CVD materials

Laboratory CVD Boron Doped Diamond Materials

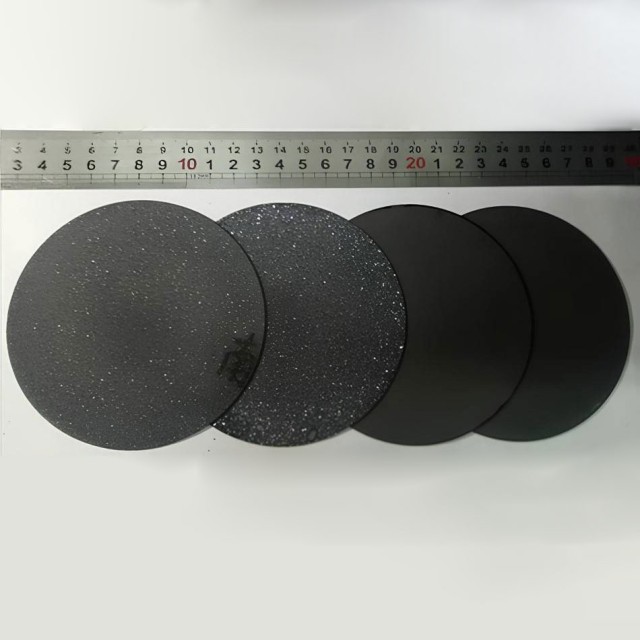

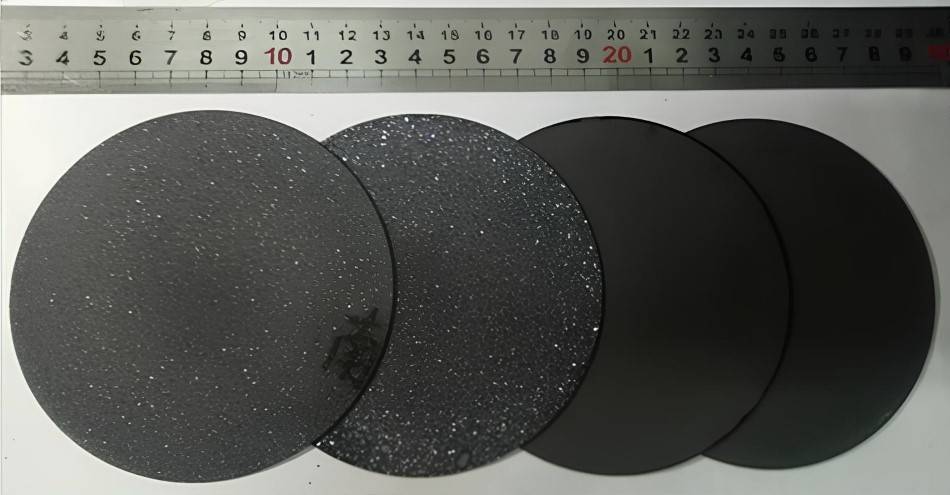

Item Number : cvdm-07

Price varies based on specs and customizations

- Diameter

- 100mm

- thickness

- 0.3-2mm

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

Chemical Vapor Deposition (CVD) boron-doped diamond is a unique material that combines the extraordinary properties of diamond with controllable electrical conductivity. By precisely introducing boron atoms into the diamond lattice during CVD growth, it becomes a versatile material with tailored electrical properties, ranging from insulating to highly conductive. This enables diverse applications in electronics, sensors, heat management, optics, and quantum technologies.

Applications

Chemical Vapor Deposition (CVD) boron-doped diamond is a versatile material with exceptional properties, offering unique solutions to challenges across multiple industries, from electronics to quantum technologies. Its continued development and integration into various applications hold great promise for advancing technology and scientific research in the years to come.

- Electronics: High-power electronic devices, high-frequency transistors, diodes, field-effect transistors (FETs)

- Sensors: Temperature, pressure, radiation, gas composition

- Heat Management: Heat spreaders, heat sinks, thermal management solutions

- Optics and Photonics: Optical windows, lenses, substrate for quantum optics experiments

- Quantum Technologies: Quantum computing, quantum communication, quantum sensing applications

Features

-

Exceptional Thermal Conductivity: CVD boron-doped diamond possesses outstanding thermal conductivity, enabling efficient dissipation of heat in high-power electronics, laser systems, and microelectronics.

-

Tailorable Electrical Conductivity: Through precise control of boron concentration during the CVD growth process, the electrical conductivity of CVD boron-doped diamond can be customized over a wide range, from insulating to highly conductive.

-

Broad Spectral Transparency: CVD boron-doped diamond exhibits transparency across a broad spectral range, making it suitable for applications in optics and photonics, such as optical windows and lenses.

-

Color Center Hosting: Boron-doped diamond can host color centers, which are defects in the diamond lattice that exhibit unique optical properties. These color centers have applications in quantum optics experiments and quantum information processing.

-

High Breakdown Voltage: CVD boron-doped diamond can withstand high breakdown voltages, making it ideal for high-power electronic devices operating in harsh environments.

-

High Carrier Mobility: Boron-doped diamond possesses high carrier mobility, enabling faster switching speeds and improved performance in electronic devices.

-

Wide Potential Window: Boron-doped diamond has a wide potential window of approximately 3.5 V, allowing for the application of "over-potentials" to stimulate high-energy chemical reactions.

-

Low Background Currents: Boron-doped diamond electrodes exhibit low background currents in cyclic voltammetry scans due to the small capacitance-layer at the semiconductor-like interface with electrolyte solutions.

-

Chemical Inertness: CVD boron-doped diamond is chemically inert, making it resistant to corrosion and suitable for harsh environments.

-

Quantum Properties: Boron-doped diamond has promising applications in quantum technologies, such as quantum computing, quantum communication, and quantum sensing, due to its long coherence times and ability to host individual quantum bits (qubits) at room temperature.

Principle

Chemical Vapor Deposition (CVD) boron-doped diamond is created by introducing boron atoms into the diamond lattice during the CVD growth process. This doping process controls the material's electrical conductivity, allowing for customization from insulating to highly conductive.

Advantages

-

Semiconducting Behavior: Boron doping introduces charge carriers into the diamond lattice, enabling control of electrical conductivity, ranging from insulating to highly conductive, making it suitable for various electronic applications.

-

High Thermal Conductivity: Boron-doped diamond possesses exceptional thermal conductivity, surpassing other semiconductors, enabling efficient heat dissipation in high-power electronic devices, laser systems, and microelectronics.

-

Wide Spectral Transparency: Boron-doped diamond exhibits transparency across a broad spectral range, from ultraviolet to infrared, making it valuable for optical windows, lenses, and applications in optics and photonics.

-

Color Centers: Boron-doped diamond can host color centers, which are atomic-scale defects with unique optical and spin properties. These color centers find applications in quantum technologies, including quantum computing, quantum communication, and quantum sensing.

-

Chemical Inertness: Boron-doped diamond is chemically inert, resistant to harsh environments, and compatible with various chemicals, making it suitable for applications in corrosive or extreme conditions.

-

Mechanical Hardness: Boron-doped diamond inherits the exceptional mechanical hardness of diamond, providing durability and resistance to wear and tear, even in demanding applications.

-

Tailored Electrical Properties: The concentration of boron atoms can be precisely controlled during the CVD growth process, allowing for customization of the material's electrical conductivity over a wide range, enabling optimization for specific applications.

-

Low Temperature Deposition: Chemical Vapor Deposition (CVD) process is typically carried out at low temperatures, enabling integration with a wide range of substrates and compatibility with various device fabrication processes.

-

Industrial Compatibility: CVD boron-doped diamond is compatible with industrial manufacturing processes, enabling scalable and cost-effective production, making it suitable for high-volume applications.

Specification

| Available dimension: | Diameter100mm, thickness 0.3-2mm |

|---|---|

| Boron Concentration [B]: | 2 to 6 x 1020 Atoms /cm3, averaged over 0.16 mm2 |

| Bulk Resistivity (Rv): | 2 to 1.8 x 10-3 Ohm m, ± 0.25 x 10-3 Ohm m |

| Solvent Window: | >3.0V |

Trusted by Industry Leaders

FAQ

What Are The Main Applications Of Diamond Materials?

What Are The Key Advantages And Applications Of Chemical Vapor Deposition (CVD) Boron-doped Diamond?

What Are The Advantages Of Using Diamond Materials In Industrial Applications?

What Is CVD Diamond Machine?

How Is Boron Doping Achieved During The Growth Of Diamond Films?

What Types Of Diamond Materials Are Available?

How Does A CVD Diamond Machine Work?

What Is The Relationship Between The Concentration Of Boron Atoms And The Electrical Conductivity Of The Diamond Film?

What Is The Principle Behind The Use Of Diamond Materials In Cutting Tools?

What Are The Advantages Of Using CVD Diamond Machines?

How Can The Electrical Conductivity Of The Diamond Film Be Tailored?

Why Is Synthetic Diamond Preferred Over Natural Diamond In Industrial Applications?

What Considerations Should Be Made When Selecting A CVD Diamond Machine?

What Are The Limitations Or Challenges Associated With The Fabrication Of Boron-doped Diamond Films?

What Are The Common Applications Of Diamonds Produced By CVD Diamond Machines?

4.8 / 5

I have been using this product for a while now and it has been great. The delivery was fast and the product is of great quality. I would definitely recommend this product to others.

4.7 / 5

I am very happy with this product. It is well-made and durable. I would definitely buy it again.

4.9 / 5

This product is amazing! It is so easy to use and it works great. I would definitely recommend it to anyone.

4.6 / 5

This product is great! It is well-made and durable. I would definitely buy it again.

4.8 / 5

I am very happy with this product. It is well-made and durable. I would definitely buy it again.

4.7 / 5

This product is amazing! It is so easy to use and it works great. I would definitely recommend it to anyone.

4.9 / 5

This product is great! It is well-made and durable. I would definitely buy it again.

4.6 / 5

I am very happy with this product. It is well-made and durable. I would definitely buy it again.

4.8 / 5

This product is amazing! It is so easy to use and it works great. I would definitely recommend it to anyone.

4.7 / 5

This product is great! It is well-made and durable. I would definitely buy it again.

4.9 / 5

I am very happy with this product. It is well-made and durable. I would definitely buy it again.

4.6 / 5

This product is amazing! It is so easy to use and it works great. I would definitely recommend it to anyone.

4.8 / 5

This product is great! It is well-made and durable. I would definitely buy it again.

4.7 / 5

I am very happy with this product. It is well-made and durable. I would definitely buy it again.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

CVD Diamond Domes for Industrial and Scientific Applications

Discover CVD diamond domes, the ultimate solution for high-performance loudspeakers. Made with DC Arc Plasma Jet technology, these domes deliver exceptional sound quality, durability, and power handling.

Related Articles

An Introduction to Chemical Vapor Deposition (CVD)

Chemical vapor deposition, or CVD, is a coating process that involves the use of gaseous reactants to produce thin films and coatings of high quality.

Understanding the CVD Diamond Machine and How It Works

CVD (Chemical Vapor Deposition) diamond creation process involves the deposition of carbon atoms onto a substrate using a gas phase chemical reaction. The process starts with the selection of a high-quality diamond seed, which is then placed in a growth chamber along with a carbon-rich gas mixture.

Chemical Vapor Deposition (CVD) of Graphene Challenges and Solutions

Chemical Vapor Deposition (CVD) is a widely adopted method for the production of high-quality graphene.

Advantages and Disadvantages of Chemical Vapor Deposition (CVD)

Chemical vapor deposition (CVD) is a versatile thin-film deposition technique widely used in various industries. Explore its advantages, disadvantages, and potential new applications.

How CVD is Used in the Semiconductor Industry

CVD has revolutionized the semiconductor industry, enabling the production of high-performance electronic devices with enhanced functionality and reliability.

CVD Machines for Thin Film Deposition

Chemical Vapor Deposition (CVD) is a widely used technique for deposition of thin films on various substrates.

CVD Systems Common Problems and How to Solve Them

Understanding the basics of CVD systems and their importance is crucial for optimizing the process and solving common problems encountered during operation.

A Comprehensive Guide to MPCVD: Diamond Synthesis and Applications

Explore the fundamentals, advantages, and applications of Microwave Plasma Chemical Vapor Deposition (MPCVD) in diamond synthesis. Learn about its unique capabilities and how it compares to other diamond growth methods.

Why PECVD is Essential for Microelectronic Device Fabrication

PECVD (Plasma-Enhanced Chemical Vapor Deposition) is a popular thin film deposition technique used in microelectronics device fabrication.

Understanding the PECVD Method

PECVD is a plasma-enhanced chemical vapor deposition process that is widely used in the production of thin films for various applications.

A Step-by-Step Guide to the PECVD Process

PECVD is a type of chemical vapor deposition process that uses plasma to enhance the chemical reactions between the gas-phase precursors and the substrate.

Comparing Chemical Vapor Deposition and Physical Vapor Deposition

Chemical Vapor Deposition (CVD) VS Physical Vapor Deposition (PVD)