Introduction to X-ray Fluorescence Sample Preparation

Overview of Sample Preparation Importance

X-ray fluorescence spectrometry hinges on meticulous sample preparation to guarantee accurate and reliable results. This crucial step ensures that both standard and analytical samples undergo identical preparation processes, thereby maintaining the repeatability and reproducibility of the analysis.

To underscore the significance of sample preparation, consider the following key points:

-

Reduce Heterogeneity: Proper preparation techniques help in minimizing the variability within samples, ensuring that the analysis is representative of the entire population. This reduces the heterogeneity of the samples, making the results more consistent and trustworthy.

-

Minimize Variability: For consistent and reproducible results, it is imperative that samples are prepared uniformly. This involves using standardized methods and equipment to handle samples, thereby eliminating any potential sources of variability.

-

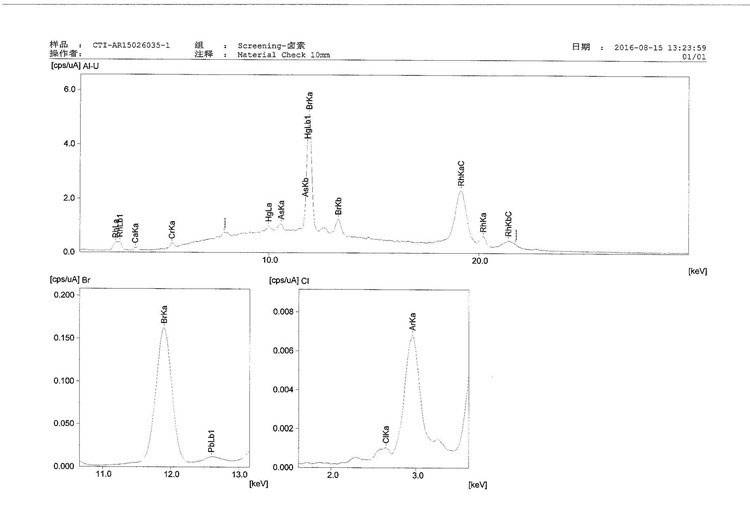

Eliminate Interference: Effective sample preparation helps in removing impurities and contaminants that could otherwise interfere with the analysis. By purifying the samples, the accuracy of the results is significantly enhanced, ensuring that the detected elements are indeed present in the sample and not due to external factors.

-

Increase Sensitivity: Advanced sample preparation techniques can amplify the sensitivity of the analysis. This allows for the detection of trace levels of analytes that might otherwise go unnoticed, providing a more comprehensive and detailed analysis of the sample.

In summary, the meticulousness of sample preparation in X-ray fluorescence spectrometry is not just a procedural step but a critical determinant of the quality and reliability of the analytical results.

Common Preparation Methods

In the realm of X-ray fluorescence (XRF) spectrometry, sample preparation is a critical step that directly impacts the accuracy and reliability of test results. This article delves into two predominant methods: the tablet method and the melting method. Each of these approaches comes with its own unique set of advantages and disadvantages, making them suitable for different analytical needs and sample types.

The tablet method is renowned for its simplicity and efficiency, making it an ideal choice for large-scale production environments. This method involves drying, crushing, and pressing the sample into a uniform tablet, which helps to reduce surface effects and enhance analytical accuracy. However, it is important to note that the tablet method does not eliminate mineral effects or particle size variations, which can limit its applicability in certain scenarios, particularly those requiring precise composition determination.

On the other hand, the melting method offers a more comprehensive approach by eliminating inconsistencies in composition, density, and particle size. This method involves pre-oxidizing metal samples and incorporating a flux to facilitate high-temperature melting. While this process is more time-consuming and requires a higher level of skill, it significantly reduces matrix effects and supports advanced analytical techniques such as standard addition and internal standard methods. The resulting glass discs must be handled with care to maintain their transparency and integrity.

In summary, the choice between the tablet and melting methods depends on various factors, including the nature of the sample, the required level of accuracy, and the specific analytical techniques being employed. Understanding the strengths and limitations of each method is essential for selecting the most appropriate preparation technique to ensure reliable and accurate XRF test results.

Tablet Method in X-ray Fluorescence

Advantages of the Tablet Method

The tablet method offers several compelling advantages in the context of X-ray fluorescence sample preparation. Firstly, its operational simplicity and rapid execution make it highly suitable for large-scale production environments. This method significantly reduces the time required for sample preparation, thereby enhancing throughput and efficiency in analytical processes.

One of the key benefits of the tablet method is its ability to mitigate surface effects, which are common sources of variability in X-ray fluorescence analysis. By pressing the sample into a uniform tablet, the method ensures a consistent surface area and density, which in turn improves the analytical accuracy of the results. This consistency is crucial for maintaining repeatability and reliability in the data generated.

Additionally, the tablet method simplifies the sample preparation process by eliminating the need for complex procedures such as pre-oxidation or the addition of flux, which are required in other methods like the melting method. This simplification not only reduces the potential for human error but also lowers the overall cost and complexity of the analytical workflow.

In summary, the tablet method's quick and straightforward nature, combined with its ability to reduce surface effects and enhance analytical accuracy, makes it a preferred choice for many large-scale production settings in X-ray fluorescence analysis.

Disadvantages of the Tablet Method

The tablet method in X-ray fluorescence (XRF) sample preparation, while advantageous in many respects, is not without its limitations. One of the most significant drawbacks is its inability to mitigate the effects of minerals and particle size variations within the sample. This inherent limitation restricts the method's applicability primarily to production control scenarios rather than precise composition determination.

Mineral Effects

Mineralogical variations can introduce significant discrepancies in XRF analysis results. Different minerals can exhibit varying degrees of fluorescence based on their atomic structures and compositions. The tablet method does not account for these differences, leading to potential inaccuracies in the reported elemental concentrations. For instance, minerals with higher atomic numbers may fluoresce more intensely, skewing the results in favor of these elements.

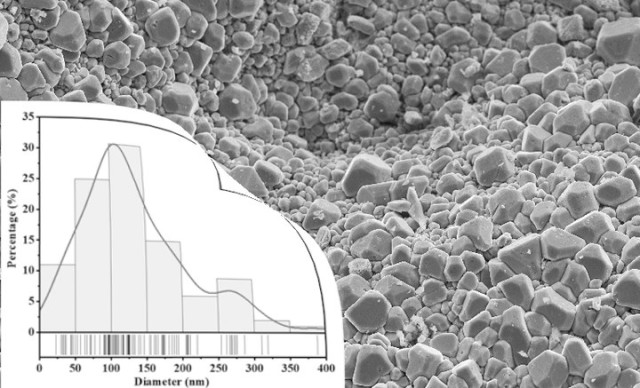

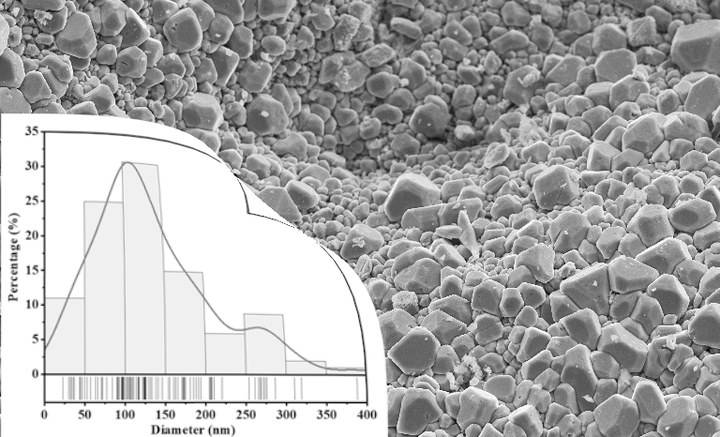

Particle Size Effects

Particle size heterogeneity is another critical factor that the tablet method fails to address effectively. The intensity of XRF signals is influenced by the size and distribution of particles within the sample. Larger particles can cause uneven packing, resulting in inconsistent X-ray penetration and fluorescence emission. This variability can lead to unreliable data, particularly in samples where particle size ranges are broad.

Limitations in Composition Determination

Given these constraints, the tablet method is best suited for routine production monitoring where consistency and speed are prioritized over absolute accuracy. For applications requiring precise composition analysis, alternative methods such as the melting method may be more appropriate. The melting method, while more complex and time-consuming, offers superior homogenization and can effectively reduce matrix effects, thereby enhancing the accuracy of composition determination.

In summary, while the tablet method offers simplicity and efficiency, its inability to handle mineral and particle size effects limits its utility in applications demanding high precision and accuracy in composition analysis.

Key Considerations in Tablet Preparation

When preparing samples for X-ray fluorescence analysis using the tablet method, several critical factors must be meticulously managed to ensure accurate and reproducible results. Firstly, sample drying is indispensable to remove any moisture content, which can otherwise lead to inconsistencies in the final tablet. The drying process should be conducted under controlled conditions to prevent any chemical or physical changes in the sample.

Once dried, the samples must be crushed to a uniform size. This step is crucial as particle size directly influences the homogeneity and density of the tablet, which in turn affects the accuracy of the X-ray fluorescence measurements. The use of appropriate grinding equipment and techniques is essential to achieve a consistent particle size distribution.

Subsequently, the crushed samples are subjected to pressing under consistent pressure and holding time. The pressure applied during this phase must be uniform to ensure that the tablet has a consistent density and thickness. Variations in pressure can lead to differences in the sample's surface area and density, which can distort the analytical results.

In addition to these primary steps, equipment cleanliness plays a pivotal role. Any residual material from previous samples can contaminate the new batch, leading to erroneous results. Regular cleaning and maintenance of the pressing equipment are therefore mandatory to maintain analytical integrity.

Lastly, filler density consistency is another critical consideration. The filler material, which is often added to the sample to improve its flow properties and binding characteristics, must have a consistent density. Any variation in the filler density can affect the overall homogeneity of the tablet, thereby compromising the analytical accuracy.

In summary, the preparation of tablets for X-ray fluorescence analysis demands meticulous attention to drying, crushing, pressing, equipment cleanliness, and filler density consistency. Each of these steps is interdependent, and their proper execution is essential to achieve reliable and reproducible results.

Melting Method in X-ray Fluorescence

Advantages of the Melting Method

The melting method offers significant advantages in X-ray fluorescence (XRF) sample preparation by addressing several critical inconsistencies that can affect analytical results. One of its primary benefits is the elimination of composition, density, and particle size inconsistencies. This uniformity is crucial for accurate and reproducible results, as it minimizes the variability that can arise from heterogeneous samples.

By homogenizing the sample through melting, this method significantly reduces matrix effects. Matrix effects, which can include absorption and enhancement effects, are common challenges in XRF analysis. These effects can lead to inaccurate quantification of elements, particularly when analyzing samples with varying compositions. The melting method mitigates these issues by creating a homogeneous matrix, thereby improving the accuracy and reliability of the analysis.

Moreover, the melting method facilitates the use of standard addition and internal standard methods. These techniques are essential for quantitative analysis, as they help to correct for variations in sample composition and instrument response. By providing a consistent matrix, the melting method allows for more precise calibration and quantification, making it particularly advantageous for complex samples where other preparation methods may fall short.

In summary, the melting method not only ensures a uniform sample matrix but also supports advanced analytical techniques, enhancing the overall quality and accuracy of XRF results.

Disadvantages of the Melting Method

While the melting method offers significant advantages in reducing matrix effects and inconsistencies, it is not without its drawbacks. One of the primary challenges is the necessity of pre-oxidizing metal samples, a process that introduces additional complexity and potential for error. Furthermore, the addition of flux during the melting process can dilute the samples, which may adversely impact the accuracy of light and trace element analysis.

Melting itself is a time-consuming procedure that demands a high level of skill and precision. The process involves careful control of temperature and flux mixing to ensure the production of a homogeneous glass disc. Any deviation from these critical parameters can lead to inconsistencies in the final sample, compromising the reliability of the X-ray fluorescence results.

Moreover, the handling and storage of the glass discs post-melting require meticulous attention. These discs are prone to loss of transparency or breakage if not stored properly, which can further complicate the analytical process and introduce additional sources of error.

Key Considerations in Melting Preparation

Proper flux mixing and high-temperature melting are essential components of the melting method in X-ray fluorescence (XRF). The process involves the meticulous blending of fluxes with the sample to ensure homogeneity and consistency, which are critical for accurate analysis. High-temperature melting, typically conducted in specialized furnaces, requires precise control over temperature and duration to fully integrate the sample with the flux, thereby minimizing matrix effects and enhancing the reproducibility of results.

Glass discs, which are the end product of the melting process, must be handled with care to preserve their integrity. These discs are often stored in controlled environments to prevent any physical damage that could lead to breakage or loss of transparency. The transparency of the glass discs is paramount as it directly impacts the quality of the XRF analysis; any loss of transparency could obscure the X-ray signals, leading to erroneous data. Therefore, careful storage and handling protocols are necessary to maintain the clarity and structural integrity of the glass discs.

Additionally, the selection of appropriate fluxes is a key consideration. Different types of fluxes have varying melting points and reactivity, which can influence the final composition of the glass disc. Choosing the right flux ensures that the sample is properly diluted, reducing the likelihood of phase separation and ensuring a uniform distribution of elements within the disc. This uniformity is crucial for accurate XRF analysis, as it minimizes the potential for analytical errors due to non-uniform sample preparation.

In summary, the success of the melting method in XRF hinges on several meticulous steps, including proper flux mixing, controlled high-temperature melting, and careful storage of glass discs. Each of these steps plays a vital role in ensuring the accuracy and reliability of the XRF analysis, making them indispensable considerations in the preparation process.

Related Products

- XRF & KBR plastic ring lab Powder Pellet Pressing Mold for FTIR

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- XRF Boric Acid Lab Powder Pellet Pressing Mold for Laboratory Use

- XRD Sample Holder X-ray Diffractometer Powder Slide

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine