MPCVD

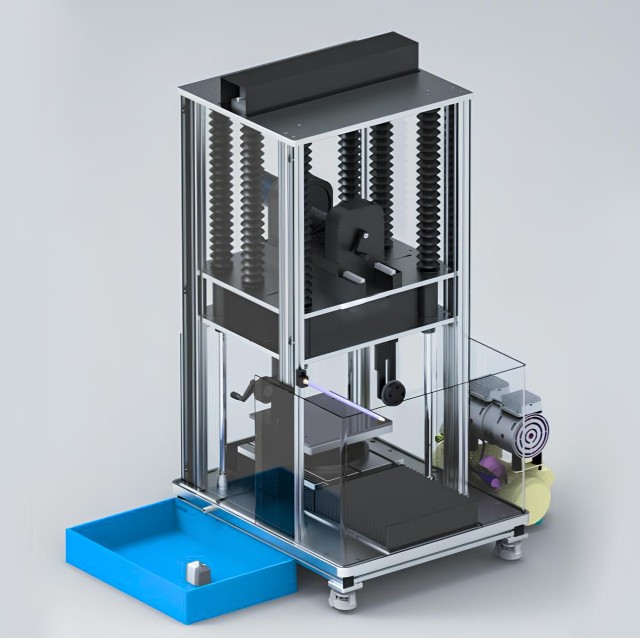

12 Inch 24 Inch High Precision Automatic Diamond Wire Cutting Machine Laboratory Saw Precision Wire EDM Cutting Machine

Item Number : CM-3

Price varies based on specs and customizations

- Power supply

- 220V 50Hz

- Power

- <475W (max)3

- Spindle motor

- AC variable frequency motor, power 250W

- Y, Z, R axis motors

- precision stepper motors 5. Cutting line wire transportation speed: 0 8m/s adjustable, digital display

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

The high precision automatic diamond wire cutting machine is a versatile cutting tool that uses a diamond wire to cut through a wide range of materials, including conductive and non-conductive materials, ceramics, glass, rocks, gems, jade, meteorites, monocrystalline silicon, silicon carbide, polycrystalline silicon, refractory bricks, epoxy boards, and ferrite bodies. It is especially suitable for cutting various brittle crystals with high hardness, high value, and easy to break. The machine features an automatic lubrication system, adjustable pressure and filling volume, and various monitoring and protection functions, making it easy to use and maintain.

Details and parts

Applications

High-precision diamond wire cutting machines are widely used in cutting various metal and non-metal composite materials, including:

- Ceramics

- Glass

- Rocks

- Gems

- Jade

- Meteorites

- Monocrystalline silicon

- Silicon carbide

- Polycrystalline silicon

- Refractory bricks

- Epoxy boards

- Ferrite bodies

These machines are especially suitable for cutting brittle crystals with high hardness, high value, and susceptibility to breakage.

Features

Diamond wire cutting machines use the unidirectional circulation or reciprocating circulation motion of the diamond wire to form a relative grinding motion between the diamond wire and the object being cut, thereby achieving the purpose of cutting. This product can cut conductive and non-conductive materials (as long as the hardness is less than diamond wire). Therefore, diamond wire cutting machines are widely used in cutting various metal and non-metal composite materials, such as ceramics, glass, rocks, gems, jade, meteorites, monocrystalline silicon, silicon carbide, polycrystalline silicon, refractory bricks, epoxy boards, ferrite Body etc. It is especially suitable for cutting various brittle crystals with high hardness, high value and easy to break.

- High precision: The diamond wire cutting machine uses a high-precision diamond wire to cut materials, which can achieve a very high precision of 0.01mm.

- Wide range of materials: The diamond wire cutting machine can cut a wide range of materials, including metals, non-metals, and composites.

- Fast cutting speed: The diamond wire cutting machine has a fast cutting speed, which can greatly improve production efficiency.

- Long service life: The diamond wire cutting machine uses a high-quality diamond wire, which has a long service life and can reduce the cost of use.

- Easy to operate: The diamond wire cutting machine is easy to operate, and even inexperienced operators can quickly master the operation skills.

Principle

The high-precision diamond wire cutting machine uses the unidirectional circulation or reciprocating circulation movement of the diamond wire to form a relative grinding motion between the diamond wire and the object being cut, thereby achieving the purpose of cutting. This product can cut conductive and non-conductive materials (as long as the hardness is less than diamond wire).

Advantages

- High precision cutting: The diamond wire cutting machine uses a diamond wire to cut materials, which can achieve high precision cutting results.

- Wide range of materials: The diamond wire cutting machine can cut a wide range of materials, including conductive and non-conductive materials, such as ceramics, glass, rocks, gems, jade, meteorites, monocrystalline silicon, silicon carbide, polycrystalline silicon, refractory bricks, epoxy boards, ferrite bodies, etc.

- Especially suitable for cutting brittle crystals: The diamond wire cutting machine is especially suitable for cutting various brittle crystals with high hardness, high value, and easy to break.

- Automated control panel: The control panel of the diamond wire cutting machine is automated and easy to operate, which can be operated by one person and saves labor costs.

- Well-known electronic components: The diamond wire cutting machine uses well-known electronic components, which are more stable and can be used for a long time.

- Hydraulic balance device: The diamond wire cutting machine has a hydraulic balance device, which makes the machine movement more stable and quick.

- Heating system: The diamond wire cutting machine has a heating system and heating pipe, which can quickly conduct heat to each layer.

Technical specifications

| Power supply | 220V 50Hz |

|---|---|

| Power | <475W (max)3 |

| Spindle motor | AC variable frequency motor, power 250W |

| Y, Z, R-axis motors | precision stepper motors |

| Cutting line wire transportation speed | 0-8m/s adjustable,digital display |

| Total length of cutting line | ≤ 150m |

| Cutting line diamete | ≤ 0.45mm |

| Y-axis travel | ≤ 300mm, digital display |

| Z-axis travel | ≤ 300mm, digital display |

| Y and Z axis feed indication accuracy | 0.01mm |

| Workbench corner | 0-360 ˚ Resolution 0.01 ˚ Digital display |

| Workbench repeat positioning accuracy | <0.032 ˚ |

| Cutting sample size | Ø 300mm × 300mm (max) |

Trusted by Industry Leaders

FAQ

What Is A Laboratory Saw And What Is It Used For?

What Are The Main Applications Of Diamond Materials?

What Is The Purpose Of A Diamond Wire Cutting Machine?

What Are The Applications Of A Diamond Wire Cutting Machine?

What Are The Main Types Of Laboratory Saws?

What Are The Advantages Of Using Diamond Materials In Industrial Applications?

How Does A Diamond Wire Cutting Machine Work?

What Types Of Diamond Materials Are Available?

What Are The Advantages Of Using A Diamond Wire Cutting Machine?

What Is The Principle Behind The Use Of Diamond Materials In Cutting Tools?

What Materials Can Be Cut Using A Laboratory Saw?

Why Is Synthetic Diamond Preferred Over Natural Diamond In Industrial Applications?

4.7 / 5

I'm very impressed with the speed of delivery, it arrived within 3 days of ordering. The machine is well-made and easy to use. I've been using it for a few weeks now and have had no problems with it. I would definitely recommend this machine to anyone looking for a high-quality diamond wire cutting machine.

4.8 / 5

This machine is a great value for money. It's very affordable, but it doesn't compromise on quality. I've used it to cut a variety of materials, including glass, ceramics, and metal, and it's performed flawlessly every time. I'm very happy with this purchase.

4.9 / 5

I've been using this machine for over a year now and it's still going strong. It's very durable and well-made. I've had no problems with it at all. I would definitely recommend this machine to anyone looking for a reliable and durable diamond wire cutting machine.

4.7 / 5

The technological advancement of this machine is impressive. It's very easy to use and it cuts materials with great precision. I'm very happy with this purchase.

4.8 / 5

I'm very impressed with the quality of this machine. It's made of high-quality materials and it's very well-built. I've been using it for a few months now and it's still working perfectly. I would definitely recommend this machine to anyone looking for a high-quality diamond wire cutting machine.

4.9 / 5

I've been using this machine for over a year now and it's still working perfectly. It's very reliable and I've never had any problems with it. I would definitely recommend this machine to anyone looking for a reliable diamond wire cutting machine.

4.7 / 5

I'm very happy with the speed of delivery, it arrived within 3 days of ordering. The machine is well-made and easy to use. I've been using it for a few weeks now and have had no problems with it. I would definitely recommend this machine to anyone looking for a high-quality diamond wire cutting machine.

4.8 / 5

This machine is a great value for money. It's very affordable, but it doesn't compromise on quality. I've used it to cut a variety of materials, including glass, ceramics, and metal, and it's performed flawlessly every time. I'm very happy with this purchase.

4.9 / 5

I've been using this machine for over a year now and it's still going strong. It's very durable and well-made. I've had no problems with it at all. I would definitely recommend this machine to anyone looking for a reliable and durable diamond wire cutting machine.

4.7 / 5

The technological advancement of this machine is impressive. It's very easy to use and it cuts materials with great precision. I'm very happy with this purchase.

4.8 / 5

I'm very impressed with the quality of this machine. It's made of high-quality materials and it's very well-built. I've been using it for a few months now and it's still working perfectly. I would definitely recommend this machine to anyone looking for a high-quality diamond wire cutting machine.

4.9 / 5

I've been using this machine for over a year now and it's still working perfectly. It's very reliable and I've never had any problems with it. I would definitely recommend this machine to anyone looking for a reliable diamond wire cutting machine.

4.7 / 5

I'm very happy with the speed of delivery, it arrived within 3 days of ordering. The machine is well-made and easy to use. I've been using it for a few weeks now and have had no problems with it. I would definitely recommend this machine to anyone looking for a high-quality diamond wire cutting machine.

4.8 / 5

This machine is a great value for money. It's very affordable, but it doesn't compromise on quality. I've used it to cut a variety of materials, including glass, ceramics, and metal, and it's performed flawlessly every time. I'm very happy with this purchase.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

High Precision Diamond Wire Cutting Machine Laboratory Saw Precision Wire EDM Cutting Machine

The high precision diamond wire cutting machine is a versatile and precise cutting tool designed specifically for material researchers. It utilizes a continuous diamond wire cutting mechanism, enabling precise cutting of brittle materials such as ceramics, crystals, glass, metals, rocks, and various other materials.

Precision Wire Saw Laboratory Cutting Machine with 800mm x 800mm Workbench for Diamond Single Wire Circular Small Cutting

Diamond wire cutting machines are mainly used for precision cutting of ceramics, crystals, glass, metals, rocks, thermoelectric materials, infrared optical materials, composite materials, biomedical materials and other material analysis samples. Especially suitable for precision cutting of ultra-thin plates with thickness up to 0.2mm.

Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

Learn about Cylindrical Resonator MPCVD Machine, the microwave plasma chemical vapor deposition method used for growing diamond gemstones and films in the jewelry and semi-conductor industries. Discover its cost-effective advantages over traditional HPHT methods.

915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

915MHz MPCVD Diamond Machine and its multi-crystal effective growth, the maximum area can reach 8 inches, the maximum effective growth area of single crystal can reach 5 inches. This equipment is mainly used for the production of large-size polycrystalline diamond films, the growth of long single crystal diamonds, the low-temperature growth of high-quality graphene, and other materials that require energy provided by microwave plasma for growth.

24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

Looking for a reliable Hydraulic Heated Lab Press? Our 24T / 40T model is perfect for material research labs, pharmacy, ceramics, and more. With a small footprint and the ability to work inside a vacuum glove box, it's the efficient and versatile solution for your sample preparation needs.

Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

Get your exclusive CVD furnace with KT-CTF16 Customer Made Versatile Furnace. Customizable sliding, rotating, and tilting functions for precise reactions. Order now!

Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

KT-PE12 Slide PECVD System: Wide power range, programmable temp control, fast heating/cooling with sliding system, MFC mass flow control & vacuum pump.

Square Lab Press Mold for Laboratory Applications

Create uniform samples easily with Square Lab Press Mold - available in various sizes. Ideal for battery, cement, ceramics, and more. Custom sizes available.

Narrow Band Pass Filters for Precision Applications

A narrow bandpass filter is an expertly engineered optical filter specifically designed to isolate a narrow range of wavelengths while effectively rejecting all other wavelengths of light.

Hybrid High Energy Vibratory Ball Mill for Lab Use

KT-BM400 is used for rapid grinding or mixing of dry, wet and frozen small amount of samples in the laboratory. It can be configured with two 50ml ball mill jars

Polygon Press Mold for Lab

Discover precision polygon press molds for sintering. Ideal for pentagon-shaped parts, our molds ensure uniform pressure and stability. Perfect for repeatable, high-quality production.

Square Bidirectional Pressure Mold for Lab Use

Discover precision in molding with our Square Bidirectional Pressure Mold. Ideal for creating diverse shapes and sizes, from squares to hexagons, under high pressure and uniform heating. Perfect for advanced material processing.

Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

The High Temperature Hot Press is a machine specifically designed for pressing, sintering and processing materials in a high temperature environment. It is capable of operating in the range of hundreds of degrees Celsius to thousands of degrees Celsius for a variety of high temperature process requirements.

Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

The High Temperature Hot Press is a machine specifically designed for pressing, sintering and processing materials in a high temperature environment. It is capable of operating in the range of hundreds of degrees Celsius to thousands of degrees Celsius for a variety of high temperature process requirements.

Lab Sterile Slapping Type Homogenizer for Tissue Mashing and Dispersing

The slapping sterile homogenizer can effectively separate the particles contained in and on the surface of solid samples, ensuring that the mixed samples in the sterile bag are fully representative.

Related Articles

Diamond Growing Machines For Modern Machining and Need for New Cutting Tools

Diamonds have become popular due to their exceptional hardness, superior thermal conductivity, and chemical stability.

Understanding the CVD Diamond Machine and How It Works

CVD (Chemical Vapor Deposition) diamond creation process involves the deposition of carbon atoms onto a substrate using a gas phase chemical reaction. The process starts with the selection of a high-quality diamond seed, which is then placed in a growth chamber along with a carbon-rich gas mixture.

The Ethics of Diamond Growing Machines

Lab-grown diamonds have gained significant popularity in recent years due to their ethical and environmental benefits.

The Pros and Cons of Different Lab Diamond Machine Methods

Lab-grown diamonds, also known as synthetic diamonds, are man-made diamonds produced in a laboratory setting.

Isostatic Pressing of Ceramics: Process and Precision

When it comes to producing high-quality ceramic components, one of the most crucial processes is isostatic pressing. This technique ensures the uniformity and precision required for manufacturing ceramics used in various industries. Isostatic pressing involves carefully selecting the pressing powders and controlling the tools to achieve the desired uniformity. By understanding the process of isostatic pressing, manufacturers can ensure the production of ceramics that meet the strict standards of dimensional accuracy and performance.

How to Achieve Uniform Pressure with Warm Isostatic Press

Warm Isostatic Pressing (WIP) is a manufacturing process that subjects materials to high pressure and high temperature simultaneously. The process involves using an isostatic press to apply uniform pressure to the material from all directions while it is heated to a specific temperature.

Advancements in Engineering Ceramic Materials

Explores new engineering ceramics with exceptional properties and applications in harsh environments, comparing them to traditional materials.

Why Your Laminator Keeps Ruining Documents—And How to Stop It for Good

Tired of your laminator turning thermal prints or photos into black smudges? Discover the simple reason it happens and how to choose the right method.

Techniques and Methods of Freeze Pulverization for Powdered Rubber

An overview of various methods for producing powdered rubber through freeze pulverization, including liquid nitrogen and air turbine expander cold methods.

Why Your Leather Embossing Is Inconsistent—And How to Fix It for Good

Struggling with faint, blurry, or scorched leather embossing? Discover the scientific reason it fails and how to achieve perfect, repeatable results.