sterilization equipment

Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

Item Number : KT-P01

Price varies based on specs and customizations

- Electric Tension

- 220V

- LCD Display

- Knob Interface

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

A horizontal autoclave steam sterilizer, also known as an autoclave, is a type of equipment used for sterilizing various materials using steam under high pressure. It is commonly employed in medical, laboratory, and industrial settings to eliminate bacteria, viruses, fungi, and other microorganisms.

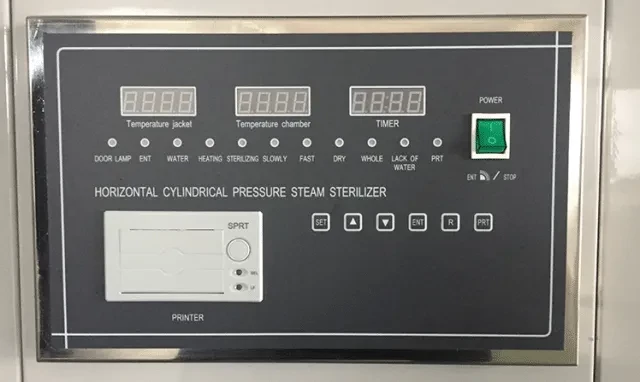

Detail & Parts

Performance and Features

- The sterilization process is automatically controlled without supervision and is easy to use.

- It has a drying function to achieve the drying effect of sterilized items.

- Equipped with over-temperature and over-pressure automatic protection devices.

- Safety interlock device: When the door is not closed tightly, steam cannot enter the inner body and an alarm will be issued. When the pressure in the sterilization chamber is greater than 0.027MPa, the door will be interlocked and cannot be opened.

- Overpressure protection: the safety valve automatically releases pressure protection when the pressure exceeds the working pressure.

- Low water level protection device: It cannot start when the water reaches the high water level, and it will automatically cut off the power when the low water level is missing.

- Over-current protection: The power circuit breaker will cut off the power automatically when the current is overloaded.

- The sterilization chamber is made of stainless steel.

Specifications

| Model | KT-150YDA | KT-200YDA | KT-280YDA | KT-400YDA | KT-500YDA |

| Sterilization chamber volume | 150L φ440×1000 | 200L φ515×1000 | 280L φ600×1000 | 400L φ700×1100 | 500L φ700×1300mm |

| Fixed work stress | 0.22Mpa | ||||

| Rated working temperature | 134℃ | ||||

| Sterilization temperature selection | 40℃-134℃ | ||||

| Timing time selection range | 0-60min | ||||

| Heat uniformity of sterilization room | ≤±2℃ | ||||

| Power/supply voltage | 9kw/380V 50Hz | 9kw/380V 50Hz | 12kw/380V 50Hz | 18kw/380V 50Hz | 18kw/380V 50Hz |

| Dimensions (mm) | 1400×600×1300 | 1400×670×1650 | 1400×770×1780 | 1430×880×1830 | 1800×900×1820 |

| Transport size (mm) | 1560×750×1850 | 1560×820×1850 | 1680×920×2100 | 1600×1050×2100 | 1850×1050×2100 |

| Gross weight/net weight | 320/240kg | 350/260kg | 465/365Kg | 530/420Kg | 580/470Kg |

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

FAQ

What Are Some Common Applications Of Sterilization Autoclaves?

How Long Does A Typical Sterilization Autoclave Cycle Take?

Can Autoclave Sterilization Be Validated For Effectiveness?

Can Autoclave Sterilization Damage Certain Materials?

How Should Autoclave Sterilization Be Monitored And Documented?

4.9 / 5

This autoclave is a lifesaver in our lab. It's easy to use and sterilizes everything quickly and efficiently.

4.8 / 5

I've been using this autoclave for a few months now and I'm very impressed with its performance. It's fast, reliable, and easy to operate.

4.7 / 5

This is the best autoclave I've ever used. It's so easy to use and it sterilizes everything perfectly.

4.6 / 5

I would highly recommend this autoclave to anyone who needs a reliable and efficient way to sterilize their lab equipment.

4.8 / 5

This autoclave is a great value for the price. It's well-made and it does a great job of sterilizing our lab equipment.

4.9 / 5

I'm very happy with this autoclave. It's easy to use and it sterilizes everything quickly and efficiently.

4.7 / 5

This autoclave is a great addition to our lab. It's easy to use and it sterilizes everything perfectly.

4.6 / 5

I would highly recommend this autoclave to anyone who needs a reliable and efficient way to sterilize their lab equipment.

4.8 / 5

This autoclave is a great value for the price. It's well-made and it does a great job of sterilizing our lab equipment.

4.9 / 5

I'm very happy with this autoclave. It's easy to use and it sterilizes everything quickly and efficiently.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

Portable autoclave sterilization pressure is a device that uses pressure saturated steam to quickly and effectively sterilize items.

Mini SS High Pressure Autoclave Reactor for Laboratory Use

Mini SS High Pressure Reactor - Ideal for medicine, chemical, and scientific research industries. Programmed heating temp and stirring speed, up to 22Mpa pressure.

Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

Discover the versatility of Stainless High Pressure Reactor - a safe and reliable solution for direct and indirect heating. Built with stainless steel, it can withstand high temperatures and pressures. Learn more now.

Laboratory Horizontal Autoclave Steam Sterilizer Lab Microcomputer Sterilizer

The horizontal autoclave steam sterilizer adopts the method of gravity displacement to remove the cold air in the inner chamber, so that the content of steam cold air in the inner chamber is less, and the sterilization is more reliable.

Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

Vertical pressure steam sterilizer is a kind of sterilization equipment with automatic control, which is composed of heating system, microcomputer control system and overheating and overpressure protection system.

Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

The pulsating vacuum desktop steam sterilizer is a compact and reliable device used for rapid sterilization of medical, pharmaceutical, and research items.

Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

Portable autoclave sterilization pressure is a device that uses pressure saturated steam to quickly and effectively sterilize items.

Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

The pulse vacuum lifting sterilizer is a state-of-the-art equipment for efficient and precise sterilization. It uses pulsating vacuum technology, customizable cycles, and a user-friendly design for easy operation and safety.

Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

The herbal powder sterilization autoclave machine for Chinese medicine uses saturated steam for effective sterilization. It utilizes the heat and penetrative properties of steam, achieves sterilization after heat preservation, and maintains a good drying effect with a dedicated drying system.

Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

Liquid crystal display automatic vertical sterilizer is a safe, reliable and automatic control sterilization equipment, which is composed of heating system, microcomputer control system and overheating and overvoltage protection system.

Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

The desktop fast steam sterilizer is a compact and reliable device used for rapid sterilization of medical, pharmaceutical, and research items.

Desktop Fast High Pressure Laboratory Autoclave Sterilizer 16L 24L for Lab Use

The desktop fast steam sterilizer is a compact and reliable device used for rapid sterilization of medical, pharmaceutical, and research items.

High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

Discover the applications of Hydrothermal Synthesis Reactor - a small, corrosion-resistant reactor for chemical labs. Achieve rapid digestion of insoluble substances in a safe and reliable way. Learn more now.

Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

The desktop fast steam sterilizer is a compact and reliable device used for rapid sterilization of medical, pharmaceutical, and research items. It efficiently sterilizes surgical instruments, glassware, medicines, and resistant materials, making it suitable for various applications.

Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

This laboratory-scale high-pressure reactor is a high-performance autoclave engineered for precision and safety in demanding research and development environments.

Anti-Cracking Press Mold for Lab Use

The anti-cracking press mold is a specialized equipment designed for molding various shapes and sizes of film using high pressure and electric heating.

Laboratory High Pressure Vacuum Tube Furnace

KT-PTF High Pressure Tube Furnace: Compact split tube furnace with strong positive pressure resistance. Working temp up to 1100°C and pressure up to 15Mpa. Also works under controller atmosphere or high vacuum.

Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

Split cold isostatic presses are capable of providing higher pressures, making them suitable for testing applications that require high pressure levels.

Round Bidirectional Press Mold for Lab

The round bidirectional press mold is a specialized tool used in high-pressure molding processes, particularly for creating intricate shapes from metal powders.

Related Articles

The Thermodynamics of a Perfect Seal: A Component-Level Approach to Sterilization

Learn why autoclaving your entire electrolytic cell destroys the seal. A guide to understanding material properties and protecting your experiments.

Comprehensive Overview of Warm Isostatic Press and Its Applications

Warm isostatic pressing (WIP) is a variant of cold isostatic pressing (CIP) that includes a heating element. It employs warm water or a similar medium to apply uniform pressure to powdered products from all directions. WIP is a cutting-edge technology that enables isostatic pressing at a temperature that does not exceed the boiling point of the liquid medium.

Understanding Isostatic Pressing: Process, Benefits, Limitations, and Applications

Isostatic pressing is a manufacturing process that offers numerous benefits and applications in various industries. It involves subjecting a material to equal pressure from all directions to achieve uniform density and shape. This method is particularly advantageous compared to other production techniques.

Affordable Rotavapor How to Save on Your Purchase

Rotavapor is a laboratory equipment that is used for distillation, purification, and concentration of liquid samples. It is a vital tool for chemists, biologists, and other researchers who work with various types of solvents and chemicals.

Laboratory Safety: High Pressure Equipment and Reactors

This article discusses safety measures and precautions for using high pressure equipment and reactors in laboratories, including case studies and detailed usage instructions.

Basic Cleaning and Disinfection Equipment in the Laboratory

Overview of essential lab cleaning and disinfection tools and their operational principles.

Hazards and Safety Precautions of Laboratory Pressure Vessels

An overview of the dangers and safety measures for pressure vessels in laboratory settings.

PVD Sputtering Targets and Hot Isostatic Pressing: Part 2

This article discusses the manufacturing and optimization of PVD sputtering targets, focusing on techniques like hot isostatic pressing and high pressure heat treatment.

Preparation Technologies and Applications of High-Purity Metals

An in-depth look at the definition, preparation technologies, and applications of high-purity metals.

The Invisible Variable: Why Electrolytic Cell Hygiene Defines Data Integrity

Master the art of electrolytic cell maintenance. Discover how a strict cleaning protocol prevents cross-contamination and secures reproducible electrochemical results.

The 'Machine Press' Myth: Why Your Custom Lab Furniture Is Warping—And How to Fix It for Good

Stop blaming the 'machine press.' Learn why plywood fails and discover the 3 key factors—adhesive, grade, ply count—to select durable materials for your lab.

The Silent Variable: Why Meticulous Cell Care Defines Electrochemical Truth

Discover why rigorous maintenance of super-sealed electrolytic cells is the secret to reproducible data. Expert tips on cleaning, storage, and electrode care.