Introduction to Cold Isostatic Pressing Technology

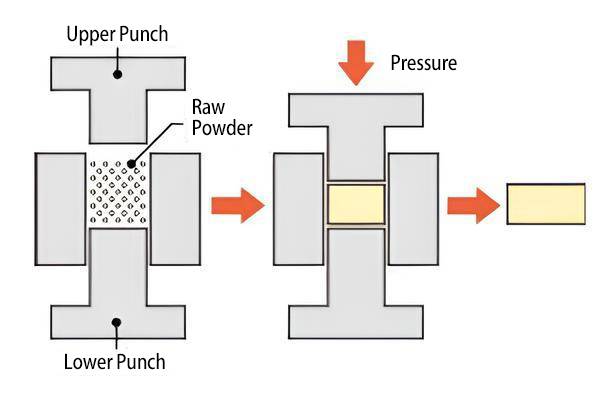

Definition and Mechanism

Cold isostatic pressing technology is a sophisticated process that facilitates isostatic pressing at ambient temperatures. This method employs rubber or plastic as the mold material, which is then subjected to pressure via a liquid or elastomer medium. The pressure exerted can reach up to 600MPa, ensuring uniform compression across all directions.

The mechanism behind cold isostatic pressing involves enclosing the material within a flexible mold, typically made of rubber or plastic. This mold is then immersed in a pressure vessel filled with a liquid or elastomer. As the pressure is applied, the medium evenly distributes the force, compressing the material uniformly from all sides. This process ensures that the material achieves a high and consistent density, making it ideal for applications requiring precise shape and density control.

Key components of the system include the pressure vessel, the flexible mold, and the pressure medium. The pressure vessel is designed to withstand high pressures, ensuring safety and efficiency during the pressing process. The flexible mold, made of materials like rubber or plastic, allows for the shaping of complex geometries without compromising the integrity of the material. The pressure medium, whether liquid or elastomer, plays a crucial role in distributing the pressure evenly, thereby achieving isostatic conditions.

This technology is particularly advantageous in industries where maintaining the shape and density of materials is critical. It overcomes the limitations of traditional pressing methods, which often result in shape distortion and inconsistent density. By ensuring uniform pressure distribution, cold isostatic pressing technology enables the production of high-quality components with minimal shrinkage and excellent shape control.

Advantages of Cold Isostatic Pressing

Cold isostatic pressing (CIP) offers several distinct advantages that enhance the quality and efficiency of the manufacturing process. One of the most significant benefits is the uniform density it achieves in green sheets. This uniformity ensures that the material undergoes consistent shrinkage during subsequent processes like sintering, which is crucial for maintaining dimensional accuracy and structural integrity. The even distribution of pressure across all parts of the material is a key factor in achieving this uniformity, as it eliminates the potential for density variations that could lead to defects or inconsistencies in the final product.

Moreover, CIP significantly improves green strength, which refers to the material's ability to withstand manipulation before it is fully hardened. High green strength allows for faster sintering and machining, thereby increasing production turnover and reducing overall processing time. This strength also facilitates the handling of delicate shapes and structures, making it easier to produce complex geometries without compromising the material's integrity.

Another notable advantage is the uniform strength imparted to the product. Unlike uniaxial pressing, CIP provides more homogeneous product properties, allowing for greater precision in controlling the dimensions of the finished product. This homogeneity is particularly beneficial in industries where exact specifications are critical, such as in the production of high-precision components for aerospace or medical devices.

Additionally, CIP offers greater flexibility in the shape and size of the finished product. It allows for the creation of longer aspect ratios, such as long, thin pellets, which are challenging to produce using other pressing methods. This flexibility extends to the processing of materials with diverse characteristics and shapes, further broadening the range of applications for which CIP is suitable.

Finally, the technology's ability to improve powder compaction leads to enhanced densification, which is essential for achieving high-performance materials. This improved compaction not only enhances the material's mechanical properties but also reduces cycle times, thereby improving overall productivity.

Applications in Industry

Powder Metallurgy

Cold isostatic pressing plays a pivotal role in the realm of powder metallurgy, particularly in the production of intricate, large-scale components. This technology is instrumental in crafting complex-shaped cemented carbide rolls, which are essential for various industrial applications, including the manufacturing of top hammers used in the production of artificial diamonds. The process is also adept at handling powder materials with significant height-to-diameter ratios, ensuring uniform density and minimal distortion.

In the context of powder metallurgy, cold isostatic pressing is not merely a manufacturing technique but a cornerstone of precision engineering. It allows for the creation of materials that are otherwise unattainable through traditional melting or forming methods. For instance, tungsten carbide, a material renowned for its hardness and wear resistance, is often produced using powder metallurgy techniques. These techniques involve bonding tungsten carbide particles with cobalt, resulting in a material that is indispensable for cutting tools and various industrial applications.

Moreover, the versatility of cold isostatic pressing extends to the fabrication of a wide array of components, including sintered filters, porous oil-impregnated bearings, and electrical contacts. The sintering process, which is integral to powder metallurgy, ensures that the powdered particles are bonded together at temperatures just below the melting point of the primary metal. This results in parts that are not only highly accurate but also possess superior mechanical properties.

The significance of cold isostatic pressing in powder metallurgy cannot be overstated. It is a process that has evolved with technological advancements, becoming the go-to method for producing critical components such as bushings, bearings, and gears. By eliminating the need for subtractive manufacturing processes, it not only reduces material waste but also enhances the cost-effectiveness of the final product.

Food Processing

In the realm of food processing, cold isostatic pressing (CIP) emerges as a pivotal technique for low-temperature sterilization and enzyme inactivation. This method not only ensures the elimination of harmful microorganisms but also effectively deactivates enzymes that could otherwise lead to spoilage. By maintaining a low-temperature environment, CIP preserves the intrinsic qualities of food products, including their original taste, vibrant color, and nutritional integrity.

The process involves applying uniform pressure to food products enclosed in a flexible mold, typically made of rubber or plastic, while submerged in a liquid or elastomer medium. This uniform pressure, which can reach up to 600MPa, ensures that the food is subjected to consistent treatment, thereby enhancing its safety and quality. The low-temperature application minimizes the risk of thermal degradation, which is common in traditional high-temperature sterilization methods, thus preserving the delicate flavors and textures of the food.

Moreover, CIP's ability to maintain high and uniform density in food products results in minimal shrinkage and superior shape retention. This is particularly advantageous for foods that require precise shaping and presentation, such as delicate pastries or intricate confections. The technology's efficacy in preserving the nutritional content of foods is also noteworthy, as it prevents the loss of vitamins and minerals that are often compromised during high-temperature processing.

In summary, cold isostatic pressing in food processing represents a significant advancement in food preservation technology, offering a balance between safety, quality, and nutritional value.

Ceramics

The application of cold isostatic pressing technology in the ceramic industry is particularly noteworthy for its ability to produce high-quality, specialized ceramic products. Among these, alumina grinding balls, aluminum titanate liquid tubes, and high-voltage electromagnetic insulators stand out as prime examples of the technology's efficacy. These items demand exceptional mechanical, thermal, and chemical stability, properties that traditional ceramics have long been known for.

Historically, ceramics have been valued for their durability and versatility, finding applications in everything from cooking vessels to sculpted figures. The process typically involves shaping clay, either alone or mixed with materials like silica sand, into desired forms. These shapes are then dried and hardened through a process known as sintering, which occurs in high-temperature kilns or furnaces.

As technological advancements have progressed, the utility of ceramics has expanded significantly. Today, ceramic products can be broadly categorized into several groups, each benefiting from the precision and uniformity that cold isostatic pressing technology offers. This method ensures that even complex shapes maintain high density and minimal shrinkage, making it an ideal choice for the production of advanced ceramic components.

Related Products

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Vacuum Cold Mounting Machine for Sample Preparation

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

Related Articles

- Application of Hot Isostatic Pressing Technology in Special Ceramic Preparation

- Cold Isostatic Pressing (CIP): A Proven Process for High-Performance Parts Manufacturing

- Exploring the Applications of Isostatic Pressing

- Additive Manufacturing for Isostatic Pressing: Bridging New Technology with Traditional Manufacturing

- Automatic isostatic press operation steps