Milling Equipment

High Energy Vibratory Laboratory Ball Mill Grinding Mill Single Tank Type

Item Number : KT-VB100

Price varies based on specs and customizations

- Maximum injection size

- < 1 mm

- Sample particle size range

- 0.1-20um

- Maximum processing volume

- 80ml

- Sample minimum throughput

- 1g

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

High-energy vibration ball mill is a small desktop laboratory grinding instrument. It uses 1700r/min high-frequency three-dimensional vibration to make the sample achieve the result of grinding or mixing. It is used in a ball mill jar with a volume of 50ml or 80ml, and the minimum processing capacity 1g, it is used to test the treatment of a small amount or a small amount of samples. The processing efficiency of the K-VB300 high-energy vibratory ball mill is 3-5 times that of the planetary ball mill. It can be ball-milled or mixed with different particle sizes and materials by dry and wet methods. Various solids, suspensions and pastes, and can also be equipped with a vacuum ball mill tank to achieve vacuum or inert gas protection grinding.

- Processing principle: impact force | friction force

- Application sample characteristics: fine | medium-low hardness | brittle | dry or low viscosity

- Processing Type: Grinding | Blending

- Main functions: combination lock | continuous and intermittent operation | emergency stop | intermittent timer | run timer | memory | overload protection | heat dissipation | windows

Applications

The High Energy Vibratory Ball Mill (Single Tank Type) is a versatile and powerful tool used in various scientific and industrial applications. This equipment is particularly effective for grinding, mixing, and homogenizing hard and brittle materials, as well as for mechanical alloying. Its high-energy impact mechanism allows for rapid and efficient size reduction, making it ideal for producing ultra-fine particles. Here are the main application areas of this product:

- Materials Science: Used for the preparation of metals, alloys, ceramics, and minerals, facilitating research and development in these fields.

- Pharmaceuticals: Essential for grinding pharmaceutical ingredients to fine powders, which is crucial for the formulation of drugs.

- Electronics: Involved in the production of materials used in electronics, such as ceramics and magnetic materials, ensuring the fine granularity required for these applications.

- Chemical Industry: Employed for mixing and grinding chemicals, aiding in the production of various chemical compounds and products.

- Ceramics Industry: Useful for grinding raw materials used in the ceramic industry, contributing to the production of high-quality ceramics.

- Environmental Science: Used in the analysis and preparation of samples from environmental studies, such as soil and rock samples.

- Food and Beverage Industry: Can be used for grinding food ingredients, aiding in the production of high-quality food products.

- Research and Development: Widely used in laboratories for R&D purposes across various scientific disciplines, due to its efficiency and precision in sample preparation.

Features

The High Energy Vibratory Ball Mill (Single Tank Type) is a cutting-edge laboratory equipment designed for efficient and rapid size reduction of hard and brittle materials. This mill is engineered to deliver high kinetic energy through the use of balls or beads, facilitating the grinding, crushing, and impacting of materials with exceptional speed and intensity. Ideal for applications in electronics, ceramics, chemicals, and pharmaceuticals, this mill stands out for its robust construction, versatile operation, and safety features, ensuring long-term reliability and user safety.

- High Efficiency Grinding: Utilizes high kinetic energy to quickly reduce material size, making it ideal for producing ultra-fine particles in a short time.

- Versatile Operation: Suitable for both wet and dry milling, accommodating a variety of materials and grinding conditions.

- Robust Construction: Engineered to withstand constant vibration and long grinding times, ensuring durability and reliability.

- Safety Features: Equipped with advanced safety mechanisms to allow for unattended operation, crucial when handling potentially hazardous materials.

- Customizable Options: Offers a range of tank linings including stainless steel, ceramic, and various polymers to suit specific material requirements and enhance the milling process.

- Wide Application Range: Applicable in diverse industries including electronics, ceramics, chemicals, and pharmaceuticals, making it a versatile tool in material research and development.

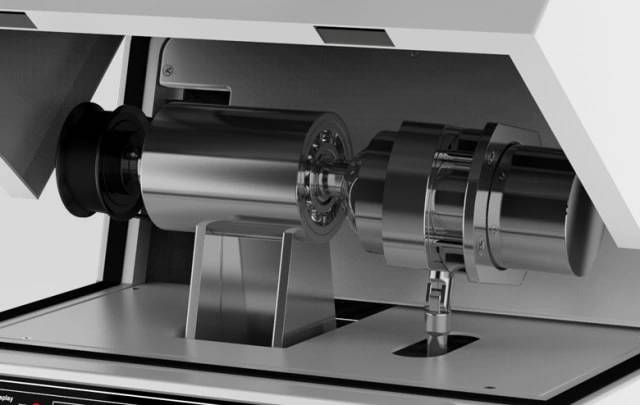

Detail & Parts

Advantages

The High Energy Vibratory Ball Mill (Single Tank Type) offers a range of significant advantages that make it a superior choice for various grinding applications. Here are some of the key benefits:

- High Grinding Efficiency: This ball mill is designed to achieve rapid grinding of materials, particularly effective for hard and brittle substances. It can produce particles at a sub-micron level, ensuring a high degree of fineness and uniformity in the final product.

- Simple Maintenance: With its straightforward structure, the ball mill is easy to maintain and operate. Regular maintenance involves simple tasks such as monitoring material addition and basic equipment upkeep, ensuring continuous and efficient operation.

- Wide Range of Applications: Capable of grinding a variety of materials, including magnetic materials, inorganic non-metallic materials, organic chemical materials, and biomedical materials, this mill is versatile and adaptable to different industrial needs.

- High Precision: The grinding process in this mill is highly precise, allowing for fine grinding that meets stringent quality standards. This precision is crucial for applications requiring high-quality end products.

- Safe and Reliable: Engineered to withstand constant vibration and long grinding durations, the mill is equipped with robust safety features. This ensures safe operation even when handling potentially hazardous solvents and when left unattended for extended periods.

- Versatile Operation: Suitable for both dry and wet ball milling, the mill is adaptable to various working conditions. It is particularly useful in industries such as electronics, ceramics, chemicals, and pharmaceuticals, where material fineness and purity are critical.

- Customizable Options: The tank lining can be customized with materials such as stainless steel, ceramic (alumina), zirconia, tile, nylon, PTFE, edible grade rubber, or polyurethane, enhancing its suitability for specific industrial applications and ensuring compatibility with various materials.

These advantages highlight the High Energy Vibratory Ball Mill's (Single Tank Type) effectiveness and reliability in delivering high-quality grinding solutions across diverse industries.

Technical specifications

| Maximum injection size | < 1 mm |

| Sample particle size range | 0.1-20um |

| Maximum processing volume | 80ml |

| Sample minimum throughput | 1g |

| Ball milling tank speed | 1700r/min |

| Movement mode of ball mill jar | High-frequency three-dimensional motion |

| Ball mill material | Tungsten carbide | Zirconia | Stainless steel optional |

| Number of ball mill jars | 1 |

| Ball mill tank volume | 25ml / 50ml / 80ml optional |

| Grinding ball material | Tungsten carbide | Zirconia | Stainless steel optional |

| Grinding method | Dry Grinding | Wet Grinding | Vacuum Grinding |

| Electrical description | 220V AC, 50-60Hz, 250W |

| Power port | National Standard | European Standard | American Standard | British Standard, etc. |

| Net weight | 35kg |

| Dimensions (L*W*H) | 430*318*268mm |

| Protection class | IP65 |

| Standard: | CE |

Warnings

Operator safety is the top important issue! Please operate the equipment with cautions. Working with inflammable& explosive or toxic gases is very dangerous, operators must take all necessary precautions before starting the equipment. Working with positive pressure inside the reactors or chambers is dangerous, operator must fellow the safety procedures strictly. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

4.8 / 5

I was amazed by how well-built this mill is! It's sturdy and strong, and it can handle even the toughest grinding jobs.

4.9 / 5

This ball mill is a game-changer! It's incredibly efficient and produces ultra-fine particles in just a matter of minutes.

4.7 / 5

The safety features on this mill are top-notch. I feel confident using it, knowing that it has multiple layers of protection.

4.8 / 5

The programmable milling segment is a lifesaver! It allows me to customize the grinding process for different materials.

4.9 / 5

I was impressed by how quiet this mill is. It operates with minimal noise and vibration, which is a huge plus in a laboratory setting.

4.7 / 5

The LCD control panel makes it easy to operate this mill. It's user-friendly and intuitive, even for someone who's new to ball mills.

4.8 / 5

The heavy-duty design of this mill ensures that it can withstand years of use. It's built to last and can handle even the most demanding applications.

4.9 / 5

The customer service from KINTEK SOLUTION is outstanding! They were incredibly helpful and responsive when I had a question about the mill.

4.7 / 5

This mill is incredibly versatile. It can grind a wide range of materials, from hard ceramics to soft metals.

4.8 / 5

The speed of delivery was exceptional. I received the mill within a few days of placing my order.

4.9 / 5

The value for money is unbeatable. This mill is incredibly affordable, especially considering its high-quality construction and features.

4.7 / 5

The durability of this mill is impressive. It has been in operation for months and shows no signs of wear or tear.

4.8 / 5

The technological advancement of this mill is remarkable. It incorporates the latest grinding technology, resulting in superior performance.

4.9 / 5

I highly recommend this mill to anyone in need of a high-quality and reliable grinding solution. It's worth every penny!

4.7 / 5

This mill has exceeded my expectations. It's efficient, durable, and easy to use. I couldn't be happier with my purchase.

4.8 / 5

The customizable power supply is a great feature. It allows me to use the mill with different power ratings, depending on my location and needs.

4.9 / 5

I'm thoroughly impressed with this ball mill. It's a valuable addition to my laboratory and has made my research work much more efficient.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

High Energy Vibratory Ball Mill for Lab Use

The high-energy vibrating ball mill is a high-energy oscillating and impacting multifunctional laboratory ball mill. The table-top type is easy to operate, small in size, comfortable and safe.

High Energy Planetary Ball Mill Milling Machine for Laboratory

The biggest feature is that the high energy planetary ball mill can not only perform fast and effective grinding, but also has good crushing ability

Lab Vibration Mill

Vibration Mill for Efficient Sample Preparation, Suitable for Crushing and Grinding a Variety of Materials with Analytical Precision. Supports Dry / Wet / Cryogenic Grinding and Vacuum/Inert Gas Protection.

High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

The KT-P2000H uses a unique Y-axis planetary trajectory, and utilizes the collision, friction and gravity between the sample and the grinding ball.

Laboratory Single Horizontal Jar Mill

KT-JM3000 is a mixing and grinding instrument for placing a ball milling tank with a volume of 3000ml or less. It adopts frequency conversion control to realize timing, constant speed, direction change, overload protection and other functions.

Mini Planetary Ball Mill Machine for Laboratory Milling

Discover the KT-P400 desktop planetary ball mill, ideal for grinding and mixing small samples in the lab. Enjoy stable performance, long service life, and practicality. Functions include timing and overload protection.

High Energy Planetary Ball Mill for Laboratory Horizontal Tank Type Milling Machine

KT-P4000H uses the unique Y-axis planetary motion trajectory, and utilizes the collision, friction and gravity between the sample and the grinding ball to have a certain anti-sinking ability, which can obtain better grinding or mixing effects and further improve the sample output.

Laboratory Disc Cup Vibratory Mill for Sample Grinding

The vibrating disc mill is suitable for non-destructive crushing and fine grinding of samples with large particle sizes, and can quickly prepare samples with analytical fineness and purity.

High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

The KT-P2000E is a new product derived from the vertical high-energy planetary ball mill with a 360°rotation function. The product not only has the characteristics of the vertical high-energy ball mill, but also has a unique 360°rotation function for the planetary body.

Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

Grind to perfection with alumina/zirconia grinding jars and balls. Available in volume sizes from 50ml to 2500ml, compatible with various mills.

High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

The KT-P4000E is a new product derived from the vertical high-energy planetary ball mill with a 360° swivel function. Experience faster, uniform, and smaller sample output results with 4 ≤1000ml ball mill jars.

Disc Cup Vibrating Mill Multi-Platform for Lab

The multi-platform vibrating disc mill is suitable for non-destructive crushing and fine grinding of samples with large particle sizes. It is suitable for crushing and grinding applications of medium-hard, high-hard, brittle, fibrous, and elastic materials.

High Energy Vibratory Laboratory Ball Mill Double Tank Type

High-energy vibration ball mill is a small desktop laboratory grinding instrument. It uses 1700r/min high-frequency three-dimensional vibration to make the sample achieve the result of grinding or mixing.

Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

Grind and mill with ease using metal alloy grinding jars with balls. Choose from 304/316L stainless steel or tungsten carbide and optional liner materials. Compatible with various mills and features optional functions.

Laboratory Micro Tissue Grinding Mill Grinder

KT-MT10 is a miniature ball mill with a compact structure design. The width and depth are only 15X21 cm, and the total weight is only 8 kg. It can be used with a minimum 0.2ml centrifuge tube or a maximum 15ml ball mill jar.

Laboratory Ten-Body Horizontal Jar Mill for Lab Use

The Ten-body horizontal jar mill is for 10 ball mill pots (3000ml or less). It has frequency conversion control, rubber roller movement, and PE protective cover.

Laboratory High Throughput Tissue Grinding Mill Grinder

KT-MT is a high-quality, small, and versatile tissue grinder used for crushing, grinding, mixing, and cell wall breaking in various fields, including food, medical, and environmental protection. It is equipped with 24 or 48 2ml adapters and ball grinding tanks and is widely employed for DNA, RNA, and protein extraction.

Laboratory Four-Body Horizontal Jar Mill

The four-body horizontal tank mill ball mill can be used with four horizontal ball mill tanks with a volume of 3000ml. It is mostly used for mixing and grinding laboratory samples.

Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

Discover the versatile stainless steel dry powder/liquid horizontal ball mill with ceramic/polyurethane lining. Ideal for ceramic, chemical, metallurgical, and building materials industries. High grinding efficiency and uniform particle size.

Related Articles

Choosing the Best Material for Ball Mill: Essential Factors and Recommendations

Discover the best material for ball mill applications and grinding success. Learn about the features and benefits of stainless steel, ceramic, agate, and tungsten carbide media. Find out how to ensure grinding success and the ideal grinding jars and media for planetary ball milling. Explore the applications of ball mills and the advantages of high-energy ball mills for ultra-fine particles.

Disc / Cup Vibratory Mill: A Comprehensive Guide for Laboratory Experts

Discover the world of Disc / Cup Vibratory Mills! This comprehensive guide provides an in-depth understanding of their types, working principles, advantages, and applications in various industries, including pharmaceuticals, chemicals, and food processing.

Disc / Cup Vibratory Mill: A Comprehensive Guide to Grinding Equipment

Discover the world of Disc / Cup Vibratory Mills! This guide covers everything from types and features to applications and benefits. Explore the versatility of these mills for grinding various materials in industries like pharmaceuticals, food, and chemicals.

Disc / Cup Vibratory Mill: A Comprehensive Guide to Its Functions and Applications

Discover the world of Disc / Cup Vibratory Mills with our in-depth guide. Learn about their working principles, applications, advantages, and key features. Explore the various types of vibratory mills and their suitability for different industries.

Three-Dimensional Vibrating Sieve: Working Principle and Application Fields

Discover the working principle and application fields of the three-dimensional vibrating screener. Learn how this laboratory equipment uses vibration force to efficiently separate and analyze granular materials. Explore its uses in the pharmaceutical, chemical, and various other industries.

The Ultimate Guide to the Application and Benefits of Vibratory Sieve Shaker in Laboratory Testing

Discover the extensive application of vibratory sieve shaker in laboratory testing for industries such as food, medicine, chemical, and more. Learn about the benefits of using a sieve shaker.

Features of Different Laboratory Mills: An Overview

Laboratory mills are specialized machines used to reduce non-homogenous batch samples into smaller, representative samples that are more uniform in composition.

Revolutionizing Lab Efficiency: The Ultimate Guide to Laboratory Sieving Machines

Discover the common sieving methods used in laboratory analysis. Learn about single sieve and sieve set sieving, dry and wet sieving, and other techniques for effective particle separation. Find out how sieving has evolved over time and its importance in quality assurance.

Sieving technology for particle size analysis and its applications

Introducing screening technology, explaining the working principle of vibrating screens and the advantages of using them for particle size analysis in screening technology. Learn about the types of vibrating screens and how to choose one.

Maximizing Grinding Efficiency: The Power of Planetary Ball Mills

Discover why planetary ball mills offer higher grinding efficiency than ordinary ball mills. Learn about the technology behind their high-performance all-round capabilities. Find out the key factors influencing the productivity and specific energy consumption of ball mills.

Unlocking the Power of Sieving Machines: Functions, Applications and Maintenance

Discover the significance of sieving machines in various industries and the essential functions they serve. Learn about the the maintenance requirements for optimal performance. Explore the benefits of using sieve shakers for automating the particle separation process.

Development and Principles of Frozen Tissue Crushers

Explore the history, classification, and principles of frozen tissue crushers, including grinding ball selection and how to choose the right crusher.