Introduction to Disc / Cup Vibratory Mills

Vibratory mills are laboratory workhorses employed for grinding materials into fine powders. They excel in processing small quantities for analysis or sample preparation. Among vibratory mills, disc and cup mills stand out. Disc mills utilize a rotating disc to grind materials, while cup mills employ a cup-shaped chamber. Both types harness vibrations to facilitate grinding.

Types of Disc / Cup Vibratory Mills

Disc vibratory mills and cup vibratory mills are two types of vibratory mills that are used to grind materials. Vibratory mills use a vibrating motion to grind materials, which is different from other types of mills that use a rotating motion.

Disc vibratory mills use a rotating disc to grind materials. The disc is mounted on a shaft that vibrates at high speed. The material to be ground is placed on the disc, and the vibrations cause the material to move around the disc and grind against each other. Disc vibratory mills are often used to grind materials that are difficult to grind, such as ceramics and metals.

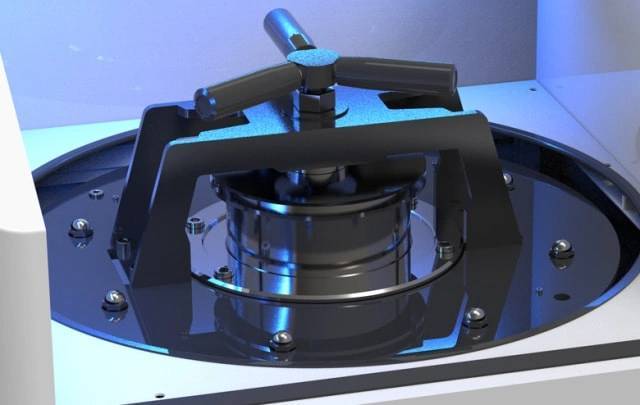

Cup vibratory mills use a cup-shaped grinding chamber. The cup is mounted on a shaft that vibrates at high speed. The material to be ground is placed in the cup, and the vibrations cause the material to move around the cup and grind against the walls of the cup. Cup vibratory mills are often used to grind materials that are not very hard, such as powders and granules.

Disc vibratory mills and cup vibratory mills are both versatile and can be used to grind a wide variety of materials. They are also relatively inexpensive to operate and maintain. However, disc vibratory mills are generally more powerful than cup vibratory mills and can grind materials to a finer size.

Advantages of disc vibratory mills:

- Can grind materials to a finer size than cup vibratory mills

- More powerful than cup vibratory mills

- Can grind materials that are difficult to grind, such as ceramics and metals

Advantages of cup vibratory mills:

- Less expensive to operate and maintain than disc vibratory mills

- Can grind materials that are not very hard, such as powders and granules

- Versatile and can be used to grind a wide variety of materials

Features of Disc / Cup Vibratory Mills

Disc and cup vibratory mills offer a wide range of features that enhance their functionality and efficiency. These features include:

Variable speed control: This feature allows users to adjust the grinding speed based on the material being processed. Different materials have different grinding requirements, and being able to adjust the speed ensures that the mill is operating at the optimal speed for the material being processed. This can help to improve the efficiency of the grinding process and produce a more consistent product.

Timer: A timer enables users to set the grinding time to ensure consistent results. This is important for applications where the grinding time needs to be precisely controlled. For example, in the production of pharmaceuticals, the grinding time can affect the potency of the drug. Being able to set the grinding time ensures that the drug is ground to the correct consistency.

Safety features: Safety features protect users from potential hazards, such as overheating or overfilling the grinding chamber. These features can include things like automatic shut-offs and alarms.

Easy-to-clean design: A design that is easy to clean facilitates quick and efficient cleaning after each use. This is important for applications where the mill is used to process different materials. Being able to clean the mill quickly and easily helps to prevent cross-contamination of materials.

In addition to these features, disc and cup vibratory mills also offer a number of other benefits, including:

- Compact size: Disc and cup vibratory mills are compact in size, making them ideal for use in small spaces.

- Low noise: These mills operate at a low noise level, making them ideal for use in environments where noise is a concern.

- Energy efficiency: Disc and cup vibratory mills are energy efficient, making them a cost-effective option for grinding materials.

Overall, disc and cup vibratory mills offer a wide range of features and benefits that make them ideal for a variety of grinding applications.

Applications of Disc / Cup Vibratory Mills

Disc and cup vibratory mills are versatile tools used in various industries and applications. Some common applications include:

Pharmaceuticals:

- Grinding active pharmaceutical ingredients (APIs) into fine powders for drug formulations.

- Preparing materials for drug delivery systems, such as nanoparticles and microspheres.

- Homogenizing and mixing pharmaceutical formulations.

Food:

- Processing spices, herbs, and other food products into powders or pastes.

- Grinding grains and cereals into flours.

- Preparing food additives and supplements.

Chemicals:

- Grinding chemicals for use in research, development, and production.

- Preparing catalysts and other materials for chemical reactions.

- Homogenizing and mixing chemical formulations.

Materials science:

- Preparing materials for characterization and analysis.

- Grinding and mixing materials for electronic devices.

- Producing nanoparticles and other advanced materials.

Other applications:

- Grinding and mixing pigments and dyes for paints and inks.

- Preparing materials for cosmetics and personal care products.

- Recycling and waste management.

Disc and cup vibratory mills offer several advantages over other types of grinding equipment, including:

- Versatility: They can be used to grind a wide range of materials, from soft to hard, and from dry to wet.

- Efficiency: They can achieve high grinding efficiency in a relatively short time.

- Uniformity: They produce uniform and consistent grinding results.

- Scalability: They are available in various sizes and capacities, from small laboratory models to large industrial units.

Due to their versatility and effectiveness, disc and cup vibratory mills are valuable tools in a wide range of industries and applications.

Benefits of Disc / Cup Vibratory Mills

Vibratory mills employ high-speed vibrations to efficiently grind materials into fine powders. They offer precise control over the grinding process through variable speed and timer settings. Their versatility extends to a wide range of materials, from soft to hard. Additionally, their compact design makes them ideal for space-constrained environments.

Advantages of Vibratory Mills:

1. Enhanced Power and Extended Lifetime: Vibratory mills utilize a universal shaft and vee-belts to transmit power from a nonvibrating electric motor to the grinding bowls. This arrangement delivers more power and optimizes motor life by isolating it from direct vibrations.

2. Versatile Capacity and Excellent Efficiency: Multiple grinding bowls with varying capacities can be installed in vibratory mills, allowing for simultaneous processing of up to four different materials. They can efficiently grind a maximum total sample weight of 1600 grams.

3. Flexibility and Adaptability: Vibratory mills combine various grinding mechanisms, such as jet milling, impact milling, and media milling, in a single system. This versatility allows for a wide range of particle size distributions and accommodates different materials. Quick rotor changes enable rapid conversion between grinding principles.

4. Wide Application and Exceptional Grinding: Vibratory mills are used to grind ores, minerals, ferroalloys, ceramics, soils, aggregates, and chemicals. With their high grinding efficiency, they can typically achieve 95% minus 75-50 microns within 3 minutes.

5. High Output and Low Maintenance: Vibratory mills are suitable for high-volume mineral laboratories and remote laboratories with limited maintenance capabilities. Their simplicity of maintenance reduces downtime and contributes to high overall equipment effectiveness (OEE).

6. Optimal Efficiency and Reduced Production Time: Vibratory mills have the highest power-to-basket ratio, resulting in maximum output with minimal bead consumption and waste. They offer a 50% reduction in production time compared to traditional mills and up to 30% against other immersion mills.

Choosing the Right Disc / Cup Vibratory Mill

When selecting a disc or cup vibratory mill, consider the following factors:

Capacity:

Determine the volume of material that needs to be ground. Disc and cup vibratory mills come in various capacities, so it's important to choose one that can handle the required amount of material.

Material Type:

Choose a mill that is compatible with the material being processed. Different materials have different grinding characteristics, so it's important to select a mill that can effectively grind the specific material.

Features:

Identify the desired features, such as variable speed control, timer, and safety features. Variable speed control allows for precise adjustment of the grinding speed, while a timer can be used to set the grinding time. Safety features, such as a lid interlock, help to prevent accidents.

Budget:

Set a budget and compare the costs of different models. Disc and cup vibratory mills vary in price depending on their capacity, features, and brand. It's important to find a mill that meets your needs and budget.

Additional Considerations:

In addition to the factors mentioned above, there are a few other things to consider when choosing a disc or cup vibratory mill:

- Noise Level: Disc and cup vibratory mills can be noisy, so it's important to consider the noise level when choosing a model. If noise is a concern, look for a mill with a sound enclosure.

- Maintenance: Disc and cup vibratory mills require regular maintenance, such as cleaning and lubrication. It's important to choose a mill that is easy to maintain.

- Warranty: Most disc and cup vibratory mills come with a warranty. The length of the warranty can vary, so it's important to compare warranties before purchasing a mill.

Conclusion

Disc and cup vibratory mills are versatile and efficient laboratory equipment for grinding materials into fine powders. Their variable speed control, precise control, and compact design make them ideal for a wide range of applications in industries such as pharmaceuticals, food, chemicals, and materials science. By understanding the types, features, and benefits of these mills, users can select the right equipment for their specific needs and achieve optimal grinding results.

Related Products

- Laboratory Disc Cup Vibratory Mill for Sample Grinding

- Disc Cup Vibrating Mill Multi-Platform for Lab

- Lab Vibration Mill

- Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

- High Energy Vibratory Laboratory Ball Mill Grinding Mill Single Tank Type

Related Articles

- Disc / Cup Vibratory Mill: A Comprehensive Guide to Its Functions and Applications

- Laboratory Crushers: A Comprehensive Guide to Their Uses and Functionality

- The Scientific Principle of Sieving: Understanding Particle Size Distribution and Laboratory Test Sieves

- Sieving technology for particle size analysis and its applications

- Features of Different Laboratory Mills: An Overview