Introduction to Modern Machining and Need for New Cutting Tools

The field of machining has experienced significant advancements in recent times. With the need for precision and efficiency, there is a corresponding demand for cutting-edge tools to match. Traditional cutting tools made from materials like tungsten carbide have limitations such as wear and tear and the inability to work on harder materials. This has led to the development of super-hard materials like diamonds for use in cutting tools. Diamonds have become popular due to their exceptional hardness, superior thermal conductivity, and chemical stability. The need for diamond cutting tools is further driven by the demand for precision and efficiency in modern machining.

Table of Contents

- Introduction to Modern Machining and Need for New Cutting Tools

- Advantages of Diamond as a Super-Hard Tool Material

- Types of Diamond Cutting Tool Materials

- Other Industrial Uses of Diamonds

- Advantages of Lab-Grown Diamonds in Reducing Carbon Footprint

- Overview of MPCVD and HPHT methods for creating lab-grown diamonds

- Advantages of MPCVD system for diamond growth

- Working Process of MPCVD Machine

- Advantages of Using Diamond Growing Machines

Advantages of Diamond as a Super-Hard Tool Material

Diamond is one of the hardest materials on earth, and its unique physical and chemical properties make it an ideal material for a wide range of applications. In the field of machining, diamond offers several advantages as a super-hard tool material.

Exceptional Hardness and Wear Resistance

One of the main advantages of using diamond as a super-hard tool material is its exceptional hardness and wear resistance. This makes it ideal for cutting, drilling, and grinding even the hardest materials, such as cemented carbide, nickel, and glass. Diamond tools can maintain their sharpness and cutting performance for longer periods, which results in higher production rates and cost savings.

High Thermal Conductivity

Diamond tools are also highly resistant to heat, which makes them suitable for use in high-temperature applications. This is due to the high thermal conductivity of diamond, which allows it to dissipate heat quickly and efficiently. This property is particularly important in the machining of ductile and soft materials, such as aluminum and copper, where excessive heat can cause deformation and other surface quality issues.

Consistent Quality and Properties

Additionally, synthetic diamonds offer greater consistency in terms of quality and properties compared to natural diamonds, which can vary widely in terms of purity and crystalline structure. This consistency makes it easier to manufacture diamond-based tools with specific properties and characteristics, such as high thermal conductivity or low coefficient of friction. This enables manufacturers to produce tools that meet specific customer requirements and standards.

Cost-Effective Alternative

Finally, synthetic diamonds are also more affordable than natural diamonds, making them a cost-effective alternative for many industrial and scientific applications. This is because synthetic diamonds can be produced in larger quantities and with greater consistency, which reduces production costs and increases the availability of diamond-based tools in the market.

In conclusion, the use of diamond as a super-hard tool material offers numerous advantages for the development of high-performance tools and materials that can improve efficiency, reliability, and quality in a wide range of industries. From exceptional hardness and wear resistance to high thermal conductivity and consistent quality, diamond tools are becoming increasingly popular in modern machining technology.

Types of Diamond Cutting Tool Materials

Diamond cutting tools are widely used in various industries, including jewelry, electronics, and cutting tools. There are several types of materials used in diamond cutting tools, which are as follows:

1. Synthetic Diamonds

Synthetic diamonds are created using diamond growing machines that use a process called chemical vapor deposition. These diamonds are almost identical to natural diamonds in terms of their physical and chemical properties. Synthetic diamonds are more environmentally friendly than natural diamonds, as they do not require mining and do not contribute to environmental degradation. One of the main advantages of using synthetic diamonds is that they allow for the production of large, high-quality diamonds at a fraction of the cost of natural diamonds.

2. Cubic Boron Nitride (CBN)

CBN is a synthetic material that is similar to diamond in terms of its hardness and durability. It is ideal for cutting hard materials like steel and ceramic. CBN is commonly used in metalworking applications, including cutting tools, grinding wheels, and honing stones.

3. Tungsten Carbide

Tungsten carbide is a metal alloy that is often used as a substrate for diamond coatings. It provides a strong and durable base for the diamond to adhere to. Tungsten carbide is commonly used in cutting tools for machining and drilling applications.

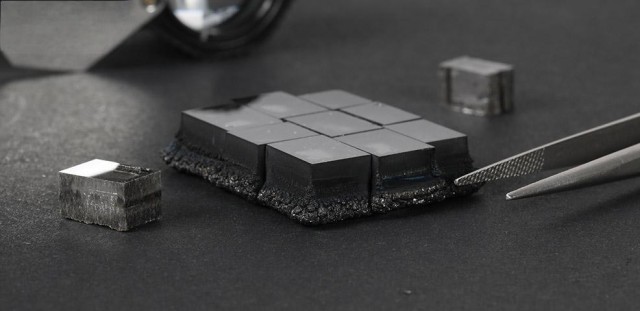

4. Polycrystalline Diamond (PCD)

Polycrystalline diamond is the most common form of diamond used in cutting tools. It is made from micron-sized diamond grains that are dispersed in a metal matrix, usually cobalt, and sintered onto the tool. PCD-tipped tools can be found in mining and cutting applications.

5. Single-Crystal Diamond

Single-crystal diamond is used in several areas of optics, including heat spreaders inside laser cavities, diffractive optics, and as the optical gain medium in Raman lasers. Recent advances in the HPHT and CVD synthesis techniques have improved the purity and crystallographic structure perfection of single-crystalline diamond enough to replace silicon as a diffraction grating and window material in high-power radiation sources, such as synchrotrons.

In conclusion, the choice of materials for diamond cutting tools will depend on the specific application and the properties required for the cutting tool. Each material has its own unique properties and advantages. The use of diamond growing machines and the variety of materials available for diamond cutting tools have revolutionized the diamond industry and have made diamond technology more accessible and affordable for a variety of applications.

Other Industrial Uses of Diamonds

Diamonds are not only valuable for their beauty and elegance, but they also have a wide range of industrial applications due to their hardness, durability, and resistance to heat and corrosion. In this section, we will discuss some of the other industrial uses of diamonds.

Diamond-tipped Drill Bits for Oil and Gas Exploration

Diamonds are used in the oil and gas industry to make drill bits that are capable of cutting through hard rocks and minerals. These drill bits are coated with diamond particles, which make them much more efficient and long-lasting than traditional drill bits.

Diamond-Coated Tools for Cutting and Polishing

Diamonds are used in the manufacturing industry to make cutting and polishing tools. These tools are coated with diamond particles, which make them much more efficient and durable than traditional tools. Diamond-coated tools are commonly used in the automotive industry, the aerospace industry, and the construction industry.

Diamond Windows for Use in Lasers and Other High-Tech Equipment

Diamonds are also used in high-tech equipment, such as lasers and X-ray machines, to make windows that are transparent to high-energy radiation. Diamond windows are much more durable and resistant to heat than traditional windows made of glass or plastic.

Lab-Grown Diamonds

As lab-grown diamonds grow in popularity, many industries are turning to them as a more sustainable and cost-effective alternative to mined diamonds. Lab-grown diamonds are more durable and pure than natural diamonds, making them ideal for use in a wide range of applications, from cutting tools to high-tech electronics.

Conclusion

In conclusion, diamonds have a wide range of industrial applications due to their unique properties, such as hardness, durability, and resistance to heat and corrosion. Other industrial uses of diamonds include diamond-tipped drill bits for oil and gas exploration, diamond-coated tools for cutting and polishing, and diamond windows for use in lasers and other high-tech equipment. As the demand for sustainable and cost-effective alternatives to mined diamonds grows, lab-grown diamonds are becoming increasingly popular in many industries.

Advantages of Lab-Grown Diamonds in Reducing Carbon Footprint

Lab-grown diamonds offer numerous advantages over traditional diamond mining, including a reduced carbon footprint. This section will explore how lab-grown diamonds are a more sustainable and environmentally friendly option for those looking to reduce their carbon footprint.

Energy Efficiency

Lab-grown diamonds require significantly less energy to produce than mined diamonds. According to the University of Delaware Energy and Environment Professor Dr Saleem Ali, "on the environmental side, there is no question that synthetic diamonds will be less impactful than mined diamonds." This energy efficiency translates to a lower carbon footprint, making lab-grown diamonds a more sustainable option.

Reduced Emissions

Lab-grown diamonds emit fewer greenhouse gases during the manufacturing process than mined diamonds. This is because lab-grown diamonds are produced using controlled conditions, which makes the process more efficient and less wasteful. This reduction in emissions makes lab-grown diamonds an environmentally friendly option for those who want to reduce their carbon footprint.

Ethical Considerations

Diamond mining can have a significant impact on the environment, including deforestation, soil erosion, and water pollution. In addition, diamond mining can be associated with human rights abuses, such as child labor and exploitation. Lab-grown diamonds eliminate the ethical concerns surrounding diamond mining, making them a more sustainable and responsible option.

Versatility

Because lab-grown diamonds are grown under controlled conditions, they can be created in a variety of shapes and sizes, making them more versatile than mined diamonds. This versatility allows designers to create unique and innovative designs that may not have been possible with natural diamonds.

Cost-Effective

Lab-grown diamonds are also more cost-effective than natural diamonds. They can be up to 50% cheaper than mined diamonds, making them an attractive option for those who want a high-quality diamond without the high price tag. This cost-effectiveness also makes lab-grown diamonds more accessible to a wider range of consumers, providing more people with the opportunity to enjoy the beauty of a diamond.

In conclusion, lab-grown diamonds offer numerous advantages over traditional diamond mining, including a reduced carbon footprint, energy efficiency, reduced emissions, ethical considerations, versatility, and cost-effectiveness. These benefits make lab-grown diamonds a more sustainable and responsible option for those looking to invest in precious stones.

Overview of MPCVD and HPHT methods for creating lab-grown diamonds

Lab-grown diamonds have become a popular alternative to natural diamonds, with diamond growing machines being one of the most effective ways to produce them. There are two main methods for creating diamonds using a diamond growing machine: microwave plasma chemical vapor deposition (MPCVD) and high-pressure high-temperature (HPHT).

MPCVD Method for Creating Lab-Grown Diamonds

MPCVD machines use a mixture of hydrogen and methane gas to create a plasma field that breaks down the carbon molecules and allows them to attach to a diamond substrate. The process takes place in a vacuum chamber and typically produces smaller diamonds. The diamonds produced through MPCVD are of higher purity compared to those produced using the HPHT method, and the production process consumes less energy. One of the main advantages of the MPCVD method is that it facilitates the production of larger diamonds, with a 3 inches substrate growing area and a maximum batch load of up to 45 pieces of diamonds.

HPHT Method for Creating Lab-Grown Diamonds

HPHT machines use extreme heat and pressure to replicate the conditions under which natural diamonds form. A small diamond seed is placed in a chamber with carbon and subjected to high pressure and high temperature to create a larger diamond. This process can produce diamonds of various sizes and shapes. The HPHT method is capable of producing diamonds with different colors, and the color of these diamonds is generally high, so there is often no need for post-growth treatment.

Advantages of Using Diamond Growing Machines

There are several advantages to using diamond growing machines to create lab-grown diamonds. Firstly, the process is more environmentally friendly than traditional diamond mining. It also allows for greater control over the quality and characteristics of the diamonds produced, making them more consistent and reproducible. Additionally, lab-grown diamonds are often less expensive than natural diamonds, making them a more accessible option for consumers.

In conclusion, both MPCVD and HPHT methods are effective ways to produce lab-grown diamonds. The choice between the two methods depends on the desired diamond characteristics and the intended use of the diamond. Regardless of the method used, diamond growing machines represent a significant advancement in the field of diamond production and provide a sustainable alternative to traditional mining practices.

Advantages of MPCVD system for diamond growth

The Microwave Plasma Chemical Vapor Deposition (MPCVD) system is a highly efficient and reliable diamond growing machine that has many advantages over traditional mining methods. Here are some of the key benefits of using the MPCVD system for diamond growth.

High-Quality Diamonds

The MPCVD system can produce high-quality diamonds of various sizes and shapes, which can meet the specific needs of different industries. The diamonds produced by the MPCVD system are of superior quality compared to other forms of diamond produced in the laboratory such as polycrystalline diamond (PCD), high-pressure high-temperature (HPHT) diamond, and natural diamond.

Fast Growth Rates

The MPCVD system can grow diamonds at a much faster rate than the traditional mining method. The growth rate varies depending on the stage design and methane concentration, but it can reach up to 150 µm/h. This means that manufacturers can produce larger quantities of diamonds in a shorter time frame, reducing production costs and increasing profit margins.

Environmentally Friendly

Diamond growing machines are environmentally friendly, as they do not require extensive mining and excavation activities that can lead to soil erosion and other environmental damages. The MPCVD system uses a carbon-containing gas and a microwave plasma to grow diamonds, which is a clean and eco-friendly process.

Large-Sized Diamond Growth

The MPCVD method is advantageous for large-sized diamond growth at a lower cost, making it an ideal solution for applications of semi-conductor diamonds, optics diamond growth, and the large jewelry diamond market needs. Compared to the HPHT method for lab-grown diamonds, the microwave CVD method enables large-area diamond growth at a lower cost.

Smooth and Continuous Adjustment of Microwave Power

Compared to other CVD techniques for growing diamond, the MPCVD system enables smooth and continuous adjustment of microwave power and stable control of the reaction temperature, which avoids crystal seeds falling off the substrate due to arcing and flame failure.

The MPCVD system is a practical and efficient option for producing diamonds for industrial and commercial purposes. Its high-quality diamonds, fast growth rates, and environmentally friendly process make it a cost-effective and sustainable alternative to traditional diamond mining.

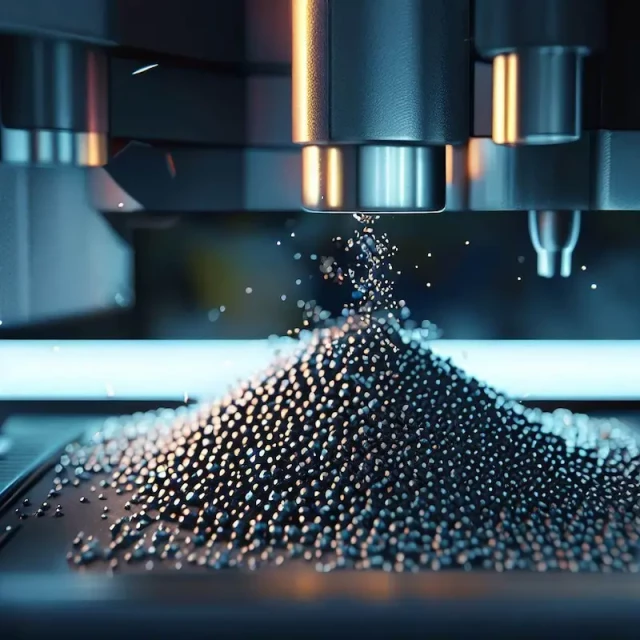

Working Process of MPCVD Machine

The Microwave Plasma Chemical Vapor Deposition (MPCVD) machine is one of the most popular types of diamond growing machines. The machine works by creating a high-temperature plasma using microwaves, which is then used to deposit carbon atoms onto a diamond seed. This process allows for the controlled growth of a diamond, with the ability to produce large, high-quality diamonds in a matter of weeks.

The Process of Diamond Growing

The MPCVD machine works by introducing a carbon-containing gas, such as methane, aliphatic or aromatic hydrocarbons, alcohols, ketones, amines, ethers, or carbon monoxide, into a vacuum chamber. The gas is then excited into a plasma state using high-frequency (2.45GHz) and high-power (kW) microwave radiation. The plasma is created by colliding electrons with each other, generating violent oscillations and promoting collisions between other atoms, groups, and molecules in the resonant cavity. This effectively increases the ionization of the reaction gas and generates a higher density of plasma.

Diamond Seed

To start the diamond growth process, a diamond seed, which is a small piece of diamond, is placed in the chamber. The diamond seed provides a surface for the carbon atoms to deposit onto and act as a template for the growth of the diamond.

Controlled Growth of Diamond

The carbon atoms in the excited gas are then deposited onto the diamond seed, allowing for the controlled growth of the diamond. The growth of diamond is influenced by several factors such as temperature, gas composition, and deposition time. By controlling these factors, the MPCVD machine can produce high-quality diamonds with consistent size and properties.

Advantages of MPCVD Machine

The use of an MPCVD machine for diamond production offers several advantages. Firstly, it is a more environmentally friendly option, as it eliminates the need for diamond mining and reduces carbon emissions. Secondly, it is a more cost-effective option, as it requires less energy and resources than traditional mining methods. Finally, the MPCVD machine allows for greater control over the diamond growing process, resulting in more consistent and higher quality diamonds.

Conclusion

In conclusion, the MPCVD machine is a valuable tool in the diamond industry, as it allows for the cost-effective and sustainable production of high-quality diamonds. The working process of the MPCVD machine involves the controlled deposition of carbon atoms onto a diamond seed, resulting in the growth of high-quality diamonds in a matter of weeks. The advantages of using this machine include its environmental friendliness, cost-effectiveness, and ability to produce consistent and high-quality diamonds.

Advantages of Using Diamond Growing Machines

Flexibility in Size and Color

Diamond growing machines offer the advantage of flexibility when it comes to the size and color of the diamonds produced. Unlike natural diamonds, which are limited in size and color by their natural formation process, diamond growing machines can create diamonds in a variety of sizes and colors to suit the needs of jewelers and consumers alike.

Faster Production Process

Another advantage of using diamond growing machines is their ability to produce diamonds much faster than traditional mining methods. The production time for a natural diamond can take millions of years, whereas diamond growing machines can produce high-quality diamonds in a matter of weeks. This faster production process makes it possible to meet the growing demand for diamonds in a more efficient manner.

Lower Cost and Accessibility

Perhaps the most significant advantage of using diamond growing machines is the lower cost of production. Traditional mining methods can be expensive and time-consuming, driving up the cost of natural diamonds. Diamond growing machines, on the other hand, have significantly lower production costs, resulting in lower prices for consumers. This has made diamonds more accessible to a wider range of consumers, further increasing their popularity.

Sustainable and Environmentally Friendly

Diamond growing machines also offer advantages in terms of sustainability and environmental impact. Large-scale mining operations can have a significant negative impact on the environment through land disturbance, water pollution, and other factors. Diamond growing machines eliminate the need for these mining operations, resulting in a more sustainable and environmentally friendly process for producing high-quality diamonds.

Identical Quality to Natural Diamonds

Diamond growing machines use advanced technology to replicate the natural process of diamond formation, resulting in diamonds that are virtually identical to those found in nature. This means that the quality of diamonds produced by these machines is on par with natural diamonds, with no discernible difference in quality or appearance.

In conclusion, the advantages of using diamond growing machines are numerous. They offer flexibility in size and color, faster production times, lower costs and increased accessibility, sustainable and environmentally friendly processes, and identical quality to natural diamonds. All these factors have contributed to the popularity of diamond growing machines and their increasing use in the diamond industry.

Related Products

- High Precision Diamond Wire Cutting Machine Laboratory Saw Precision Wire EDM Cutting Machine

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Precision Wire Saw Laboratory Cutting Machine with 800mm x 800mm Workbench for Diamond Single Wire Circular Small Cutting

- 12 Inch 24 Inch High Precision Automatic Diamond Wire Cutting Machine Laboratory Saw Precision Wire EDM Cutting Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

Related Articles

- How To Turn XRF analysis sample preparation Into Success

- Understanding the CVD Diamond Machine and How It Works

- The Pros and Cons of Different Lab Diamond Machine Methods

- How to Achieve Uniform Pressure with Warm Isostatic Press

- Unlocking the Power of Sieving Machines: Functions, Applications and Maintenance