Milling Equipment

Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

Item Number : KT-M

Price varies based on specs and customizations

- Cylinder volume

- 200~2000 L

- Loading volume

- 90~900 L

- Motor power

- 4~30 kW

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Product Application

The stainless steel dry powder/liquid horizontal ball mill with ceramic/polyurethane lining is a versatile and essential piece of equipment in various industries. Its primary applications span across multiple sectors, including:

- Ceramic Industry: Ideal for grinding ceramic raw materials such as feldspar, quartz, and clay. This ensures that the materials are refined to the desired particle size, essential for producing high-quality ceramic products.

- Chemical Industry: Used to grind various chemical raw materials, including pigments, dyes, and catalysts. The uniform grinding process ensures consistent chemical reactions and product quality.

- Metallurgical Industry: Suitable for grinding various ores and metal powders, aiding in the refinement and processing of metals.

- Building Materials Industry: Employed for grinding materials like cement, limestone, and gypsum, contributing to the production of high-quality building materials.

Product Feature

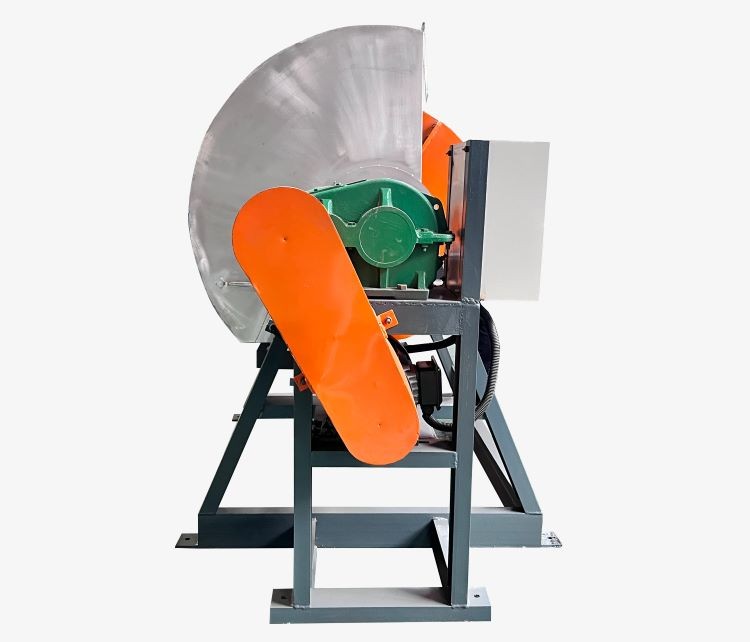

The stainless steel dry powder/liquid horizontal ball mill with ceramic/polyurethane lining boasts several key features that make it a superior choice for grinding applications:

- Efficient Grinding: The horizontal cylinder structure ensures that the grinding medium is in full contact with the material, resulting in high grinding efficiency and uniform product particle size.

- Easy Operation: The equipment features a simple structure, making it easy to operate and maintain. This simplicity reduces the learning curve for operators and minimizes downtime.

- Wide Range of Application: Capable of grinding materials of various hardness and particle sizes, making it suitable for a broad spectrum of industries.

- Energy Saving and Environmental Protection: The advanced transmission system and sealing technology ensure low energy consumption and noise levels, meeting stringent environmental standards.

- Quality Assurance: Constructed from high-quality materials and utilizing advanced technology, the equipment offers stable and reliable performance with a long service life.

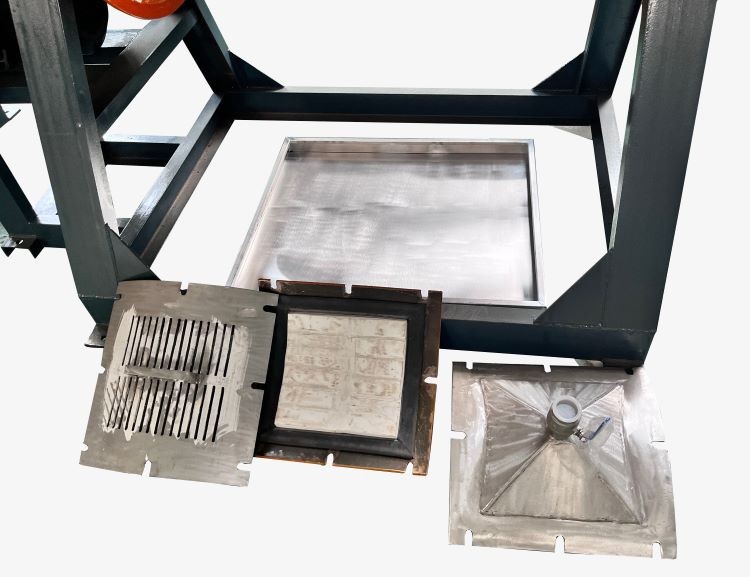

Detail & Parts

Working Principle

The working principle of the stainless steel dry powder/liquid horizontal ball mill with ceramic/polyurethane lining is based on the rotation of a horizontal cylinder filled with grinding media (steel balls or ceramic balls). The material to be ground is introduced into the cylinder, where it is subjected to the following processes:

- Impact and Friction: As the cylinder rotates, the grinding media inside it is lifted to a certain height and then falls, creating impact forces on the material. Additionally, the friction between the grinding media and the material further breaks down the particles.

- Mixing and Grinding: The continuous rotation of the cylinder ensures that the material is thoroughly mixed and ground, achieving the desired particle size and uniformity.

- Control and Monitoring: The operation of the ball mill is controlled via a motor that regulates the speed and duration of the grinding process. Operators can monitor the wear of the grinding media and the material, ensuring optimal performance and efficiency.

Product Advantage

The stainless steel dry powder/liquid horizontal ball mill with ceramic/polyurethane lining offers several distinct advantages that set it apart from other grinding equipment:

- High Grinding Efficiency: The horizontal cylinder design maximizes contact between the grinding media and the material, resulting in faster and more efficient grinding.

- Uniform Particle Size: The consistent impact and friction ensure that the final product has a uniform particle size, crucial for quality control in various industries.

- Easy Maintenance: The simple structure and design make routine maintenance straightforward, reducing downtime and operational costs.

- Energy Efficiency: The advanced transmission system and sealing technology minimize energy consumption, making it an environmentally friendly choice.

- Durability and Reliability: Constructed from high-quality stainless steel and featuring a robust design, the equipment offers long-lasting performance and reliability.

This comprehensive product introduction highlights the key features, applications, working principle, and advantages of the stainless steel dry powder/liquid horizontal ball mill with ceramic/polyurethane lining, making it an ideal choice for industries requiring efficient and reliable grinding solutions.

Technical specifications

| Specification | KT-M200 | KT-M300 | KT-M500 | KT-M1000 | KT-M1500 | KT-M2000 |

|---|---|---|---|---|---|---|

| Grinding drum speed | 50 | 50 | 45 | 35 | 32 | 30 |

| Motor power(kw) | 4 | 4 | 5.5 | 11 | 15 | 30 |

| Grinding drum capacity | 200L | 300L | 500L | 1000L | 1500L | 2000L |

| Loading volume | 90L | 135L | 220L | 450L | 700L | 900L |

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

FAQ

What Is A Laboratory Ball Mill?

What Are The Applications Of A Laboratory Ball Mill?

What Are The Main Types Of Laboratory Ball Mills?

What Is The Working Principle Of A Laboratory Ball Mill?

What Are The Advantages Of Using A Laboratory Ball Mill?

What Materials Can Be Processed Using A Laboratory Ball Mill?

What Are The Key Features Of A High-energy Planetary Ball Mill?

What Is The Difference Between A Planetary Ball Mill And A Vibratory Ball Mill?

4.8 / 5

Exceptional quality and durability. This mill has significantly improved our lab's efficiency.

4.7 / 5

Value for money. The mill's technological advancements are impressive and have reduced our processing time.

4.9 / 5

Highly efficient and easy to operate. The ceramic lining ensures minimal contamination.

4.8 / 5

Outstanding performance. The mill's versatility has expanded our research capabilities.

4.7 / 5

Reliable and durable. The polyurethane lining is a game-changer for our materials.

4.9 / 5

Excellent build quality. The mill's energy efficiency has lowered our operational costs.

4.8 / 5

Fast delivery and top-notch service. The mill exceeded our expectations in every way.

4.7 / 5

Impressive technological features. This mill has become indispensable in our lab.

4.9 / 5

Sturdy and efficient. The mill's horizontal design is perfect for our grinding needs.

4.8 / 5

Great value and performance. The mill's durability and ease of maintenance are remarkable.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Laboratory Ten-Body Horizontal Jar Mill for Lab Use

The Ten-body horizontal jar mill is for 10 ball mill pots (3000ml or less). It has frequency conversion control, rubber roller movement, and PE protective cover.

Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

The vertical cabinet structure combined with ergonomic design enables users to obtain the best comfortable experience in standing operation. The maximum processing capacity is 2000ml, and the speed is 1200 revolutions per minute.

High Energy Planetary Ball Mill Milling Machine for Laboratory

The biggest feature is that the high energy planetary ball mill can not only perform fast and effective grinding, but also has good crushing ability

High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

The KT-P4000E is a new product derived from the vertical high-energy planetary ball mill with a 360° swivel function. Experience faster, uniform, and smaller sample output results with 4 ≤1000ml ball mill jars.

High Energy Vibratory Ball Mill for Lab Use

The high-energy vibrating ball mill is a high-energy oscillating and impacting multifunctional laboratory ball mill. The table-top type is easy to operate, small in size, comfortable and safe.

High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

The KT-P2000E is a new product derived from the vertical high-energy planetary ball mill with a 360°rotation function. The product not only has the characteristics of the vertical high-energy ball mill, but also has a unique 360°rotation function for the planetary body.

High Energy Planetary Ball Mill Milling Machine for Laboratory

Experience fast and effective sample processing with the F-P2000 high-energy planetary ball mill. This versatile equipment offers precise control and excellent grinding capabilities. Perfect for laboratories, it features multiple grinding bowls for simultaneous testing and high output. Achieve optimal results with its ergonomic design, compact structure, and advanced features. Ideal for a wide range of materials, it ensures consistent particle size reduction and low maintenance.

Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

Grind to perfection with alumina/zirconia grinding jars and balls. Available in volume sizes from 50ml to 2500ml, compatible with various mills.

Lab Vibration Mill

Vibration Mill for Efficient Sample Preparation, Suitable for Crushing and Grinding a Variety of Materials with Analytical Precision. Supports Dry / Wet / Cryogenic Grinding and Vacuum/Inert Gas Protection.