Milling Equipment

Laboratory Hybrid Tissue Grinding Mill

Item Number : KT-MT20

Price varies based on specs and customizations

- Recommended maximum injection size

- < 8 mm

- Sample particle size range

- ~5 um

- Grinding platform

- 2

- Vibration frequency

- 180-1800 r/min

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

K-MT20 is used for rapid grinding or mixing of dry, wet and frozen small amount of samples in the laboratory. It can be configured with two 50ml ball mill jars, and can also be configured with a variety of cell wall breaking adapters of different specifications for biological cell wall breaking and DNA /RNA and protein extraction, its structure design is compact, simple in appearance, desktop operation, small in size, adopts frequency conversion LCD screen control interface to realize timing, speed regulation, intermittent grinding and other functions, and the setting is simple and fast, and the display is intuitive. It is safe and stable to complete the sample processing in a few minutes after pressing the key. It can be widely used in many types of samples including hard, medium and low hardness, brittle, dry, viscous, fibrous, soft and elastic.

- Processing principle: impact force | friction force

- Application sample characteristics: hard | medium-low hardness | brittle | dry | viscous | fibrous | soft | elastic

- Processing Type: Grinding | Blending | Homogenization | Cell Disruption | Freeze Grinding

- Main functions: continuous operation | intermittent operation | timing | speed regulation | alternate variable speed operation | power failure memory | overload protection

Applications

The Hybrid Tissue Grinder is a versatile and efficient tool designed for various applications in industries such as food processing, manufacturing, steel grinding, recycling, and pharmaceuticals. This equipment is particularly beneficial for grinding and homogenizing a wide range of materials, including wet, soft, brittle, elastic, hard, dry, and fibrous substances. The grinder's ability to reduce materials to sizes as small as 2 microns and below, coupled with its use of compressed air instead of moving parts, makes it an ideal choice for maintaining sample integrity and preventing thermal degradation in heat-sensitive materials.

- Food Processing: Ideal for grinding high-temperature sensitive food items like cheese, dried fruits, and oily spices, ensuring flavor preservation.

- Manufacturing: Effective in pulverizing materials like carbon black without causing thermal degradation, essential for plastics, rubbers, pigments, and coatings.

- Steel Grinding: Helps in managing excessive heat generated during high-speed grinding processes by providing a cooling effect.

- Recycling: Efficiently crushes and prepares recyclable materials such as bottles, glass, tires, leather, and plastics for reuse.

- Pharmaceuticals: Used for pulverizing pharmaceutical powders, maintaining the efficacy of temperature-sensitive materials by preventing thermal degradation.

- Research and Development: Supports personalized grinding needs with a low-cost, plug-and-play setup, suitable for various laboratory grinding and homogenization tasks.

Advantages

The Hybrid Tissue Grinder offers a range of advantages that enhance laboratory efficiency and effectiveness. Key benefits include:

- Increased Productivity: The grinder optimizes particle size and increases throughput, leading to higher productivity in sample preparation.

- Elimination of Caking: The design prevents caking of products within the mill, ensuring smooth operation and maintenance.

- Decreased Wear: The use of advanced materials and design reduces wear on grinding equipment, extending the lifespan of the machinery.

- Separation of Composite Materials: The grinder effectively separates composite materials, aiding in the purity and quality of the final product.

- Higher Production Rate: With its efficient grinding mechanism, the Hybrid Tissue Grinder achieves a higher production rate, saving time and resources.

- Lower Energy Consumption: The grinder operates with lower energy consumption compared to traditional methods, making it more environmentally friendly and cost-effective.

- Fine Particle Size: It produces a fine particle size, which is crucial for many applications requiring high precision and uniformity.

- Uniform Particle Distribution: The grinder ensures a more uniform particle distribution, enhancing the quality and consistency of the ground materials.

- Lower Grinding Cost: The overall cost of grinding is reduced due to the efficiency and durability of the Hybrid Tissue Grinder.

- Improved Pouring Properties: Finely ground materials improve the pouring properties of the product, making it easier to handle and use in various applications.

- Easy Maintenance and Cleaning: The grinder features quick coupling mechanisms that allow for easy disassembly and cleaning, ensuring no contamination and maintaining the integrity of the samples.

- Compact Design: Its small footprint allows for efficient space utilization in the laboratory, making it a practical choice for tight spaces.

- Versatility: The grinder is suitable for a large number of different materials, making it a versatile tool in the lab.

Features

The Hybrid Tissue Grinder is a versatile and efficient tool designed for grinding and homogenizing a wide range of materials, from soft tissues to hard substances. This advanced laboratory equipment offers a combination of features that not only enhance its functionality but also provide significant benefits to users in terms of efficiency, versatility, and ease of use. Here are the key features that make the Hybrid Tissue Grinder a standout choice for various laboratory applications:

- Dual-Mode Operation: The grinder is designed to handle both dry and wet grinding processes, allowing users to switch between modes as needed. This dual functionality eliminates the need for multiple machines, saving space and reducing initial investment costs.

- Rotor-Stator Homogenization: Equipped with a rotor-stator system, the grinder efficiently processes samples by subjecting them to strong shear forces. This method is particularly effective for creating emulsions and blends, ensuring a smooth and uniform consistency.

- Bead Milling Capability: The inclusion of a bead mill enhances the grinder's ability to disperse and grind tiny particles in a slurry. The rotor-driven bead motion provides intense shear and collision forces, ideal for achieving fine particle sizes.

- Blade Type Homogenizers: With blades rotating at high speeds, the grinder generates significant shearing effects, suitable for a variety of materials including fibrous and elastic substances.

- High-Pressure Homogenization: Capable of handling materials with Mohs hardness ranging from 1 to 10, the grinder uses compressed air to achieve size reduction down to 2 microns or below. This feature is particularly beneficial for processing hard materials without the need for moving parts.

- Interchangeable Liners: Available in materials like Polyurethane, Stainless Steel, Nylon, and PTFE, the interchangeable liners ensure compatibility with different types of samples, reducing the risk of contamination and enhancing the durability of the grinder.

- Automatic Control System: The grinder comes with an automatic control system that simplifies operation and ensures consistent results. This feature is particularly useful for repetitive tasks and for maintaining high standards of precision in sample preparation.

- Customizable Design: Recognizing the unique needs of each laboratory, the Hybrid Tissue Grinder can be customized to meet specific requirements, ensuring that it is perfectly suited to the user's research and development needs.

These features collectively make the Hybrid Tissue Grinder an indispensable tool for laboratories looking to enhance their sample preparation processes, offering versatility, efficiency, and precision in a single, compact unit.

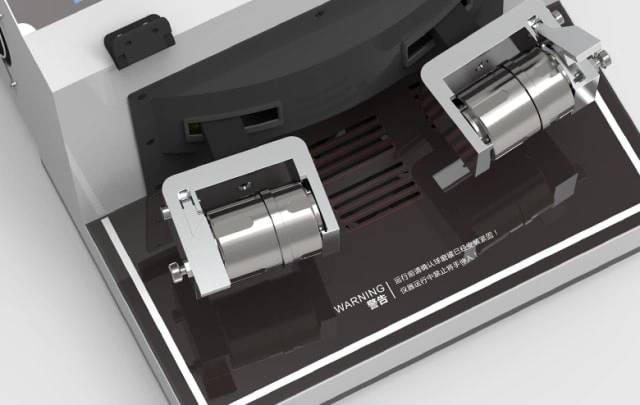

Detail & Parts

Technical specifications

| Recommended maximum injection size | < 8 mm |

| Sample particle size range | ~5 um |

| Grinding method | dry grinding | wet grinding | low temperature grinding |

| Grinding platform (number of tanks) | 2 |

| Movement mode | Y plane arc reciprocating movement |

| Vibration frequency | 180-1800 r/min |

| Control mode | LCD screen frequency conversion control |

| Time setting | 59:59:59 (h/m/s) |

| Ball mill material | tungsten carbide | zirconia | stainless steel | MC nylon | PTFE, etc. |

| Ball mill jar volume | 50ml | 30ml |

| Ball mill tank sealing method | sealing ring + thread fastening |

| Grinding ball size | 1-25m optional |

| Grinding ball material | tungsten carbide | zirconia | agate | stainless steel |

| Cell breaking adapter volume | 10X0.2ml | 5X2ml | 5X5ml |

| Electrical description | 100-110V/200-240V AC, 50-60Hz, 150W |

| Power port | National Standard | European Standard | American Standard | British Standard, etc. |

| Net weight | 48kg |

| Dimensions (length, width and height) | 470*360*250 |

| Protection class | IP63 |

| Standard | CE |

Warnings

Operator safety is the top important issue! Please operate the equipment with cautions. Working with inflammable& explosive or toxic gases is very dangerous, operators must take all necessary precautions before starting the equipment. Working with positive pressure inside the reactors or chambers is dangerous, operator must fellow the safety procedures strictly. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

4.9 / 5

The Hybrid Tissue Grinder is a game-changer in our lab. Its versatility and efficiency make it an indispensable tool for our research.

4.8 / 5

I'm very impressed with the Hybrid Tissue Grinder. It's incredibly easy to clean and maintain, saving us valuable time in the lab.

4.7 / 5

The Hybrid Tissue Grinder has exceeded our expectations. Its advanced technology delivers consistent and precise results, making it a reliable asset in our lab.

4.9 / 5

The Hybrid Tissue Grinder is an absolute lifesaver. It handles even the most challenging samples with ease, making our work so much easier.

4.8 / 5

I highly recommend the Hybrid Tissue Grinder. Its user-friendly design and intuitive interface make it a breeze to operate, even for beginners.

4.7 / 5

The Hybrid Tissue Grinder is a valuable addition to our lab. Its durability and longevity ensure that it will be a reliable companion for years to come.

4.9 / 5

The Hybrid Tissue Grinder is worth every penny. Its innovative features and exceptional performance make it an unbeatable choice for any laboratory.

4.8 / 5

The Hybrid Tissue Grinder has revolutionized our sample preparation process. Its speed and efficiency have significantly improved our productivity.

4.7 / 5

The Hybrid Tissue Grinder is an excellent investment. Its versatility and adaptability make it suitable for a wide range of applications, making it an indispensable tool in our lab.

4.9 / 5

The Hybrid Tissue Grinder is simply amazing. Its ease of use and exceptional results make it an absolute joy to work with.

4.8 / 5

The Hybrid Tissue Grinder has exceeded our expectations. Its compact design and powerful performance make it an ideal choice for space-constrained laboratories.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Laboratory High Throughput Tissue Grinding Mill Grinder

KT-MT is a high-quality, small, and versatile tissue grinder used for crushing, grinding, mixing, and cell wall breaking in various fields, including food, medical, and environmental protection. It is equipped with 24 or 48 2ml adapters and ball grinding tanks and is widely employed for DNA, RNA, and protein extraction.

Laboratory Micro Tissue Grinding Mill Grinder

KT-MT10 is a miniature ball mill with a compact structure design. The width and depth are only 15X21 cm, and the total weight is only 8 kg. It can be used with a minimum 0.2ml centrifuge tube or a maximum 15ml ball mill jar.

Laboratory Single Horizontal Jar Mill

KT-JM3000 is a mixing and grinding instrument for placing a ball milling tank with a volume of 3000ml or less. It adopts frequency conversion control to realize timing, constant speed, direction change, overload protection and other functions.

Mini Planetary Ball Mill Machine for Laboratory Milling

Discover the KT-P400 desktop planetary ball mill, ideal for grinding and mixing small samples in the lab. Enjoy stable performance, long service life, and practicality. Functions include timing and overload protection.

Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

Grind to perfection with alumina/zirconia grinding jars and balls. Available in volume sizes from 50ml to 2500ml, compatible with various mills.

Laboratory Four-Body Horizontal Jar Mill

The four-body horizontal tank mill ball mill can be used with four horizontal ball mill tanks with a volume of 3000ml. It is mostly used for mixing and grinding laboratory samples.

Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

Grind and mill with ease using metal alloy grinding jars with balls. Choose from 304/316L stainless steel or tungsten carbide and optional liner materials. Compatible with various mills and features optional functions.

Lab Vibration Mill

Vibration Mill for Efficient Sample Preparation, Suitable for Crushing and Grinding a Variety of Materials with Analytical Precision. Supports Dry / Wet / Cryogenic Grinding and Vacuum/Inert Gas Protection.

Laboratory Ten-Body Horizontal Jar Mill for Lab Use

The Ten-body horizontal jar mill is for 10 ball mill pots (3000ml or less). It has frequency conversion control, rubber roller movement, and PE protective cover.

Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

Discover the Liquid Nitrogen Cryogenic Grinding Machine, perfect for lab use, ultra-fine pulverization, and preserving material properties. Ideal for pharmaceuticals, cosmetics, and more.

High Energy Vibratory Laboratory Ball Mill Double Tank Type

High-energy vibration ball mill is a small desktop laboratory grinding instrument. It uses 1700r/min high-frequency three-dimensional vibration to make the sample achieve the result of grinding or mixing.

High Energy Vibratory Laboratory Ball Mill Grinding Mill Single Tank Type

High-energy vibration ball mill is a small desktop laboratory grinding instrument.It can be ball-milled or mixed with different particle sizes and materials by dry and wet methods.

Laboratory Disc Cup Vibratory Mill for Sample Grinding

The vibrating disc mill is suitable for non-destructive crushing and fine grinding of samples with large particle sizes, and can quickly prepare samples with analytical fineness and purity.

Disc Cup Vibrating Mill Multi-Platform for Lab

The multi-platform vibrating disc mill is suitable for non-destructive crushing and fine grinding of samples with large particle sizes. It is suitable for crushing and grinding applications of medium-hard, high-hard, brittle, fibrous, and elastic materials.

Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

The vertical cabinet structure combined with ergonomic design enables users to obtain the best comfortable experience in standing operation. The maximum processing capacity is 2000ml, and the speed is 1200 revolutions per minute.

Laboratory Horizontal Planetary Ball Mill Milling Machine

Improve sample uniformity with our Horizontal Planetary Ball Mills. KT-P400H reduces sample deposition and KT-P400E has multi-directional capabilities. Safe, convenient and efficient with overload protection.

Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

Controlled environment lab press machine for glove box. Specialized equipment for material pressing and shaping with high precision digital pressure gauge.

Related Articles

Key Features of the Micro Tissue Grinder: Usage, Advantages, and Applications

Discover the key features of the Micro Tissue Grinder, including usage instructions, advantages, and application fields. Learn the principles and structure of the Micro Tissue Grinder, and explore its benefits in sample preparation and industrial settings.

The Three Stages of Lab Crushing: A Comprehensive Guide

Learn about the three stages of crushing: primary, secondary, and tertiary, and how they are used in sample preparation for scientific analysis. Discover the different types of crushers and their applications in reducing bulky materials into smaller particles.

What is a Laboratory Crusher Used For?

Discover the uses and working mechanism of laboratory crushers. Explore various types of crushing equipment and their applications. Learn how laboratory crushers play a crucial role in scientific analysis and environmental studies.

Laboratory Crushers: A Comprehensive Guide to Their Uses and Functionality

Laboratory crushers play a crucial role in scientific research and analysis. These crushers, commonly known as jaw crushers, are indispensable in obtaining accurate and consistent results for sample preparation.

Features of Different Laboratory Mills: An Overview

Laboratory mills are specialized machines used to reduce non-homogenous batch samples into smaller, representative samples that are more uniform in composition.

PTFE Cleaning Racks: The Ultimate Guide to Cleaning and Drying Labware

In this comprehensive guide, we'll delve into the world of PTFE cleaning racks, exploring their benefits, applications, and the best practices for cleaning and drying labware to ensure optimal performance and longevity.

FTIR Pellet Press The Game-Changer in Spectroscopy Analysis

Fourier Transform Infrared Spectroscopy (FTIR) is a widely used analytical technique in the field of chemistry and materials science. It is a non-destructive method that allows the identification and quantification of chemical compounds in a sample.

In-depth Analysis of Tablet Press Machine R&D Lab Model (1)

The Tablet Press Machine R&D Model, also known as a single punch tablet press, is designed for the development and small batch production of tablets. It is widely used in industries such as pharmacy, chemical, food, and metallurgy. This machine operates automatically, continuously filling, pressing, and ejecting tablets. Its key features include high precision filling, low noise, low material consumption, and smooth operation. It is particularly useful for research and development in laboratories, hospitals, and plants, catering to small-scale production needs.

Understanding the Principles and Applications of Isostatic Pressing

In this process, the powder is filled in a mold and sealed tightly. This occurs outside the pressure vessel. After filling the mold with powder, the mold is submerged in the pressure fluid within the pressure vessel. Then isostatic pressure is applied to the external surface of the mold, compressing the powder into a solid mass.

Development and Principles of Frozen Tissue Crushers

Explore the history, classification, and principles of frozen tissue crushers, including grinding ball selection and how to choose the right crusher.

Technologies for Extracting Active Ingredients from Plants

Review of modern and traditional methods for extracting plant active ingredients, focusing on efficiency, cost, and environmental impact.

Laboratory Sample Preparation and Digestion Equipment

Overview of essential lab equipment for sample preparation and digestion.