Milling Equipment

High Energy Planetary Ball Mill for Laboratory Horizontal Tank Type Milling Machine

Item Number : KT-P4000H

Price varies based on specs and customizations

- Maximum injection size

- < 10mm

- Sample particle size range

- 0.1-20um

- Maximum processing volume

- 4000ml

- Maximum speed of the ball mill:

- 800 r/min

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

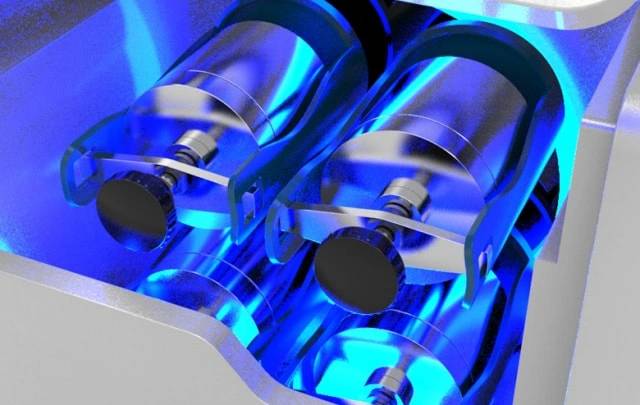

KT-P4000H uses the unique Y-axis planetary motion trajectory, and utilizes the collision, friction and gravity between the sample and the grinding ball to have a certain anti-sinking ability, which can obtain better grinding or mixing effects and further improve the sample output. Uniformity and precision, the product configuration can be used with 4 ball milling tanks with a volume of 1000ml or less.

Principle

The High Energy Planetary Ball Mill (Horizontal Tank Type) operates by rotating grinding jars on a sun wheel, each jar rotating in the opposite direction, generating high-energy impact and friction through centrifugal and Coriolis forces, enabling ultrafine and nano-sized material production.

Applications

The High Energy Planetary Ball Mill (Horizontal Tank Type) is a versatile and high-performance laboratory equipment designed for fine grinding, mixing, and homogenizing of a wide range of materials. This type of mill is particularly effective for processing hard, medium-hard, soft, brittle, tough, and moist materials, making it an essential tool in various scientific and industrial applications. The mill's ability to operate in dry, wet, or inert gas environments enhances its utility across different sectors. Here are the main application areas of the High Energy Planetary Ball Mill:

- Material Science and Research: Used for mechanical alloying and activation, this mill is crucial for synthesizing new materials and conducting advanced materials research.

- Pharmaceutical Industry: Ideal for the grinding and homogenization of pharmaceutical ingredients to achieve the desired particle size for drug formulations.

- Chemical Processing: Effective in the comminution of chemicals for various industrial processes, including the production of fine powders and pastes.

- Ceramic and Mineral Processing: Suitable for grinding hard and brittle materials like ceramics and minerals to prepare them for further processing or analysis.

- Environmental Science: Employed in the preparation of samples for environmental testing and analysis, particularly in the study of soil and sediments.

- Food and Beverage Industry: Used for the fine grinding of food ingredients and the preparation of homogeneous mixtures for product development.

- Nanotechnology: Essential for producing nano-sized particles and materials, which are critical in the development of nanotechnology applications.

- Colloidal Grinding: Capable of producing ultra-fine particles suitable for colloidal suspensions and other applications requiring very small particle sizes.

Advantages

The High Energy Planetary Ball Mill (Horizontal Tank Type) offers several significant advantages for laboratory work and material processing:

- Enhanced Grinding Efficiency: The unique design of planetary ball mills, where jars rotate on their own axis in the opposite direction of the sun wheel, generates both centrifugal and Coriolis forces. This mechanism significantly increases the grinding energy, allowing for the production of finer particle sizes compared to traditional ball mills.

- High-Speed Milling Capabilities: The impact energy of the milling balls in a planetary ball mill can be up to 40 times higher than that due to gravitational acceleration. This high-energy environment enables rapid and efficient milling, reducing process times and enhancing the fineness of the powder.

- Versatility in Particle Size Reduction: These mills are capable of producing nano powders ranging from 2 to 20 nm in size. The ability to adjust the speed of rotation allows for precise control over the particle size, making it suitable for a wide range of applications requiring different particle sizes.

- Cost-Effective and Simple Operation: Planetary ball mills are relatively inexpensive and easy to operate, making them a practical choice for routine laboratory work. The mechanical nature of the process simplifies the operational requirements and reduces the need for complex setups or additional equipment.

- Crystal Defect Production: The high-energy milling process in these machines can introduce crystal defects, which can be beneficial for certain applications that require specific material properties or modifications.

- Horizontal Milling Advantages: The horizontal configuration of these mills is particularly advantageous for wet grinding processes. It allows for highly efficient use of small media, reduces product loss, and minimizes contamination and solvent loss. This setup also enhances color strength, gloss durability, and yield in processed materials.

- Consistent and Predictable Performance: The design and operation of horizontal planetary ball mills ensure consistent performance, making them reliable tools for achieving uniform fine powder and predictable outcomes in various milling applications.

These advantages make the High Energy Planetary Ball Mill (Horizontal Tank Type) a high-performance all-rounder in routine laboratory work, capable of meeting the demands of ultrafine and nano-sized material synthesis.

Features

The High Energy Planetary Ball Mill (Horizontal Tank Type) is a versatile and high-performance laboratory equipment designed for fine grinding, mixing, and homogenizing of various materials. This mill is particularly beneficial for researchers and scientists who require rapid and efficient size reduction of hard, medium-hard, soft, brittle, tough, and moist materials. Key features of this mill include:

- High-speed and versatile operation: The mill is capable of grinding materials dry, in suspension, or in inert gas, making it suitable for a wide range of applications.

- Rapid and efficient size reduction: The high-energy impact of grinding balls in rotating grinding bowls results in rapid and efficient size reduction of materials.

- Mechanical alloying and activation: The mill can be used for mechanical alloying and activation in materials research, providing a comprehensive solution for material synthesis.

- Ultra-fine particle production: The combination of centrifugal and Coriolis forces allows for the production of even smaller particle sizes compared to other types of ball mills.

- Powerful impact and frictional forces: The rapid acceleration of particles within the grinding jar produces powerful impact forces between the balls and sample material, as well as additional grinding action through frictional forces.

Detail & Parts

Functions

- Continuous and intermittent operation

- Emergency stop

- Timing

- Power failure memory

- Overload and hazardous operation protection

- LED Lighting

- Shockproof and Sound Absorbing

- Heat Dissipation

Technical specifications

| Grinding principle | Impact | Friction | Gravity |

| Suitable materials | Small and medium-low hardness; brittle; dry or wet |

| Materials input size | < 10 mm |

| Materials output size | 0.1-20 um |

| Processing volume | 4000ml |

| Disc panspeed | 800 r/min |

| Grinding panmaterial | Tungsten carbide;Ceramic; Agate; Stainless steel; Harden steel; Nylon, etc. |

| Planetary disk space movement mode | Y-axis planetary movement |

| Motor power | 100-120V/200-240V AC ,50-60Hz,750W |

| Net weight | 115kg |

| Dimensions | L720*W560*H510 mm |

| Protection level | IP65 |

| Quality standards | CE |

Warnings

Operator safety is the top important issue! Please operate the equipment with cautions. Working with inflammable& explosive or toxic gases is very dangerous, operators must take all necessary precautions before starting the equipment. Working with positive pressure inside the reactors or chambers is dangerous, operator must fellow the safety procedures strictly. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

FAQ

What Is A High Energy Planetary Ball Mill (Horizontal Tank Type)?

How Does The High Energy Planetary Ball Mill Differ From Other Types Of Ball Mills?

5.0 / 5

The ball mill from KINTEK SOLUTION is a game-changer for our lab. The speed of delivery was impressive, and the quality of the machine is top-notch.

4.8 / 5

We've been using the ball mill for a few months now, and it has exceeded our expectations. It's easy to operate and maintain, and the results are consistent.

4.9 / 5

The customer service from KINTEK SOLUTION is outstanding. They were very helpful in answering our questions and providing technical support.

4.7 / 5

The ball mill is a valuable addition to our lab. It's helped us improve the efficiency of our research and has opened up new possibilities for our projects.

4.9 / 5

The durability of the ball mill is exceptional. We've been using it for over a year now, and it's still performing like new.

5.0 / 5

The ball mill from KINTEK SOLUTION is a great investment. It's a reliable and versatile piece of equipment that has helped us achieve our research goals.

4.8 / 5

We're very satisfied with the overall performance of the ball mill. It's a well-designed and well-built machine that meets all of our requirements.

4.7 / 5

The ball mill is a great value for money. It's affordable, yet it doesn't compromise on quality or performance.

4.9 / 5

The technological advancement of the ball mill is impressive. It's equipped with the latest features and capabilities that make our research work easier and more efficient.

5.0 / 5

The ball mill from KINTEK SOLUTION is a must-have for any lab that needs to perform grinding and mixing tasks. It's a powerful and versatile machine that can handle a wide range of materials.

4.8 / 5

We're very happy with the ball mill. It's a reliable and durable machine that has helped us improve the efficiency of our lab work.

4.7 / 5

The customer service from KINTEK SOLUTION is excellent. They're always willing to help and provide support whenever we need it.

4.9 / 5

The ball mill is a great addition to our lab. It's helped us reduce the time and effort required to prepare samples for analysis.

5.0 / 5

The ball mill from KINTEK SOLUTION is a valuable asset to our lab. It's a versatile and powerful machine that has helped us achieve our research goals.

4.8 / 5

We're very satisfied with the overall performance of the ball mill. It's a well-designed and well-built machine that meets all of our requirements.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

The KT-P2000H uses a unique Y-axis planetary trajectory, and utilizes the collision, friction and gravity between the sample and the grinding ball.

High Energy Planetary Ball Mill Milling Machine for Laboratory

The biggest feature is that the high energy planetary ball mill can not only perform fast and effective grinding, but also has good crushing ability

High Energy Planetary Ball Mill Milling Machine for Laboratory

Experience fast and effective sample processing with the F-P2000 high-energy planetary ball mill. This versatile equipment offers precise control and excellent grinding capabilities. Perfect for laboratories, it features multiple grinding bowls for simultaneous testing and high output. Achieve optimal results with its ergonomic design, compact structure, and advanced features. Ideal for a wide range of materials, it ensures consistent particle size reduction and low maintenance.

High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

The KT-P2000E is a new product derived from the vertical high-energy planetary ball mill with a 360°rotation function. The product not only has the characteristics of the vertical high-energy ball mill, but also has a unique 360°rotation function for the planetary body.

Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

The vertical cabinet structure combined with ergonomic design enables users to obtain the best comfortable experience in standing operation. The maximum processing capacity is 2000ml, and the speed is 1200 revolutions per minute.

High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

The KT-P4000E is a new product derived from the vertical high-energy planetary ball mill with a 360° swivel function. Experience faster, uniform, and smaller sample output results with 4 ≤1000ml ball mill jars.

Laboratory Horizontal Planetary Ball Mill Milling Machine

Improve sample uniformity with our Horizontal Planetary Ball Mills. KT-P400H reduces sample deposition and KT-P400E has multi-directional capabilities. Safe, convenient and efficient with overload protection.

Laboratory Ten-Body Horizontal Jar Mill for Lab Use

The Ten-body horizontal jar mill is for 10 ball mill pots (3000ml or less). It has frequency conversion control, rubber roller movement, and PE protective cover.

High Energy Vibratory Laboratory Ball Mill Double Tank Type

High-energy vibration ball mill is a small desktop laboratory grinding instrument. It uses 1700r/min high-frequency three-dimensional vibration to make the sample achieve the result of grinding or mixing.

Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

Discover the versatile stainless steel dry powder/liquid horizontal ball mill with ceramic/polyurethane lining. Ideal for ceramic, chemical, metallurgical, and building materials industries. High grinding efficiency and uniform particle size.

High Energy Vibratory Laboratory Ball Mill Grinding Mill Single Tank Type

High-energy vibration ball mill is a small desktop laboratory grinding instrument.It can be ball-milled or mixed with different particle sizes and materials by dry and wet methods.

Laboratory Four-Body Horizontal Jar Mill

The four-body horizontal tank mill ball mill can be used with four horizontal ball mill tanks with a volume of 3000ml. It is mostly used for mixing and grinding laboratory samples.

Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

zirconia ceramic ball have the characteristics of high strength, high hardness, PPM wear level, high fracture toughness, good wear resistance, and high specific gravity.

Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

The horizontal autoclave steam sterilizer adopts the gravity displacement method to remove the cold air in the inner chamber, so that the inner steam and cold air content is less, and the sterilization is more reliable.

Related Articles

Maximizing Grinding Efficiency: The Power of Planetary Ball Mills

Discover why planetary ball mills offer higher grinding efficiency than ordinary ball mills. Learn about the technology behind their high-performance all-round capabilities. Find out the key factors influencing the productivity and specific energy consumption of ball mills.

Advantages of Planetary Ball Mill in Laboratory Applications

Discover the advantages of using planetary ball mills in laboratory settings. Learn about its ability to produce fine powder, suitability for toxic materials, wide range of applications, continuous operation, and usage for milling abrasive materials. Explore how planetary ball mills differ from traditional milling machines and their function in creating ultrafine and nano-sized materials.

Planetary Ball Mills: Research Tools for Efficient Mixing and Nanoscale Grinding

Planetary ball mills are indispensable tools in modern laboratories, serving a crucial role in the mixing, fine grinding, and preparation of small samples. These mills are particularly adept at dispersing nanomaterials and facilitating the development and small-scale production of high-tech materials.

Disc / Cup Vibratory Mill: A Comprehensive Guide to Its Functions and Applications

Discover the world of Disc / Cup Vibratory Mills with our in-depth guide. Learn about their working principles, applications, advantages, and key features. Explore the various types of vibratory mills and their suitability for different industries.

Choosing the Best Material for Ball Mill: Essential Factors and Recommendations

Discover the best material for ball mill applications and grinding success. Learn about the features and benefits of stainless steel, ceramic, agate, and tungsten carbide media. Find out how to ensure grinding success and the ideal grinding jars and media for planetary ball milling. Explore the applications of ball mills and the advantages of high-energy ball mills for ultra-fine particles.

Disc / Cup Vibratory Mill: A Comprehensive Guide for Laboratory Experts

Discover the world of Disc / Cup Vibratory Mills! This comprehensive guide provides an in-depth understanding of their types, working principles, advantages, and applications in various industries, including pharmaceuticals, chemicals, and food processing.

The fascinating technology (HPHT & CVD) of the diamond growing machine

They are created using either the High Pressure High Temperature (HPHT) process or the Chemical Vapor Deposition (CVD) technique, both of which mimic the natural conditions under which diamonds are formed.

Comprehensive Guide to Filter Press Pilot Testing

Filter press pilot testing serves the purpose of collecting data necessary for accurately sizing a full-scale filter press system. This data includes various parameters such as cake solids, cake density, total processing time, processing time for each step, slurry feed solids, slurry pH, chemical conditioning dosages, and maximum operating pressure for each process step. Additionally, other data like filtrate suspended solids, slurry pH, and specific chemical analysis required by the process may also be collected.

Exploring the Applications of Isostatic Pressing

Isostatic pressing is a powder metallurgy technique that applies equal pressure from all directions to a compacted powder. There are two types of isostatic pressing: cold isostatic pressing (CIP) and hot isostatic pressing (HIP). CIP uses pressure at room temperature, while HIP applies heat and pressure to the powder.

The Invisible Variable: Why Electrolytic Cell Hygiene Defines Your Data

Proper electrolytic cell maintenance prevents dangerous reactions and ensures data integrity. Learn the critical "no metal brush" rule and safety protocols.

Advanced International Plant Extraction Science and Technology

Exploring cutting-edge methods in essential oil extraction, including supercritical CO2, supramolecular, and targeted extraction techniques.

Why Your High-Temperature Furnace Elements Fail: The Critical Difference in Silicon Carbide

Furnace downtime from failing SiC heating elements costs time and money. Discover the critical material difference that ensures reliability in extreme applications.