MPCVD

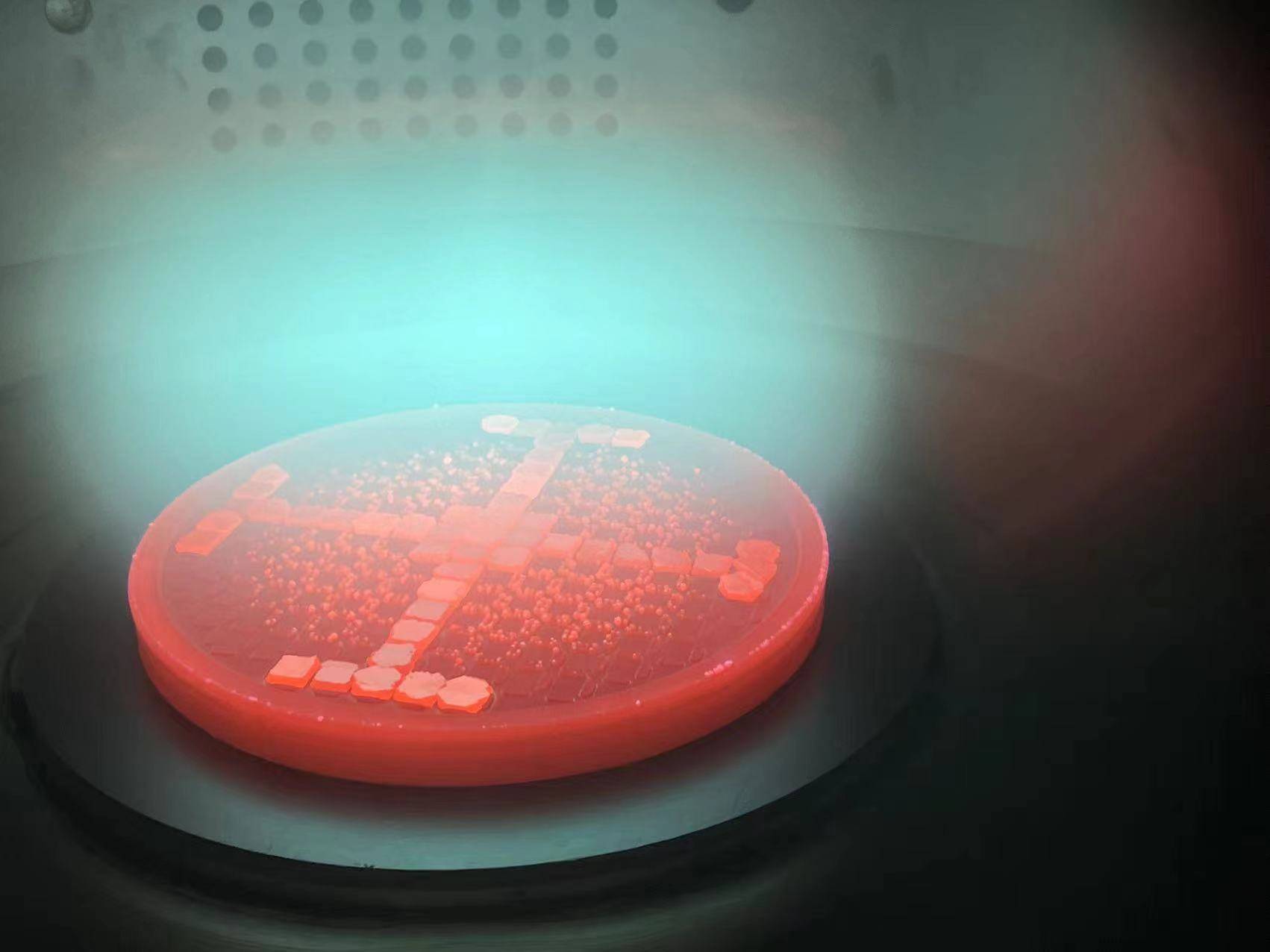

915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

Item Number : MP-CVD-101

Price varies based on specs and customizations

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduce

The MPCVD Diamond Machine is a revolutionary technology that utilizes Microwave Plasma Chemical Vapor Deposition (MPCVD) to synthesize diamonds. This advanced method enables faster crystal growth, higher production capacity, and enhanced diamond quality compared to traditional techniques.

The MPCVD Diamond Machine allows for precise control of microwave power and reaction temperature, eliminating issues faced in other CVD methods. By optimizing the reaction chamber design and process parameters, it achieves stable plasma discharge, crucial for producing high-quality, large-size single-crystal diamonds.

The versatility of the MPCVD Diamond Machine extends to its ability to create diamonds in various colors, including white, yellow, pink, and blue. Moreover, it offers customizable production to cater to specific market demands.

Application

MPCVD Diamond Machines are widely used in various industries due to the unique properties of diamonds, such as their hardness, stiffness, high thermal conductivity, low thermal expansion, radiation-hardness, and chemical inertness. Here are some of the main application areas of MPCVD Diamond Machines:

- Diamond gemstones: MPCVD is the primary equipment used for growing high-quality, large-size diamond gemstones.

- Diamond films: MPCVD is used to grow diamond films for a variety of applications, including large-size diamond substrates for the semiconductor industry and diamond cutting or drilling tools.

- Industrial applications: MPCVD is used to produce diamond coatings for cutting tools, drill bits, and other industrial applications where extreme hardness and durability are required.

- Biomedical applications: MPCVD is used to produce diamond coatings for medical implants, such as artificial joints and dental implants, where biocompatibility and durability are essential.

- Optoelectronics: MPCVD is used to produce diamond windows and substrates for optoelectronic devices, such as high-power lasers and detectors, where high thermal conductivity and low thermal expansion are critical.

Detail & Parts

Principle

Microwave Plasma Chemical Vapor Deposition (MPCVD) is a chemical vapor deposition process that utilizes a continuous microwave source to generate and sustain a highly reactive plasma composed of reacting chemicals and essential catalysts. MPCVD is widely employed to deposit diamond layers—methane and hydrogen are introduced and utilized to cultivate new diamond on a diamond-seeded substrate.

Features

The MPCVD Diamond Machine features several advantages that benefit customers:

- Faster crystal growth speed: 10-100 times faster than traditional methods, resulting in increased production efficiency.

- More production capacity: Enables higher production capacity in a single batch, allowing for larger-scale diamond synthesis.

- Higher quality performance:Produces diamonds with higher hardness and toughness than natural diamonds, ensuring durability and longevity.

- More diversified colors: Supports the production of diamonds in a range of colors, including white, yellow, pink, and blue, catering to diverse market demands.

- Higher diamond purity: Produces diamonds with higher purity than natural diamond Type II, ensuring exceptional optical properties and suitability for various applications.

- Multi-style customization: Offers customizable designs to meet specific market requirements, providing tailored solutions for different industries.

Technical specifications

|

Microwave system (according to optional power supply) |

|

|---|---|

|

Vacuum system and reaction chamber |

|

|

Sample holder system |

|

|

Gas system |

|

|

System cooling |

|

|

Temperature measurement method |

|

SL901A Equipment key part list

| serial number | Module name | Remark |

|---|---|---|

| 1 | Microwave power supply | Standard domestic magnetron: Yingjie Electric / Distinguish power supply Domestic solid-state source: Watson (+30,000) Imported magnetron: MKS/ pastoral (+100, 000) |

| 2 | Waveguide, three pins, mode converter, upper resonator | Self made |

| 3 | Vacuum reaction chamber (upper chamber, lower chamber, connectors) | Self made |

| 4 | Infrared thermometers, optical displacement components, brackets | Infrared thermometers, optical displacement components, Fuji Gold Siemens + Schneider brackets |

| 5 | Water-cooling table motion components (cylinders, workpieces, etc.) | |

| 6 | Ceramic thin film vacuum gauge,Pirani vacuum gauge | Inficon |

| 7 | Vacuum valve components (ultra-high vacuum gate valve, precision pneumatic valve*2, electromagnetic vacuum charging differential valve) | Fujikin + Zhongke + Himat |

| 8 | Vacuum pump and connecting pipe fittings, tee, KF25 bellows*2, adapter | Pump: Flyover 16L |

| 9 | Metal microwave sealing ring*2; metal vacuum sealing ring*1; Quartz plate | Quartz: Shanghai FeilihuaSemiconductor Grade High Purity Quartz |

| 10 | Circulating water components (joints, diverter blocks, flow detectors) | Japanese SMC/CKD |

| 11 | Pneumatic part (CKD filter, airtac multi-way solenoid valve, pipe fittings and adapters) | |

| 12 | Gas connector, EP gas pipe, VCR connector, filter 0.0023μm *1, filter 10μm*2 | Fujikin |

| 13 | Machine casing, stainless steel table, universal wheels, feet, bracket fastening screws, etc | custom processing |

| 14 | Gas flow meter*6 (including one pressure control) | Standard seven-star , optional Fuji Gold ( +34,000 ) / Alicat (42,000) |

| 15 | Gas plate processing (5-way gas, filter*5, pneumatic valve*5, manual valve*6, pipeline welding) | Fuji Gold |

| 16 | PLC automatic control | Siemens + Schneider |

| 17 | Molybdenum table | |

Advantages

- Faster crystal growth speed - 10-100 times faster than traditional methods

- More production capacity - more production capacity in a single batch

- Higher quality performance - higher hardness and toughness than natural diamonds

- More diversified colors - white, yellow, pink, blue, etc.

- Higher diamond purity - purer than natural diamond Type

- Multi style customization can be customized according to different market

Trusted by Industry Leaders

FAQ

What Is Mpcvd?

What Is Mpcvd Machine?

What Are The Advantages Of Mpcvd?

Are CVD Diamonds Real Or Fake?

4.8 / 5

I'm marvelled by the MPCVD machine's ability to produce high-purity diamonds with minimal energy consumption.

4.9 / 5

The MPCVD machine has revolutionized diamond synthesis, enabling the production of larger diamonds with exceptional quality.

4.7 / 5

I highly recommend the MPCVD machine for its durability and cost-effectiveness. It's a game-changer in diamond synthesis.

4.6 / 5

The MPCVD machine is user-friendly and requires minimal maintenance. It's a valuable asset for any laboratory.

4.8 / 5

The MPCVD machine has enabled us to produce high-quality diamonds for various industrial applications. It's a reliable and efficient machine.

4.9 / 5

The MPCVD machine's ability to adjust microwave power and control reaction temperature precisely is remarkable. It ensures consistent and high-quality diamond synthesis.

4.7 / 5

The MPCVD machine stands out with its large-area stable discharge plasma, which enables the production of high-quality, large-sized single crystal diamonds.

4.6 / 5

I'm thoroughly impressed with the MPCVD machine's ability to avoid contamination and produce purer diamonds compared to traditional methods.

4.8 / 5

The MPCVD machine is an excellent choice for laboratories seeking to produce high-quality diamonds for research and industrial applications.

4.9 / 5

The MPCVD machine has exceeded our expectations. It's a valuable addition to our laboratory, enabling us to produce diamonds with remarkable properties.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

Learn about Cylindrical Resonator MPCVD Machine, the microwave plasma chemical vapor deposition method used for growing diamond gemstones and films in the jewelry and semi-conductor industries. Discover its cost-effective advantages over traditional HPHT methods.

Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

KT-PE12 Slide PECVD System: Wide power range, programmable temp control, fast heating/cooling with sliding system, MFC mass flow control & vacuum pump.

Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

Get your exclusive CVD furnace with KT-CTF16 Customer Made Versatile Furnace. Customizable sliding, rotating, and tilting functions for precise reactions. Order now!

Related Articles

The Process of Fabricating a CVD Diamond By MPCVD Machine

CVD diamond machines have gained significant importance in various industries and scientific research.

The Advancements in MPCVD Systems for Large Size Single Crystal Diamonds

Advancements in MPCVD systems have enabled the production of larger and higher quality single-crystal diamonds, offering promising potential for future applications.

A Comprehensive Guide to MPCVD: Diamond Synthesis and Applications

Explore the fundamentals, advantages, and applications of Microwave Plasma Chemical Vapor Deposition (MPCVD) in diamond synthesis. Learn about its unique capabilities and how it compares to other diamond growth methods.

A beginner's guide to MPCVD machines

MPCVD (Microwave Plasma Chemical Vapor Deposition) is a process used to deposit thin films of material onto a substrate using plasma generated by microwaves.

Plasma Enhanced Chemical Vapor Deposition (PECVD): A Comprehensive Guide

Learn everything you need to know about Plasma Enhanced Chemical Vapor Deposition (PECVD), a thin film deposition technique used in the semiconductor industry. Explore its principles, applications, and benefits.

CVD Machines for Thin Film Deposition

Chemical Vapor Deposition (CVD) is a widely used technique for deposition of thin films on various substrates.

Understanding PECVD: A Guide to Plasma-Enhanced Chemical Vapor Deposition

PECVD is a useful technique for creating thin film coatings because it allows for the deposition of a wide variety of materials, including oxides, nitrides, and carbides.

Understanding the CVD Diamond Machine and How It Works

CVD (Chemical Vapor Deposition) diamond creation process involves the deposition of carbon atoms onto a substrate using a gas phase chemical reaction. The process starts with the selection of a high-quality diamond seed, which is then placed in a growth chamber along with a carbon-rich gas mixture.

Diamond Growing Machines For Modern Machining and Need for New Cutting Tools

Diamonds have become popular due to their exceptional hardness, superior thermal conductivity, and chemical stability.

Chemical Vapor Deposition (CVD) of Graphene Challenges and Solutions

Chemical Vapor Deposition (CVD) is a widely adopted method for the production of high-quality graphene.

Comparing the Performance of PECVD and HPCVD in Coating Applications

Although both PECVD & HFCVD are used for coating applications, they differ in terms of deposition methods, performance, and suitability for specific applications.

The Role of Plasma in PECVD Coatings

PECVD (Plasma Enhanced Chemical Vapor Deposition) is a type of thin film deposition process that is widely used for creating coatings on various substrates. In this process, a plasma is used to deposit thin films of various materials onto a substrate.