Milling Equipment

Laboratory Four-Body Horizontal Jar Mill

Item Number : KT-HJM

Price varies based on specs and customizations

- Processing type

- grinding | mixing

- Maximum injection size

- < 5 mm

- Sample particle size range

- 1-20um

- Number of ball mill jars

- 4

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Principle

The Four-Body Horizontal Jar Mill operates on the principle of impact and friction, utilizing rotating grinding jars and an opposing sun wheel. This configuration ensures efficient grinding by causing the grinding media to collide with the material, reducing it to fine particles. The rotational speeds and movements are adjustable, allowing for precise control over the grinding process.

Applications

The Four-Body Horizontal Jar Mill is a specialized piece of laboratory equipment designed for efficient and precise grinding of materials. This machine is particularly useful in various scientific and industrial applications where fine particle size reduction is required. The main application areas of the Four-Body Horizontal Jar Mill include:

- Material Science: Used for grinding and homogenizing materials for further analysis or synthesis, such as ceramic powders, metal oxides, and composite materials.

- Pharmaceuticals: Essential for the preparation of drug formulations by reducing the particle size of active pharmaceutical ingredients (APIs) and excipients.

- Chemical Industry: Employed in the production of fine chemicals and catalysts, where uniform particle size distribution is critical for product performance.

- Mineral Processing: Utilized for the grinding of ores and minerals to facilitate their separation and extraction processes.

- Environmental Analysis: Helps in the preparation of samples for environmental testing, such as soil and sediment analysis, by reducing the particle size for accurate chemical analysis.

- Food and Beverage Industry: Used in the grinding of food ingredients to achieve the desired texture and consistency in products.

These applications highlight the versatility and importance of the Four-Body Horizontal Jar Mill in various sectors, ensuring high-quality results in material processing and analysis.

Features of Four-Body Horizontal Jar Mill

The Four-Body Horizontal Jar Mill is a versatile and efficient laboratory grinding solution designed for high-impact milling tasks. This mill stands out for its simplicity, precision, and ease of maintenance, making it an ideal choice for researchers and lab technicians in various industries. Here are the key features that make the Four-Body Horizontal Jar Mill a standout choice for your laboratory needs:

- Simplified Design for Ease of Use and Maintenance: With only four major components, the mill head is designed for rapid maintenance and configuration. This minimalistic approach reduces downtime and lowers maintenance costs, ensuring that your lab operations remain efficient and uninterrupted.

- High Shear Precision for Consistent Results: The micrometer-style gap adjustment dial allows for fine-tuning of the mechanical shear, ensuring precise and repeatable results. This feature is crucial for achieving on-specification production in various applications, from colloidal grinding to material dispersion.

- Front Load Clamped-Chamber Design for Accessibility: The sanitary design of the mill head allows for easy access to all internal parts. This facilitates quick inspection, cleaning, and configuration, enhancing the overall efficiency and hygiene of the milling process.

- Versatile Milling Options: The mill supports both wet and dry milling, with milling jars available in various materials and sizes. This versatility accommodates a wide range of applications and materials, making it a flexible choice for diverse laboratory needs.

- Powerful Impact and Grinding Action: The design of the jar mill ensures that powerful impact forces are generated between the balls and the sample material, enhancing the grinding efficiency. Additionally, the frictional forces contribute to thorough and effective grinding, ideal for achieving the desired particle size and consistency in your samples.

- Resilience to Abrasion: The construction of the horizontal mill is designed to resist abrasion, ensuring a longer operational life and reducing the need for frequent replacements or repairs.

- Low Maintenance Requirements: With relatively low operation, control, and maintenance requirements, the horizontal jar mill is a user-friendly option that does not require extensive technical expertise to operate and maintain.

- Consistent and Predictable Performance: The consistent performance of the horizontal jar mill ensures that the output is predictable and meets the required specifications, making it a reliable choice for various industrial applications.

These features collectively ensure that the Four-Body Horizontal Jar Mill provides a reliable, efficient, and versatile solution for your laboratory grinding needs, enhancing productivity and precision in your research and development processes.

Detail & Parts

Advantages

The Four-Body Horizontal Jar Mill offers a range of advantages that make it an ideal choice for wet grinding applications. Here are some of the key benefits:

- Highly Efficient Media Use: The horizontal design allows for the efficient use of small media sizes, ranging from 0.25 mm to 2 mm. This precision in media size utilization enhances the grinding efficiency and ensures optimal results.

- Reduced Product Loss: With a horizontal mill, there is a significant reduction in product loss compared to other milling methods. This efficiency in retaining the product during the milling process leads to cost savings and improved yield.

- Enhanced Color Strength and Gloss Durability: The horizontal jar mill is particularly effective in maintaining and even enhancing the color strength and gloss durability of the materials being processed. This is crucial for products where these attributes are critical.

- Significant Time Savings: The process time can be reduced by as much as 300% with a horizontal mill. This dramatic reduction in processing time not only increases productivity but also lowers energy costs associated with prolonged milling operations.

- Cost-Effective: Raw material costs can be reduced by about 5% due to the optimized grinding process and reduced wastage. This cost-effectiveness is a significant advantage for industries looking to minimize expenses without compromising on quality.

- Minimal Contamination and Clean-Up: The horizontal mill design minimizes contamination risks and requires minimal clean-up. This feature is essential for maintaining the purity of the materials and reducing downtime for maintenance.

- Resilience to Abrasion: The construction of the horizontal mill is designed to resist abrasion, ensuring a longer operational life and reducing the need for frequent replacements or repairs.

- Low Maintenance Requirements: With relatively low operation, control, and maintenance requirements, the horizontal jar mill is a user-friendly option that does not require extensive technical expertise to operate and maintain.

- Consistent and Predictable Performance: The consistent performance of the horizontal jar mill ensures that the output is predictable and meets the required specifications, making it a reliable choice for various industrial applications.

Functions

- continuous grinding

- intermittent grinding

- alternate grinding

- timing

- Speed regulation

- Power off memory

- LED lighting

- PC Windows

Technical specifications

| Processing principle | Friction |

| Application sample features | Fine | Medium to low hardness | Brittle | Dry or low viscous |

| Processing type | grinding | mixing |

| Maximum injection size | < 5 mm |

| Sample particle size range | 1-20um |

| Number of ball mill jars | 4 |

| The largest ball milling tank volume available | 3000ml |

| Available minimum milling jar volume | 250ml |

| Ball mill tank optional material | Zirconia | Tungsten Carbide Agate | Nylon Stainless Steel | Polyurethane etc |

| Grinding media optional type | Spherical | Cylindrical |

| Grinding ball optional material | Zirconia | Tungsten Carbide Agate | Stainless Steel | Corundum |

| Grinding method | Dry grinding | wet grinding |

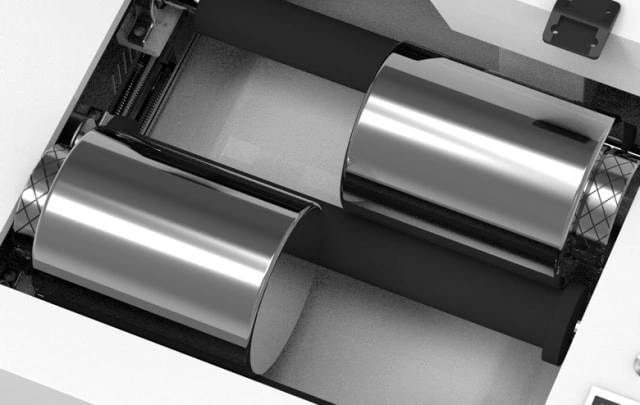

| Number of rubber rollers: | 3 sticks |

| Rubber roller speed | 900 r/min |

| Rubber roller cover material | Polyurethane |

| Rubber roller movement method | electric control |

| net weight | 88kg |

| Dimensions | 670*660*310mm |

| Protection class | IP65 |

| standard | CE |

Warnings

Operator safety is the top important issue! Please operate the equipment with cautions. Working with inflammable& explosive or toxic gases is very dangerous, operators must take all necessary precautions before starting the equipment. Working with positive pressure inside the reactors or chambers is dangerous, operator must fellow the safety procedures strictly. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

4.9 / 5

The jar rolling mill's variable speed drive is an asset for adapting to different jar sizes and grinding conditions, ensuring optimal performance.

4.8 / 5

The tumbler mill's high efficiency and focus on energy utilization are impressive, leading to exceptional milling results.

4.7 / 5

The intelligent basket mill's spiral feeding mechanism and innovative mixing system prevent excess air incorporation, ensuring product quality.

4.9 / 5

The faster grinding speed and minimal temperature rise of the basket mill are game-changers, enabling efficient and precise processing.

4.8 / 5

The lab basket mill's versatility across materials and its recirculation technology make it an exceptional choice for small-batch processing.

4.7 / 5

The three roll mills machine's high shear force and multiple cycles deliver finely dispersed and homogenized substances, ideal for demanding applications.

4.9 / 5

The colloid mill's simplicity, ease of maintenance, and precise shear adjustment ensure consistent and repeatable production.

4.8 / 5

The four-body horizontal tank mill ball mill's versatility for mixing and grinding laboratory samples makes it an invaluable tool.

4.7 / 5

The mill's continuous, intermittent, and alternate grinding options, along with timing and speed regulation, provide unmatched flexibility.

4.9 / 5

The mill's power off memory, LED lighting, and PC Windows compatibility enhance user convenience and control.

4.8 / 5

The mill's IP65 protection class ensures reliable operation in various environments, making it a durable choice.

4.7 / 5

The mill's CE certification guarantees compliance with safety and quality standards, giving users peace of mind.

4.9 / 5

The mill's three rubber rollers with a speed of 900 r/min and polyurethane cover ensure efficient and effective grinding.

4.8 / 5

The mill's compact dimensions (670*660*310mm) and relatively low net weight (88kg) make it space-saving and portable.

4.7 / 5

The mill's availability in various ball mill tank materials, grinding media types, and grinding methods caters to diverse processing needs.

4.9 / 5

The mill's dry and wet grinding capabilities make it a versatile solution for different applications and materials.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

Grind and mill with ease using metal alloy grinding jars with balls. Choose from 304/316L stainless steel or tungsten carbide and optional liner materials. Compatible with various mills and features optional functions.

High Energy Planetary Ball Mill for Laboratory Horizontal Tank Type Milling Machine

KT-P4000H uses the unique Y-axis planetary motion trajectory, and utilizes the collision, friction and gravity between the sample and the grinding ball to have a certain anti-sinking ability, which can obtain better grinding or mixing effects and further improve the sample output.

Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

Discover the versatile stainless steel dry powder/liquid horizontal ball mill with ceramic/polyurethane lining. Ideal for ceramic, chemical, metallurgical, and building materials industries. High grinding efficiency and uniform particle size.

Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

Grind to perfection with alumina/zirconia grinding jars and balls. Available in volume sizes from 50ml to 2500ml, compatible with various mills.

Laboratory Horizontal Planetary Ball Mill Milling Machine

Improve sample uniformity with our Horizontal Planetary Ball Mills. KT-P400H reduces sample deposition and KT-P400E has multi-directional capabilities. Safe, convenient and efficient with overload protection.

Laboratory Single Horizontal Jar Mill

KT-JM3000 is a mixing and grinding instrument for placing a ball milling tank with a volume of 3000ml or less. It adopts frequency conversion control to realize timing, constant speed, direction change, overload protection and other functions.

Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

The vertical cabinet structure combined with ergonomic design enables users to obtain the best comfortable experience in standing operation. The maximum processing capacity is 2000ml, and the speed is 1200 revolutions per minute.

High Energy Planetary Ball Mill Milling Machine for Laboratory

The biggest feature is that the high energy planetary ball mill can not only perform fast and effective grinding, but also has good crushing ability

Lab Vibration Mill

Vibration Mill for Efficient Sample Preparation, Suitable for Crushing and Grinding a Variety of Materials with Analytical Precision. Supports Dry / Wet / Cryogenic Grinding and Vacuum/Inert Gas Protection.

Laboratory Ten-Body Horizontal Jar Mill for Lab Use

The Ten-body horizontal jar mill is for 10 ball mill pots (3000ml or less). It has frequency conversion control, rubber roller movement, and PE protective cover.

High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

The KT-P2000E is a new product derived from the vertical high-energy planetary ball mill with a 360°rotation function. The product not only has the characteristics of the vertical high-energy ball mill, but also has a unique 360°rotation function for the planetary body.

High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

The KT-P4000E is a new product derived from the vertical high-energy planetary ball mill with a 360° swivel function. Experience faster, uniform, and smaller sample output results with 4 ≤1000ml ball mill jars.

Laboratory Disc Cup Vibratory Mill for Sample Grinding

The vibrating disc mill is suitable for non-destructive crushing and fine grinding of samples with large particle sizes, and can quickly prepare samples with analytical fineness and purity.

Laboratory Grinding Mill Mortar Grinder for Sample Preparation

KT-MG200 mortar grinder can be used for mixing and homogenizing powder, suspension, paste and even viscous samples. It can help users realize the ideal operation of sample preparation with more regularization and higher repeatability.

Laboratory Micro Tissue Grinding Mill Grinder

KT-MT10 is a miniature ball mill with a compact structure design. The width and depth are only 15X21 cm, and the total weight is only 8 kg. It can be used with a minimum 0.2ml centrifuge tube or a maximum 15ml ball mill jar.

Related Articles

Features of Different Laboratory Mills: An Overview

Laboratory mills are specialized machines used to reduce non-homogenous batch samples into smaller, representative samples that are more uniform in composition.

Disc / Cup Vibratory Mill: A Comprehensive Guide for Laboratory Experts

Discover the world of Disc / Cup Vibratory Mills! This comprehensive guide provides an in-depth understanding of their types, working principles, advantages, and applications in various industries, including pharmaceuticals, chemicals, and food processing.

Planetary Ball Mills: Research Tools for Efficient Mixing and Nanoscale Grinding

Planetary ball mills are indispensable tools in modern laboratories, serving a crucial role in the mixing, fine grinding, and preparation of small samples. These mills are particularly adept at dispersing nanomaterials and facilitating the development and small-scale production of high-tech materials.

Understanding the Advantages and Disadvantages of Ball Mills in Laboratory and Industrial Applications

Discover the pros and cons of using ball mills for grinding materials. Explore the potential applications of ball mills for various industries.

The Advantages of Ball Milling in Laboratory Applications: high capacity and reliability

Discover the numerous advantages of ball milling in laboratory applications. Explore the working principles, applications, and advantages of ball mills, along with the impact of ball mill speed on size reduction. Learn how ball milling compares to traditional milling machines.

Working Principle of Vertical Ball Mill : Impact, Attrition, and Size Reduction

Discover the working principle of vertical ball mills through impact and attrition mechanisms. Learn how materials like iron ore and ceramics are ground to a fine medium. Explore the construction, operations, advantages of vertical mills in this detailed guide.

Hydraulic Hot Press: Principles, Components, Features, Advantages, and Applications

An in-depth look at the hydraulic hot press, its components, features, advantages, and applications.