CVD materials

CVD Diamond Domes for Industrial and Scientific Applications

Item Number : cvdm-06

Price varies based on specs and customizations

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

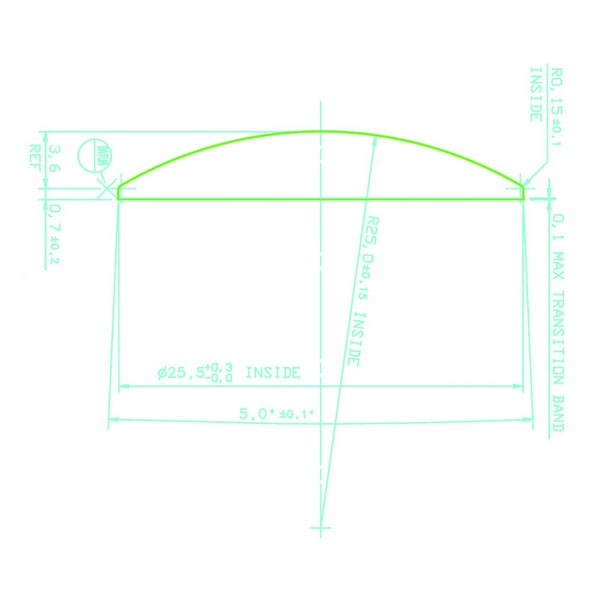

CVD diamond dome is a freestanding diamond dome prepared by DC Arc Plasma Jet, which is suitable for high-performance loudpeakers. It is made by DC Arc Plasma Jet, which guarantees the conformal high-quality growth of synthetic diamond on a 3-D carrier. The synthetic diamond could subsequently be removed from the carrier as free-standing, free of cracks, and with high yields. This product has excellent thermal stability and high thermal conductivity, resulting in a high-cone break-up frequency, low total harmonic distortion (THD), and high power tolerance.

Applications

CVD diamond tweeter domes are suitable for high performance loudspeakers. The domes are made by DC Arc Plasma Jet, which guaranteed the conformal high quality growth of synthetic diamond on a 3-D carrier. The synthetic diamond could subsequently be removed from the carrier as free-standing domes, free of cracks, and with high yields.

- High performance loudspeakers

- High-quality coatings on various materials to enhance their properties

- Cutting tools

- Optical windows

- Electronic components

- Graphene production

Features

-

High quality semitransparent polycrystalline diamond: Enables excellent sound transmission and clarity.

-

Excellent thermal stability and high thermal conductivity: Ensures efficient heat dissipation and prevents distortion.

-

High cone break-up frequency: Delivers accurate and detailed high-frequency reproduction.

-

Low total harmonic distortion (THD): Minimizes unwanted distortion and preserves the purity of the audio signal.

-

High power tolerance: Withstands high power levels without compromising performance or reliability.

-

Customizable color: Allows for a variety of aesthetic options to match different loudspeaker designs.

-

Purer inside: CVD diamonds have fewer impurities, resulting in exceptional clarity and brilliance.

Principle

DC Arc plasma jet technique is used to deposit a conformal high quality synthetic diamond on a 3-D carrier. The synthetic diamond can be subsequently removed from the carrier as free-standing domes, free of cracks, and with high yields.

Advantages

- High-quality semitransparent polycrystalline diamond

- Excellent thermal stability and high thermal conductivity

- High cone breakup frequency

- Low total harmonic distortion (THD)

- High power tolerance

Trusted by Industry Leaders

FAQ

What Are The Main Applications Of Diamond Materials?

What Is CVD (Chemical Vapor Deposition) And What Are Its Key Advantages?

What Are CVD Diamond Domes?

What Are The Advantages Of CVD Diamond Domes?

What Are The Advantages Of Using Diamond Materials In Industrial Applications?

What Are Some Common Applications Of CVD Materials?

What Applications Are CVD Diamond Domes Used For?

What Types Of Diamond Materials Are Available?

What Types Of CVD Materials Are Available?

Are CVD Diamond Domes Expensive?

What Is The Principle Behind The Use Of Diamond Materials In Cutting Tools?

How Does CVD Diamond Enhance The Performance Of Cutting Tools?

Why Is Synthetic Diamond Preferred Over Natural Diamond In Industrial Applications?

What Makes CVD Diamond Domes Suitable For High-performance Loudspeakers?

How Does CVD Diamond Improve Thermal Management In Electronic Devices?

4.9 / 5

CVD diamond domes are a breakthrough in loudspeaker technology, providing exceptional sound quality with their high thermal stability and low distortion.

4.8 / 5

The customizable color options of CVD diamond domes allow us to create unique and visually stunning loudspeakers that complement any design aesthetic.

4.7 / 5

CVD diamond domes have significantly improved the performance of our high-power loudspeakers, delivering crystal-clear sound even at high volumes.

4.9 / 5

The high cone break-up frequency of CVD diamond domes ensures accurate and detailed reproduction of high-frequency sounds, making them ideal for discerning audiophiles.

4.8 / 5

The excellent thermal stability of CVD diamond domes makes them highly durable and resistant to thermal stress, ensuring consistent performance over long periods of use.

4.7 / 5

CVD diamond domes offer a perfect balance of sound quality, durability, and versatility, making them an excellent choice for both professional and home audio applications.

4.9 / 5

The high-quality semitransparent polycrystalline diamond material used in CVD diamond domes provides exceptional sound transmission and clarity, resulting in a truly immersive audio experience.

4.8 / 5

The low total harmonic distortion (THD) of CVD diamond domes minimizes unwanted distortion, preserving the purity and integrity of the audio signal.

4.7 / 5

CVD diamond domes are a cost-effective solution for enhancing the performance of loudspeakers, offering exceptional value for money compared to traditional materials.

4.9 / 5

The fast delivery and excellent customer support from KINTEK SOLUTION made the purchase of CVD diamond domes a seamless and hassle-free experience.

4.8 / 5

CVD diamond domes are a game-changer for high-performance loudspeakers, offering a combination of sound quality, durability, and versatility that is unmatched by any other material.

4.7 / 5

The high thermal conductivity of CVD diamond domes ensures efficient heat dissipation, preventing distortion and ensuring consistent performance even under demanding conditions.

4.9 / 5

The customizable color options of CVD diamond domes allow us to create loudspeakers that are not only sonically excellent but also visually stunning.

4.8 / 5

CVD diamond domes have significantly improved the sound quality of our loudspeakers, delivering a wider frequency response and more detailed soundstage.

4.7 / 5

The excellent thermal stability of CVD diamond domes makes them highly reliable and long-lasting, ensuring years of trouble-free operation.

4.9 / 5

CVD diamond domes are a worthwhile investment for any audio enthusiast who demands the best possible sound quality from their loudspeakers.

4.8 / 5

The high cone break-up frequency of CVD diamond domes ensures accurate and detailed reproduction of high-frequency sounds, making them ideal for critical listening.

4.7 / 5

CVD diamond domes offer a perfect balance of sound quality, durability, and versatility, making them an excellent choice for both professional and home audio applications.

4.9 / 5

The excellent customer support from KINTEK SOLUTION was instrumental in helping us choose the right CVD diamond domes for our specific application.

4.8 / 5

CVD diamond domes are a true innovation in loudspeaker technology, offering a level of performance that was previously unattainable.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

CVD Diamond Dressing Tools for Precision Applications

Experience the Unbeatable Performance of CVD Diamond Dresser Blanks: High Thermal Conductivity, Exceptional Wear Resistance, and Orientation Independence.

CVD Diamond for Thermal Management Applications

CVD diamond for thermal management: High-quality diamond with thermal conductivity up to 2000 W/mK, ideal for heat spreaders, laser diodes, and GaN on Diamond (GOD) applications.

CVD Diamond Optical Windows for Lab Applications

Diamond optical windows: exceptional broad band infrared transparency, excellent thermal conductivity & low scattering in infrared, for high-power IR laser & microwave windows applications.

CVD Diamond Cutting Tool Blanks for Precision Machining

CVD Diamond Cutting Tools: Superior Wear Resistance, Low Friction, High Thermal Conductivity for Non-Ferrous Materials, Ceramics, Composites Machining

Laboratory CVD Boron Doped Diamond Materials

CVD boron-doped diamond: A versatile material enabling tailored electrical conductivity, optical transparency, and exceptional thermal properties for applications in electronics, optics, sensing, and quantum technologies.

CVD Diamond Wire Drawing Die Blanks for Precision Applications

CVD diamond wire drawing die blanks: superior hardness, abrasion resistance, and applicability in wire drawing various materials. Ideal for abrasive wear machining applications like graphite processing.

Related Articles

How CVD Coating Can Help You Achieve High Purity and Density

The CVD process offers several advantages over other coating techniques, such as high purity, uniformity, and the ability to deposit coatings with high-density.

Advantages of Using CVD Tube Furnace for Coating

CVD coatings have several advantages over other coating methods, such as high purity, density, and uniformity, making them ideal for many applications in various industries.

Comparing CVD Synthetic Diamonds and HPHT Cultivated Diamonds: What are the Differences?

Both CVD and HPHT diamonds are considered to be real diamonds, as they are made up of pure carbon and have the same physical and chemical properties as natural diamonds.

How to Check if Your Diamond is CVD-Produced

When it comes to buying a diamond, it's important to understand the difference between a naturally occurring diamond and one produced using CVD technology.

The Ethics of Diamond Growing Machines

Lab-grown diamonds have gained significant popularity in recent years due to their ethical and environmental benefits.

The Pros and Cons of Different Lab Diamond Machine Methods

Lab-grown diamonds, also known as synthetic diamonds, are man-made diamonds produced in a laboratory setting.

Market Prospects and Applications of CVD Diamonds

Explores the unique properties of CVD diamonds, their preparation methods, and diverse applications in various fields.

Advanced Applications of Cultivated Diamonds in Semiconductors and High-End Manufacturing

Discusses the use of cultivated diamonds in semiconductors, heat dissipation, and advanced manufacturing.

MPCVD Cultured Diamond Revolutionizes the Industry

Explores the impact of MPCVD cultured diamonds on various industries and strategies for cost reduction and efficiency improvement.

MPCVD Single Crystal Diamond Applications in Semiconductor and Optical Display Fields

This article discusses the applications of MPCVD single crystal diamond in semiconductor and optical display fields, highlighting its superior properties and potential impact on various industries.

CVD Diamond Optical Windows: Advancing High-Tech Optical Applications in Extreme Environments

Exploring the benefits of CVD diamond optical windows for high-end applications in extreme environments, including aerospace, military, and scientific research.

Progress in Microwave Plasma Chemical Vapor Deposition for Large-Size Single Crystal Diamond Preparation

This article discusses the advancements and challenges in preparing large-size single-crystal diamonds using microwave plasma chemical vapor deposition (MPCVD) techniques.