fine ceramics

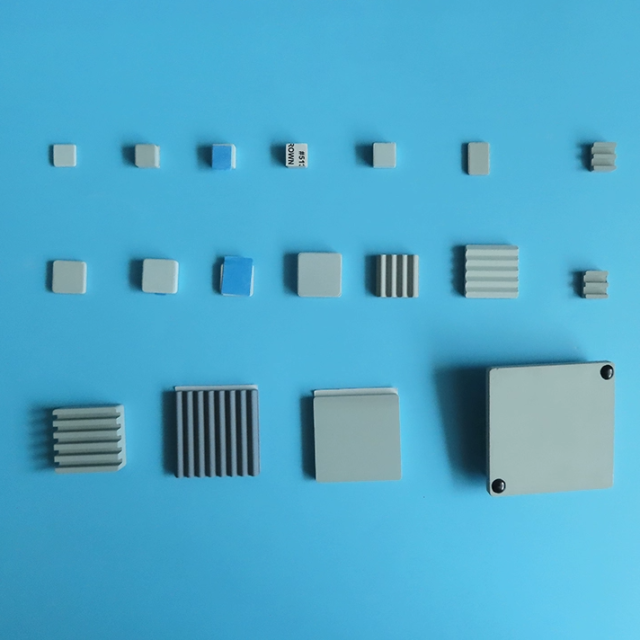

Silicon Carbide (SIC) Ceramic Sheet Flat Corrugated Heat Sink for Engineering Advanced Fine Ceramics

Item Number : KM-DT01

Price varies based on specs and customizations

- Material

- Silicon carbide

- Specification

- See the form

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

Silicon carbide (sic) ceramic sheets are environmentally friendly materials primarily used in the LED lighting and electronic industries. They offer efficient solutions for heat transfer and dissipation in the electronics and optoelectronics sectors. These sheets excel in insulation performance and high thermal conductivity, preventing leakage and breakdown while ensuring electrical safety and effective heat transfer. Their high infrared radiation rate enables efficient heat dissipation, while their low coefficient of expansion minimizes thermal stress and the risk of mechanical failure.

- IC, chipset, CPU, MOS: Silicon carbide ceramic sheets are suitable for heat dissipation of various integrated circuits and electronic components.

- LED lighting radiator: used for heat dissipation of LED lighting products, to ensure the best performance of LEDs and prolong the service life of LEDs.

- Thin LCD TVs and set-top boxes: These ceramic sheets are used for thermal management of thin LCD TVs and set-top boxes.

- Networking equipment: Applied to access points, routers, ADSL modems and network switches to ensure efficient cooling.

- Information technology: Silicon carbide ceramic sheets are used in motherboards, notebook computers, graphics cards, and memory modules to effectively dissipate heat.

- Power Supply: Used in power modules and power transistors to maintain proper operating temperature and improve performance.

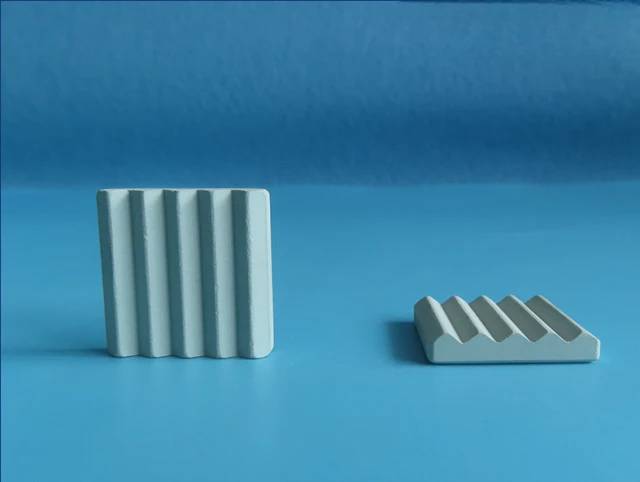

Detail & Parts

Technical specifications

| 25*25*3mm | 30*30*5mm | 40*404mm | 50*50*5mm |

| 25*25*5mm | 30*30*5mm | 40*40*5mm | 60*60*5mm |

| 25*25*5mm | 30*30*8mm | 40*40*5mm | 60*60*8mm |

| 25*25*8mm | 30*30*10mm | 40*40*7mm | |

| 25*25*10mm | 35*35*10mm | 40*40*8mm | |

| 30*30*2.5mm | 40*40*3mm | 50*50*5mm |

The produce we show are available in different sizes and custom sizes are available on request.

Advantages

- Environmental protection: Silicon carbide ceramic sheets are made of green and environmentally friendly materials, which meet ROHS environmental protection requirements.

- Effective heat dissipation: Compared with copper and aluminum, they have superior heat dissipation performance, ensuring the life and reliability of electronic products.

- Compact and lightweight: The small size and light weight of these ceramic chips allow for efficient product design and layout.

- Anti-interference and anti-static: It has excellent electrical properties, including insulation, high temperature resistance, oxidation resistance, acid and alkali resistance, and has effective anti-interference and anti-static effects.

Trusted by Industry Leaders

FAQ

What Are The Main Applications Of Fine Ceramics?

What Are The Main Types Of Fine Ceramics?

What Is The Principle Behind Fine Ceramics?

What Are The Advantages Of Using Fine Ceramics?

4.8 / 5

Fast delivery and excellent packaging, the quality of the product is superb, will definitely order again.

5.0 / 5

Amazing product! It perfectly fits my needs and exceeded my expectations. Highly recommended!

4.7 / 5

Great value for money. The product is well-designed and durable, worth every penny.

4.9 / 5

Top-notch quality and craftsmanship. I'm impressed with its performance and durability.

5.0 / 5

Cutting-edge technology that outperforms other products in the market. Simply outstanding!

4.8 / 5

The product is a testament to innovation and quality. Highly satisfied with my purchase.

4.9 / 5

Excellent product that meets all my requirements. I highly recommend it to anyone looking for a reliable solution.

5.0 / 5

Exceptional product that delivers exceptional results. I'm thrilled with my purchase.

4.8 / 5

Outstanding product with remarkable features. I'm thoroughly impressed with its performance.

4.9 / 5

Game-changing product that revolutionizes the industry. I'm amazed by its capabilities.

5.0 / 5

Unparalleled product that sets a new standard for quality and innovation. Highly recommended!

4.7 / 5

Impressive product that combines functionality and aesthetics seamlessly. I'm delighted with my purchase.

4.8 / 5

Revolutionary product that changes the way I work. I'm grateful for its efficiency and reliability.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Silicon Carbide (SIC) Ceramic Plate for Engineering Advanced Fine Ceramics

Silicon nitride (sic) ceramic is an inorganic material ceramic that does not shrink during sintering. It is a high-strength, low-density, high-temperature-resistant covalent bond compound.

Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

Silicon carbide (sic) ceramic sheet is composed of high-purity silicon carbide and ultra-fine powder, which is formed by vibration molding and high-temperature sintering.

Advanced Engineering Fine Ceramics Alumina Ceramic Saggar for Fine Corundum

Alumina sagger products have the characteristics of high temperature resistance, good thermal shock stability, small expansion coefficient, anti-stripping, and good anti-powdering performance.

Precision Machined Silicon Nitride (SiN) Ceramic Sheet for Engineering Advanced Fine Ceramics

Silicon nitride plate is a commonly used ceramic material in the metallurgical industry due to its uniform performance at high temperatures.

Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

Zirconia insulating ceramic gasket has high melting point, high resistivity, low thermal expansion coefficient and other properties, making it an important high temperature resistant material, ceramic insulating material and ceramic sunscreen material.

Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

Boron nitride ((BN) is a compound with high melting point, high hardness, high thermal conductivity and high electrical resistivity. Its crystal structure is similar to graphene and harder than diamond.

Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

zirconia ceramic ball have the characteristics of high strength, high hardness, PPM wear level, high fracture toughness, good wear resistance, and high specific gravity.

Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

Experience the advantages of Silicon Carbide (SiC) Heating Element: Long service life, high corrosion and oxidation resistance, fast heating speed, and easy maintenance. Learn more now!

Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

The air pressure sintering furnace is a high-tech equipment commonly used for the sintering of advanced ceramic materials. It combines vacuum sintering and pressure sintering techniques to achieve high-density and high-strength ceramics.

Advanced Engineering Fine Ceramics Aluminum Nitride (AlN) Ceramic Sheet

Aluminum nitride (AlN) has the characteristics of good compatibility with silicon. It is not only used as a sintering aid or reinforcing phase for structural ceramics, but its performance far exceeds that of alumina.

Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

The hole structure of the ceramic heat sink increases the heat dissipation area in contact with the air, which greatly enhances the heat dissipation effect, and the heat dissipation effect is better than that of super copper and aluminum.

Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

Alumina ceramics have good electrical conductivity, mechanical strength and high temperature resistance, while zirconia ceramics are known for their high strength and high toughness and are widely used.

Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

In the journey of scientific exploration and industrial production, every detail is crucial. Our arc-shaped alumina ceramic crucibles, with their excellent high temperature resistance and stable chemical properties, have become a powerful assistant in laboratories and industrial fields. They are made of high-purity alumina materials and manufactured through precision processes to ensure excellent performance in extreme environments.

High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

High temperature wear-resistant insulating alumina plate has excellent insulation performance and high temperature resistance.

Engineering Advanced Fine Ceramics Aluminium Oxide Al2O3 Ceramic Washer for Wear-Resistant Applications

Alumina wear-resistant ceramic washer are used for heat dissipation, which can replace aluminum heat sinks, with high temperature resistance and high thermal conductivity.

Precision Machined Yttrium Stabilized Zirconia Ceramic Rod for Engineering Advanced Fine Ceramics

Zirconia ceramic rods are prepared by isostatic pressing, and a uniform, dense and smooth ceramic layer and transition layer are formed at high temperature and high speed.

Precision Machined Yttria Stabilized Zirconia Ceramic Plate for Engineering Advanced Fine Ceramics

Yttrium-stabilized zirconia has the characteristics of high hardness and high temperature resistance, and has become an important material in the field of refractories and special ceramics.

High Quality Alumina Ceramic Screw for Engineering Advanced Fine Ceramics with High Temperature Resistance and Insulation

Alumina ceramic screws are fastening components made of 99.5% alumina, ideal for extreme applications requiring excellent thermal resistance, electrical insulation and chemical resistance.

Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

Alumina ceramic crucibles are used in some materials and metal melting tools, and flat-bottomed crucibles are suitable for melting and processing larger batches of materials with better stability and uniformity.

Related Articles

Precautions for installing silicon carbide stick

Precautions for installing silicon carbide stic.

Electrode Fixture Guide: Types, Design, and Applications

Discover the comprehensive guide to electrode fixtures, covering various types, design considerations, and their indispensable role in industries like electroplating, welding, and electrochemical cells.

What Makes Hot Isostatic Pressing So Effective

Hot Isostatic Pressing (HIP) is a manufacturing process that uses high temperature and pressure to improve the mechanical properties of materials. The process involves placing a part in a sealed chamber and subjecting it to high temperatures and pressures.

Precision Ceramic Materials for Energy Conversion Applications

Overview of various ceramic materials used in energy conversion technologies, including heaters, piezoelectric ceramics, and solid oxide fuel cells.

Precision Ceramics in Semiconductor Applications

Exploring the use of precision ceramics in semiconductor equipment, their properties, and manufacturing processes.

Engineering Ceramic Materials: Applications in Aerospace, Electronic Information, New Energy, and Environmental Protection

This article explores the diverse applications of engineering ceramic materials across aerospace, electronic information, new energy, and environmental protection sectors.

AI Chip Advancement Driven by Metallic New Materials

Explores how AI chip upgrades are fueled by new metal materials, impacting computing power and semiconductor manufacturing.

Technical Overview of Silicon-Carbon Anode Materials Prepared by CVD Method

This article discusses the key technical aspects of silicon-carbon anode materials prepared via CVD, focusing on their synthesis, performance improvements, and industrial application potential.

MPCVD Single Crystal Diamond Applications in Semiconductor and Optical Display Fields

This article discusses the applications of MPCVD single crystal diamond in semiconductor and optical display fields, highlighting its superior properties and potential impact on various industries.

The Rise of Glass Substrates in Advanced Semiconductor Packaging

Explores the shift towards glass substrates in advanced semiconductor packaging, their advantages, and challenges.

Applications of PECVD Nano-Coating Technology in Electronic Devices

PECVD nano-coating technology enhances durability and reliability in various electronic devices.

The 5 Hottest Advanced Ceramic Powders Currently Available!

An overview of the top 5 advanced ceramic powders: High Purity Aluminum Oxide, Boehmite, Aluminum Nitride, Silicon Nitride, and Spherical Alumina, highlighting their applications and market trends.