Milling Equipment

Laboratory Disc Cup Vibratory Mill for Sample Grinding

Item Number : KT-DVM

Price varies based on specs and customizations

- Maximum injection size

- <15 mm

- Sample particle size range

- <20um

- Batch effective processing capacity

- 15-500ml

- Grinding disc speed

- 1500 r/min

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

The vibrating disc mill is a versatile laboratory equipment used for non-destructive crushing and fine grinding of various materials. It employs a high-speed circular motion to squeeze, collide, and rub samples, enabling rapid preparation of analytical-grade samples with particle sizes ranging from 15 mm to 20 microns. The mill supports dry, wet, cryogenic, vacuum, and inert gas protection grinding, ensuring sample purity. Its high load capacity, smooth operation, and short screening time make it ideal for processing medium-hard, hard, brittle, fibrous, and elastic materials.

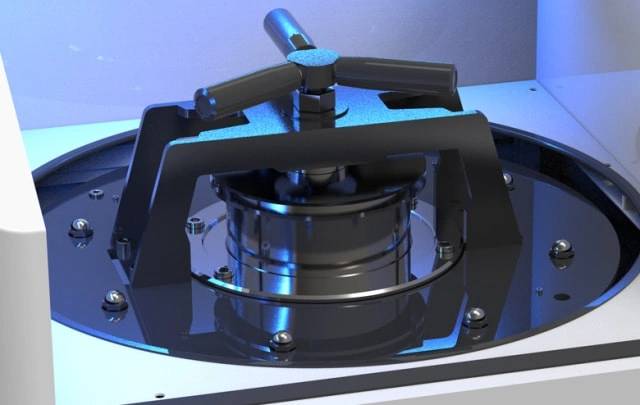

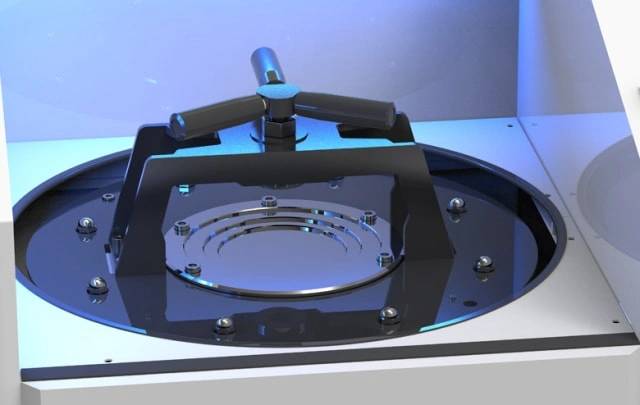

Detail & Parts

Applications

Vibrating disc mills and basket mills are widely used in various industries for sample preparation and material processing. Their main application areas include:

- Materials science: Sample preparation for X-ray diffraction (XRD), X-ray fluorescence (XRF), scanning electron microscopy (SEM), transmission electron microscopy (TEM), and other analytical techniques.

- Pharmaceuticals: Grinding of active pharmaceutical ingredients (APIs), excipients, and other pharmaceutical materials.

- Food processing: Grinding of spices, herbs, nuts, and other food products.

- Chemicals:Grinding of catalysts, pigments, dyes, and other chemical compounds.

- Electronics: Grinding of electronic waste, printed circuit boards (PCBs), and other electronic materials.

- Mining and metallurgy: Grinding of ores, minerals, and other mining materials.

- Environmental science: Sample preparation for soil, sediment, and other environmental analysis.

Features

The vibrating disc mill is a versatile piece of laboratory equipment that can be used for a variety of applications. Some of its key features include:

- High load capacity: The vibrating disc mill can handle large sample sizes, making it ideal for processing bulk materials.

- Extremely smooth operation and short screening time: The mill's smooth operation and short screening time make it efficient and easy to use.

- High separation efficiency: The mill's high separation efficiency ensures that the desired particle size is achieved.

- Wear-free and maintenance-free drives: The mill's drives are wear-free and maintenance-free, reducing downtime and maintenance costs.

Principle

A disc vibratory mill pulverizes materials through a process of high-speed circular motion. The sample, placed within a grinding disc kit, is subjected to intense squeezing, collision, and rubbing. This action effectively reduces the particle size of the sample, yielding analytical fineness and purity in a short timeframe (typically 3-5 minutes). The mill supports various grinding methods, including dry grinding, wet grinding, cryogenic grinding, vacuum grinding, and inert gas protection grinding.

Advantages

- High load capacity

- Extremely smooth operation and short screening time

- High separation efficiency

- The drives operate wear-free and require no maintenance

- More Power & Lifetime

- Various Capacity & Excellent Efficiency

Technical specifications

| Model | KT-DVM300 | KT-DVM600 |

| Maximum injection size | <15 mm | <15 mm |

| Sample particle size range | <20 um | <20 um |

| Batch effective processing volume | 15-250 ml | 15-500 ml |

| Grinding disc speed | 1500 r/min | 1500 r/min |

| Vacuum/inert protection grinding | support | support |

| Movement mode | circular movement | circular movement |

| Time setting | 9999min | 9999min |

| Number of grinding discs | 1 | 1 |

| Grinding disc volume | 50ml | 100ml | 250ml | 100ml | 250ml | 500ml |

| Grinding disc material | tungsten carbide | zirconia | agate | stainless steel, etc. | tungsten carbide | zirconia | agate | stainless steel, etc. |

| Grinding method | dry grinding | wet grinding | dry grinding | wet grinding |

| Electrical description | 380V, 50-60Hz, 1.5KW | 380V, 50-60Hz, 1.5KW |

| Power port | European standard | American standard | British standard | Australian standard, etc. | European standard | American standard | British standard | Australian standard, etc. |

| Net weight | 218kg | 228kg |

| Dimensions (W*D*H) | 780*650*1080mm | 780*650*1080mm |

| Protection class | IP65 | IP65 |

| Standard | CE | CE |

| Additional configurations can be added | cryogenic liquid nitrogen cooling | touch operating system | grinding disc temperature and pressure monitoring | cryogenic liquid nitrogen cooling | touch operating system | grinding disc temperature and pressure monitoring |

Warnings

Operator safety is the top important issue! Please operate the equipment with cautions. Working with inflammable& explosive or toxic gases is very dangerous, operators must take all necessary precautions before starting the equipment. Working with positive pressure inside the reactors or chambers is dangerous, operator must fellow the safety procedures strictly. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

4.8 / 5

The vibratory grinder is a lifesaver for our lab. It quickly grinds small pieces to the right size.

4.9 / 5

This lab mill is a game-changer. It's efficient, quiet, and produces consistent results.

4.7 / 5

This machine is a workhorse. It's been running smoothly for months without any issues.

5.0 / 5

I'm impressed with the build quality and performance of this vibratory mill. It's a great value for the price.

4.6 / 5

The programmable milling segment is a lifesaver. It allows me to customize the grinding process to my specific needs.

4.8 / 5

The safety mechanism is a great feature. It gives me peace of mind knowing that the machine will automatically shut off if there's a problem.

5.0 / 5

The LCD control panel is easy to use and informative. It provides all the necessary information at a glance.

4.9 / 5

This mill is a breeze to clean and maintain. It saves me valuable time and effort.

4.7 / 5

The customized power supply is a nice touch. It allows me to use the machine anywhere in the world.

5.0 / 5

The grinding jars and sun wheel are made of high-quality materials. They're durable and long-lasting.

4.8 / 5

The impact and friction principle of this mill produces excellent results. My samples are always evenly ground.

4.7 / 5

The multiple grinding bowls are a great feature. They allow me to grind different samples simultaneously.

5.0 / 5

The cryogenic grinding option is a game-changer for my research. It allows me to grind samples at extremely low temperatures.

4.9 / 5

The LED lighting and observation window are helpful features. They allow me to monitor the grinding process closely.

4.8 / 5

The high load capacity and short screening time make this mill a valuable asset to my lab.

4.7 / 5

The wear-free drives and maintenance-free operation save me time and money.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Lab Vibration Mill

Vibration Mill for Efficient Sample Preparation, Suitable for Crushing and Grinding a Variety of Materials with Analytical Precision. Supports Dry / Wet / Cryogenic Grinding and Vacuum/Inert Gas Protection.

High Energy Vibratory Laboratory Ball Mill Double Tank Type

High-energy vibration ball mill is a small desktop laboratory grinding instrument. It uses 1700r/min high-frequency three-dimensional vibration to make the sample achieve the result of grinding or mixing.

Disc Cup Vibrating Mill Multi-Platform for Lab

The multi-platform vibrating disc mill is suitable for non-destructive crushing and fine grinding of samples with large particle sizes. It is suitable for crushing and grinding applications of medium-hard, high-hard, brittle, fibrous, and elastic materials.

High Energy Vibratory Ball Mill for Lab Use

The high-energy vibrating ball mill is a high-energy oscillating and impacting multifunctional laboratory ball mill. The table-top type is easy to operate, small in size, comfortable and safe.

Mini Planetary Ball Mill Machine for Laboratory Milling

Discover the KT-P400 desktop planetary ball mill, ideal for grinding and mixing small samples in the lab. Enjoy stable performance, long service life, and practicality. Functions include timing and overload protection.

High Energy Vibratory Laboratory Ball Mill Grinding Mill Single Tank Type

High-energy vibration ball mill is a small desktop laboratory grinding instrument.It can be ball-milled or mixed with different particle sizes and materials by dry and wet methods.

Laboratory Grinding Mill Mortar Grinder for Sample Preparation

KT-MG200 mortar grinder can be used for mixing and homogenizing powder, suspension, paste and even viscous samples. It can help users realize the ideal operation of sample preparation with more regularization and higher repeatability.

Laboratory Micro Tissue Grinding Mill Grinder

KT-MT10 is a miniature ball mill with a compact structure design. The width and depth are only 15X21 cm, and the total weight is only 8 kg. It can be used with a minimum 0.2ml centrifuge tube or a maximum 15ml ball mill jar.

Laboratory Four-Body Horizontal Jar Mill

The four-body horizontal tank mill ball mill can be used with four horizontal ball mill tanks with a volume of 3000ml. It is mostly used for mixing and grinding laboratory samples.

Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

Grind to perfection with alumina/zirconia grinding jars and balls. Available in volume sizes from 50ml to 2500ml, compatible with various mills.

Laboratory Horizontal Planetary Ball Mill Milling Machine

Improve sample uniformity with our Horizontal Planetary Ball Mills. KT-P400H reduces sample deposition and KT-P400E has multi-directional capabilities. Safe, convenient and efficient with overload protection.

Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

The vertical cabinet structure combined with ergonomic design enables users to obtain the best comfortable experience in standing operation. The maximum processing capacity is 2000ml, and the speed is 1200 revolutions per minute.

Laboratory Single Horizontal Jar Mill

KT-JM3000 is a mixing and grinding instrument for placing a ball milling tank with a volume of 3000ml or less. It adopts frequency conversion control to realize timing, constant speed, direction change, overload protection and other functions.

Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

Grind and mill with ease using metal alloy grinding jars with balls. Choose from 304/316L stainless steel or tungsten carbide and optional liner materials. Compatible with various mills and features optional functions.

Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

KT-T200TAP is a slapping and oscillating sieving instrument for laboratory desktop use, with 300 rpm horizontal circular motion and 300 vertical slapping motions to simulate manual sieving to help sample particles pass through better.

Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

KT-VD200 can be used for sieving tasks of dry and wet samples in the laboratory. The screening quality is 20g-3kg. The product is designed with a unique mechanical structure and an electromagnetic vibrating body with a vibration frequency of 3000 times per minute.

Laboratory Hybrid Tissue Grinding Mill

KT-MT20 is a versatile laboratory device used for rapid grinding or mixing of small samples, whether dry, wet, or frozen. It comes with two 50ml ball mill jars and various cell wall breaking adapters for biological applications such as DNA/RNA and protein extraction.

Laboratory High Throughput Tissue Grinding Mill Grinder

KT-MT is a high-quality, small, and versatile tissue grinder used for crushing, grinding, mixing, and cell wall breaking in various fields, including food, medical, and environmental protection. It is equipped with 24 or 48 2ml adapters and ball grinding tanks and is widely employed for DNA, RNA, and protein extraction.

Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

The KT-V200 product focuses on solving common sieving tasks in the laboratory. It is suitable for sieving 20g-3kg dry samples.

Related Articles

Disc / Cup Vibratory Mill: A Comprehensive Guide to Grinding Equipment

Discover the world of Disc / Cup Vibratory Mills! This guide covers everything from types and features to applications and benefits. Explore the versatility of these mills for grinding various materials in industries like pharmaceuticals, food, and chemicals.

Disc / Cup Vibratory Mill: A Comprehensive Guide for Laboratory Experts

Discover the world of Disc / Cup Vibratory Mills! This comprehensive guide provides an in-depth understanding of their types, working principles, advantages, and applications in various industries, including pharmaceuticals, chemicals, and food processing.

Disc / Cup Vibratory Mill: A Comprehensive Guide to Its Functions and Applications

Discover the world of Disc / Cup Vibratory Mills with our in-depth guide. Learn about their working principles, applications, advantages, and key features. Explore the various types of vibratory mills and their suitability for different industries.

Features of Different Laboratory Mills: An Overview

Laboratory mills are specialized machines used to reduce non-homogenous batch samples into smaller, representative samples that are more uniform in composition.

Sieving technology for particle size analysis and its applications

Introducing screening technology, explaining the working principle of vibrating screens and the advantages of using them for particle size analysis in screening technology. Learn about the types of vibrating screens and how to choose one.

Three-Dimensional Vibrating Sieve: Working Principle and Application Fields

Discover the working principle and application fields of the three-dimensional vibrating screener. Learn how this laboratory equipment uses vibration force to efficiently separate and analyze granular materials. Explore its uses in the pharmaceutical, chemical, and various other industries.

What is a Laboratory Crusher Used For?

Discover the uses and working mechanism of laboratory crushers. Explore various types of crushing equipment and their applications. Learn how laboratory crushers play a crucial role in scientific analysis and environmental studies.

Laboratory Crushers: A Comprehensive Guide to Their Uses and Functionality

Laboratory crushers play a crucial role in scientific research and analysis. These crushers, commonly known as jaw crushers, are indispensable in obtaining accurate and consistent results for sample preparation.

The Scientific Principle of Sieving: Understanding Particle Size Distribution and Laboratory Test Sieves

Learn about the scientific principle of sieving, including the process of separating particles based on size, types of laboratory test sieves. Discover how sieving impacts various industries and the accuracy of particle sizing measurements.

Key Features of the Micro Tissue Grinder: Usage, Advantages, and Applications

Discover the key features of the Micro Tissue Grinder, including usage instructions, advantages, and application fields. Learn the principles and structure of the Micro Tissue Grinder, and explore its benefits in sample preparation and industrial settings.

The Pros and Cons of Different Lab Diamond Machine Methods

Lab-grown diamonds, also known as synthetic diamonds, are man-made diamonds produced in a laboratory setting.

The Ultimate Guide to the Application and Benefits of Vibratory Sieve Shaker in Laboratory Testing

Discover the extensive application of vibratory sieve shaker in laboratory testing for industries such as food, medicine, chemical, and more. Learn about the benefits of using a sieve shaker.