Semiconductor Industry

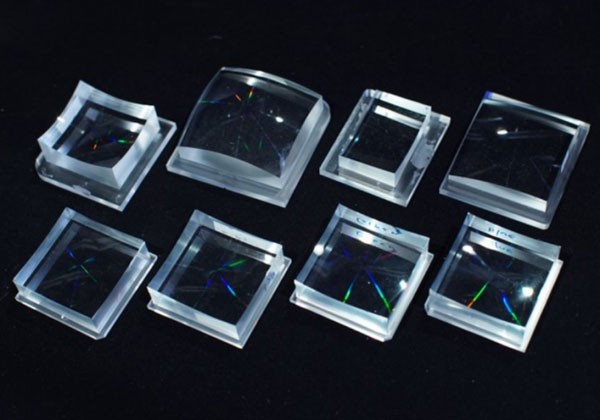

Chip Substrate

Diamond materials, recognized as third-generation semiconductor materials, exhibit exceptional properties that make them highly suitable for various advanced electronic applications. These materials boast high thermal conductivity, which ensures efficient heat dissipation, critical for maintaining the performance and longevity of integrated circuit chips. Additionally, diamond's high breakdown field and high carrier mobility enable it to handle high-frequency and high-power operations with minimal energy loss, making it an ideal choice for cutting-edge electronic devices.

Moreover, the low dielectric constant of diamond materials reduces signal delay and power consumption, further enhancing their utility in ultra-high frequency high-power electronic devices. This combination of properties positions diamond substrates as a transformative material in the semiconductor industry, promising to drive innovation in integrated circuits and beyond.

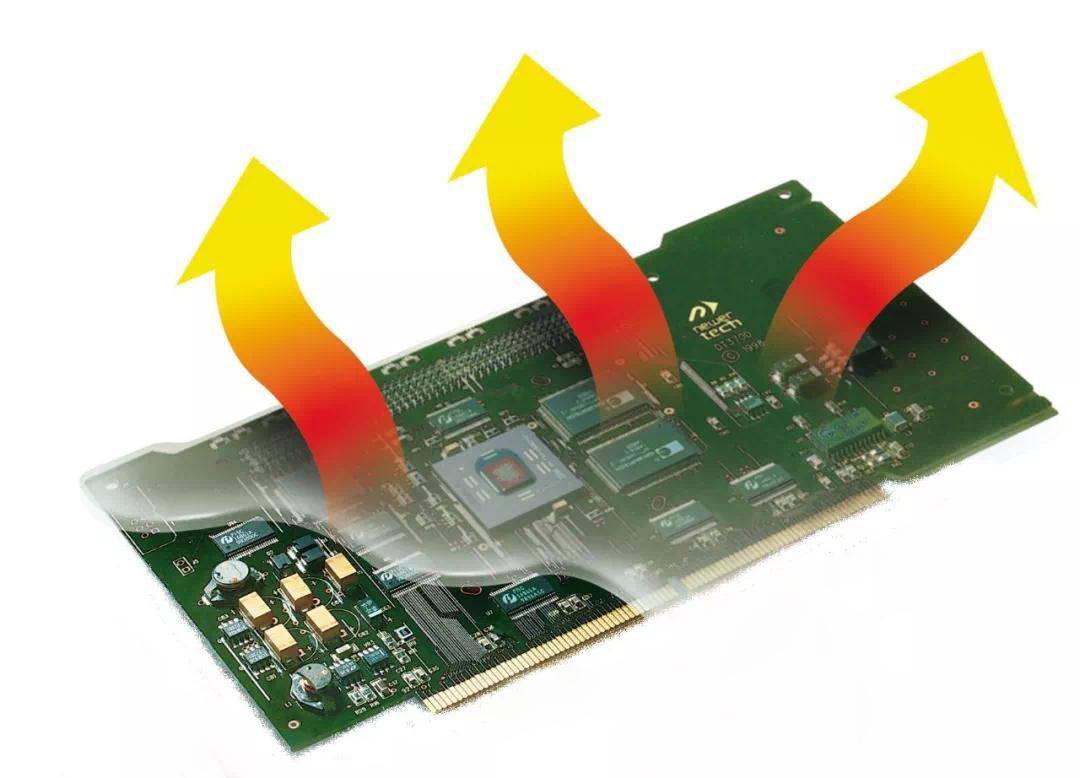

Chip Heat Dissipation Materials

Monocrystalline diamond stands out as the most ideal material for heat dissipation in high-power, high-density devices due to its exceptional thermal conductivity. This property is crucial for maintaining optimal performance and longevity in advanced technologies such as 5G chips and laser diode arrays. The high thermal conductivity of monocrystalline diamond ensures that it can efficiently dissipate heat, preventing thermal degradation and enhancing the overall reliability of these devices.

In the realm of 5G technology, where chips operate at unprecedented speeds and power levels, the ability to manage heat is paramount. Monocrystalline diamond's superior thermal management capabilities make it an indispensable component in these high-performance systems. Similarly, in laser diode arrays, which are used in a variety of applications from telecommunications to medical devices, the efficient heat dissipation provided by monocrystalline diamond ensures stable and consistent operation.

Moreover, the unique properties of monocrystalline diamond, including its high breakdown field and carrier mobility, further enhance its suitability for these applications. These attributes not only improve the thermal management but also contribute to the overall efficiency and performance of the devices. As the demand for faster, more powerful, and more compact electronic devices continues to grow, the role of monocrystalline diamond as a key heat dissipation material will become increasingly significant.

Optical Display Field

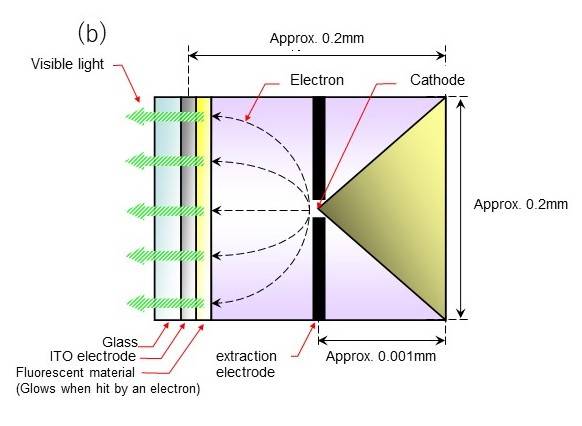

Cold Cathode Field Emission Display (FED)

The Cold Cathode Field Emission Display (FED) stands as a pioneering technology in the realm of self-luminous flat-panel displays, leveraging the exceptional properties of single crystal diamond materials. This innovative display technology capitalizes on diamond's unparalleled optical, mechanical, thermal, and electrical characteristics to deliver a superior viewing experience.

One of the key advantages of FED is its remarkable brightness. The inherent transparency and high refractive index of single crystal diamond enable the creation of displays with unparalleled luminance, ensuring that images are vivid and clear even under direct sunlight. This makes FED ideal for applications requiring high visibility, such as outdoor digital signage and military equipment.

In addition to brightness, FEDs offer exceptional grayscale and color fidelity. The precise control over electron emission in diamond-based FEDs allows for a wide range of grayscale levels, resulting in highly detailed and lifelike images. The material's ability to emit light across the visible spectrum ensures rich and accurate color reproduction, setting FED apart from traditional displays.

Resolution is another area where FED excels. The high electron mobility and low dielectric constant of single crystal diamond contribute to the creation of displays with ultra-high resolutions. This means that FEDs can render images with an extraordinary level of detail, making them suitable for applications demanding high-definition visuals, such as medical imaging and advanced gaming consoles.

Furthermore, FEDs boast an impressive response speed. The rapid electron emission and conduction properties of diamond enable these displays to switch between colors and grayscale levels at lightning speeds, ensuring smooth and fluid motion in fast-paced visuals. This makes FED an excellent choice for applications requiring rapid updates, such as high-speed data visualization and real-time simulations.

In summary, the Cold Cathode Field Emission Display (FED) leverages the exceptional properties of single crystal diamond to deliver a self-luminous flat-panel display with unparalleled advantages in brightness, grayscale, color, resolution, and response speed. This makes FED a promising technology for a wide range of applications, from consumer electronics to specialized industrial and military uses.

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Laboratory CVD Boron Doped Diamond Materials

- CVD Diamond for Thermal Management Applications

Related Articles

- Understanding PECVD: A Guide to Plasma-Enhanced Chemical Vapor Deposition

- Plasma Enhanced Chemical Vapor Deposition (PECVD): A Comprehensive Guide

- A beginner's guide to MPCVD machines

- The Advancements in MPCVD Systems for Large Size Single Crystal Diamonds

- The Process of Fabricating a CVD Diamond By MPCVD Machine