unprecedented levels of efficiency and performance, paving the way for next-generation products and processes.

Advantages

Ultra-micro pulverization technology stands out for its numerous advantages, making it a transformative force in the food industry. One of its most notable benefits is its ability to achieve fast speed and low-temperature pulverization. This dual capability ensures that delicate nutrients and flavors are preserved, minimizing degradation during the pulverization process.

The technology excels in producing fine particle sizes with uniform distribution. This uniformity is crucial for enhancing the texture and consistency of food products, making them more appealing to consumers. Additionally, the fine particles improve the overall mouthfeel and solubility of the food, leading to better consumer satisfaction.

Another significant advantage is the saving of raw materials. By achieving high pulverization efficiency, the technology reduces waste and optimizes the use of raw ingredients. This not only lowers production costs but also contributes to more sustainable food processing practices.

Moreover, ultra-micro pulverization helps in reducing pollution. The precision of the process minimizes the generation of dust and other waste materials, making it an environmentally friendly option. This aligns with the growing global emphasis on sustainable and eco-friendly industrial practices.

The technology also improves chemical reaction speeds. Fine particles have a larger surface area, which accelerates chemical reactions, leading to faster and more efficient processing. This is particularly beneficial in food manufacturing, where rapid reactions can enhance product quality and consistency.

Finally, ultra-micro pulverization enhances nutrient absorption in food. The finely divided particles allow for better dispersion and interaction with digestive enzymes, improving the bioavailability of nutrients. This results in more nutritious and health-promoting food products, which are increasingly valued in today's health-conscious market.

In summary, the advantages of ultra-micro pulverization technology—fast speed, low-temperature processing, fine particle size, material savings, pollution reduction, improved reaction speeds, and enhanced nutrient absorption—collectively position it as a superior method for food processing.

Applications in the Food Industry

Food Processing Techniques

In the realm of food processing, several techniques have been developed to refine and enhance the quality of food products. These techniques include airflow, high-frequency vibration, rotary ball (rod) mill, and rotary roller. Each method has its unique advantages and applications, contributing to the diverse needs of the food industry.

| Technique | Description | Advantages |

|---|---|---|

| Airflow | Utilizes air currents to separate and process particles. | Efficient for delicate materials; reduces mechanical damage. |

| High-Frequency Vibration | Employs rapid vibrations to agitate and process materials. | Suitable for materials requiring precise handling; high throughput. |

| Rotary Ball (Rod) Mill | Uses rotating cylinders filled with grinding media to crush materials. | Effective for bulk processing; versatile for various material types. |

| Rotary Roller | Involves compressing materials between rotating rollers. | Ideal for creating uniform textures; suitable for large-scale operations. |

Among these, gas flow type ultramicrocrushing stands out as the most advanced technique. This method leverages gas dynamics to achieve ultra-fine particle sizes, typically below 25μm. The gas flow type ultramicrocrushing offers several benefits, including:

- Enhanced Interfacial Activity: The ultra-fine particles improve the surface area, leading to better chemical reactions and nutrient absorption.

- Uniform Particle Distribution: Ensures consistency in product quality and performance.

- Energy Efficiency: Reduces energy consumption compared to traditional methods.

- Environmental Benefits: Minimizes waste and pollution by optimizing the use of raw materials.

These advanced techniques not only enhance the processing efficiency but also contribute to the overall quality and nutritional value of food products.

Specific Applications

Ultra-micro pulverization technology has found extensive applications across multiple sectors of the food industry, each benefiting from its unique capabilities. In the soft drinks sector, this technology is employed to enhance the dispersion and stability of flavorings and nutrients, resulting in a smoother texture and improved taste. For fruit and vegetable processing, the technology ensures that the pulverized particles are fine enough to preserve the natural color, flavor, and nutrients, while also extending the shelf life of the products.

In grocery processing, ultra-micro pulverization is used to create finely ground powders from grains and legumes, which are then used in various food formulations, enhancing their nutritional profile and ease of use. The seafood processing industry leverages this technology to produce high-quality fish powders and protein isolates, which are essential for enriching pet foods and dietary supplements.

Moreover, in the realm of functional foods, ultra-micro pulverization plays a crucial role in the production of nutrient-dense powders that can be easily incorporated into everyday foods, boosting their health benefits. Lastly, in spice and seasoning processing, the technology ensures that the spices are ground to a uniform, ultra-fine consistency, enhancing their solubility and flavor release, thereby improving the overall taste and aroma of the final product.

Each of these applications underscores the versatility and effectiveness of ultra-micro pulverization technology in enhancing the quality and nutritional value of food products across the industry.

Related Products

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Disc Cup Vibrating Mill Multi-Platform for Lab

- Small Cryogenic Grinder Cryomill Cryogrinder with Liquid Nitrogen for Laboratory Use

- Lab Vibration Mill

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill with Screw Feeder