Milling Equipment

Laboratory Grinding Mill Mortar Grinder for Sample Preparation

Item Number : KT-MG200

Price varies based on specs and customizations

- Maximum injection size

- < 8 mm

- Sample particle size range

- 10-20um

- Batch effective processing capacity

- 10-190ml

- Maximum speed

- 100 rpm

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

KT-MG200 mortar grinder can be used for mixing and homogenizing powder, suspension, paste and even viscous samples. It can help users realize the ideal operation of sample preparation with more regularization and higher repeatability. The heavy manual grinding is replaced by more accurate machinery and electronics, which can bring you a more relaxed experience. F-RM200 can be equipped with cooling or heating equipment according to the needs. The instrument is small in size, light in weight, easy to use, easy to clean, and the consumables are also easy to disassemble and easy to clean. ) selection and replacement are simple and convenient, and can be applied to the application of different samples in different industries.

Processing principle: pressure | friction

Application sample characteristics: soft | hard | brittle | paste

Processing Type: Grinding

Main functions: timing | speed regulation | pause | gap grinding | password lock | observation window | feeding window | LED lighting

Features of Mortar Grinder

Mortar grinders are essential tools in laboratories for the efficient and precise grinding and mixing of various materials. These machines are designed to handle a wide range of materials, from soft biological samples to hard ceramics, ensuring a consistent and fine particle size that is crucial for many analytical and research applications. Here are some key features that make mortar grinders a valuable asset in any laboratory setting:

- Versatility in Material Processing: Mortar grinders can handle a diverse range of materials, making them suitable for laboratories that deal with different types of samples. This versatility ensures that the equipment can be used for multiple applications, enhancing its utility and cost-effectiveness.

- Precise Control Over Grinding Parameters: With adjustable speed settings and grinding times, users can fine-tune the grinding process to achieve the desired particle size and consistency. This precision is crucial for ensuring the accuracy and reliability of subsequent analyses.

- Ease of Use and Maintenance: Modern mortar grinders are designed with user-friendly interfaces and easy-to-clean components. This not only simplifies the operation but also reduces downtime for maintenance, thereby increasing productivity in the laboratory.

- Durability and Reliability: Constructed with high-quality materials, mortar grinders are built to withstand the rigors of frequent use and harsh grinding conditions. This durability ensures a long service life and consistent performance, minimizing the need for frequent replacements or repairs.

- Safety Features: Safety is a paramount concern in laboratory settings. Mortar grinders are equipped with safety mechanisms such as interlocks and emergency stop buttons, which protect users from accidental injuries and ensure compliance with safety standards.

- Integration with Laboratory Information Management Systems (LIMS): Some advanced models can be integrated with LIMS, allowing for automated data recording and process monitoring. This integration enhances the efficiency of laboratory workflows and ensures data integrity.

By incorporating these features, mortar grinders provide laboratories with a reliable and efficient means of preparing samples for various analytical procedures, thereby contributing to the overall productivity and success of scientific research and development.

Advantages

The Mortar Grinder stands out with its array of benefits that cater to various laboratory needs:

- Low-wear and Low-maintenance Design: The Mortar Grinder is engineered to minimize wear and tear, ensuring longevity and reducing the need for frequent maintenance, which saves time and resources.

- Operator Friendly Replacement of Grinding Vessels: The design allows for easy and quick replacement of grinding vessels, making it user-friendly and efficient for operators.

- Grinding Vessels in Steel or Ceramic: The availability of grinding vessels in both steel and ceramic options allows for customization to suit specific material requirements, enhancing versatility.

- Sound-insulated Housing: The machine features a sound-insulated housing that reduces noise levels, creating a more comfortable working environment.

- Safe Footing and Quiet Running: The Mortar Grinder provides a stable and secure base, ensuring safety, and operates quietly, contributing to a peaceful lab setting.

- Easy Operation: The intuitive design of the machine makes it straightforward to operate, reducing the learning curve for new users and improving overall lab productivity.

- Material Suction: The high-speed rotation of the self-priming pump blade generates a strong suction force, effectively drawing material into the grinding basket for efficient processing.

- Dispersion: The centrifugal force from the high-speed dispersing disc accelerates material dispersion, ensuring a thorough and high-efficiency mixing process.

- Dispersing Grinder with Excellent Efficiency: The combination of high-speed self-priming pump blades and dispersing discs results in a highly efficient grinding and dispersion cycle, eliminating material turning and circulation dead ends.

The Mortar Grinder is compatible with various grinding methods

- Vibratory Grinding: Ideal for processing small pieces of jaw-crushed samples to a suitable size, ensuring a consistent grind.

- Cryogenic Grinding: Offers increased productivity, elimination of caking, decreased wear on equipment, separation of composite materials, higher production rates, lower energy consumption, fine particle size, uniform particle distribution, lower grinding costs, improved pouring properties, and reduction in microbial load.

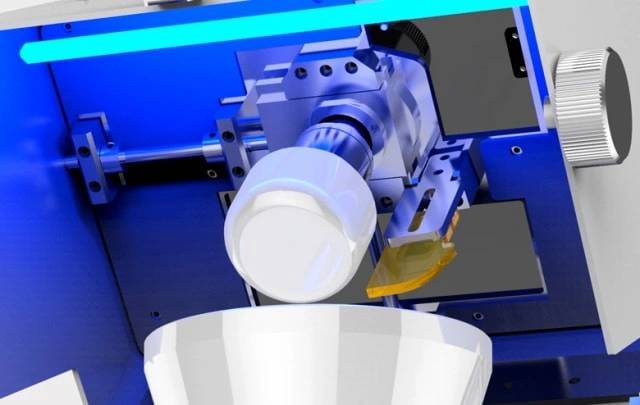

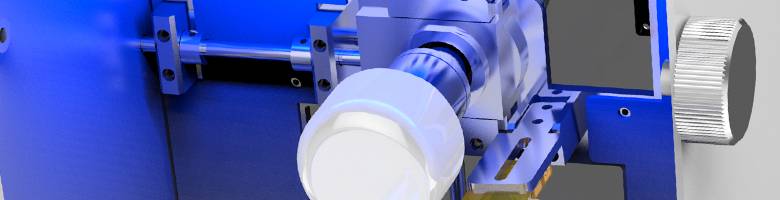

Detail & Parts

Technical specifications

| Suitable materials | soft | hard | brittle | pulpy |

| Treatment type | grinding |

| Maximum injection size | < 8 mm |

| Sample particle size range | < 10-20um |

| Batch effective processing capacity | 10-190ml |

| Maximum speed | 100 rpm |

| Mortar volume | 700ml |

| Mortar material | Zirconia | Tungsten Carbide | Onyx | Stainless Steel Available |

| Pestle material | Zirconia | Tungsten Carbide | Onyx | Stainless Steel Available |

| Material of pestle | Type 304 stainless steel |

| Usher and pestle pressure adjustment | Adjust the handle vertically |

| Usher and pestle position adjustment | Knob for lateral adjustment |

| Scraper material | PTFE | Nylon Optional |

| Scraper adjustment | Adjustable pressure | Adjustable lateral position |

| Grinding time setting | 9999 h | min | s |

| Stop time setting | 9999 h | min | s |

| Grinding method | Dry Grinding | Wet Grinding | Cryogenic Grinding |

| Net weight | 38 kg |

| Overall dimension | 310*330*430 mm |

| Electrical description | 110-220V, 50-60Hz, 150W |

| Protection level | IP65 |

| Quality standard | CE |

Warnings

Operator safety is the top important issue! Please operate the equipment with cautions. Working with inflammable& explosive or toxic gases is very dangerous, operators must take all necessary precautions before starting the equipment. Working with positive pressure inside the reactors or chambers is dangerous, operator must fellow the safety procedures strictly. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

FAQ

What Is A Laboratory Crusher Used For?

How Does A Laboratory Crusher Work?

What Are The Main Features Of A Laboratory Jaw Crusher?

What Is The Working Principle Of A Laboratory Jaw Crusher?

What Are The Advantages Of Using A Laboratory Crusher?

4.8 / 5

A great machine for grinding samples. Easy to use and clean, and the results are consistent.

4.9 / 5

The mortar grinder is a lifesaver in our lab. It's so much faster and easier than grinding samples by hand.

4.7 / 5

This mortar grinder is a great value for the price. It's well-made and does a great job of grinding samples.

4.8 / 5

I'm really happy with this mortar grinder. It's easy to use and clean, and it produces consistent results.

4.9 / 5

The mortar grinder is a great addition to our lab. It's made our sample preparation process much faster and easier.

4.7 / 5

This mortar grinder is a great investment. It's durable and does a great job of grinding samples.

4.8 / 5

I'm very impressed with this mortar grinder. It's easy to use and clean, and it produces very fine powders.

4.9 / 5

The mortar grinder is a great time-saver in our lab. It's much faster than grinding samples by hand.

4.7 / 5

This mortar grinder is a great value for the money. It's well-made and does a great job of grinding samples.

4.8 / 5

I'm really happy with this mortar grinder. It's easy to use and clean, and it produces consistent results.

4.9 / 5

The mortar grinder is a great addition to our lab. It's made our sample preparation process much faster and easier.

4.7 / 5

This mortar grinder is a great investment. It's durable and does a great job of grinding samples.

4.8 / 5

I'm very impressed with this mortar grinder. It's easy to use and clean, and it produces very fine powders.

4.9 / 5

The mortar grinder is a great time-saver in our lab. It's much faster than grinding samples by hand.

4.7 / 5

This mortar grinder is a great value for the money. It's well-made and does a great job of grinding samples.

4.8 / 5

I'm really happy with this mortar grinder. It's easy to use and clean, and it produces consistent results.

4.9 / 5

The mortar grinder is a great addition to our lab. It's made our sample preparation process much faster and easier.

4.7 / 5

This mortar grinder is a great investment. It's durable and does a great job of grinding samples.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Lab Vibration Mill

Vibration Mill for Efficient Sample Preparation, Suitable for Crushing and Grinding a Variety of Materials with Analytical Precision. Supports Dry / Wet / Cryogenic Grinding and Vacuum/Inert Gas Protection.

Mini Planetary Ball Mill Machine for Laboratory Milling

Discover the KT-P400 desktop planetary ball mill, ideal for grinding and mixing small samples in the lab. Enjoy stable performance, long service life, and practicality. Functions include timing and overload protection.

Laboratory Disc Cup Vibratory Mill for Sample Grinding

The vibrating disc mill is suitable for non-destructive crushing and fine grinding of samples with large particle sizes, and can quickly prepare samples with analytical fineness and purity.

Laboratory Micro Tissue Grinding Mill Grinder

KT-MT10 is a miniature ball mill with a compact structure design. The width and depth are only 15X21 cm, and the total weight is only 8 kg. It can be used with a minimum 0.2ml centrifuge tube or a maximum 15ml ball mill jar.

Laboratory High Throughput Tissue Grinding Mill Grinder

KT-MT is a high-quality, small, and versatile tissue grinder used for crushing, grinding, mixing, and cell wall breaking in various fields, including food, medical, and environmental protection. It is equipped with 24 or 48 2ml adapters and ball grinding tanks and is widely employed for DNA, RNA, and protein extraction.

Laboratory Single Horizontal Jar Mill

KT-JM3000 is a mixing and grinding instrument for placing a ball milling tank with a volume of 3000ml or less. It adopts frequency conversion control to realize timing, constant speed, direction change, overload protection and other functions.

Laboratory Four-Body Horizontal Jar Mill

The four-body horizontal tank mill ball mill can be used with four horizontal ball mill tanks with a volume of 3000ml. It is mostly used for mixing and grinding laboratory samples.

Laboratory Hybrid Tissue Grinding Mill

KT-MT20 is a versatile laboratory device used for rapid grinding or mixing of small samples, whether dry, wet, or frozen. It comes with two 50ml ball mill jars and various cell wall breaking adapters for biological applications such as DNA/RNA and protein extraction.

Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

Grind and mill with ease using metal alloy grinding jars with balls. Choose from 304/316L stainless steel or tungsten carbide and optional liner materials. Compatible with various mills and features optional functions.

Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

Grind to perfection with alumina/zirconia grinding jars and balls. Available in volume sizes from 50ml to 2500ml, compatible with various mills.

Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

Discover the Liquid Nitrogen Cryogenic Grinding Machine, perfect for lab use, ultra-fine pulverization, and preserving material properties. Ideal for pharmaceuticals, cosmetics, and more.

Nature Agate Mortar and Pestle for Grinding and Mixing

Get high-quality grinding results with Nature Agate Mortar and Pestle. Available in various sizes with shining polished grinding surfaces.

Laboratory Ten-Body Horizontal Jar Mill for Lab Use

The Ten-body horizontal jar mill is for 10 ball mill pots (3000ml or less). It has frequency conversion control, rubber roller movement, and PE protective cover.

Disc Cup Vibrating Mill Multi-Platform for Lab

The multi-platform vibrating disc mill is suitable for non-destructive crushing and fine grinding of samples with large particle sizes. It is suitable for crushing and grinding applications of medium-hard, high-hard, brittle, fibrous, and elastic materials.

Assemble Lab Cylindrical Press Mold

Get reliable and precise molding with Assemble Lab Cylindrical Press Mold. Perfect for ultra-fine powder or delicate samples, widely used in material research and development.

High Energy Vibratory Laboratory Ball Mill Grinding Mill Single Tank Type

High-energy vibration ball mill is a small desktop laboratory grinding instrument.It can be ball-milled or mixed with different particle sizes and materials by dry and wet methods.

Related Articles

What is a Laboratory Crusher Used For?

Discover the uses and working mechanism of laboratory crushers. Explore various types of crushing equipment and their applications. Learn how laboratory crushers play a crucial role in scientific analysis and environmental studies.

Laboratory Crushers: A Comprehensive Guide to Their Uses and Functionality

Laboratory crushers play a crucial role in scientific research and analysis. These crushers, commonly known as jaw crushers, are indispensable in obtaining accurate and consistent results for sample preparation.

The Three Stages of Lab Crushing: A Comprehensive Guide

Learn about the three stages of crushing: primary, secondary, and tertiary, and how they are used in sample preparation for scientific analysis. Discover the different types of crushers and their applications in reducing bulky materials into smaller particles.

Key Features of the Micro Tissue Grinder: Usage, Advantages, and Applications

Discover the key features of the Micro Tissue Grinder, including usage instructions, advantages, and application fields. Learn the principles and structure of the Micro Tissue Grinder, and explore its benefits in sample preparation and industrial settings.

Development and Principles of Frozen Tissue Crushers

Explore the history, classification, and principles of frozen tissue crushers, including grinding ball selection and how to choose the right crusher.

Laboratory Sample Preparation and Digestion Equipment

Overview of essential lab equipment for sample preparation and digestion.

Navigating XRD Testing Challenges

Guide on XRD applications, sample preparation, and data analysis.

Sample Preparation Methods in X-ray Fluorescence and Their Impact on Test Results

Explores the tablet and melting methods in X-ray fluorescence, detailing their advantages, disadvantages, and key considerations.

Comprehensive Application of Cold Isostatic Pressing Technology

An overview of the wide-ranging applications of cold isostatic pressing technology across various industries.