Introduction to Plant Active Ingredient Extraction

Importance of Extraction Techniques

The extraction and separation of active ingredients from plants play a pivotal role in the pharmaceutical and herbal medicine industries. This process is essential for several key reasons:

-

Reducing Toxicity: By isolating active compounds, extraction techniques help eliminate harmful substances, thereby reducing the risk of adverse reactions in consumers.

-

Improving Efficacy: Precise extraction methods ensure that the therapeutic properties of the plant are preserved and enhanced, leading to more effective treatments.

-

Controlling Product Quality: Standardized extraction processes allow for consistent quality control, ensuring that each batch of medicinal product meets the same high standards.

-

Expanding Medicinal Plant Resources: Efficient extraction technologies enable the utilization of a wider range of plant species, unlocking new potential for medical treatments and remedies.

The significance of these techniques extends beyond just the extraction process; they are fundamental to the advancement and sustainability of herbal medicine practices.

Evolution of Extraction Technologies

The evolution of extraction technologies in the realm of traditional Chinese medicine (TCM) has been significantly propelled by advancements in modern science and technology. These innovations have not only diversified the array of extraction techniques available but also enhanced their efficiency and precision, thereby accelerating the growth and modernization of the TCM industry.

Traditional extraction methods, while foundational, often faced challenges such as process complexity, lengthy extraction cycles, and high solvent consumption. Modern technologies, however, have introduced a spectrum of sophisticated techniques that address these limitations. For instance, ultrasonic extraction leverages ultrasonic waves to disrupt plant cells, thereby accelerating the dissolution of active ingredients. This method is particularly effective for extracting complex compounds such as alkaloids and terpenoids.

Similarly, microwave-assisted extraction (MAE) has proven to be a game-changer. By using microwave energy, MAE can efficiently extract active ingredients while also aiding in the removal of pesticide residues. This technology not only offers substantial economic benefits but also has the potential to revolutionize traditional herb consumption methods.

Supercritical fluid extraction (SFE), which utilizes supercritical fluids like CO2, is another notable advancement. SFE is particularly adept at extracting non-polar and weakly polar substances, making it highly applicable in the pharmaceutical and food industries. This method stands out for its ability to achieve high purity and selectivity while being environmentally friendly.

Moreover, enzymatic extraction has emerged as a promising technique. By employing enzymes, this method reduces mass transfer resistance, thereby increasing the extraction rates and purity of active ingredients. Enzymatic extraction is particularly beneficial for its ability to maintain the integrity and biological activity of the extracted compounds.

In summary, the evolution of extraction technologies has been marked by a shift from traditional, labor-intensive methods to modern, high-efficiency techniques. These advancements have not only improved the efficacy and quality of TCM products but also positioned the industry for continued growth and innovation.

Traditional Extraction Methods

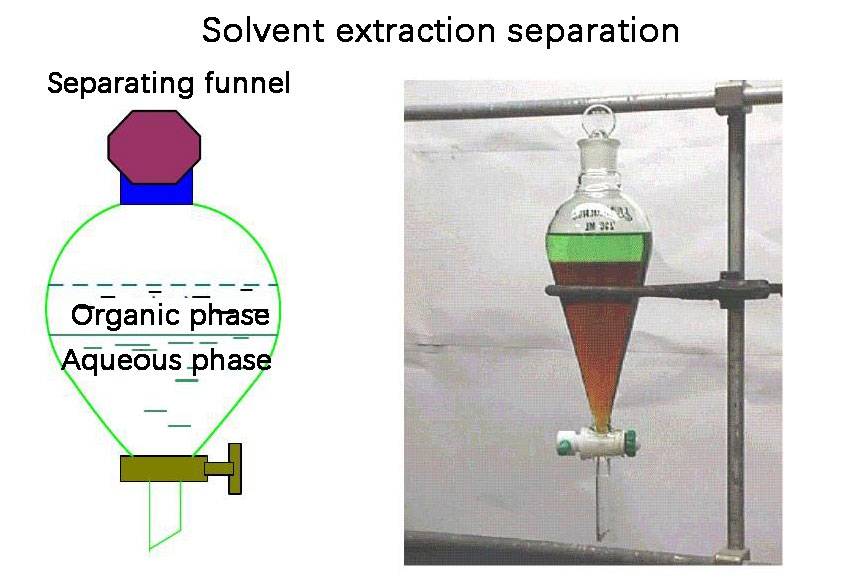

Solvent Separation and Extraction

Traditional methods such as solvent separation, extraction, and precipitation have long been employed to refine plant extracts. These techniques, while effective in isolating active ingredients, are not without their challenges. One of the primary issues is the complexity of the process, which often involves multiple steps and intricate procedures to achieve the desired purity. This complexity not only increases the likelihood of errors but also necessitates a high level of expertise to manage effectively.

Moreover, the lengthy cycles associated with these traditional methods can be a significant drawback. The time required for solvent separation and extraction can range from several hours to days, depending on the specific plant material and the targeted compounds. This prolonged duration not only slows down the production process but also ties up valuable resources for extended periods.

Another critical concern is the high consumption of solvents. Traditional extraction methods typically rely on large volumes of organic solvents, such as hexane, ethanol, or methanol, to dissolve and separate the desired compounds from the plant matrix. This high solvent usage not only raises operational costs but also poses environmental and safety risks. The disposal of large quantities of solvent waste can lead to significant environmental impact, including soil and water pollution, as well as the generation of hazardous air pollutants.

In summary, while traditional solvent separation and extraction methods have their place in the industry, they come with inherent challenges that can hinder efficiency, increase costs, and pose environmental risks.

Modern Extraction Technologies

Ultrasonic Extraction

Ultrasonic extraction represents a significant advancement in the field of plant active ingredient extraction, leveraging high-frequency sound waves to enhance the efficiency of the process. This technology operates by generating cavitation bubbles within the plant material, which implode upon reaching a critical size. These implosions create localized high-pressure zones that effectively rupture plant cell walls, thereby facilitating the release of intracellular compounds.

The primary advantage of ultrasonic extraction lies in its ability to accelerate the dissolution of target compounds, such as alkaloids and terpenoids, which are known for their medicinal properties. By breaking down the structural barriers within plant tissues, ultrasonic waves significantly reduce the time required for extraction, making the process both faster and more efficient. This method is particularly well-suited for extracting a wide range of bioactive compounds, including those that are traditionally difficult to isolate using conventional techniques.

Moreover, ultrasonic extraction offers versatility, as it can be applied to various plant materials without the need for harsh chemicals or high temperatures, which can degrade sensitive compounds. This makes it an environmentally friendly alternative to traditional solvent-based extraction methods, which often involve complex processes, long extraction cycles, and significant solvent consumption.

In summary, ultrasonic extraction not only enhances the yield and purity of extracted compounds but also aligns with contemporary demands for sustainable and efficient extraction technologies. Its ability to break down plant cells and accelerate ingredient dissolution positions it as a valuable tool in the modern extraction toolkit, contributing to the advancement of both pharmaceutical and food industries.

Microwave-Assisted Extraction

Microwave-Assisted Extraction (MAE) has emerged as a transformative technology in the realm of plant active ingredient extraction. This method leverages microwave energy to enhance the efficiency of extracting valuable compounds while simultaneously reducing the presence of harmful pesticide residues. The economic benefits of MAE are substantial, as it significantly accelerates the extraction process and minimizes the use of solvents, thereby lowering operational costs.

Moreover, MAE holds the potential to revolutionize traditional herb consumption methods. By enabling the rapid and efficient extraction of active ingredients, MAE can facilitate the development of new herbal products with enhanced efficacy and safety profiles. This technology not only streamlines the production process but also opens up new avenues for the application of herbal remedies in modern healthcare settings.

In summary, MAE represents a significant advancement in extraction technologies, offering a blend of efficiency, cost-effectiveness, and the potential to innovate traditional herbal medicine practices.

Supercritical Fluid Extraction

Supercritical Fluid Extraction (SFE) is a sophisticated technique that employs supercritical fluids, particularly carbon dioxide (CO₂), to extract non-polar and weakly polar substances. This method is particularly favored in the pharmaceutical and food industries due to its precision and efficiency.

In the pharmaceutical sector, SFE is utilized to isolate and purify active ingredients from plant materials, ensuring high purity and potency. The ability to extract specific compounds without altering their chemical structure is a significant advantage, making SFE indispensable in drug development and production.

Similarly, the food industry leverages SFE for the extraction of flavors, aromas, and essential oils. This technique allows for the preservation of the natural properties of these substances, which is crucial for maintaining the quality and authenticity of food products. The use of CO₂ as a solvent in SFE is also environmentally friendly, as it leaves no residues and can be easily recycled.

SFE operates by maintaining CO₂ at a temperature and pressure above its critical point, where it exhibits properties of both a gas and a liquid. This unique state allows CO₂ to penetrate plant materials effectively and selectively extract target compounds. The process is highly controllable, enabling the extraction of specific compounds based on their solubility and volatility.

The applications of SFE extend beyond the pharmaceutical and food industries. It is also used in the extraction of essential oils, perfumes, and even in the recovery of valuable compounds from waste materials. The versatility and efficiency of SFE make it a cornerstone technology in the pursuit of high-quality, pure, and sustainable extracts.

Enzymatic Extraction

Enzymatic extraction represents a sophisticated approach in the realm of plant active ingredient extraction, leveraging the power of enzymes to optimize the process. By employing specific enzymes, this method effectively breaks down the plant cell walls and cellular matrix, significantly reducing mass transfer resistance. This reduction in resistance facilitates a more efficient extraction process, allowing for higher extraction rates and a greater purity of the active ingredients.

The use of enzymes in this context is particularly advantageous as it mimics natural biological processes, leading to a gentler extraction method compared to mechanical or chemical alternatives. This biological approach not only enhances the yield and purity of the desired compounds but also minimizes damage to the active ingredients, preserving their structural integrity and biological activity.

Moreover, enzymatic extraction is adaptable to various plant materials and can be tailored to target specific types of active ingredients, such as polysaccharides, proteins, and secondary metabolites. This versatility makes it a valuable tool in the pharmaceutical and food industries, where the quality and efficacy of the extracted compounds are paramount.

In summary, enzymatic extraction stands out as a refined and effective technique in the extraction of plant active ingredients, offering enhanced rates and purity while maintaining the integrity of the extracted compounds.

Membrane Ultrafiltration

Membrane ultrafiltration stands out as a pivotal technology in the purification and separation of traditional Chinese medicine (TCM) ingredients. This method is renowned for its ability to preserve the biological activity and stability of the extracted compounds, ensuring that the therapeutic properties of the TCM ingredients remain intact throughout the purification process.

The mechanism of ultrafiltration involves the use of semi-permeable membranes that allow the passage of solvent molecules while retaining larger molecules, such as active ingredients and macromolecules. This selective retention is crucial for the effective separation of valuable compounds from impurities, thereby enhancing the purity and efficacy of the final product.

In the context of TCM, ultrafiltration is particularly advantageous due to its gentle processing conditions. Unlike some traditional methods that may involve harsh chemicals or high temperatures, ultrafiltration operates under mild conditions, minimizing the risk of degradation or denaturation of the sensitive bioactive compounds found in TCM. This preservation of biological activity is essential for maintaining the holistic effectiveness of the medicinal formulations.

Moreover, ultrafiltration offers a scalable and cost-effective solution for large-scale production. Its ability to handle high volumes of material while maintaining consistent quality makes it a preferred choice for industrial applications in the TCM industry. The technology's efficiency in terms of both time and resource utilization further underscores its importance in modernizing the extraction processes of TCM ingredients.

In summary, membrane ultrafiltration not only facilitates the purification and separation of TCM ingredients but also ensures the retention of their biological activity and stability, thereby contributing to the advancement of the TCM industry.

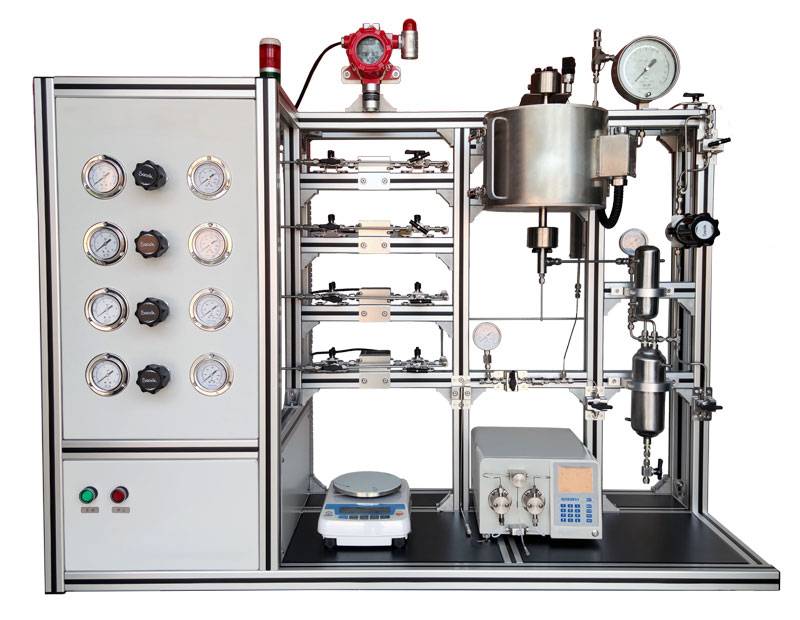

Ultra-High Pressure Technology

Ultra-High Pressure (UHP) technology stands out as a cutting-edge method in the realm of active ingredient extraction, offering a unique blend of speed, efficiency, and energy conservation. This technology leverages extreme pressures to facilitate the extraction process, making it particularly suitable for applications in both the food processing and pharmaceutical industries.

In food processing, UHP technology is employed to enhance the quality and safety of products. By subjecting food materials to high pressures, it can inactivate enzymes, microorganisms, and other harmful substances, thereby extending the shelf life and improving the nutritional profile of foods. This method is particularly beneficial for preserving delicate flavors and nutrients in fresh produce, juices, and dairy products.

In the pharmaceutical field, UHP technology plays a crucial role in the extraction of bioactive compounds from plants. The high pressure conditions can effectively disrupt plant cell walls, allowing for the rapid and efficient release of active ingredients. This not only reduces the extraction time but also minimizes energy consumption, making it a sustainable alternative to traditional methods. The extracted compounds can then be used in the formulation of various pharmaceutical products, contributing to advancements in drug development and delivery.

Moreover, UHP technology offers a significant advantage in terms of process control. The precise pressure levels can be adjusted to target specific compounds, ensuring high purity and yield. This level of control is particularly valuable in the pharmaceutical industry, where the quality and consistency of active ingredients are paramount.

In summary, UHP technology represents a significant leap forward in the extraction of active ingredients from plants. Its application in food processing and pharmaceuticals underscores its potential to revolutionize these industries by offering a fast, efficient, and low-energy alternative to traditional extraction methods.

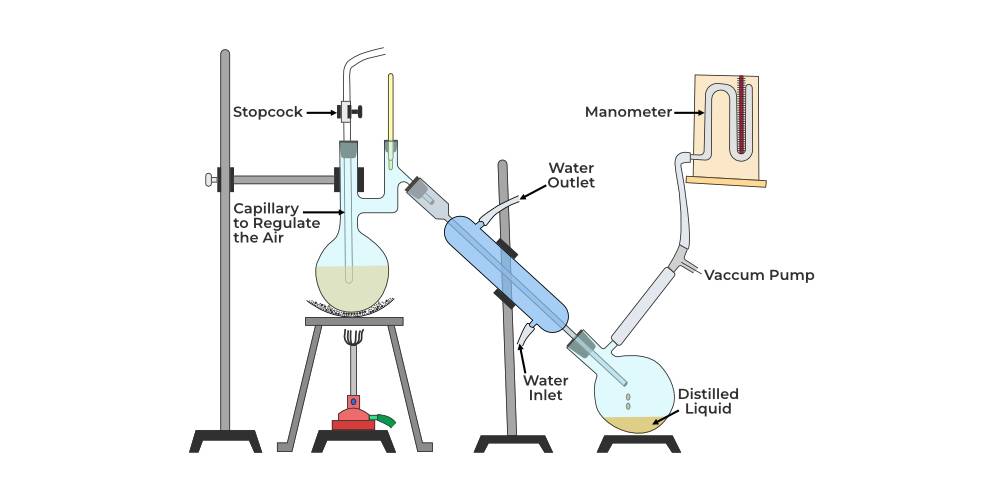

Molecular Distillation

Molecular distillation is a specialized form of vacuum distillation that operates under extremely low pressure, typically below 0.01 torr (1.3 Pa). This process is characterized by its ability to handle high-boiling point and heat-sensitive materials, making it particularly effective in various extraction processes. Unlike conventional distillation methods, molecular distillation operates in the free molecular flow regime, where the mean free path of molecules is comparable to the size of the equipment. This regime allows for the separation and purification of complex and thermally sensitive molecules, such as vitamins and polyunsaturated fatty acids, without subjecting them to high temperatures for extended periods.

In molecular distillation, the gaseous phase no longer exerts significant pressure on the substance to be evaporated, thus the rate of evaporation is independent of pressure. This is because the continuum assumptions of fluid dynamics no longer apply, and mass transport is governed by molecular dynamics. As a result, a short path between the hot surface (where the feed is heated) and the cold surface (where the distillate is condensed) is necessary. This is typically achieved by suspending a hot plate covered with a film of feed next to a cold plate, ensuring a direct line of sight between the two surfaces.

The process of molecular distillation is characterized by short-term exposure of the distillate liquid to high temperatures in high vacuum (around 10−4 mmHg) within the distillation column. The small distance between the evaporator and the condenser, typically around 2 cm, ensures efficient heat transfer and minimizes thermal degradation of the sensitive materials. This makes molecular distillation an ideal choice for the purification and concentration of natural products, particularly those that are prone to thermal decomposition.

Molecular distillation is widely used in industries such as pharmaceuticals and food processing, where the need for high purity and minimal thermal exposure is paramount. Its ability to separate and purify heat-sensitive compounds without compromising their integrity makes it a valuable tool in the extraction and refinement of active ingredients from plants.

Comparative Analysis of Extraction Methods

Evaluation of Modern vs. Traditional Methods

Modern extraction techniques have revolutionized the industry with their efficiency and cost-effectiveness. Techniques such as ultrasonic extraction, microwave-assisted extraction (MAE), and supercritical fluid extraction (SFE) offer rapid processing times and reduced solvent consumption, making them highly economical. For instance, ultrasonic technology not only breaks down plant cells to accelerate ingredient dissolution but also caters to a wide range of plant extracts, including alkaloids and terpenoids. Similarly, MAE is not only effective in extracting active ingredients but also in removing pesticide residues, thereby enhancing the safety and quality of the final product.

However, traditional methods still hold significant value, particularly in contexts where process familiarity and operational simplicity are critical. Traditional techniques like solvent separation and extraction, although more complex and time-consuming, have been refined over centuries and are deeply rooted in cultural and historical practices. These methods, while less efficient in terms of time and resources, often yield high-quality extracts that have been trusted for generations.

| Aspect | Modern Methods | Traditional Methods |

|---|---|---|

| Efficiency | High (rapid processing, reduced solvent use) | Low to moderate (longer cycles, higher solvent consumption) |

| Cost-Effectiveness | High (economical due to reduced time and resources) | Moderate to low (higher operational costs due to longer processing times) |

| Quality of Extracts | High (pure, consistent quality due to controlled processes) | High (trusted quality, often preferred for specific applications) |

| Environmental Impact | Low (reduced solvent use, less waste generation) | High (higher solvent consumption, more waste) |

| Operational Complexity | High (requires specialized equipment and expertise) | Low to moderate (familiar processes, less need for specialized skills) |

The choice between modern and traditional methods is not binary but context-dependent. A comprehensive analysis is essential to determine the optimal selection, considering factors such as the type of plant material, the desired quality of the extract, and the specific requirements of the end product. This nuanced approach ensures that the most suitable method is chosen, balancing the benefits of innovation with the reliability of established practices.

Future Directions in Extraction Technology

Integration and Innovation

Future advancements in the field of plant active ingredient extraction are poised to blend the best of traditional and modern methodologies. This convergence will not only preserve the time-tested practices that have been integral to traditional medicine but also incorporate the cutting-edge innovations that modern science has to offer. One such innovation involves the strategic application of electric and magnetic fields, which have shown potential in enhancing the efficiency and effectiveness of extraction processes.

Electric fields, for instance, can be used to selectively target and disrupt plant cell membranes, facilitating the release of intracellular compounds more efficiently. This method can significantly reduce the time and energy required for extraction, making it a more sustainable option. Similarly, magnetic fields can be employed to manipulate magnetic particles that have been coated with extraction solvents or enzymes, thereby streamlining the extraction process and improving yield.

Moreover, the integration of these technologies with existing modern methods, such as ultrasonic extraction and microwave-assisted extraction, could lead to the development of hybrid techniques that offer the combined benefits of each approach. This could result in higher purity extracts with reduced processing times, ultimately contributing to the advancement of both the pharmaceutical and food industries.

In essence, the future of plant active ingredient extraction lies in the harmonious integration of traditional wisdom and modern innovation, driven by the application of advanced physical fields to optimize and revolutionize the extraction process.

Towards Sustainable and Efficient Extraction

The future of plant active ingredient extraction is poised to undergo a significant transformation, shifting towards technologies that are not only safer and more efficient but also easier to operate and more cost-effective. This paradigm shift is driven by the urgent need for environmentally friendly practices that minimize ecological impact while maximizing yield and purity.

Key Advantages of Future Technologies

| Feature | Description |

|---|---|

| Safety | Reduced risk of chemical exposure and operational hazards. |

| Efficiency | Enhanced extraction rates and purity of active ingredients. |

| Operational Simplicity | Streamlined processes that require less technical expertise. |

| Cost-Effectiveness | Lower operational and maintenance costs. |

| Environmental Impact | Minimized ecological footprint through reduced waste and energy consumption. |

Emerging Technologies

- Green Solvents: Utilization of biodegradable solvents that reduce environmental pollution.

- Biotechnological Approaches: Application of enzymes and microbial cultures to enhance extraction processes.

- Advanced Separation Techniques: Integration of membrane technologies and chromatography for higher purity and yield.

These advancements promise to revolutionize the extraction industry, making it more sustainable and aligned with global environmental and economic goals.

Related Products

- lab cryogenic grinding use liquid-nitrogen for pulverizing plastic raw materials and heat sensitive materials

- Laboratory Hybrid Tissue Grinding Mill